R. N. PATIL ET AL. 1017

0

50000

100000

150000

200000

250000

0 2040608

Impedance @ (0.1 Hz)

Coating Thickness (µm)

0

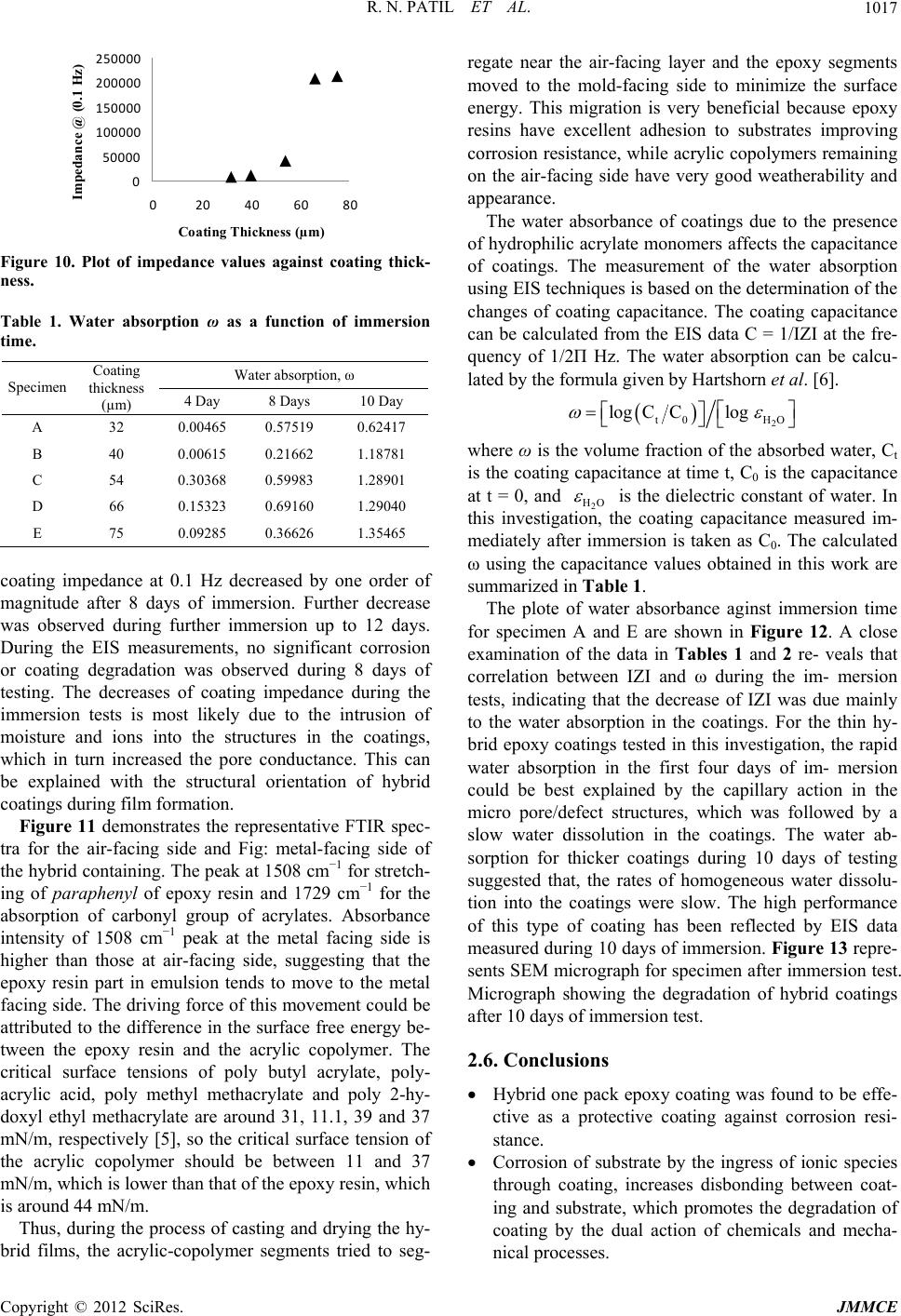

Figure 10. Plot of impedance values against coating thick-

ness.

Table 1. Water absorption ω as a function of immersion

time.

Water absorption, ω

Specimen

Coating

thickness

(µm) 4 Day 8 Days 10 Day

A 32 0.00465 0.57519 0.62417

B 40 0.00615 0.21662 1.18781

C 54 0.30368 0.59983 1.28901

D 66 0.15323 0.69160 1.29040

E 75 0.09285 0.36626 1.35465

coating impedance at 0.1 Hz decreased by one order of

magnitude after 8 days of immersion. Further decrease

was observed during further immersion up to 12 days.

During the EIS measurements, no significant corrosion

or coating degradation was observed during 8 days of

testing. The decreases of coating impedance during the

immersion tests is most likely due to the intrusion of

moisture and ions into the structures in the coatings,

which in turn increased the pore conductance. This can

be explained with the structural orientation of hybrid

coatings during film formation.

Figure 11 demonstrates the representative FTIR spec-

tra for the air-facing side and Fig: metal-facing side of

the hybrid containing. The peak at 1508 cm−1 for stretch-

ing of paraphenyl of epoxy resin and 1729 cm−1 for the

absorption of carbonyl group of acrylates. Absorbance

intensity of 1508 cm−1 peak at the metal facing side is

higher than those at air-facing side, suggesting that the

epoxy resin part in emulsion tends to move to the metal

facing side. The driving force of this movement could be

attributed to the difference in the surface free energy be-

tween the epoxy resin and the acrylic copolymer. The

critical surface tensions of poly butyl acrylate, poly-

acrylic acid, poly methyl methacrylate and poly 2-hy-

doxyl ethyl methacrylate are around 31, 11.1, 39 and 37

mN/m, respectively [5], so the critical surface tension of

the acrylic copolymer should be between 11 and 37

mN/m, which is lower than that of the epoxy resin, which

is around 44 mN/m.

Thus, during the process of casting and drying the hy-

brid films, the acrylic-copolymer segments tried to seg-

regate near the air-facing layer and the epoxy segments

moved to the mold-facing side to minimize the surface

energy. This migration is very beneficial because epoxy

resins have excellent adhesion to substrates improving

corrosion resistance, while acrylic copolymers remaining

on the air-facing side have very good weatherability and

appearance.

The water absorbance of coatings due to the presence

of hydrophilic acrylate monomers affects the capacitance

of coatings. The measurement of the water absorption

using EIS techniques is based on the determination of the

changes of coating capacitance. The coating capacitance

can be calculated from the EIS data C = 1/IZI at the fre-

quency of 1/2Π Hz. The water absorption can be calcu-

lated by the formula given by Hartshorn et al. [6].

2

t0 HO

logCClog

where ω is the volume fraction of the absorbed water, Ct

is the coating capacitance at time t, C0 is the capacitance

at t = 0, and 2

HO

is the dielectric constant of water. In

this investigation, the coating capacitance measured im-

mediately after immersion is taken as C0. The calculated

ω using the capacitance values obtained in this work are

summarized in Table 1.

The plote of water absorbance aginst immersion time

for specimen A and E are shown in Figure 12. A close

examination of the data in Tables 1 and 2 re- veals that

correlation between IZI and ω during the im- mersion

tests, indicating that the decrease of IZI was due mainly

to the water absorption in the coatings. For the thin hy-

brid epoxy coatings tested in this investigation, the rapid

water absorption in the first four days of im- mersion

could be best explained by the capillary action in the

micro pore/defect structures, which was followed by a

slow water dissolution in the coatings. The water ab-

sorption for thicker coatings during 10 days of testing

suggested that, the rates of homogeneous water dissolu-

tion into the coatings were slow. The high performance

of this type of coating has been reflected by EIS data

measured during 10 days of immersion. Figure 13 repre-

sents SEM micrograph for specimen after immersion test.

Micrograph showing the degradation of hybrid coatings

after 10 days of immersion test.

2.6. Conclusions

Hybrid one pack epoxy coating was found to be effe-

ctive as a protective coating against corrosion resi-

stance.

Corrosion of substrate by the ingress of ionic species

through coating, increases disbonding between coat-

ing and substrate, which promotes the degradation of

coating by the dual action of chemicals and mecha-

nical processes.

Copyright © 2012 SciRes. JMMCE