H. JOARDAR ET AL.

994

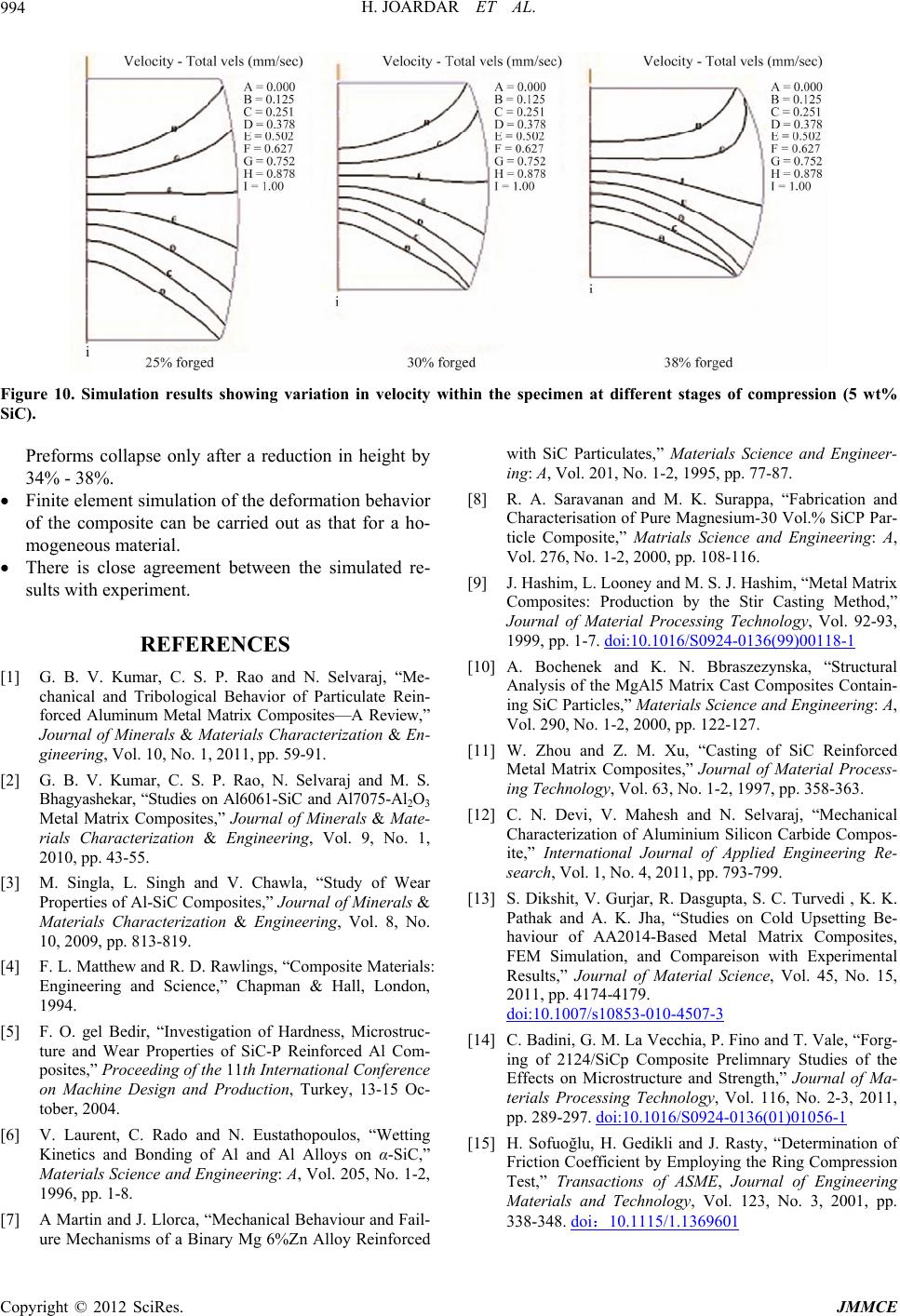

Figure 10. Simulation results showing variation in velocity within the specimen at different stages of compression (5 wt%

SiC).

Preforms collapse only after a reduction in height by

34% - 38%.

Finite element simulation of the deformation behavior

of the composite can be carried out as that for a ho-

mogeneous material.

There is close agreement between the simulated re-

sults with experiment.

REFERENCES

[1] G. B. V. Kumar, C. S. P. Rao and N. Selvaraj, “Me-

chanical and Tribological Behavior of Particulate Rein-

forced Aluminum Metal Matrix Composites—A Review,”

Journal of Minerals & Materials Characterization & En-

gineering, Vol. 10, No. 1, 2011, pp. 59-91.

[2] G. B. V. Kumar, C. S. P. Rao, N. Selvaraj and M. S.

Bhagyashekar, “Studies on Al6061-SiC and Al7075-Al2O3

Metal Matrix Composites,” Journal of Minerals & Mate-

rials Characterization & Engineering, Vol. 9, No. 1,

2010, pp. 43-55.

[3] M. Singla, L. Singh and V. Chawla, “Study of Wear

Properties of Al-SiC Composites,” Journal of Minerals &

Materials Characterization & Engineering, Vol. 8, No.

10, 2009, pp. 813-819.

[4] F. L. Matthew and R. D. Rawlings, “Composite Materials:

Engineering and Science,” Chapman & Hall, London,

1994.

[5] F. O. gel Bedir, “Investigation of Hardness, Microstruc-

ture and Wear Properties of SiC-P Reinforced Al Com-

posites,” Proceeding of the 11th International Conference

on Machine Design and Production, Turkey, 13-15 Oc-

tober, 2004.

[6] V. Laurent, C. Rado and N. Eustathopoulos, “Wetting

Kinetics and Bonding of Al and Al Alloys on α-SiC,”

Materials Science and Engineering: A, Vol. 205, No. 1-2,

1996, pp. 1-8.

[7] A Martin and J. Llorca, “Mechanical Behaviour and Fail-

ure Mechanisms of a Binary Mg 6%Zn Alloy Reinforced

with SiC Particulates,” Materials Science and Engineer-

ing: A, Vol. 201, No. 1-2, 1995, pp. 77-87.

[8] R. A. Saravanan and M. K. Surappa, “Fabrication and

Characterisation of Pure Magnesium-30 Vol.% SiCP Par-

ticle Composite,” Matrials Science and Engineering: A,

Vol. 276, No. 1-2, 2000, pp. 108-116.

[9] J. Hashim, L. Looney and M. S. J. Hashim, “Metal Matrix

Composites: Production by the Stir Casting Method,”

Journal of Material Processing Technology, Vol. 92-93,

1999, pp. 1-7. doi:10.1016/S0924-0136(99)00118-1

[10] A. Bochenek and K. N. Bbraszezynska, “Structural

Analysis of the MgAl5 Matrix Cast Composites Contain-

ing SiC Particles,” Materials Science and Engineering: A,

Vol. 290, No. 1-2, 2000, pp. 122-127.

[11] W. Zhou and Z. M. Xu, “Casting of SiC Reinforced

Metal Matrix Composites,” Journal of Material Process-

ing Technology, Vol. 63, No. 1-2, 1997, pp. 358-363.

[12] C. N. Devi, V. Mahesh and N. Selvaraj, “Mechanical

Characterization of Aluminium Silicon Carbide Compos-

ite,” International Journal of Applied Engineering Re-

search, Vol. 1, No. 4, 2011, pp. 793-799.

[13] S. Dikshit, V. Gurjar, R. Dasgupta, S. C. Turvedi , K. K.

Pathak and A. K. Jha, “Studies on Cold Upsetting Be-

haviour of AA2014-Based Metal Matrix Composites,

FEM Simulation, and Compareison with Experimental

Results,” Journal of Material Science, Vol. 45, No. 15,

2011, pp. 4174-4179.

doi:10.1007/s10853-010-4507-3

[14] C. Badini, G. M. La Vecchia, P. Fino and T. Vale, “Forg-

ing of 2124/SiCp Composite Prelimnary Studies of the

Effects on Microstructure and Strength,” Journal of Ma-

terials Processing Technology, Vol. 116, No. 2-3, 2011,

pp. 289-297. doi:10.1016/S0924-0136(01)01056-1

[15] H. Sofuoğlu, H. Gedikli and J. Rasty, “Determination of

Friction Coefficient by Employing the Ring Compression

Test,” Transactions of ASME, Journal of Engineering

Materials and Technology, Vol. 123, No. 3, 2001, pp.

338-348. doi:10.1115/1.1369601

Copyright © 2012 SciRes. JMMCE