Paper Menu >>

Journal Menu >>

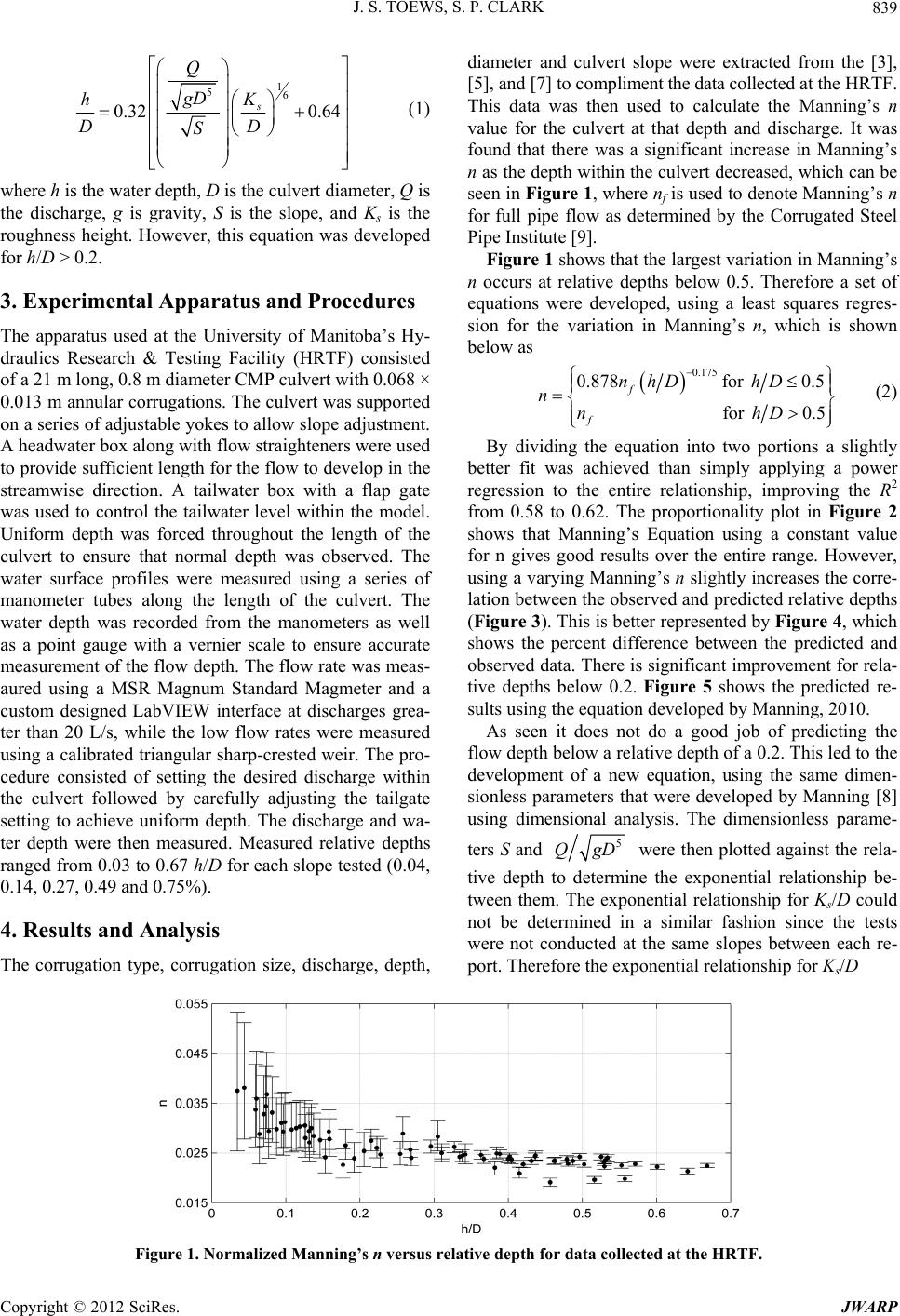

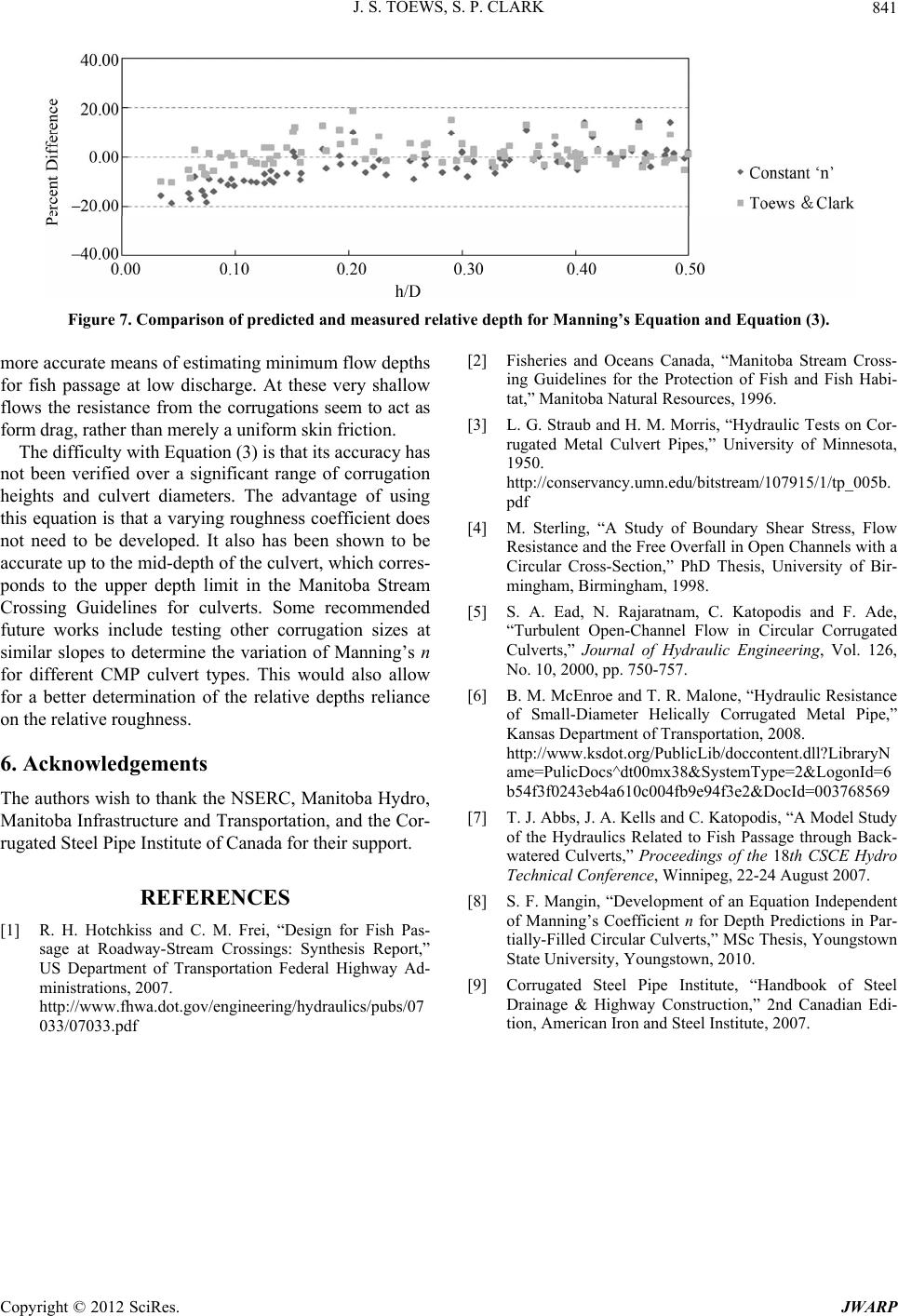

Journal of Water Resource and Protection, 2012, 4, 838-841 http://dx.doi.org/10.4236/jwarp.2012.410096 Published Online October 2012 (http://www.SciRP.org/journal/jwarp) Relative Depth Effects on Corrugated Culvert Roughness Jonathan Scott Toews, Shawn Paul Clark* Civil Engineering, University of Manitoba, Winnipeg, Canada Email: *clarks@cc.umanitoba.ca Received August 20, 2012; revised September 18, 2012; accepted October 20, 2012 ABSTRACT Fish passage is important to the overall health of an ecosystem. Therefore, it is important to be able to accurately predict flow conditions within a stream crossing for high and low flow periods. This paper evaluates the effect of relative water depth on the hydraulic roughness of culverts at low discharge. A 21 m long, 0.8 m diameter corrugated steel pipe with 0.068 × 0.013 m annular corrugations was used. For relative depths below 0.5, Manning’s n was found to increase with decreasing relative depth. An equation was developed to predict relative depths below 0.5 within a corrugated steel pipe based on the corrugation height, slope and culvert diameter. While Manning’s equation does perform reasonably well, the percent difference from the measured to predicted water levels warrants the use of an additional prediction method at low flows. Keywords: Culverts; Fish Passage; Low Flows; Roughness; Manning’s Equation 1. Introduction The process of fish migration and movement within riv- ers and streams is important for the health of the local ecosystem. When fish have the opportunity to move freely in any habitat they desire, they will generally flourish. The construction of culverts may become a bar- rier to fish, which may have a harmful effect on fish pas- sage. High water velocities commonly present a barrier to fish passage, typically corresponding to peak flows from spring run-off. At low flows, however, shallow wa- ter depths within a culvert may become a barrier to fish passage, thus requiring a minimum depth within a culvert [1]. During the spawning period it is recommended by the Manitoba Stream Crossing Guidelines that the depth should not exceed half the diameter of the pipe [2]. This leads to the motivation of this paper, which looks into the effect of small relative depths (h/D ≤ 0.5) on the Man- ning’s n value within a culvert. 2. Literature Review The majority of previous work on partially full circular culverts did not involve evaluation of the effect of rela- tive depth on Manning’s n. Straub and Morris [3] com- pleted tests on corrugated metal pipe (CMP) culverts with three diameters of 0.46, 0.61, and 0.91 m. The cor- rugation size used for these tests was 0.068 × 0.013 m, with a slope of 0.20% and a length of 65.8 m. A total of 36 tests were conducted for all three diameters with rela- tive depths ranging between 0.30 and 0.90. Sterling [4] completed tests in smooth open channels of circular cross-section to determine the characteristics of fully developed turbulent flow. The pipe had a diameter of 0.24 m in a 22 m long tilting flume. Relative depths for their tests ranged from 0.10 to 0.89. Results showed that Manning’s n tended to increase with decreasing relative depth. Ead et al. [5] completed tests on a 0.622 m di- ameter CMP culvert with 0.068 × 0.013 m corrugations at slopes of 0.55%, 1.14% and 2.55%. Relative depths ranged between 0.15 and 0.55. Kansas Department of Transportation [6] completed research on helical CMP culverts with 0.068 × 0.013 m corrugations for three diameters of 0.46, 0.38 and 0.30 m. These culverts were each tested at a single slope which was 0.39%, 0.85% and 0.68% respectively for each di- ameter. The range of relative depths observed within this study was 0.29 to 0.90. From this data it is also noted that Manning’s n increases as the depth decreases within a CMP culvert. Abbs et al. [7] completed work on a 0.5 m diameter CMP culvert with 0.068 × 0.013 mm corruga- tions set on a 0.72% slope. For the purpose of the current paper, results of only two tests have been used. Mangin [8] compiled numerous data sets to develop an equation that could predict the water depth within a cir- cular channel for open channel flow without the need to predict Manning’s n. Dimensional analysis was per- formed to determine the most appropriate variables to predict the relative depth, resulting in Equation (1): *Corresponding author. C opyright © 2012 SciRes. JWARP  J. S. TOEWS, S. P. CLARK 839 16 0.64 s 5 0.32 Q gD K h DD S (1) where h is the water depth, D is the culvert diameter, Q is the discharge, g is gravity, S is the slope, and Ks is the roughness height. However, this equation was developed for h/D > 0.2. 3. Experimental Apparatus and Procedures The apparatus used at the University of Manitoba’s Hy- draulics Research & Testing Facility (HRTF) consisted of a 21 m long, 0.8 m diameter CMP culvert with 0.068 × 0.013 m annular corrugations. The culvert was supported on a series of adjustable yokes to allow slope adjustment. A headwater box along with flow straighteners were used to provide sufficient length for the flow to develop in the streamwise direction. A tailwater box with a flap gate was used to control the tailwater level within the model. Uniform depth was forced throughout the length of the culvert to ensure that normal depth was observed. The water surface profiles were measured using a series of manometer tubes along the length of the culvert. The water depth was recorded from the manometers as well as a point gauge with a vernier scale to ensure accurate measurement of the flow depth. The flow rate was meas- aured using a MSR Magnum Standard Magmeter and a custom designed LabVIEW interface at discharges grea- ter than 20 L/s, while the low flow rates were measured using a calibrated triangular sharp-crested weir. The pro- cedure consisted of setting the desired discharge within the culvert followed by carefully adjusting the tailgate setting to achieve uniform depth. The discharge and wa- ter depth were then measured. Measured relative depths ranged from 0.03 to 0.67 h/D for each slope tested (0.04, 0.14, 0.27, 0.49 and 0.75%). 4. Results and Analysis The corrugation type, corrugation size, discharge, depth, diameter and culvert slope were extracted from the [3], [5], and [7] to compliment the data collected at the HRTF. This data was then used to calculate the Manning’s n value for the culvert at that depth and discharge. It was found that there was a significant increase in Manning’s n as the depth within the culvert decreased, which can be seen in Figure 1, where nf is used to denote Manning’s n for full pipe flow as determined by the Corrugated Steel Pipe Institute [9]. Figure 1 shows that the largest variation in Manning’s n occurs at relative depths below 0.5. Therefore a set of equations were developed, using a least squares regres- sion for the variation in Manning’s n, which is shown below as 0.175 0.878for 0.5 for 0.5 f f nhD hD nnhD (2) By dividing the equation into two portions a slightly better fit was achieved than simply applying a power regression to the entire relationship, improving the R2 from 0.58 to 0.62. The proportionality plot in Figure 2 shows that Manning’s Equation using a constant value for n gives good results over the entire range. However, using a varying Manning’s n slightly increases the corre- lation between the observed and predicted relative depths (Figure 3). This is better represented by Figure 4, which shows the percent difference between the predicted and observed data. There is significant improvement for rela- tive depths below 0.2. Figure 5 shows the predicted re- sults using the equation developed by Manning, 2010. As seen it does not do a good job of predicting the flow depth below a relative depth of a 0.2. This led to the development of a new equation, using the same dimen- sionless parameters that were developed by Manning [8] using dimensional analysis. The dimensionless parame- 5 QgDters S and were then plotted against the rela- tive depth to determine the exponential relationship be- tween them. The exponential relationship for Ks/D could not be determined in a similar fashion since the tests were not conducted at the same slopes between each re- port. Therefore the exponential relationship for Ks/D Figure 1. Normalized Manning’s n versus relative depth for data collected at the HRTF. Copyright © 2012 SciRes. JWARP  J. S. TOEWS, S. P. CLARK 840 Figure 2. Proportionality plot of predicted vs observed h/D using a constant Manning’s n. Figure 3. Proportionality plot of predicted vs observed h/D using a varying Manning’s n. Figure 4. Comparison of predicted and measured relative depth for Ma nning’s Equation using a constant and varying n. Figure 5. Proportionality plot for Manning’s Equation. and trend multiplier were then optimized to minimize the total error between predicted and observed relative depths. The final form of the equation is 0.463 5 0.641 hQ S D gD 0.169 0.247 s K D (3) As seen in Figures 6 and 7, this equation accurately predicts relative depths below 0.5. However the model error tends to increase as the relative depth increases past this threshold. This was determined not to be an issue Figure 6. Proportionality plot for Equation (3). since Manning’s Equation is accurate in this region. 5. Conclusions Results indicate that Manning’s Equation using a constant n value does a reasonable job of predicting the uniform depth within CMP culverts over a wide range of water depths despite the fact that the roughness coefficient has been shown to increase with decreasing h/D. At very low water depths (h/D < 0.15) Equation (3) performs better than Manning’s Equation, and may be a Copyright © 2012 SciRes. JWARP  J. S. TOEWS, S. P. CLARK 841 Figure 7. Comparison of predicted and measured relative depth for Manning’s Equation and Equation (3). more accurate means of estimating minimum flow depths for fish passage at low discharge. At these very shallow flows the resistance from the corrugations seem to act as form drag, rather than merely a uniform skin friction. The difficulty with Equation (3) is that its accuracy has not been verified over a significant range of corrugation heights and culvert diameters. The advantage of using this equation is that a varying roughness coefficient does not need to be developed. It also has been shown to be accurate up to the mid-depth of the culvert, which corres- ponds to the upper depth limit in the Manitoba Stream Crossing Guidelines for culverts. Some recommended future works include testing other corrugation sizes at similar slopes to determine the variation of Manning’s n for different CMP culvert types. This would also allow for a better determination of the relative depths reliance on the relative roughness. 6. Acknowledgements The authors wish to thank the NSERC, Manitoba Hydro, Manitoba Infrastructure and Transportation, and the Cor- rugated Steel Pipe Institute of Canada for their support. REFERENCES [1] R. H. Hotchkiss and C. M. Frei, “Design for Fish Pas- sage at Roadway-Stream Crossings: Synthesis Report,” US Department of Transportation Federal Highway Ad- ministrations, 2007. http://www.fhwa.dot.gov/engineering/hydraulics/pubs/07 033/07033.pdf [2] Fisheries and Oceans Canada, “Manitoba Stream Cross- ing Guidelines for the Protection of Fish and Fish Habi- tat,” Manitoba Natural Resources, 1996. [3] L. G. Straub and H. M. Morris, “Hydraulic Tests on Cor- rugated Metal Culvert Pipes,” University of Minnesota, 1950. http://conservancy.umn.edu/bitstream/107915/1/tp_005b. pdf [4] M. Sterling, “A Study of Boundary Shear Stress, Flow Resistance and the Free Overfall in Open Channels with a Circular Cross-Section,” PhD Thesis, University of Bir- mingham, Birmingham, 1998. [5] S. A. Ead, N. Rajaratnam, C. Katopodis and F. Ade, “Turbulent Open-Channel Flow in Circular Corrugated Culverts,” Journal of Hydraulic Engineering, Vol. 126, No. 10, 2000, pp. 750-757. [6] B. M. McEnroe and T. R. Malone, “Hydraulic Resistance of Small-Diameter Helically Corrugated Metal Pipe,” Kansas Department of Transportation, 2008. http://www.ksdot.org/PublicLib/doccontent.dll?LibraryN ame=PulicDocs^dt00mx38&SystemType=2&LogonId=6 b54f3f0243eb4a610c004fb9e94f3e2&DocId=003768569 [7] T. J. Abbs, J. A. Kells and C. Katopodis, “A Model Study of the Hydraulics Related to Fish Passage through Back- watered Culverts,” Proceedings of the 18th CSCE Hydro Technical Conference, Winnipeg, 22-24 August 2007. [8] S. F. Mangin, “Development of an Equation Independent of Manning’s Coefficient n for Depth Predictions in Par- tially-Filled Circular Culverts,” MSc Thesis, Youngstown State University, Youngstown, 2010. [9] Corrugated Steel Pipe Institute, “Handbook of Steel Drainage & Highway Construction,” 2nd Canadian Edi- tion, American Iron and Steel Institute, 2007. Copyright © 2012 SciRes. JWARP |