F. SANTANA-ROBLES ET AL.

268

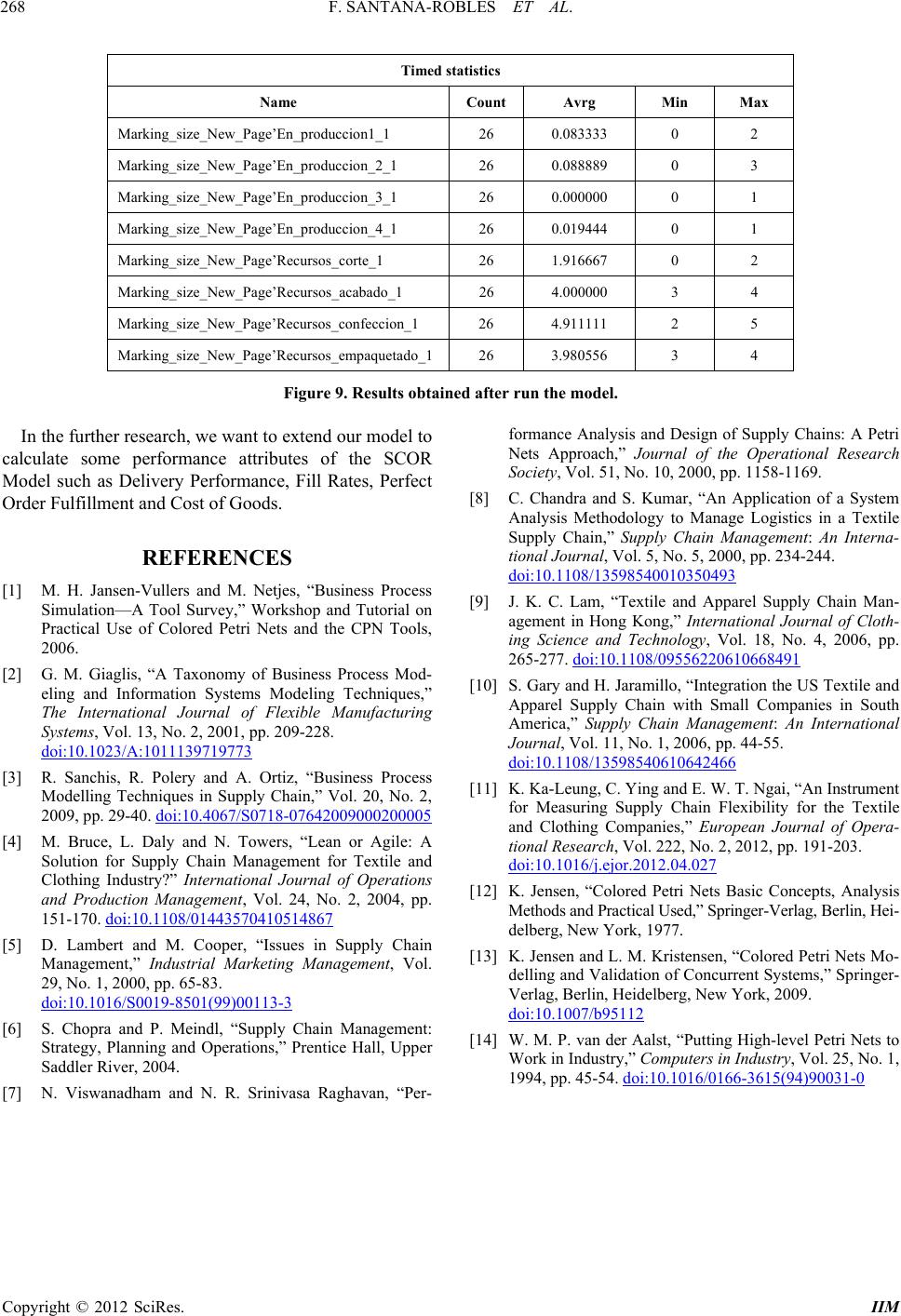

Timed statistics

Name Count Avrg Min Max

Marking_size_New_Page’En_produccion1_1 26 0.083333 0 2

Marking_size_New_Page’En_produccion_2_1 26 0.088889 0 3

Marking_size_New_Page’En_produccion_3_1 26 0.000000 0 1

Marking_size_New_Page’En_produccion_4_1 26 0.019444 0 1

Marking_size_New_Page’Recursos_corte_1 26 1.916667 0 2

Marking_size_New_Page’Recursos_acabado_1 26 4.000000 3 4

Marking_size_New_Page’Recursos_confeccion_1 26 4.911111 2 5

Marking_size_New_Page’Recursos_empaquetado_1 26 3.980556 3 4

Figure 9. Results obtained after run the model.

In the further research, we want to extend our model to

calculate some performance attributes of the SCOR

Model such as Delivery Performance, Fill Rates, Perfect

Order Fulfillment and Cost of Goods.

REFERENCES

[1] M. H. Jansen-Vullers and M. Netjes, “Business Process

Simulation—A Tool Survey,” Workshop and Tutorial on

Practical Use of Colored Petri Nets and the CPN Tools,

2006.

[2] G. M. Giaglis, “A Taxonomy of Business Process Mod-

eling and Information Systems Modeling Techniques,”

The International Journal of Flexible Manufacturing

Systems, Vol. 13, No. 2, 2001, pp. 209-228.

doi:10.1023/A:1011139719773

[3] R. Sanchis, R. Polery and A. Ortiz, “Business Process

Modelling Techniques in Supply Chain,” Vol. 20, No. 2,

2009, pp. 29-40. doi:10.4067/S0718-07642009000200005

[4] M. Bruce, L. Daly and N. Towers, “Lean or Agile: A

Solution for Supply Chain Management for Textile and

Clothing Industry?” International Journal of Operations

and Production Management, Vol. 24, No. 2, 2004, pp.

151-170. doi:10.1108/01443570410514867

[5] D. Lambert and M. Cooper, “Issues in Supply Chain

Management,” Industrial Marketing Management, Vol.

29, No. 1, 2000, pp. 65-83.

doi:10.1016/S0019-8501(99)00113-3

[6] S. Chopra and P. Meindl, “Supply Chain Management:

Strategy, Planning and Operations,” Prentice Hall, Upper

Saddler River, 2004.

[7] N. Viswanadham and N. R. Srinivasa Raghavan, “Per-

formance Analysis and Design of Supply Chains: A Petri

Nets Approach,” Journal of the Operational Research

Society, Vol. 51, No. 10, 2000, pp. 1158-1169.

[8] C. Chandra and S. Kumar, “An Application of a System

Analysis Methodology to Manage Logistics in a Textile

Supply Chain,” Supply Chain Management: An Interna-

tional Journal, Vol. 5, No. 5, 2000, pp. 234-244.

doi:10.1108/13598540010350493

[9] J. K. C. Lam, “Textile and Apparel Supply Chain Man-

agement in Hong Kong,” International Journal of Cloth-

ing Science and Technology, Vol. 18, No. 4, 2006, pp.

265-277. doi:10.1108/09556220610668491

[10] S. Gary and H. Jaramillo, “Integration the US Textile and

Apparel Supply Chain with Small Companies in South

America,” Supply Chain Management: An International

Journal, Vol. 11, No. 1, 2006, pp. 44-55.

doi:10.1108/13598540610642466

[11] K. Ka-Leung, C. Ying and E. W. T. Ngai, “An Instrument

for Measuring Supply Chain Flexibility for the Textile

and Clothing Companies,” European Journal of Opera-

tional Research, Vol. 222, No. 2, 2012, pp. 191-203.

doi:10.1016/j.ejor.2012.04.027

[12] K. Jensen, “Colored Petri Nets Basic Concepts, Analysis

Methods and Practical Used,” Springer-Verlag, Berlin, Hei-

delberg, New York, 1977.

[13] K. Jensen and L. M. Kristensen, “Colored Petri Nets Mo-

delling and Validation of Concurrent Systems,” Springer-

Verlag, Berlin, Heidelberg, New York, 2009.

doi:10.1007/b95112

[14] W. M. P. van der Aalst, “Putting High-level Petri Nets to

Work in Industry,” Computers in Industry, Vol. 25, No. 1,

1994, pp. 45-54. doi:10.1016/0166-3615(94)90031-0

Copyright © 2012 SciRes. IIM