Preparation and in Vitro Drug Release Evaluation of Once-Daily Metformin Hydrochloride Sustained-Release Tablets 473

024681012

0

20

40

60

80

100

120

MH released (%)

Time (h)

0 month

1 month

2 month

3 month

6 month

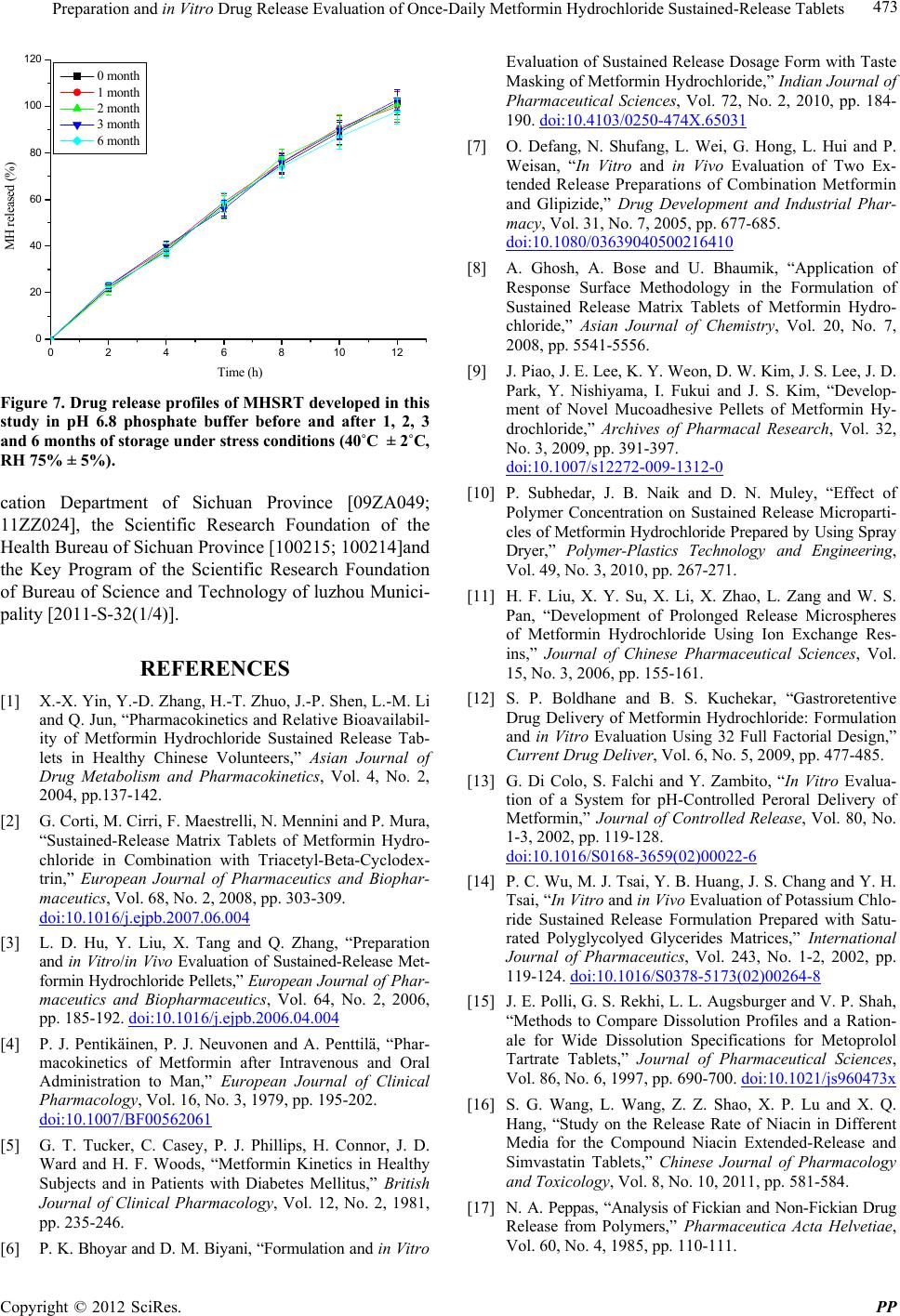

Figure 7. Drug release profiles of MHSRT develope d in this

study in pH 6.8 phosphate buffer before and after 1, 2, 3

and 6 months of storage under stress conditions (40˚C ± 2˚C,

RH 75% ± 5%).

cation Department of Sichuan Province [09ZA049;

11ZZ024], the Scientific Research Foundation of the

Health Bureau of Sichuan Province [100215; 100214]and

the Key Program of the Scientific Research Foundation

of Bureau of Science and Technology of luzhou Munici-

pality [2011-S-32(1/4)].

REFERENCES

[1] X.-X. Yin, Y.-D. Zhang, H.-T. Zhuo, J.-P. Shen, L.-M. Li

and Q. Jun, “Pharmacokinetics and Relative Bioavailabil-

ity of Metformin Hydrochloride Sustained Release Tab-

lets in Healthy Chinese Volunteers,” Asian Journal of

Drug Metabolism and Pharmacokinetics, Vol. 4, No. 2,

2004, pp.137-142.

[2] G. Corti, M. Cirri, F. Maestrelli, N. Mennini and P. Mura,

“Sustained-Release Matrix Tablets of Metformin Hydro-

chloride in Combination with Triacetyl-Beta-Cyclodex-

trin,” European Journal of Pharmaceutics and Biophar-

maceutics, Vol. 68, No. 2, 2008, pp. 303-309.

doi:10.1016/j.ejpb.2007.06.004

[3] L. D. Hu, Y. Liu, X. Tang and Q. Zhang, “Preparation

and in Vitro/in Vivo Evaluation of Sustained-Release Met-

formin Hydrochloride Pellets,” European Journal of P har -

maceutics and Biopharmaceutics, Vol. 64, No. 2, 2006,

pp. 185-192. doi:10.1016/j.ejpb.2006.04.004

[4] P. J. Pentikäinen, P. J. Neuvonen and A. Penttilä, “Phar-

macokinetics of Metformin after Intravenous and Oral

Administration to Man,” European Journal of Clinical

Pharmacology, Vol. 16, No. 3, 1979, pp. 195-202.

doi:10.1007/BF00562061

[5] G. T. Tucker, C. Casey, P. J. Phillips, H. Connor, J. D.

Ward and H. F. Woods, “Metformin Kinetics in Healthy

Subjects and in Patients with Diabetes Mellitus,” British

Journal of Clinical Pharmacology, Vol. 12, No. 2, 1981,

pp. 235-246.

[6] P. K. Bhoyar and D. M. Biyani, “Formulation and in Vitro

Evaluation of Sustained Release Dosage Form with Taste

Masking of Metformin Hydrochloride,” Indian Journal of

Pharmaceutical Sciences, Vol. 72, No. 2, 2010, pp. 184-

190. doi:10.4103/0250-474X.65031

[7] O. Defang, N. Shufang, L. Wei, G. Hong, L. Hui and P.

Weisan, “In Vitro and in Vivo Evaluation of Two Ex-

tended Release Preparations of Combination Metformin

and Glipizide,” Drug Development and Industrial Phar-

macy, Vol. 31, No. 7, 2005, pp. 677-685.

doi:10.1080/03639040500216410

[8] A. Ghosh, A. Bose and U. Bhaumik, “Application of

Response Surface Methodology in the Formulation of

Sustained Release Matrix Tablets of Metformin Hydro-

chloride,” Asian Journal of Chemistry, Vol. 20, No. 7,

2008, pp. 5541-5556.

[9] J. Piao, J. E. Lee, K. Y. Weon, D. W. Kim, J. S. Lee, J. D.

Park, Y. Nishiyama, I. Fukui and J. S. Kim, “Develop-

ment of Novel Mucoadhesive Pellets of Metformin Hy-

drochloride,” Archives of Pharmacal Research, Vol. 32,

No. 3, 2009, pp. 391-397.

doi:10.1007/s12272-009-1312-0

[10] P. Subhedar, J. B. Naik and D. N. Muley, “Effect of

Polymer Concentration on Sustained Release Microparti-

cles of Metformin Hydrochloride Prepared by Using Spray

Dryer,” Polymer-Plastics Technology and Engineering,

Vol. 49, No. 3, 2010, pp. 267-271.

[11] H. F. Liu, X. Y. Su, X. Li, X. Zhao, L. Zang and W. S.

Pan, “Development of Prolonged Release Microspheres

of Metformin Hydrochloride Using Ion Exchange Res-

ins,” Journal of Chinese Pharmaceutical Sciences, Vol.

15, No. 3, 2006, pp. 155-161.

[12] S. P. Boldhane and B. S. Kuchekar, “Gastroretentive

Drug Delivery of Metformin Hydrochloride: Formulation

and in Vitro Evaluation Using 32 Full Factorial Design,”

Current Drug Deliver, Vol. 6, No. 5, 2009, pp. 477-485.

[13] G. Di Colo, S. Falchi and Y. Zambito, “In Vitro Evalua-

tion of a System for pH-Controlled Peroral Delivery of

Metformin,” Journal of Controlled Release, Vol. 80, No.

1-3, 2002, pp. 119-128.

doi:10.1016/S0168-3659(02)00022-6

[14] P. C. Wu, M. J. Tsai, Y. B. Huang, J. S. Chang and Y. H.

Tsai, “In Vitro and in Vivo Evaluation of Potassium Chlo-

ride Sustained Release Formulation Prepared with Satu-

rated Polyglycolyed Glycerides Matrices,” International

Journal of Pharmaceutics, Vol. 243, No. 1-2, 2002, pp.

119-124. doi:10.1016/S0378-5173(02)00264-8

[15] J. E. Polli, G. S. Rekhi, L. L. Augsburger and V. P. Shah,

“Methods to Compare Dissolution Profiles and a Ration-

ale for Wide Dissolution Specifications for Metoprolol

Tartrate Tablets,” Journal of Pharmaceutical Sciences,

Vol. 86, No. 6, 1997, pp. 690-700. doi:10.1021/js960473x

[16] S. G. Wang, L. Wang, Z. Z. Shao, X. P. Lu and X. Q.

Hang, “Study on the Release Rate of Niacin in Different

Media for the Compound Niacin Extended-Release and

Simvastatin Tablets,” Chinese Journal of Pharmacology

and Toxicology, Vol. 8, No. 10, 2011, pp. 581-584.

[17] N. A. Peppas, “Analysis of Fickian and Non-Fickian Drug

Release from Polymers,” Pharmaceutica Acta Helvetiae,

Vol. 60, No. 4, 1985, pp. 110-111.

Copyright © 2012 SciRes. PP