G. PASUPATHI, P. PHILOMINATHAN

Copyright © 2012 SciRes. JMMCE

907

[4] M. Karppinnen, J. O. Lundgren and R. Liminga, “Struc-

ture of Pyroelectric Lithium Potassium Sulphate, LiKSO4,”

Acta Crystallographica Section C, Vol. 39, 1983, pp. 34-

38. doi:10.1107/S0108270183003509

[5] M. A. Pimenta, S. L. V. Vierira, F. O. V. Letelier, N. L.

Speziali and M. S. Dantas, “Ionic Conductivity in

LiK0.9Na0.1SO4 Single Crystals,” Solid State Communica-

tions, Vol. 82, No. 10, 1992, pp. 758-757.

doi:10.1016/0038-1098(92)90158-6

[6] A. Lunden and J. O. Thomas, “High Conductivity Solid

State Conductors: Recent Trends and Applications,”

World Scientific, Singapore City, 1986.

[7] H. K. Liu, M. L. Hu, W. S. Tse, D. P. Wong and S. J. Lin,

“Raman Studies of Low Temperature Phase Transition in

LiKSO4,” Chinese Journal of Physics, Vol. 36, No. 3,

1998, pp. 542-548.

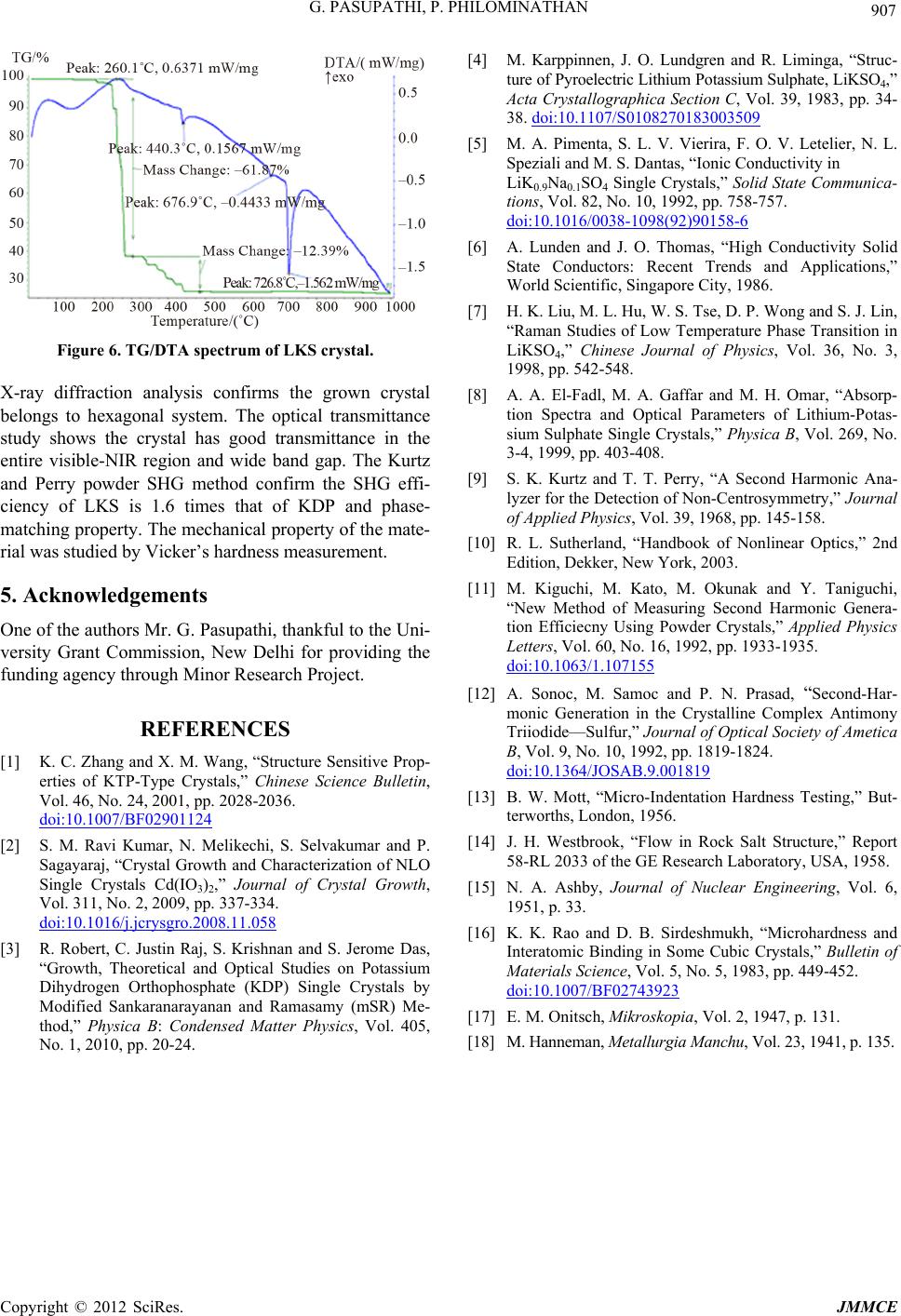

Figure 6. TG/DTA spectrum of LKS crystal.

X-ray diffraction analysis confirms the grown crystal

belongs to hexagonal system. The optical transmittance

study shows the crystal has good transmittance in the

entire visible-NIR region and wide band gap. The Kurtz

and Perry powder SHG method confirm the SHG effi-

ciency of LKS is 1.6 times that of KDP and phase-

matching property. The mechanical property of the mate-

rial was studied by Vicker’s hardness measurement.

[8] A. A. El-Fadl, M. A. Gaffar and M. H. Omar, “Absorp-

tion Spectra and Optical Parameters of Lithium-Potas-

sium Sulphate Single Crystals,” Physica B, Vol. 269, No.

3-4, 1999, pp. 403-408.

[9] S. K. Kurtz and T. T. Perry, “A Second Harmonic Ana-

lyzer for the Detection of Non-Centrosymmetry,” Journal

of Applied Physics, Vol. 39, 1968, pp. 145-158.

[10] R. L. Sutherland, “Handbook of Nonlinear Optics,” 2nd

Edition, Dekker, New York, 2003.

[11] M. Kiguchi, M. Kato, M. Okunak and Y. Taniguchi,

“New Method of Measuring Second Harmonic Genera-

tion Efficiecny Using Powder Crystals,” Applied Physics

Letters, Vol. 60, No. 16, 1992, pp. 1933-1935.

doi:10.1063/1.107155

5. Acknowledgements

One of the authors Mr. G. Pasupathi, thankful to the Uni-

versity Grant Commission, New Delhi for providing the

funding agency through Minor Research Project.

[12] A. Sonoc, M. Samoc and P. N. Prasad, “Second-Har-

monic Generation in the Crystalline Complex Antimony

Triiodide—Sulfur,” Journal of Optical Society of Ametica

B, Vol. 9, No. 10, 1992, pp. 1819-1824.

doi:10.1364/JOSAB.9.001819

REFERENCES

[1] K. C. Zhang and X. M. Wang, “Structure Sensitive Prop-

erties of KTP-Type Crystals,” Chinese Science Bulletin,

Vol. 46, No. 24, 2001, pp. 2028-2036.

doi:10.1007/BF02901124

[13] B. W. Mott, “Micro-Indentation Hardness Testing,” But-

terworths, London, 1956.

[14] J. H. Westbrook, “Flow in Rock Salt Structure,” Report

58-RL 2033 of the GE Research Laboratory, USA, 1958.

[2] S. M. Ravi Kumar, N. Melikechi, S. Selvakumar and P.

Sagayaraj, “Crystal Growth and Characterization of NLO

Single Crystals Cd(IO3)2,” Journal of Crystal Growth,

Vol. 311, No. 2, 2009, pp. 337-334.

doi:10.1016/j.jcrysgro.2008.11.058

[15] N. A. Ashby, Journal of Nuclear Engineering, Vol. 6,

1951, p. 33.

[16] K. K. Rao and D. B. Sirdeshmukh, “Microhardness and

Interatomic Binding in Some Cubic Crystals,” Bulletin of

Materials Science, Vol. 5, No. 5, 1983, pp. 449-452.

doi:10.1007/BF02743923

[3] R. Robert, C. Justin Raj, S. Krishnan and S. Jerome Das,

“Growth, Theoretical and Optical Studies on Potassium

Dihydrogen Orthophosphate (KDP) Single Crystals by

Modified Sankaranarayanan and Ramasamy (mSR) Me-

thod,” Physica B: Condensed Matter Physics, Vol. 405,

No. 1, 2010, pp. 20-24.

[17] E. M. Onitsch, Mikroskopia, Vol. 2, 1947, p. 131.

[18] M. Hanneman, Metallurgia Manchu, Vol. 23, 1941, p. 135.