E. J. MULLANEY ET AL. 397

Figure 3. Ethanol in the inorganic phosphate measurement.

200 µM potassium orthophosphate (K2HPO4) was mixed

with 0 to 10% ethanol in 1 mL 50 mM acetate buffer, pH

5.0 followed by AMA reagent and citrate. This is to rule out

any interference of ethanol in the phytase assay.

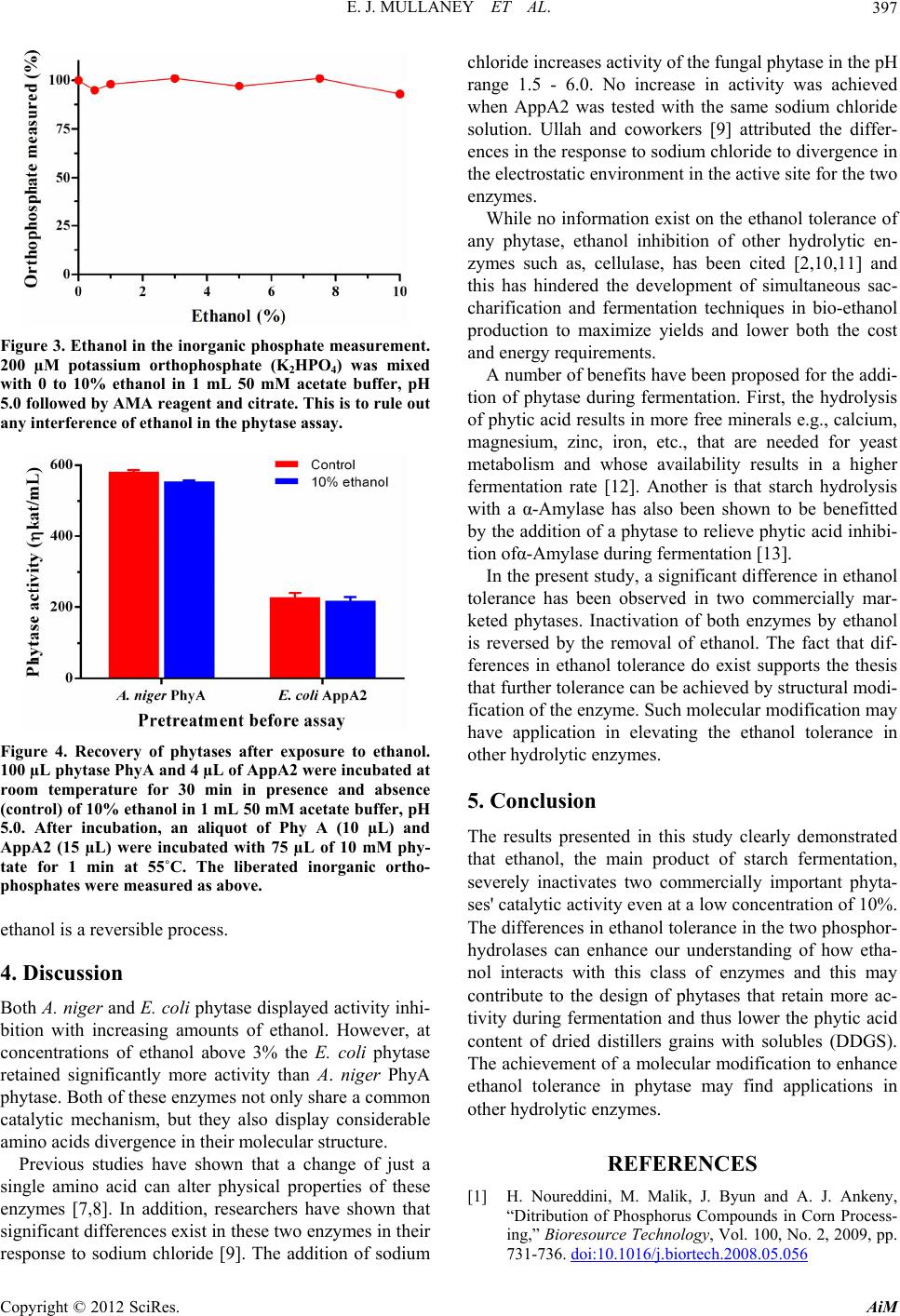

Figure 4. Recovery of phytases after exposure to ethanol.

100 µL phytase PhyA and 4 µL of AppA2 were incubated at

room temperature for 30 min in presence and absence

(control) of 10% ethanol in 1 mL 50 mM acetate buffer, pH

5.0. After incubation, an aliquot of Phy A (10 µL) and

AppA2 (15 µL) were incubated with 75 µL of 10 mM phy-

tate for 1 min at 55˚C. The liberated inorganic ortho-

phosphates were me asur e d as above.

ethanol is a reversible process.

4. Discussion

Both A. niger and E. coli phytase displayed activity inhi-

bition with increasing amounts of ethanol. However, at

concentrations of ethanol above 3% the E. coli phytase

retained significantly more activity than A. niger PhyA

phytase. Both of these enzymes not only share a common

catalytic mechanism, but they also display considerable

amino acids divergence in their molecular structure.

Previous studies have shown that a change of just a

single amino acid can alter physical properties of these

enzymes [7,8]. In addition, researchers have shown that

significant differences exist in these two enzymes in their

response to sodium chloride [9]. The addition of sodium

chloride increases activity of the fungal phytase in the pH

range 1.5 - 6.0. No increase in activity was achieved

when AppA2 was tested with the same sodium chloride

solution. Ullah and coworkers [9] attributed the differ-

ences in the response to sodium chloride to divergence in

the electrostatic environment in the active site for the two

enzymes.

While no information exist on the ethanol tolerance of

any phytase, ethanol inhibition of other hydrolytic en-

zymes such as, cellulase, has been cited [2,10,11] and

this has hindered the development of simultaneous sac-

charification and fermentation techniques in bio-ethanol

production to maximize yields and lower both the cost

and energy requirements.

A number of benefits have been proposed for the addi-

tion of phytase during fermentation. First, the hydrolysis

of phytic acid results in more free minerals e.g., calcium,

magnesium, zinc, iron, etc., that are needed for yeast

metabolism and whose availability results in a higher

fermentation rate [12]. Another is that starch hydrolysis

with a α-Amylase has also been shown to be benefitted

by the addition of a phytase to relieve phytic acid inhibi-

tion ofα-Amylase during fermentation [13].

In the present study, a significant difference in ethanol

tolerance has been observed in two commercially mar-

keted phytases. Inactivation of both enzymes by ethanol

is reversed by the removal of ethanol. The fact that dif-

ferences in ethanol tolerance do exist supports the thesis

that further tolerance can be achieved by structural modi-

fication of the enzyme. Such molecular modification may

have application in elevating the ethanol tolerance in

other hydrolytic enzymes.

5. Conclusion

The results presented in this study clearly demonstrated

that ethanol, the main product of starch fermentation,

severely inactivates two commercially important phyta-

ses' catalytic activity even at a low concentration of 10%.

The differences in ethanol tolerance in the two phosphor-

hydrolases can enhance our understanding of how etha-

nol interacts with this class of enzymes and this may

contribute to the design of phytases that retain more ac-

tivity during fermentation and thus lower the phytic acid

content of dried distillers grains with solubles (DDGS).

The achievement of a molecular modification to enhance

ethanol tolerance in phytase may find applications in

other hydrolytic enzymes.

REFERENCES

[1] H. Noureddini, M. Malik, J. Byun and A. J. Ankeny,

“Ditribution of Phosphorus Compounds in Corn Process-

ing,” Bioresource Technology, Vol. 100, No. 2, 2009, pp.

731-736. doi:10.1016/j.biortech.2008.05.056

Copyright © 2012 SciRes. AiM