Paper Menu >>

Journal Menu >>

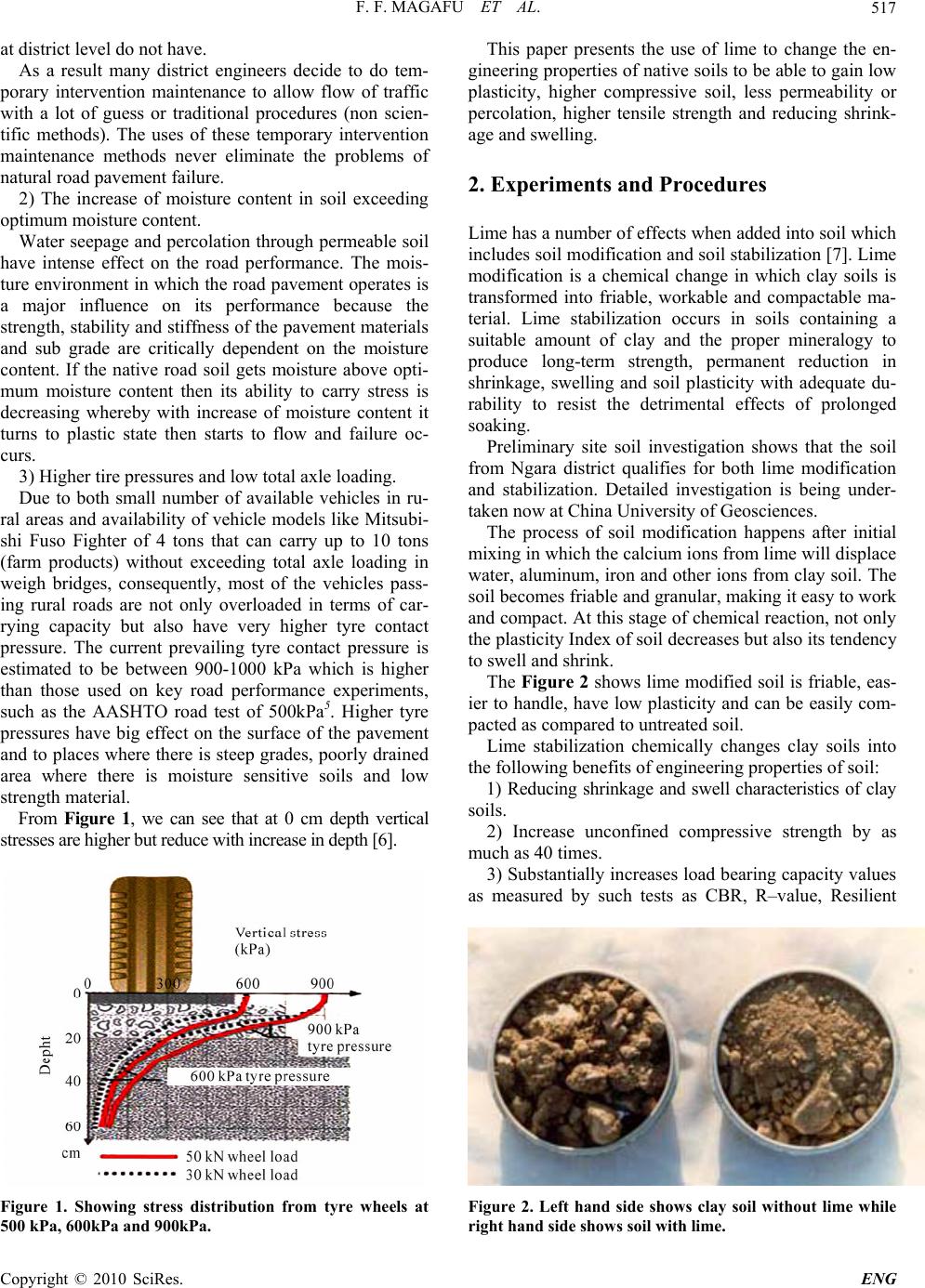

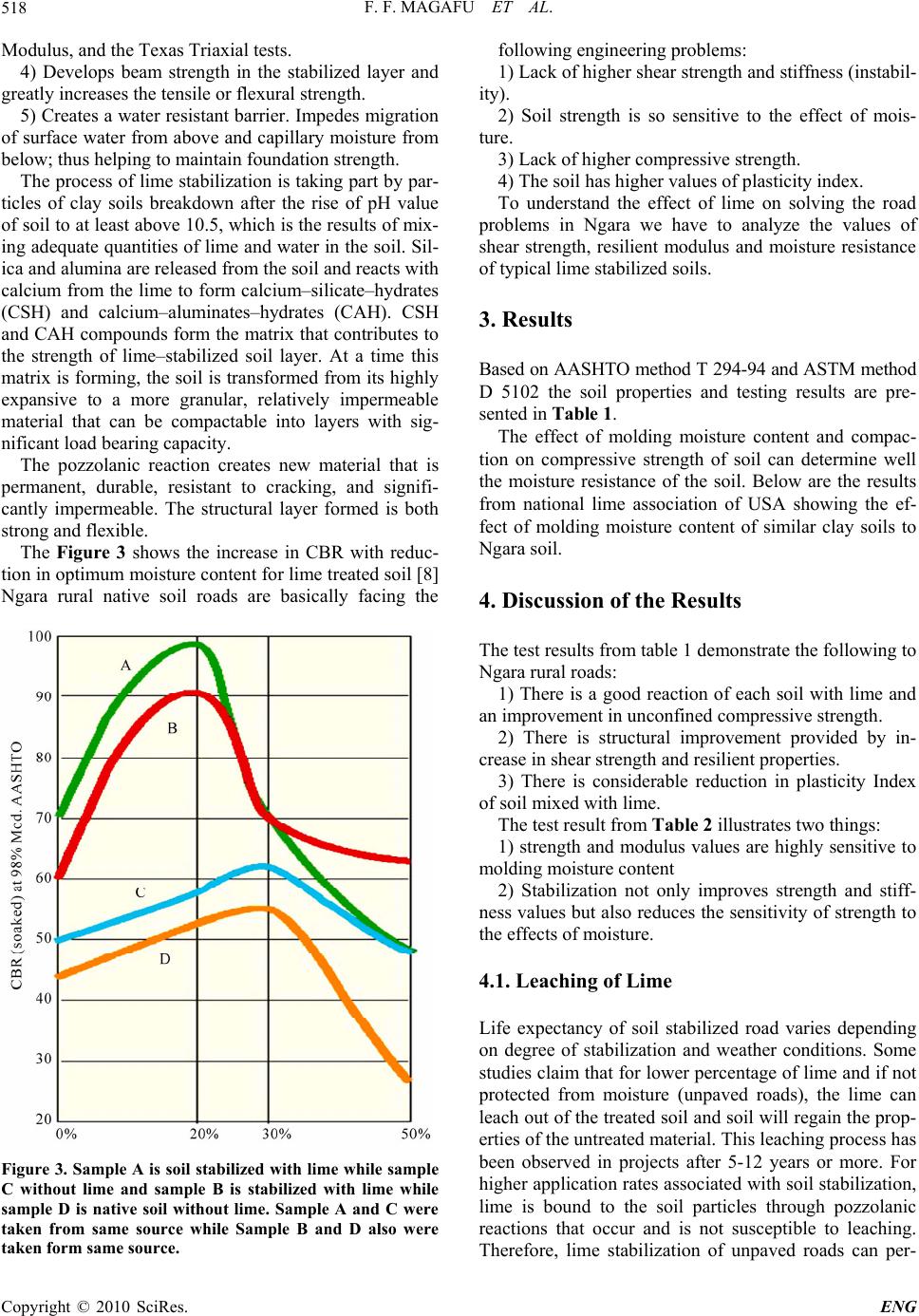

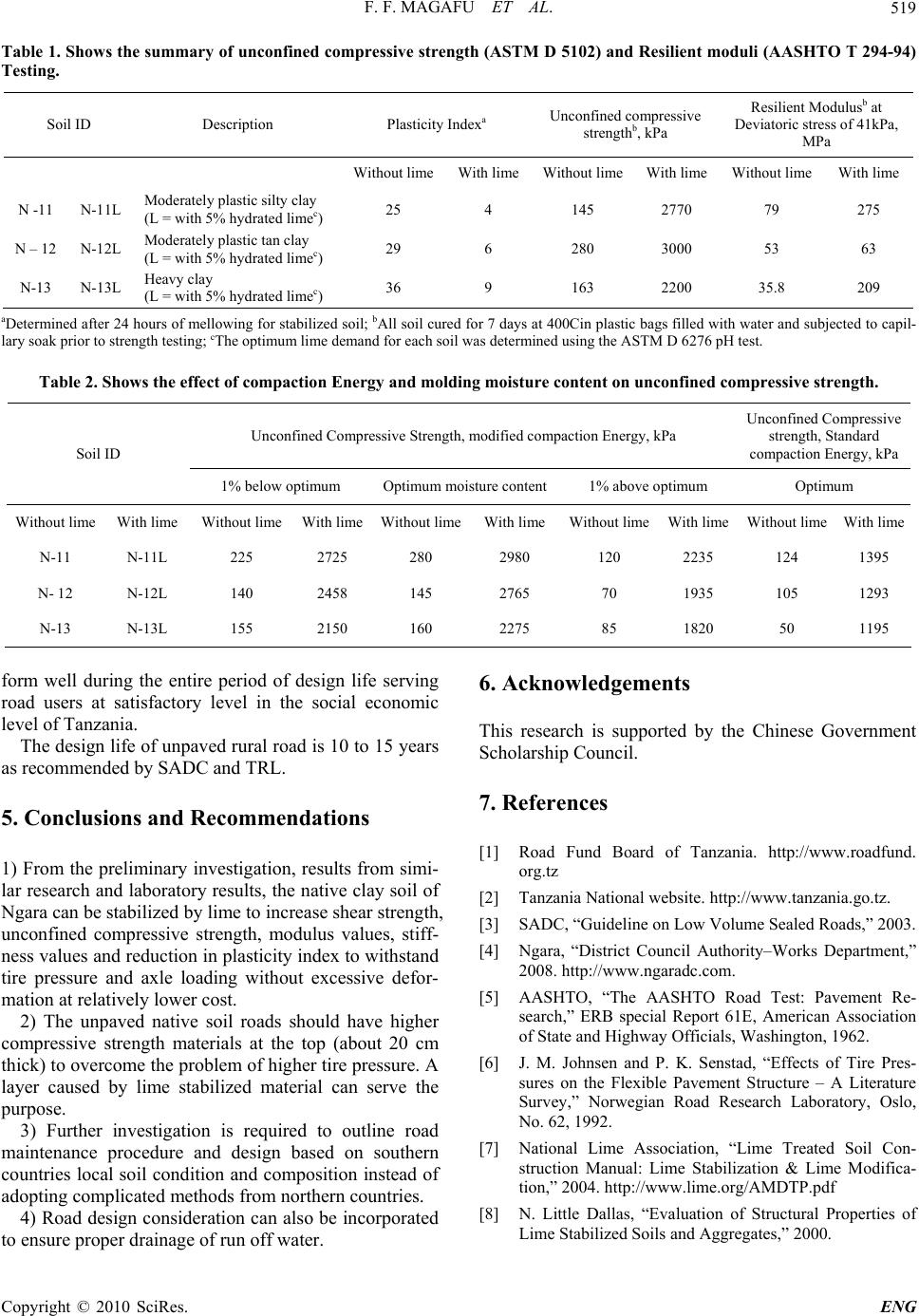

Engineering, 2010, 2, 516-519 doi:10.4236/eng.2010.27068 Published Online July 2010 (http://www.SciRP.org/journal/eng) Copyright © 2010 SciRes. ENG Utilization of Local Available Materials to Stabilize Native Soil (Earth Roads) in Tanzania—Case Study Ngara Fikiri Fredrick Magafu, Wu Li Faculty of Civil Engineering, China university of Geoscie n ces, Wuhan, China E-mail: fikirimagafu@yahoo.co.uk, lwu@cug.edu.cn Received March 5, 2010; revised March 5, 2010; accepted May 10, 2010 Abstract The native soil behavior of unpaved low volume roads and their mode of failure were studied to establish proper method of stabilizing native soils using local available materials. The use of lime and its positive ef- fect to modify and stabilize Ngara soil in Tanzania is presented in this paper. There are many methods of stabilizing soil to gain required engineering specifications. These methods range from mechanical to chemi- cal stabilization. Most of these methods are relatively expensive to be implemeted by slowly developing na- tions and the best way is to use locally available materials with relatively cheap costs affordable by their in- ternal funds. Tanzania is a country having abundantly amount of Lime. Ngara native soil roads (unpaved ru- ral roads) was studied under preliminary investigation and found to have higher plasticity, tendency of swel- ling and shrinking, low bearing capacity when wet, compressive strength of soil to have higher sensitivity to moisture and lower shear strength when wet. These soil behaviors deny road access to about 32 million peo- ple in Tanzania (80% of population) during rainy season. The detailed investigations is still going on at China university of Geosciences but other results from similar researches show that Ngara soils can be stabi- lized by lime and gain the required engineering properties. Keywords: Low Volume Roads, Higher Plasticity Index, Bearing Capacity, Shear Strength of Soil, Engineering Properties of Soils, Engineering Specifications, Swell and Shrink age 1. Introduction Road Fund Board of Tanzania was established in 1997 with the responsibility of collecting and disbursement of internal funds to road agen ts for road mainten anc e activi- ties. Tanzania is a slowly developing nation having a total road n etwork of 85,525 [1] kilometers o ut of which only 5,034 kilometers is paved. Low volume rural roads consist of 56,625 kilo meters which is unpaved and hard- ly passable throughout a year and serves more than 80% of Tanzanian population [2] (about 32 million people). Every place has its own definition of low volume roads depending on social economic development of the area. For developing countries, low volume roads are those roads carrying less than 0.5 million equivalent standard axle [3]. In reality the research conducted by Southern African Development Community (SADC) shows that in Tanzania low volume rural roads carries less than 0.1 million equivalent standard axle during de- sign period. In this paper, as for the case of Ngara District in Tan- zania, low volume roads are those district and village roads that carry less than 0.1 million equivalent standard axle of traffic during their design period. In actual, Ngara district rural roads carry less than 0.05 millions standard equivalent axle according to 2008 traffic count data analysis [4]. The design period is 10 year s. The engineering properties of native soil where un- paved roads pass through are critical parameters in the ability of road to carry and safely distribute stresses im- posed upon it without failure. The failure of Ngara low volume roads are caused mainly by the following rea- sons: 1) The use of complicated design and maintenance procedures adopted from developed countries. Tanzania is using adopted design methods from USA and European countries to design road pavements and these methods have been in use even for low volume roads. Not only the use of these methods lead to higher construction costs that can not be met by roads fund board money but also require cumbersome procedures and modern equipments that most road maintenance agencies  F. F. MAGAFU ET AL.517 at district level do not have. As a result many district engineers decide to do tem- porary intervention maintenance to allow flow of traffic with a lot of guess or traditional procedures (non scien- tific methods). The uses of these temporary intervention maintenance methods never eliminate the problems of natural road pavement failure. 2) The increase of moisture content in soil exceeding optimum moisture content. Water seepage and percolation through permeable soil have intense effect on the road performance. The mois- ture environment in which the road pavement operates is a major influence on its performance because the strength, stability and stiffness of the pav ement materials and sub grade are critically dependent on the moisture content. If the native road soil gets moisture above opti- mum moisture content then its ability to carry stress is decreasing whereby with increase of moisture content it turns to plastic state then starts to flow and failure oc- curs. 3) Higher tire pressures and low total axle loading. Due to both small number of available vehicles in ru- ral areas and availability of vehicle models like Mitsubi- shi Fuso Fighter of 4 tons that can carry up to 10 tons (farm products) without exceeding total axle loading in weigh bridges, consequently, most of the vehicles pass- ing rural roads are not only overloaded in terms of car- rying capacity but also have very higher tyre contact pressure. The current prevailing tyre contact pressure is estimated to be between 900-1000 kPa which is higher than those used on key road performance experiments, such as the AASHTO road test of 500kPa5. Higher tyre pressures have big effect on the surface of the pavement and to places where th ere is steep grades, poorly drained area where there is moisture sensitive soils and low strength material. From Figure 1, we can see that at 0 cm depth vertical stresses are higher but reduce wit h increase in de pth [6]. Figure 1. Showing stress distribution from tyre wheels at 500 kPa, 600kPa and 900kPa. This paper presents the use of lime to change the en- gineering properties of native soils to be ab le to gain low plasticity, higher compressive soil, less permeability or percolation, higher tensile strength and reducing shrink- age and swelling. 2. Experiments and Procedures Lime has a number of effects when added into soil which includes soil mod ification and soil stab ilizatio n [7]. Lime modification is a chemical change in which clay soils is transformed into friable, workable and compactable ma- terial. Lime stabilization occurs in soils containing a suitable amount of clay and the proper mineralogy to produce long-term strength, permanent reduction in shrinkage, swelling and soil plasticity with adequate du- rability to resist the detrimental effects of prolonged soaking. Preliminary site soil investigation shows that the soil from Ngara district qualifies for both lime modification and stabilization. Detailed investigation is being under- taken now at China University of Geo s ciences. The process of soil modification happens after initial mixing in which th e calcium ion s from lime will disp lace water, aluminum, iron and other ions from clay soil. The soil becomes friable and granular, making it easy to work and compact. At this stage of chemical reaction, not only the plasticity Index of soil decreases but also its tendency to swell and shrink. The Figure 2 shows lime modified soil is friable, eas- ier to handle, have low plasticity and can be easily com- pacted as compared to unt reated soil. Lime stabilization chemically changes clay soils into the following benefits of engineering properties of soil: 1) Reducing shrinkage and swell characteristics of clay soils. 2) Increase unconfined compressive strength by as much as 40 times. 3) Substantially in creases load bearing capacity values as measured by such tests as CBR, R–value, Resilient Figure 2. Left hand side shows clay soil without lime while right hand side shows soil with lime. Copyright © 2010 SciRes. ENG  F. F. MAGAFU ET AL. 518 Modulus, and th e Texas Triaxial tests. 4) Develops beam strength in the stabilized layer and greatly increases the tensile or flex ural strength. 5) Creates a water resistant barrier. Impedes migration of surface water from above and capillary moisture from below; thus helping to maintain found a tion strength. The process of lime stabilization is taking part by par- ticles of clay soils breakdown after the rise of pH value of soil to at least abov e 10.5, which is the results of mix- ing adequate quantities of lime and water in the soil. Sil- ica and alumina are released from the soil and reacts with calcium from the lime to form calcium–silicate–hydrates (CSH) and calcium–aluminates–hydrates (CAH). CSH and CAH compounds form the matrix that contributes to the strength of lime–stabilized soil layer. At a time this matrix is forming, the soil is transfor med from its hig hly expansive to a more granular, relatively impermeable material that can be compactable into layers with sig- nificant load bearing capacity. The pozzolanic reaction creates new material that is permanent, durable, resistant to cracking, and signifi- cantly impermeable. The structural layer formed is both strong and flexible. The Figure 3 shows the increase in CBR with reduc- tion in optimum moisture con tent for li me treated so il [8] Ngara rural native soil roads are basically facing the Figure 3. Sample A is soil stabilized with lime while sample C without lime and sample B is stabilized with lime while sample D is native soil without lime. Sample A and C were taken from same source while Sample B and D also were taken form same source. following engineering problems: 1) Lack of higher shear strength and stiffness (instabil- ity). 2) Soil strength is so sensitive to the effect of mois- ture. 3) Lack of higher compressive strength. 4) The soil has higher values of plasticity index. To understand the effect of lime on solving the road problems in Ngara we have to analyze the values of shear strength, resilient modulus and moisture resistance of typical lime stabilized soils. 3. Results Based on AASHTO method T 294-94 and ASTM method D 5102 the soil properties and testing results are pre- sented in Table 1. The effect of molding moisture content and compac- tion on compressive strength of soil can determine well the moisture resistance of the soil. Below are the results from national lime association of USA showing the ef- fect of molding moisture content of similar clay soils to Ngara soil. 4. Discussion of the Results The test results from table 1 demonstrate the following to Ngara rural roads: 1) There is a good reaction of each soil with lime and an improvement in unconfined compressive strength. 2) There is structural improvement provided by in- crease in shear strength and resilient properties. 3) There is considerable reduction in plasticity Index of soil mixed with lime. The test result from Table 2 illustrates two things : 1) strength and modulus values are highly sensitive to molding moisture content 2) Stabilization not only improves strength and stiff- ness values but also reduces the sensitivity of strength to the effects of moisture. 4.1. Leaching of Lime Life expectancy of soil stabilized road varies depending on degree of stabilization and weather conditions. Some studies claim that for lower percentage of lime and if not protected from moisture (unpaved roads), the lime can leach out of the treated soil and soil will regain the prop- erties of the untreated material. This leaching process has been observed in projects after 5-12 years or more. For higher application rates associated with soil stabilization, lime is bound to the soil particles through pozzolanic reactions that occur and is not susceptible to leaching. Therefore, lime stabilization of unpaved roads can per- Copyright © 2010 SciRes. ENG  F. F. MAGAFU ET AL. Copyright © 2010 SciRes. ENG 519 Table 1. Shows the summary of unconfined compressive strength (ASTM D 5102) and Resilient moduli (AASHTO T 294-94) Testing. Soil ID Description Plasticity Indexa Unconfined compressive strengthb, kPa Resilient Modulusb at Deviatoric stress of 41kPa, MPa Without limeWith limeWithout limeWith lime Without lime With lime N -11 N-11L Moderately plastic silty clay (L = with 5% hydrated limec) 25 4 145 2770 79 275 N – 12 N-12L Moderately plastic tan clay (L = with 5% hydrated limec) 29 6 280 3000 53 63 N-13 N-13L Heavy clay (L = with 5% hydrated limec) 36 9 163 2200 35.8 209 aDetermined after 24 hours of mellowing for stabilized soil; bAll soil cured for 7 days at 400Cin plastic bags filled with water and subjected to capil- lary soak prior to strength testing; cThe optimum lime demand for each soil was determined using the ASTM D 6276 pH test. Table 2. Show s the effect of compaction Energy and molding moisture content on unconfined compressive strength. Unconfined Compressive Stre ngth, modified compaction Energy, kPa Unconfined Compressive strength, Standard compaction Energy, kPa Soil ID 1% below optimum Optimum moisture content1% above optimum Optimum Without lime With lime Without lime With limeWithout limeWith limeWithout limeWith lime Without limeWith lime N-11 N-11L 225 2725 280 2980 120 2235 124 1395 N- 12 N-12L 140 2458 145 2765 70 1935 105 1293 N-13 N-13L 155 2150 160 2275 85 1820 50 1195 form well during the entire period of design life serving road users at satisfactory level in the social economic level of Tanzania. The design life of unpaved rural road is 10 to 15 years as recommended by SADC and TRL. 5. Conclusions and Recommendations 1) From the preliminary investigation, results from simi- lar research and laboratory results, the n ative clay soil of Ngara can be stabilized by lime to increase shear strength, unconfined compressive strength, modulus values, stiff- ness values and reduction in plasticity index to withstand tire pressure and axle loading without excessive defor- mation at relatively lower cost. 2) The unpaved native soil roads should have higher compressive strength materials at the top (about 20 cm thick) to overcome the problem of high er tire pressure. A layer caused by lime stabilized material can serve the purpose. 3) Further investigation is required to outline road maintenance procedure and design based on southern countries local soil condition and composition instead of adopting complicated methods from northern countries. 4) Road design consideration can also be incorporated o ensure proper drainage of run off water. t 6. Acknowledgements This research is supported by the Chinese Government Scholarship Council. 7. References [1] Road Fund Board of Tanzania. http://www.roadfund. org.tz [2] Tanzania National website. http://www.tanzania.go.tz. [3] SADC, “Guideline on Low Volume Sealed Roads,” 2003. [4] Ngara, “District Council Authority–Works Department,” 2008. http://www.ngaradc.com. [5] AASHTO, “The AASHTO Road Test: Pavement Re- search,” ERB special Report 61E, American Association of State and Highway Officials, Washington, 1962. [6] J. M. Johnsen and P. K. Senstad, “Effects of Tire Pres- sures on the Flexible Pavement Structure – A Literature Survey,” Norwegian Road Research Laboratory, Oslo, No. 62, 1992. [7] National Lime Association, “Lime Treated Soil Con- struction Manual: Lime Stabilization & Lime Modifica- tion,” 2004. http://www.lime.org/AMDTP.pdf [8] N. Little Dallas, “Evaluation of Structural Properties of Lime Stabilized Soils and Aggregates,” 2000. |