Paper Menu >>

Journal Menu >>

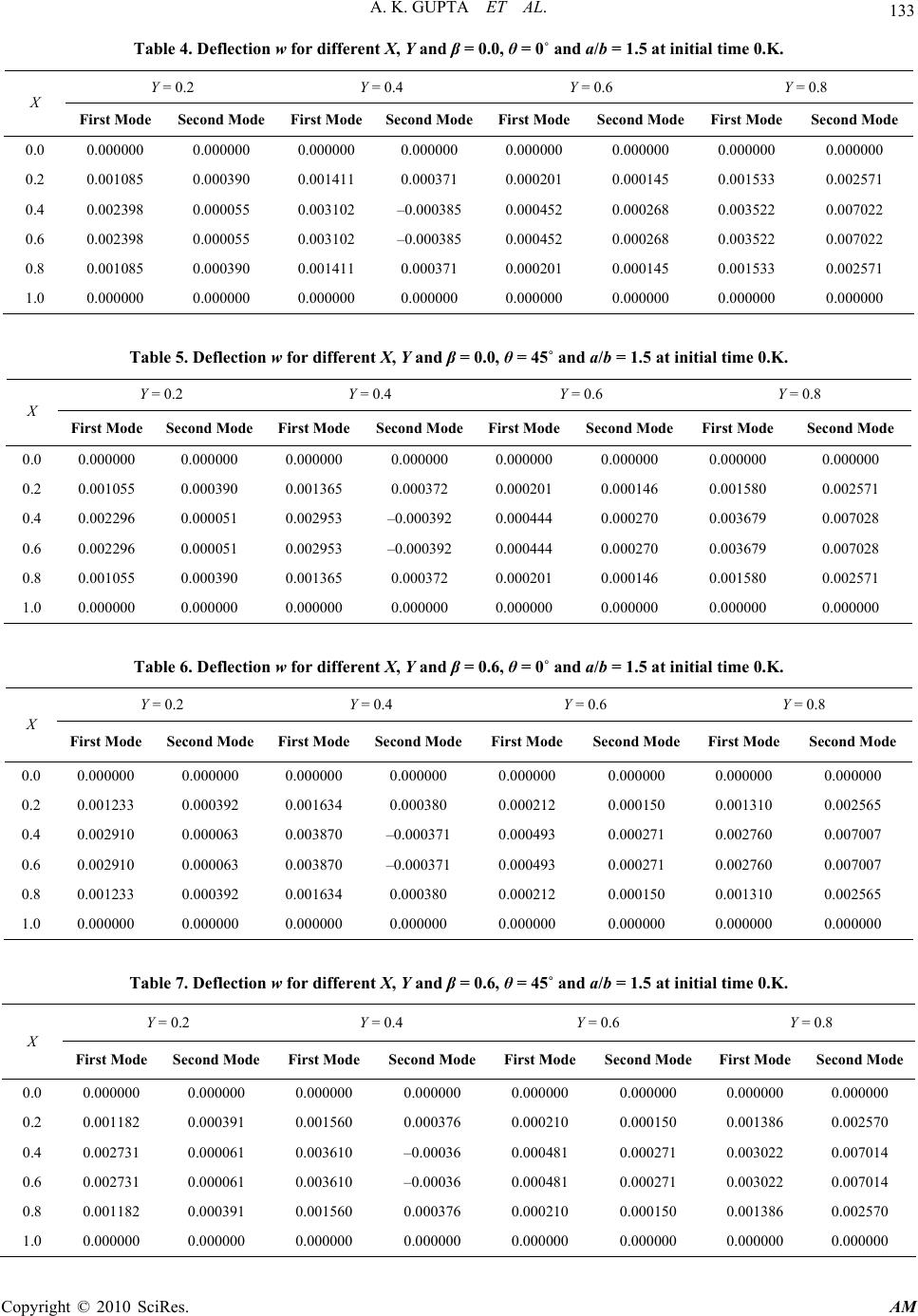

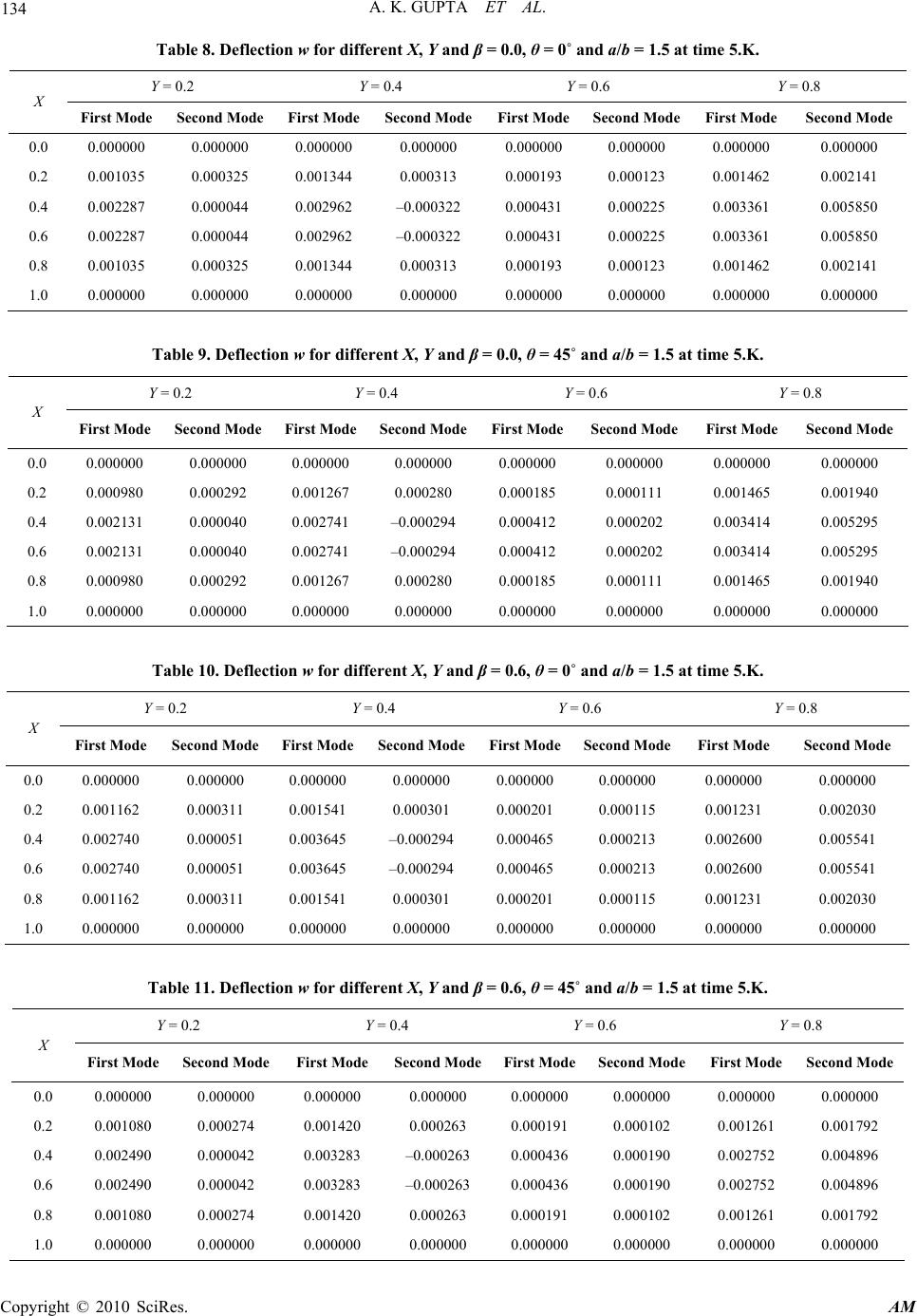

Applied Mathematics, 2010, 1, 128-136 doi:10.4236/am.2010.12017 Published Online July 2010 (http://www. SciRP.org/journal/am) Copyright © 2010 SciRes. AM Vibration of Visco-Elastic Parallelogram Plate with Parabolic Thickness Variation Arun Kumar Gupta*, Anuj Kumar, Yogesh Kumar Gupta Maharaj Singh College, Saharanpur, India E-mail: gupta_arunnitin@yahoo.co.in Received April 7, 2010; revised May 10, 2010; accepted May 17, 2010 Abstract The main objective of the present investigation is to study the vibration of visco-elastic parallelogram plate whose thickness varies parabolically. It is assumed that the plate is clamped on all the four edges and that the thickness varies parabolically in one direction i.e. along length of the plate. Rayleigh-Ritz technique has been used to determine the frequency equation. A two terms deflection function has been used as a solution. For visco-elastic, the basic elastic and viscous elements are combined. We have taken Kelvin model for visco-elasticity that is the combination of the elastic and viscous elements in parallel. Here the elastic ele- ment means the spring and the viscous element means the dashpot. The assumption of small deflection and linear visco-elastic properties of “Kelvin” type are taken. We have calculated time period and deflection at various points for different values of skew angles, aspect ratio and taper constant, for the first two modes of vibration. Results are supported by tables. Alloy “Duralumin” is considered for all the material constants used in numerical calculations. Keywords: Vibration, Parallelogram Plate, Visco-Elastic Mechanics, Parabolic Thickness, Aspect Ratio 1. Introduction The materials are being developed, depending upon the requirement and durability, so that these can be used to give better strength, flexibility, weight effectiveness and efficiency. So some new materials and alloys are utilized in making structural parts of equipment used in modern technological industries like space craft, jet engine, earth quake resistance structures, telephone industry etc. Ap- plications of such materials are due to reduction of weight and size, low expenses and enhancement in effec- tiveness and strength. It is well known that first few fre- quencies of structure should be known before finalizing the design of a structure. The study of vibration of skew plate structures is important in a wide variety of applica- tions in engineering design. Parallelogram elastic plates are widely employed nowadays in civil, aeronautical and marine structures designs. Complex shapes with variety of thickness variation are sometimes incorporated to re- duce costly material, lighten the loads, and provide ven- tilation and to alter the resonant frequencies of the struc- tures. Dynamic behavior of these structures is strongly dependent on boundary conditions, geometric shapes, material properties etc. Dhotarad and Ganesan [1] have considered vibration analysis of a rectangular plate subjected to a thermal gradient. Amabili and Garziera [2] have studied trans- verse vibrations of circular, annular plates with several combinations of boundary conditions. Ceribasi and Altay [3] introduced the free vibration analysis of super ellip- tical plates with constant and variable thickness by Ritz method. Gupta, Ansari and Sharma [4] have analyzed vibration analysis of non-homogenous circular plate of non linear thickness variation by differential quadrature method. Jain and Soni [5] discussed free vibrations of rectangular plates of parabolically varying thickness. Singh and Saxena [6] discussed the transverse vibration of rectangular plate with bi-directional thickness. Free vibrations of non-homogeneous circular plate of variable thickness resting on elastic foundation are discussed by Tomar, Gupta and Kumar [7]. Yang [8] has considered the vibration of a circular plate with varying thickness. Gupta, Ansari and Sharma [9] discussed the vibration of non-homogeneous circular Mindlin plates with variable thickness. Bambill, Rossit, Laura and Rossi [10] have analyzed transverse vibration of an orthotropic rectangu- lar plate of linearly varying thickness with a free edge. Sufficient work [11,12] is available on the vibration of a rectangular plate of variable thickness in one direction,  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 129 but none of them done on parallelogram plate. Recently Gupta, Kumar and Gupta [13] studied the vibration of visco-elastic parallelogram plate of linearly varying thic- kness. A simple model presented here is to study the eff- ect of parabolic thickness variation on vibration of visco- elastic parallelogram plate having clamped boundary co- nditions on all the four edges. The hypothesis of small deflection and linear visco-elastic properties are made. Using the separation of variables method, the governing differential equation has been solved for vibration of vis- co-elastic parallelogram plate. An approximate but quite convenient frequency equation is derived by using Ray- leigh-Ritz technique with a two-term deflection function. It is assumed that the visco-elastic properties of the plate are of the “Kelvin Type”. Time period and deflection fu- nction at different point for the first two modes of vibra- tion are calculated for various values of taper constant, aspect ratio and skew angle and results are presented in tabular form. 2. Equation of Transverse Motion The parallelogram (skew) plate is assumed to be non- uniform, thin and isotropic and the plate R be defined by the three number a, b and θ as shown in Figure 1. The skew coordinates are related to rectangular coor- dinates are sec,tan yyx The boundaries of the plate in skew coordinates are ba ,0,,0 The governing differential equation of transverse mo- tion of visco-elastic parallelogram plate of variable thi- ckness, ξ- and η- coordinates is given by [13]: 22 1cos 2 max Tp hWdd (1) Figure 1. Geometry of parallelogram plate. and 22 22 1cos() 2(1) 2 sec(,,,) VDW WW Wdd or 22 ,,, 3 222 ,, 22 ,,,, 14sin 2(sin 2cos cos)2(1sincos) 4sin VDWWW vWWv WWWWdd (2) and 2Ď0 ,t t TpT (3) A comma followed by a suffix denotes partial differ- ential with respect to that variable. Here p2 is a constant. Here solution w(ξ, η, t) can be taken in the form of products of two functions as for free transverse vibration of the parallelogram plate so that )(),(),,(tTWtw (4) where T(t) is the time function and W is the maximum displacement with respect to time t. Assuming thickness variation of parallelogram plate parabolically in ξ-direction as })/(1{ 2 0ahh (5) where β is the taper constant in ξ-direction and 0 h 0 h. The flexural rigidity D of the plate can now be written as )1(12))/(1( 2323 0vaEhD , (6) 3. Solution and Frequency Equation In using the Rayleigh-Ritz technique, one requires max- imum strain energy be equal to the maximum kinetic energy. So it is necessary for the problem consider here that 0)( max TV (7) for arbitrary variations of W satisfying relevant geomet- rical boundary conditions. For a parallelogram plate, clamped (c) along all the four edges, the boundary conditions are b at WW and a at WW ,00 ,00 , , (8) and the corresponding two-term deflection function is taken as  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 130 2 12 ()()(1)(1) ()()(1)(1) Wabab AA a bab (9) Using Equations (5) and (6) in Equations (1) and (2), one obtains 222 max 0 00 1cos(1() ) 2 ba Thp Wdd a (10) and 3 23 2 0 , 23 00 222 ,, ,, 22 223 , 42 ,, , (1())4() 24(1 )cos sinWW2()(sincos)WW 2()(1sincos)W4() sinWW()W ba Eh a VW ab av b aa v bb add b (11) Using Equations (10) and (11) in Equation (7), one obtains 0)( 1 22 1 TpV (12) where 23 2 1, 00 222 ,, ,, 22 223 , 42 ,, , (1() )4() sinWW2()(sincos)WW 2()(1sincos)W4() sinWW()W ba a VW ab av b aa v bb add b (13) and ddW a T ba 22 00 4 1))(1(cos (14) Here, 42 2 2 0 12 1a Eh (15) is a constant. But Equation (12) involves the unknown A1 and A2 arising due to the substitution of W(ξ, η) from Equation (9). These two constants are to be determined from Equation (12), as follows: 2,1,0/)( 1 22 1 n ATpVn (16) Equation (16) simplifies to the form 21,0 1211 ,n AbAbnn (17) where bn1, bn2 (n =1,2) involve parametric constants and the frequency parameter. For a non-trivial solution, the determinant of the coef- ficient of Equation (17) must be zero. So one gets the frequency equation as 0 2221 1211 bb bb (18) Here, )(1 22 111 BpFb , 22 12 2122 ()bb FpB , and )( 3 22 322 BpFb where F1, F2, F3, B1, B2, B3 involves parametric constants, skew angle and aspect ratio and given as ,)()cos sin1()(2)cos(sin)(2 4 4 3 2 22 2 222 11 I b a Iv b a Iv b a IF ,cos 5 4 1IB ,)()cos sin1()(2)cos(sin)(2 9 4 8 2 22 7 222 62 I b a Iv b a Iv b a IF ,cos10 4 2IB ,)()cos sin1()(2)cos(sin)(2 14 4 13 2 22 12 222 113 I b a Iv b a Iv b a IF ,cos 15 4 3IB Here, , 194040 1 150150 1 121275 4 22050 1 , 1981980 37 53361 4 5390 1 8085 1 , 1455300 1 396900 1 , 75075 4 10725 4 1925 2 1575 2 , 675675 2 121275 8 3675 1 11025 4 , 675675 2 121275 8 3675 1 11025 4 , 363825 113 3675 4 11025 16 1575 2 32 7 32 6 5 32 4 32 3 32 2 32 1 I I I I I I I  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 131 , 541080540 1 144288144 1 , 6172530 1 2382380 3 525525 2 210210 1 , 20158600 3 3853850 3 1926925 3 592900 1 , 524123600 3 3853850 1 15415400 19 592900 1 , 30060030 17 2004002 5 220220 1 210210 1 , 14270256 1 3841992 1 , 216580 1 175175 6 10010 1 8085 1 , 210210 1 42900 1 23100 1 22050 1 15 3 2 14 3 2 13 3 2 12 3 2 11 10 32 9 32 8 I I I I I I I I From Equation (18), one can obtains a quadratic equa- tion in p2 from which the two values of p2 can found. After determining A1 & A2 from Equation (17), one can obtain deflection function W. Choosing A1 = 1, one ob- tains A2 = (–b11/b12) and then W comes out as 2 11 12 ()(1 )(1) 1()()(1)(1). WXYabX Yab b bXYabXYab (19) Here .aY and aX 4. Differential Equation of Time Function and its Solution Time functions of free vibrations of viscoelastic plates are defined by the general ordinary differential Equation (3). Their form depends on the viscoelastic operator Ď. For Kelvin’s model, one has =1+( )()ĎňGddt (20) where, ň is viscoelastic constant and G is shear modulus. The governing differential equation of time function of a parallelogram plate of variable thickness, by using Equ- ation (20) in Equation (3), one obtains as 22 () 0 ,tt ,t TpňGT pT (21) Equation (21) is a differential equation of order two for time function T. Solution of Equation (21) comes out as 11 11 ()=( cossin) kt Tte CktCkt (22) where, 22kpňG (23) and 12 2 11( 2)kp pňG (24) Let us take initial conditions as 1and0at0T dT/dt t (25) Using initial conditions from Equation (25) in Equa- tion (22), one obtains 111 ()cos() (/)sin() kt Ttektk kkt (26) Thus, deflection w may be expressed, by using Equa- tions (26) and (19) in Equation (4), to give 2 11 12 111 ()(1)(1) 1() ()(1)(1) cos( )()sin( ) kt WXYab X Yab b b XYabXYab ektkkkt (27) Time period of vibration of the plate is given by pK /2 , (28) where p is frequency given by Equation (18). 5. Results and Discussion Time period and deflection are computed for visco-elas- tic parallelogram plate, whose thickness varies paraboli- cally, for different value of skew angle (θ), taper constant (β), and aspect ratio (a/b) at different points for first two mode of vibration. The material parameters have been taken as [14]: E = 7.08 × 1010 n/m2, G = 2.682 × 1010 n/m2, ň = 1.4612 × 106 n.s/m2, ρ = 2.80 × 103 kg/m3, ν = 0.345 and h0 = 0.01 meter. All the results are presented in the Tables 1-11. The value of time period (K) for β = 0.6, θ = 45˚ have been found to decrease 35.89% for first mode and 34.74% for second mode in comparison to rectangular plate at fixed aspect ratio (a/b = 1.5). The value of time period (K) for β = 0.6, θ = 45˚ have been found to decrease 20.54% for first mode and 21.23% for second mode in comparison to parallelogram plate of uniform thickness at fixed aspect ratio (a/b = 1.5) . Table 1 shows the results of time period (K) for dif- ferent values of taper constant (β) and fixed aspect ratio (a/b = 1.5) for two values of skew angle (θ) i.e. θ = 0˚ and θ = 45˚ for first two mode of vibration. It can be seen that the time period (K) decrease when taper constant (β) increase for first two mode of vibration. Table 2 shows the results of time period (K) for dif-  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 132 ferent values of skew angle (θ) and fixed aspect ratio (a/b = 1.5) for two values of taper constant (β) i.e. β = 0.0, β = 0.2 for first two mode of vibration. It can be seen that the time period (K) decrease when skew angle (θ) increase for first two mode of vibration. . Table 3 shows the results of time period (K) for dif- ferent values of aspect ratio (a/b) and fixed taper con- stant (β = 0.0 and β = 0.6) for two values of skew angle (θ) i.e. θ = 0˚ and θ = 45˚ for first two mode of vibration. It can be seen that the time period (K) decrease when aspect ratio (a/b) increase for first two mode of vibration. The value of deflection (w) for β = 0.6 and θ = 45˚ have been found to increase 14.19% for first mode and 1.07% for second mode in comparison to parallelogram plate of uniform thickness for initial time 0.K at X = 0.2, Y = 0.4 and a/b = 1.5. The value of deflection (w) for β = 0.6 and θ = 45˚ have been found to decrease 4.76% for first mode and 0.53% for second mode in comparison to rectangular plate for initial time 0.K at X = 0.2, Y = 0.4 and a/b = 1.5. The value of deflection (w) for β = 0.6 and θ = 45˚ have been found to increase 11.91% for first mode and decrease 6.03% for second mode in comparison to paral- lelogram plate of uniform thickness for time 5.K at X = 0.2, Y = 0.4 and a/b = 1.5. The value of deflection (w) for β = 0.6 and θ = 45˚ have been found to decrease 7.91% for first mode and 11.96% for second mode in comparison to rectangular plate for time 5.K at X = 0.2, Y = 0.4 and a/b = 1.5. Tables 4-11 show the results of deflection (w) for dif- ferent values of X, Y and fixed taper constant (β = 0.0 and β = 0.6), and aspect ratio (a/b = 1.5) for two values of skew angle (θ) i.e. θ = 0˚ and θ = 45˚ for first two mode of vibration with time 0.K and 5.K. It can be seen that deflection (w) start from zero to increase then de- crease to zero for first two mode of vibration (except second mode at Y = 0.2 and 0.4) and second mode of vibration deflection (w) at (Y = 0.2 and Y = 0.4) start zero to increase, decrease, increase, decrease and finally be- come to zero for different value of X. 6. Conclusions The Rayleigh-Ritz technique has been applied to study the effect of the taper constants on the vibration of clam- ped visco-elastic isotropic parallelogram plate with para- bolically varying thickness on the basis of classical plate theory. Table 1. Time period K (in second) for different taper con- stant (β) and a constant aspect ratio (a/b = 1.5). θ = 0˚ θ = 45˚ β First Mode Second Mode First Mode Second Mode 0.0 0.142648 0.036357 0.090306 0.023976 0.2 0.131780 0.033664 0.084639 0.022199 0.4 0.121820 0.030664 0.078029 0.020376 0.6 0.112958 0.028060 0.072148 0.018465 0.8 0.104063 0.025895 0.067140 0.017093 Table 2. Time period K (in second) for different skew angle (θ) and a constant aspect ratio (a/b = 1.5). β = 0.0 β = 0.2 θ First Mode Second Mode First Mode Second Mode 0˚ 0.142648 0.036357 0.131780 0.033664 15˚ 0.137773 0.035762 0.127248 0.032985 30˚ 0.121041 0.031427 0.112004 0.029016 45˚ 0.090306 0.023976 0.084639 0.022199 60˚ 0.051089 0.013211 0.047425 0.012143 75˚ 0.014111 0.003431 0.013235 0.003491 Table 3. Time period K (in second) for different aspect ratio (a/b). β = 0.0, θ = 0˚ β = 0.0, θ = 45˚ β = 0.6, θ = 0˚ β = 0.6, θ = 45˚ a/b First Mode Second Mode First Mode Second ModeFirst ModeSecond ModeFirst Mode Second Mode 0.5 0.172515 0.042510 0.1189167 0.029103 0.133024 0.032025 0.091918 0.022024 1.0 0.159377 0.040155 0.106213 0.027055 0.124312 0.030879 0.083221 0.020997 1.5 0.142648 0.036357 0.090306 0.023976 0.112958 0.028060 0.072148 0.018465 2.0 0.125147 0.033092 0.075399 0.020193 0.100177 0.026135 0.061061 0.016145 2.5 0.108096 0.028951 0.061982 0.016358 0.087268 0.023080 0.050393 0.013274  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 133 Table 4. Deflection w for different X, Y and β = 0.0, θ = 0˚ and a/b = 1.5 at initial time 0.K. Y = 0.2 Y = 0.4 Y = 0.6 Y = 0.8 X First Mode Second Mode First ModeSecond ModeFirst ModeSecond ModeFirst Mode Second Mode 0.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.2 0.001085 0.000390 0.001411 0.000371 0.000201 0.000145 0.001533 0.002571 0.4 0.002398 0.000055 0.003102 –0.000385 0.000452 0.000268 0.003522 0.007022 0.6 0.002398 0.000055 0.003102 –0.000385 0.000452 0.000268 0.003522 0.007022 0.8 0.001085 0.000390 0.001411 0.000371 0.000201 0.000145 0.001533 0.002571 1.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 Table 5. Deflection w for different X, Y and β = 0.0, θ = 45˚ and a/b = 1.5 at initial time 0.K. Y = 0.2 Y = 0.4 Y = 0.6 Y = 0.8 X First Mode Second Mode First Mode Second ModeFirst ModeSecond ModeFirst Mode Second Mode 0.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.2 0.001055 0.000390 0.001365 0.000372 0.000201 0.000146 0.001580 0.002571 0.4 0.002296 0.000051 0.002953 –0.000392 0.000444 0.000270 0.003679 0.007028 0.6 0.002296 0.000051 0.002953 –0.000392 0.000444 0.000270 0.003679 0.007028 0.8 0.001055 0.000390 0.001365 0.000372 0.000201 0.000146 0.001580 0.002571 1.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 Table 6. Deflection w for different X, Y and β = 0.6, θ = 0˚ and a/b = 1.5 at initial time 0.K. Y = 0.2 Y = 0.4 Y = 0.6 Y = 0.8 X First Mode Second Mode First Mode Second ModeFirst ModeSecond ModeFirst Mode Second Mode 0.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.2 0.001233 0.000392 0.001634 0.000380 0.000212 0.000150 0.001310 0.002565 0.4 0.002910 0.000063 0.003870 –0.000371 0.000493 0.000271 0.002760 0.007007 0.6 0.002910 0.000063 0.003870 –0.000371 0.000493 0.000271 0.002760 0.007007 0.8 0.001233 0.000392 0.001634 0.000380 0.000212 0.000150 0.001310 0.002565 1.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 Table 7. Deflection w for different X, Y and β = 0.6, θ = 45˚ and a/b = 1.5 at initial time 0.K. Y = 0.2 Y = 0.4 Y = 0.6 Y = 0.8 X First Mode Second Mode First Mode Second ModeFirst ModeSecond Mode First Mode Second Mode 0.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.2 0.001182 0.000391 0.001560 0.000376 0.000210 0.000150 0.001386 0.002570 0.4 0.002731 0.000061 0.003610 –0.00036 0.000481 0.000271 0.003022 0.007014 0.6 0.002731 0.000061 0.003610 –0.00036 0.000481 0.000271 0.003022 0.007014 0.8 0.001182 0.000391 0.001560 0.000376 0.000210 0.000150 0.001386 0.002570 1.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 134 Table 8. Deflection w for different X, Y and β = 0.0, θ = 0˚ and a/b = 1.5 at time 5.K. Y = 0.2 Y = 0.4 Y = 0.6 Y = 0.8 X First Mode Second Mode First ModeSecond ModeFirst ModeSecond ModeFirst Mode Second Mode 0.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.2 0.001035 0.000325 0.001344 0.000313 0.000193 0.000123 0.001462 0.002141 0.4 0.002287 0.000044 0.002962 –0.000322 0.000431 0.000225 0.003361 0.005850 0.6 0.002287 0.000044 0.002962 –0.000322 0.000431 0.000225 0.003361 0.005850 0.8 0.001035 0.000325 0.001344 0.000313 0.000193 0.000123 0.001462 0.002141 1.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 Table 9. Deflection w for different X, Y and β = 0.0, θ = 45˚ and a/b = 1.5 at time 5.K. Y = 0.2 Y = 0.4 Y = 0.6 Y = 0.8 X First Mode Second Mode First Mode Second ModeFirst ModeSecond ModeFirst Mode Second Mode 0.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.2 0.000980 0.000292 0.001267 0.000280 0.000185 0.000111 0.001465 0.001940 0.4 0.002131 0.000040 0.002741 –0.000294 0.000412 0.000202 0.003414 0.005295 0.6 0.002131 0.000040 0.002741 –0.000294 0.000412 0.000202 0.003414 0.005295 0.8 0.000980 0.000292 0.001267 0.000280 0.000185 0.000111 0.001465 0.001940 1.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 Table 10. Deflection w for different X, Y and β = 0.6, θ = 0˚ and a/b = 1.5 at time 5.K. Y = 0.2 Y = 0.4 Y = 0.6 Y = 0.8 X First Mode Second Mode First Mode Second ModeFirst ModeSecond ModeFirst Mode Second Mode 0.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.2 0.001162 0.000311 0.001541 0.000301 0.000201 0.000115 0.001231 0.002030 0.4 0.002740 0.000051 0.003645 –0.000294 0.000465 0.000213 0.002600 0.005541 0.6 0.002740 0.000051 0.003645 –0.000294 0.000465 0.000213 0.002600 0.005541 0.8 0.001162 0.000311 0.001541 0.000301 0.000201 0.000115 0.001231 0.002030 1.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 Table 11. Deflection w for different X, Y and β = 0.6, θ = 45˚ and a/b = 1.5 at time 5.K. Y = 0.2 Y = 0.4 Y = 0.6 Y = 0.8 X First Mode Second Mode First ModeSecond ModeFirst ModeSecond ModeFirst Mode Second Mode 0.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.2 0.001080 0.000274 0.001420 0.000263 0.000191 0.000102 0.001261 0.001792 0.4 0.002490 0.000042 0.003283 –0.000263 0.000436 0.000190 0.002752 0.004896 0.6 0.002490 0.000042 0.003283 –0.000263 0.000436 0.000190 0.002752 0.004896 0.8 0.001080 0.000274 0.001420 0.000263 0.000191 0.000102 0.001261 0.001792 1.0 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 135 On comparison with [13], it is concluded that: Time period K is more for non-uniform thickness in case of parabolic variation as comparison to linear varia- tion. Deflection w is less for non-uniform thickness in case of parabolic variation as comparison to linear variation. In this way, authors concluded that parabolic variation is more useful than linear variation. 7. References [1] M. S. Dhotarad and N. Ganesan, “Vibration Analysis of a Rectangular Plate Subjected to a Thermal Gradient,” Jour- nal of Sound and Vibration, Vol. 60, No. 4, 1978, pp. 481-497. [2] M. Amabili and R. Garziera, “Transverse Vibrations of Circular, Annular Plates with Several Combinations of Boundary Conditions,” Journal of Sound and Vibration, Vol. 228, No. 2, 1999, pp. 443-446. [3] S. Ceribasi and G. Altay, “Free Vibration of Super Ellip- tical Plates with Constant and Variable Thickness by Ritz Method,” Journal of Sound and Vibration, Vol. 319, No. 1-2, 2009, pp. 668-680. [4] U. S. Gupta, A. H. Ansari and S. Sharma, “Vibration Analysis of Non-Homogenous Circular Plate of Non- Linear Thickness Variation by Differential Quadrature Method,” Journal of Sound and Vibration, Vol. 298, No. 4-5, 2006, pp. 892-906. [5] R. K. Jain and S. R. Soni, “Free Vibrations of Rectangu- lar Plates of Parabolically Varying Thicknesses,” Indian Journal of Pure and Applied Mathematics, Vol. 4, No. 3, 1973, pp. 267-277. [6] B. Singh and V. Saxena, “Transverse Vibration of Rec- tangular Plate with Bidirectional Thickness Variation,” Journal of Sound and Vibration, Vol. 198, No. 1, 1996, pp. 51-65. [7] J. S. Tomar, D. C. Gupta and V. Kumar, “Free Vibrations of Non-Homogeneous Circular Plate of Variable Thick- ness Resting on Elastic Foundation,” Journal of Engi- neering Design, Vol. 1, No. 3, 1983, pp. 49-54. [8] J. S. Yang, “The Vibration of a Circular Plate with Vary- ing Thickness,” Journal of Sound and Vibration, Vol. 165, No. 1, 1993, pp. 178-184. [9] U. S. Gupta, A. H. Ansari and S. Sharma, “Vibration of Non-Homogeneous Circular Mindlin Plates with Variable Thickness,” Journal of Sound and Vibration, Vol. 302, No. 1-2, 2007, pp. 1-17. [10] D. V. Bambill, C. A. Rossit, P. A. A. Laura and R. E. Rossi, “Transverse Vibrations of an Orthotropic Rectan- gular Plate of Linearly Varying Thickness and with a Free Edge,” Journal of Sound and Vibration, Vol. 235, No. 3, 2000, pp. 530-538. [11] A. W. Leissa, “Recent Research in Plate Vibrations: Clas- sical Theory,” The Shock and Vibration Digest, Vol. 9, No. 10, 1977, pp. 13-24. [12] Z. Sobotka, “Free Vibration of Visco-Elastic Orthotropic Rectangular Plates,” Acta Technica (Czech Science Ad- vanced Views), No. 6, 1978, pp. 678-705. [13] A. K. Gupta, A. Kumar and Y. K. Gupta, “Vibration Study of Visco-Elastic Parallelogram Plate of Linearly Varying Thickness,” International Journal of Engineer- ing and Interdisciplinary Mathematics, accepted for pub- lication. [14] K. Nagaya, “Vibrations and Dynamic Response of Vis- coelastic Plates on Non-Periodic Elastic Supports,” Jour- nal of Engineering for Industry, Vol. 99, 1977, pp. 404-409.  A. K. GUPTA ET AL. Copyright © 2010 SciRes. AM 136 Appendix: List of Symbols a length of the plate, ň Visco-elastic constants, b width of the plate, w(ξ, η ,t) deflection of the plate i.e. amplitude, ξ and η co-ordinates in the plane of the plate, W(ξ,η) deflection function, h thickness of the plate at the point (ξ, η), T(t) time function, E young’s modulus, β taper constant, G shear modulus, K time period, ν Poisson’s ratio, h 0 h at ξ = 0, D ~ visco-elastic operator, a/b aspect ratio, D Eh3/12(1-ν2), flexural rigidity, θ skew angle, T max Kinetic energy, ρ mass density per unit volume of the plate material, V Strain energy, t time, λ2 12ρ (1-ν2)a4/Eh0 2, a frequency parameter |