P. A. WASEKAR ET AL.

808

tained without any purification or chemical modification

or surface treatment. Finalux G3 (wetting agent) was

obtained fr o m Fine Organics Ltd., M umbai, India.

2.2. Preparation of Composite

Concentration of cenosphere was varied upto 10 phr into

the nylon matrix. Firstly, dry blending of cenosphere and

nylon 6 was done in tumbler mixer for 15 - 20 min, using

finalux G3 as the wetting agent. Then the mix was melt

blended in a twin screw co-rotating extruder (Lab Tech

Engineering Co. Ltd., Germany) having L/D ratio of 32:1

and temperature profile from the hopper to the die as

170˚C, 190˚C, 200˚C, 210˚C, 220˚C, 230˚C, 240˚C and

250˚C. Extruded strands were water cooled at 30˚C and

pelettized. Pellets obtained were used for injection mold-

ing after pre-drying at 80˚C for 8 - 10 hrs. Injection

molding (Boolani machineries India ltd, Mumbai, India)

was done maintaining temperature profile as 210˚C,

230˚C and 250˚C from the hopper to the ejection nozzle.

Standard ASTM based samples for tensile, flexural and

impact testing were obtained from injection molding.

Samples for impact testing were notch cut before testing.

2.3. Characterization and Testing

2.3.1. Mechanica l Pro p e rties

Tensile properties; tensile strength and elongation at

break and flexural properties; flexural strength and flex-

ural modulus, were measured at ambient condition using

a universal testing machine (LR-50K, Lloyds Instrument,

UK), according to ASTM procedures D638 and D790; at

a crosshead speed of 50 mm/min and 2.8 mm/min re-

spectively. The notch for impact test was made using a

motorized notch-cutting machine (Polytest model 1, Ray

Ran, UK). Notched Izod impact strength was determined

at ambient condition according to ASTM D256 standard,

using impact tester (Avery Denison, UK) having striking

velocity of 3.46 m/s employing a 2.7 J striker.

2.3.2. Thermal Properties

Differential scanning calorimetry (Q 100 DSC, TA in-

struments Ltd., India) characterization was done to in-

vestigate the crystallization and melting behaviour of the

composite. Two consecutive heating scans were found to

minimize the influence of possible residual stresses in the

material due to any specific thermal history. Scanning

rate of 10˚C/min was maintained for both heating and

cooling cycle; whereas nitrogen gas purge rate main-

tained at 50 ml/min. Melting temperature was determined

from the second heating scan while the crystallization

temperature (Tc) from cooling scan.

2.3.3. Rheological Properties

The melt viscosity was measured using rotational rheometer

(MCR101, Anton Paar, India) with parallel plate assem-

bly having diameter of 35 mm. Samples were predried

before analysis. Viscosity was determined for sh ear rates

from 0.01 s–1 to 100 s–1 at the constant temperature of

250˚C.

2.3.4. M orp hologica l Properties

Scanning electron microscope (SEM) analysis was per-

formed with JEOL 6380 LA (Japan). Samples were frac-

tured under liquid nitrogen to avoid any disturbance to

the molecular structure and then coated with gold before

imaging.

2.3.5. X-Ray Diffr ac tion

The XRD analysis was carried out to determine the per-

centage crystallinity of the prepared co mposite. A normal

focus copper X-ray tube was operated at 30 kV and 15

mA. Sample scanning was done from 2.00˚ to 80.00˚ at

the rate of 3.00˚/min. The data processing was done us-

ing Jade 6.0 software.

2.4. Formulation

The formulations prepared are as shown in the Table 2.

Concentration of cenosphere was varied from 0 to 10 phr

of nylon 6, while concentration of wetting agent was

maintained constan t at 5 phr of nylon 6.

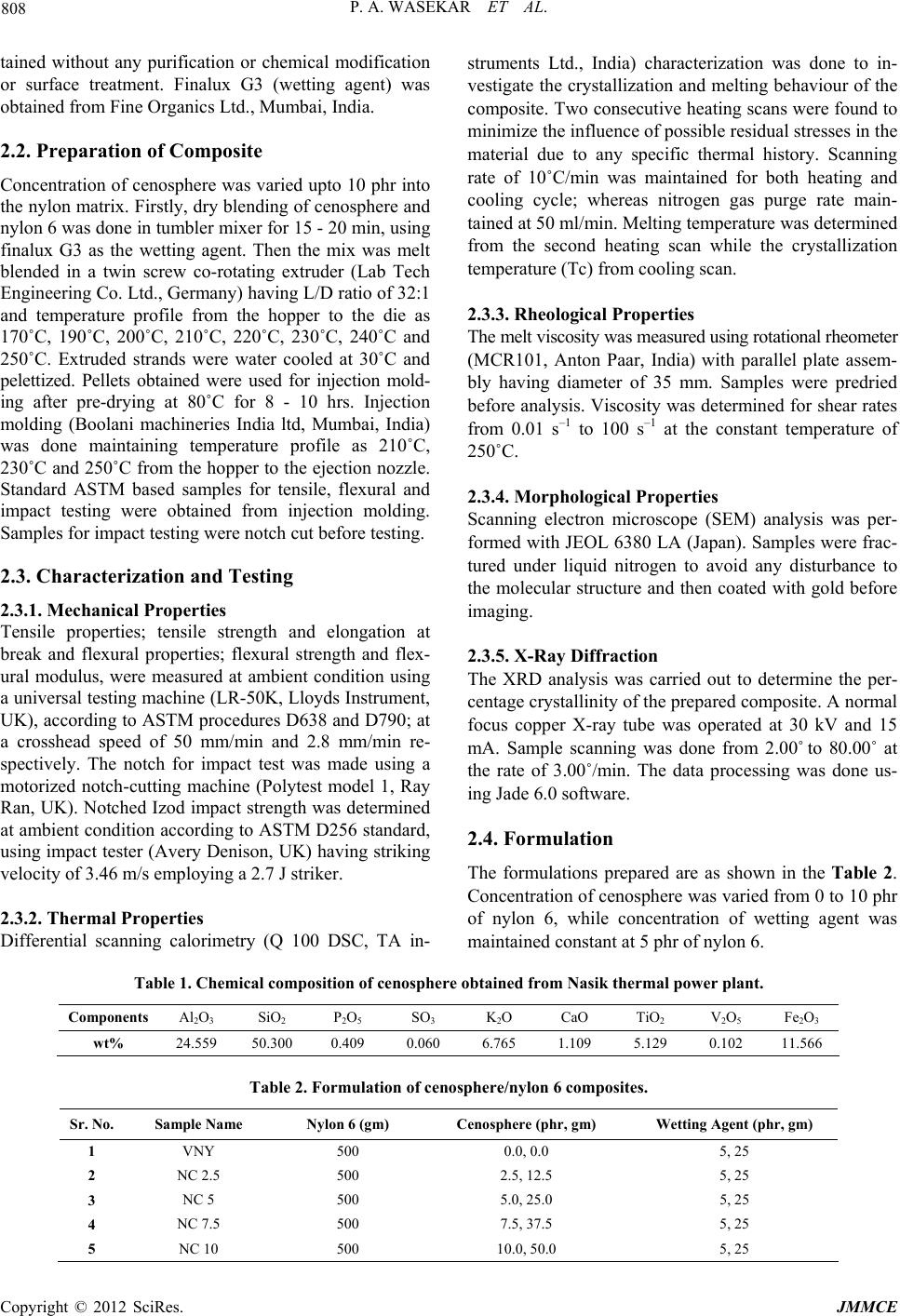

Table 1. Chemical composition of cenosphere obtained from Nasik thermal power plant.

Components Al2O3 SiO2 P

2O5 SO3 K

2O CaO TiO2 V

2O5 Fe2O3

wt% 24.559 50.300 0.409 0.060 6.765 1.109 5.129 0.102 11.566

Table 2. Formulation of cenosphere/nylon 6 composites.

Sr. No. Sample Name Nylon 6 (gm) Cenosphere (phr, gm) Wetting Agent (phr, gm)

1 VNY 500 0.0, 0.0 5, 25

2 NC 2.5 500 2.5, 12.5 5, 25

3 NC 5 500 5.0, 25.0 5, 25

4 NC 7.5 500 7.5, 37.5 5, 25

5 NC 10 500 10.0, 50.0 5, 25

Copyright © 2012 SciRes. JMMCE