B. K. C. GANESH ET AL.

742

(a)

(b)

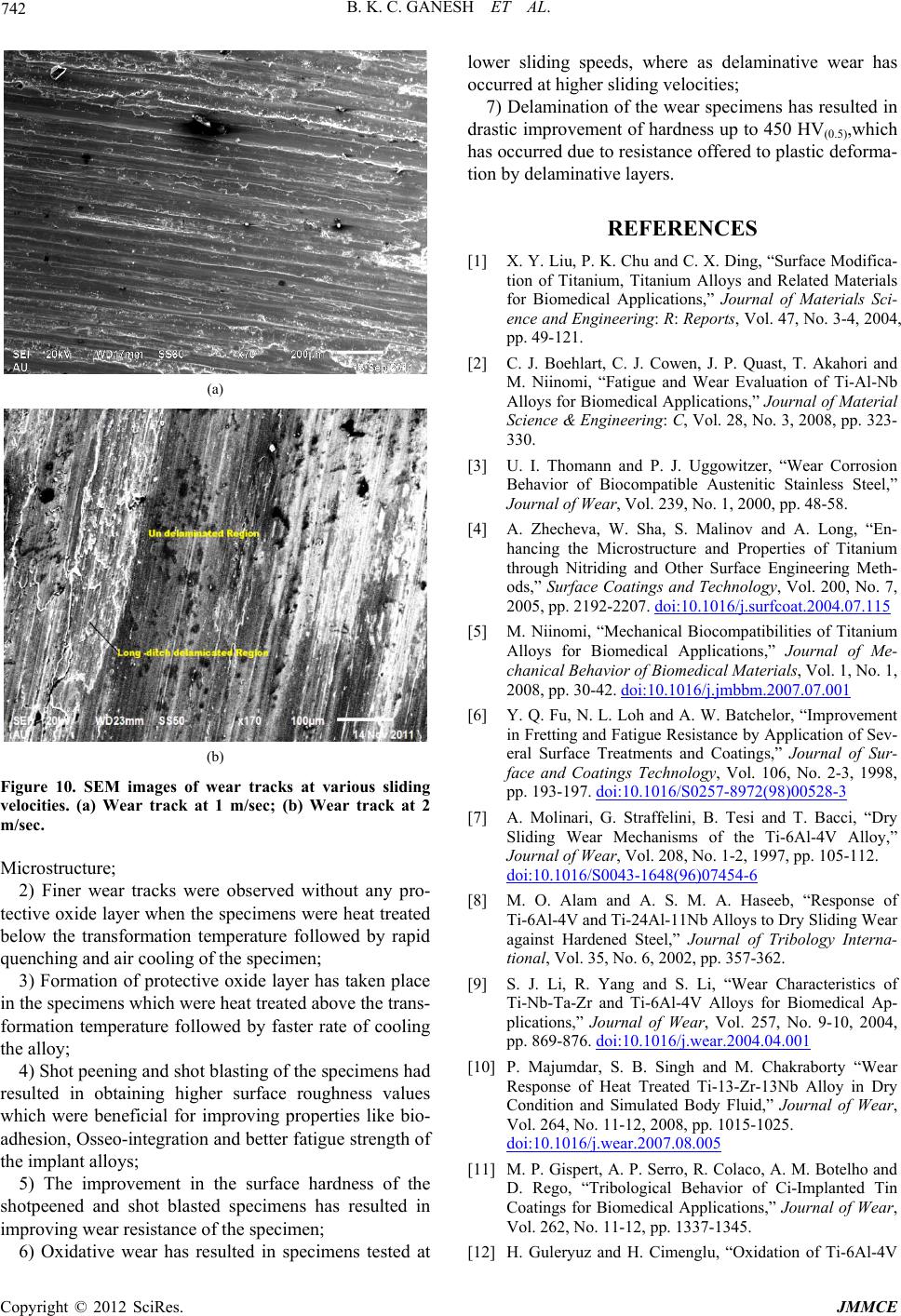

Figure 10. SEM images of wear tracks at various sliding

velocities. (a) Wear track at 1 m/sec; (b) Wear track at 2

m/sec.

Microstructure;

2) Finer wear tracks were observed without any pro-

tective oxide layer when the specimens were heat treated

below the transformation temperature followed by rapid

quenching and air cooling of the specimen;

3) Formation of protective oxide layer has taken place

in the specimens which were heat treated above the trans-

formation temperature followed by faster rate of cooling

the alloy;

4) Shot peening and shot blasting of the specimens had

resulted in obtaining higher surface roughness values

which were beneficial for improving properties like bio-

adhesion, Osseo-integration and better fatigue strength of

the implant alloys;

5) The improvement in the surface hardness of the

shotpeened and shot blasted specimens has resulted in

improving wear resistance of the specimen;

6) Oxidative wear has resulted in specimens tested at

lower sliding speeds, where as delaminative wear has

occurred at higher sliding velocities;

7) Delamination of the wear specimens has resulted in

drastic improvement of hardness up to 450 HV(0.5),which

has occurred due to resistance offered to plastic deforma-

tion by delaminative layers.

REFERENCES

[1] X. Y. Liu, P. K. Chu and C. X. Ding, “Surface Modifica-

tion of Titanium, Titanium Alloys and Related Materials

for Biomedical Applications,” Journal of Materials Sci-

ence and Engineering: R: Reports, Vol. 47, No. 3-4, 2004,

pp. 49-121.

[2] C. J. Boehlart, C. J. Cowen, J. P. Quast, T. Akahori and

M. Niinomi, “Fatigue and Wear Evaluation of Ti-Al-Nb

Alloys for Biomedical Applications,” Journal of Material

Science & Engineering: C, Vol. 28, No. 3, 2008, pp. 323-

330.

[3] U. I. Thomann and P. J. Uggowitzer, “Wear Corrosion

Behavior of Biocompatible Austenitic Stainless Steel,”

Journal of Wear, Vol. 239, No. 1, 2000, pp. 48-58.

[4] A. Zhecheva, W. Sha, S. Malinov and A. Long, “En-

hancing the Microstructure and Properties of Titanium

through Nitriding and Other Surface Engineering Meth-

ods,” Surface Coatings and Technology, Vol. 200, No. 7,

2005, pp. 2192-2207. doi:10.1016/j.surfcoat.2004.07.115

[5] M. Niinomi, “Mechanical Biocompatibilities of Titanium

Alloys for Biomedical Applications,” Journal of Me-

chanical Behavior of Biomedical Materials, Vol. 1, No. 1,

2008, pp. 30-42. doi:10.1016/j.jmbbm.2007.07.001

[6] Y. Q. Fu, N. L. Loh and A. W. Batchelor, “Improvement

in Fretting and Fatigue Resistance by Application of Sev-

eral Surface Treatments and Coatings,” Journal of Sur-

face and Coatings Technology, Vol. 106, No. 2-3, 1998,

pp. 193-197. doi:10.1016/S0257-8972(98)00528-3

[7] A. Molinari, G. Straffelini, B. Tesi and T. Bacci, “Dry

Sliding Wear Mechanisms of the Ti-6Al-4V Alloy,”

Journal of Wear, Vol. 208, No. 1-2, 1997, pp. 105-112.

doi:10.1016/S0043-1648(96)07454-6

[8] M. O. Alam and A. S. M. A. Haseeb, “Response of

Ti-6Al-4V and Ti-24Al-11Nb Alloys to Dry Sliding Wear

against Hardened Steel,” Journal of Tribology Interna-

tional, Vol. 35, No. 6, 2002, pp. 357-362.

[9] S. J. Li, R. Yang and S. Li, “Wear Characteristics of

Ti-Nb-Ta-Zr and Ti-6Al-4V Alloys for Biomedical Ap-

plications,” Journal of Wear, Vol. 257, No. 9-10, 2004,

pp. 869-876. doi:10.1016/j.wear.2004.04.001

[10] P. Majumdar, S. B. Singh and M. Chakraborty “Wear

Response of Heat Treated Ti-13-Zr-13Nb Alloy in Dry

Condition and Simulated Body Fluid,” Journal of Wear,

Vol. 264, No. 11-12, 2008, pp. 1015-1025.

doi:10.1016/j.wear.2007.08.005

[11] M. P. Gispert, A. P. Serro, R. Colaco, A. M. Botelho and

D. Rego, “Tribological Behavior of Ci-Implanted Tin

Coatings for Biomedical Applications,” Journal of Wear,

Vol. 262, No. 11-12, pp. 1337-1345.

[12] H. Guleryuz and H. Cimenglu, “Oxidation of Ti-6Al-4V

Copyright © 2012 SciRes. JMMCE