Journal of Minerals & Materials Characterization & Engineering, Vol. 11, No.4, pp.353-363, 2012 jmmce.org Printed in the USA. All rights reserved 353 Role of Heat Treatment on A l6061- Frit Particulate Composites D. Ramesh1, R. P. Sw a my2, T.K. Chandrashekar3 1Research scholar, Sri Siddhartha Institute of Technology, Tumkur-572105, India 2 Department of studies in Mechanical Engineering, University B.D.T. College of Engineering, Davangere-577004, India 3 Department of Mechanical Engineering, Sri Siddhartha Institute of Technology, Tumkur-572105, India *Corresponding Author: srirameshg@gmail.com ABSTRACT In recent decades, aluminium alloy based metal matrix composites are used in several applications. Al6061 has been used as matrix material due to its good formability, excellent mechanical properties and etc., wide spectrum of the applications in industrial sectors. Inclusion of Frit particulates as reinforcement in Al6061 alloy material system improves its hardness and decrease in density. In the present investigation Al6061-Frit particulate composites were produced by ‘VORTEX’ method with varying weight percentages of Frit particulate from 0 wt% to 10 wt% in steps of 2.The as cast matrix alloy and its composites have been subjected to solutionizing treatment at a temperature of 5300C for 2 hours followed by quenching in different media such as air, water and ice. The q uenched specimens were subjected to artificial ageing. Aged specimens were subjected to ultra-sonic test using ultra-sonic flaw detector testing apparatus to identify the common casting defects like porosity, blow holes. Macrostructure and microstructure studies were conducted on as cast and composites in order to investigate the distribution of frit particles retained in matrix material system. Micro structural studies were carried out to understand nature of structure. Density measurement was carried out on both Al6061matrix alloy and Al6061-Frit particulate composite. Hardness tests have been conducted both on Al6061 matrix alloy and Al6061-Frit particulate composite before and after heat treatment. It has been observed under identical heat treatment conditions adopted, Al6061-Frit particulate composites exhibited significant improvement in hardness when compared with Al6061 alloy. Keywor d s: MMC’s, Solutionizing, Ageing, Density, Hardness.  354 D.Ramesh, R.P.Swamy, T.K.Chandrashekar Vol.11, No.4 1. INTRODUCTION Metal matrix composites are gaining wide popularly in several sectors due to its improved mechanical properties (and lighter density) when compared with metals/alloys, especially in applications where weight and strength are of prime importance. Al/Al alloy based metal matrix compo sites are widel y used. Al all oy based MMC are bei ng used as a m aterial s ystem in several applications such as Pushrods, cylinder, piston and brake disc etc. [1]. In last decade among all the aluminium alloys, Al6061 is (popular) admired as matrix material system in development of MMC’s owing to its good corrosion resistance and excellent mechanical properties [2]. Al6061 alloy is heat treatable and as a result further increase in strength c an be ex pected [ 3-5], major focus is on processing and characterization of Al based MMC’s were reported. [ 6-8]. The type of reinf orcement and syner gic effect of heat treatm ent plays a prevailing (dominant) role command in the final mechanical properties of MMC’s meager information is available, pertaining to the heat treatment of Al based composites. In light of the above the present investigation is aimed at studying the effect of quenching media and ageing duration on the hardness property of Al6061 matrix alloy and Al6061-Frit particulate composites. Heat treatment is an operation in the fabrication of an engineering materials system. The main objective of heat treatment is to make the material system structurally and physically fit for engineering application [9]. Solution heat treatment of aluminium alloys allows the maximum concentration of hardening solute to dissolve into solution. This process is careful ly carried ou t by heat treatm ent of an allo y to a t emperature at w hich one si ngle, solid phase exists. By this heat treatment, the solute atoms that were originall y part of a two phase solid solution dissolve into solution and originates (create) as one single phase. Once the alloy has been heated to the recommended solutionizing temperature, it is quenched at a rapid rate such that the solute atoms don’t have enough time to precipitate out of the solution. As a result of the quench, a super saturated solution now exists between solute and aluminium matrix [10, 11]. Quenching is the process of rapid cooling of material systems to room temperature to preserve the solute in solution. The cooling rate needs to be fast enough to prevent solid-state diffusion and precipitation of the phase. The rapid quenching creates a saturated solution and allows for i ncreas ed h a rd n ess and m echan ical pr o pert i es o f th e mat eri al system. In additi on to this studies have shown that the highest degree of corrosion resistance have been obtained through the maximum rates of quenching [12]. Quenchin g takes pl ace in th ree dist inct s tages, namely vapour blanket stage, Boiling stage and liquid cooling stage. The vapour blanket stage begin s wh en hot part submerged an unbroken blanket surrounds the object. This blanket exists between the specimen and quenching media if the heat from the surface of the object exceeds the amount of heat needed to form maximum vapour per unit area of the object. This stage is characterized by a relatively slow cooling rate since the vapour of the quenching media surrounds the object and acts as an insulator. In this particular stage, heat is removed from the object by radiation and conduction through the vapour layer. As the component cools, the vapour blanket cannot be maintained and therefore, breaks down. After this  Vol.11, No .4 Role of Heat Treatment on Al6061- Frit 355 breakdown, the boiling stage immediately begins. The surface of the object now carries in direct contact with the fluid and result in violent boiling of the medium. This stage is characterized by rapid heat transfer through the heat of vaporization. Size and shape of the vapour bubbles are important in controlling the duration of this stage as well as its corresponding rate. As the object continues to cool below the boiling point of the medium, the boiling stage can no longer exist and it too break down giving way to liquid cooling stage. This stage, much like the vapour blanket stage, is also characterized by slow rates of heat transfer. Heat is dissipated from the object by movement of the quenching medium by conduction currents. The difference in temperature between the boiling point of the medium and actual temperatu re of the medi um is the major factor influen cing the rate o f heat transf er in liquid. Previous studies [13-18] of the ageing behavior of the composite with discontinuous ceramic reinforcement is different from that of the aluminium matrix alloys. The hardening effect of these composites by ageing depends on several factors such as (1) matrix material; (2) the type of reinforcement including its size, shape and volume fraction; (3) the processing technology; (4) the ageing temperature. There is lack of information for ageing behavior of Al6061-Frit composites. In this paper the ageing behavior of Al6061-Frit composites is compared with heat treated Al6061 matrix alloy. 2. EXPERIMENTAL 2.1 Composite Production In this s tudy, the com posi tes were fab ricated b y vortex casting set -up consisting of resistance furnace with a mechanical stirrer unit. Al6061 as matrix material and frit as reinforcement material in the fabrication of composites. The chemical composition of Al6061 matrix alloy is shown in table.1. Table 1. Chemical composition of Al6061 (wt %) Approximately 4000 grams of Al6061 alloy ingots were cut into pieces to accommodate into the graphite crucible. The temperature was raised slowly above liqideous temperature of the melt. Preheating of frit particles at 4500c was done using a muffle furnace, placed near the casting set-up, in order to remove the moisture and gases from the surface of frit particles. The chemical composition of Frit is shown in table.2. The sti rrer was r aised, p ositi oned in to the crucible. The speed range used was upto 400 rpm. The super heated molten metal was degassed; preheated frit particles were added to the molten metal and stirred continuously by mechanical stirrer. The stirring time was 10  356 D.Ramesh, R.P.Swamy, T.K.Chandrashekar Vol.11, No.4 minutes. During stirring; magnesium was added in small quantities to enhance the wettability of frit particles. The dispersion of the frit particles was achieved in accordance with the vortex method. The melt, with the reinforcement was poured into the dried, preheated permanent metallic moulds (dies). The pouring temperature was maintained at 7100C. The melt was allowed to solidify in the moulds. The addition of Frit particles into the molten alloy was varied from 2 wt % to 10 wt % in steps of 2 wt%. For the purpose of comparison, the Al6061 matrix alloy was also casted under the similar conditions. Table 2. Chemical composition of frit (wt %) 2.2 Heat Treatmen t The cast Al6061 matrix alloy and Al6061-Frit particulate composites were subjected to solutionizing treatment at a temperature 5300C for a period of 2 h using muffle furnace, followed by quenching in three different quenchants vi z; Air, W at er and Ice. Artificial ageing treatment was carried out for a duration of 2 h to 10 h in steps of 2 h. Metallographic, density, and hardness tests were carried out on both unheated and heat treated specimens. 2.3 Microstructure Micros tru ctu re st ud ies w ere con d u cted on as cast m atri x as wel l as composite specimens. The specimens were metallographically ground with emery papers from 400 to 3000 grit and polished with diamond paste. Etching was done using Keller’s reagent. For characterization NIKON Metallurgical Microscope [NIKON, CLEMEX, ELLIPSE, and LV150] was used. 2.4 Density Tes t The theoretical density was calculated using rule-of-mixture and experimentally, the density measurements were carried out on the base alloy and reinforced samples using Archimedes principle. The buoyant force on submerged object is equal to the weight of the fluid displaced. This principle is useful for determining the volume, by measuring its mass in air and its effective mass when submerged in water (density=1 g/cc).This effective mass under water will be its actual mass minus the mass of the fluid displaced. The difference between the real and effective masses therefore gives the mass of the displaced water and allows the volume of the object to be calculated. Mass divided by the volume thus determined gives a measure of the average density of the object [19]. The density of material, which is ratio of weight to volume [20, 21]. Theoretical density was derived from Halpin-Tsai equation. Density (theoretical) =ρ (DRMMC) = ρm vf(m)+ ρpvf (p) ------------(1) ρ (DRMMC)= Density of the DRMMCs, ρm= Density of matrix alloy,  Vol.11, No .4 Role of Heat Treatment on Al6061- Frit 357 ρp= Density of reinforcing particle, vf(m)= Volume fraction of the matrix, vf(p)= Volume fraction of reinforcing particle. The Density of the respective specimens were determined basically by measuring the mass and the volume by using the balance and the measuring cylinder respectively. It is then estimated from the formula given below [22, 23]. Density (gm/cc) =Mass (gm)/Volume (cc) -------------- (2) Density of reinforcement material (Frit) =2.52 g/cc. Density of matrix material (Al6061) = 2.70 g/cc. 2.5 Hardness Test Fig. 1 Pictorial view of hardness test specimens Fig. 2 Pictorial view of hardness test specimens after indentation  358 D.Ramesh, R.P.Swamy, T.K.Chandrashekar Vol.11, No.4 Hardness m eas ur em ent s wer e ca rried ou t o n t he s p ecim ens of as -cast and composites in order to compare with Al6061 matrix allo y. Round specimens of 20 mm in diameter w ere p repar ed and polished on different grits of emery paper. The polished specimens were tested using Brinell hardness tester. A load of 500 Kgf for a period of 30 seconds was applied with a ball indenter of 10 mm diameter (HB500). The test was carried out five different locations to controvert the possible effect of indenter resting on the harder particles. Hardness was determined by measuring the indentations diameter produced. The average of all the five readings was taken as the hardness of as cast and composite specimens. Figure 1 & 2 shows the hardness test specimen before and after indentation. 3. RESULTS AND DISCUSSION Fig. 3.a. Microstructure of as cast Al6061 matrix alloy Fig. 3.b. Microstructure of 6 wt % of Al6061- Frit particulate composite Fig.4 Optical micrograph of aluminium /frit composite indicating good bond between the matrix and frit particles  Vol.11, No .4 Role of Heat Treatment on Al6061- Frit 359 3.1 Microstructure The optical micrograph of the cast Al6061 and Al6061-Frit particulate composites are sho wn in Fi gure.3. a & b.The micrographs clearl y indicates the distribution of Frit particles is fairl y uniform. Further the micrograph reveals an excellent bond between the matrix alloy and the reinforcement as shown in Figure.4. 3.2 Density Figure 5 is presented with comparison of theoretical density obtained by rule of mixture and measured density values by experiment for Al6061 alloy and Al6061- Frit studied. The results reveal that the presence of frit particles has an effect on the density of the MMC`s. From figure it can be concluded that the experimental and theoretical density values are in line with each other and confirms the suitability of the liquid metallurgy route for the successful composite fabrication. This result is similar to that of other researchers [24]. M. Ramachandra et.al. [19] reported the density of the reinforced particulates has effect on the density of the MMC`s and variation of density with reinforcement content is in line with experimental density values of Al6061-frit composites. It is observed that as the weight % of the reinforcement increases the density of the composites decreases. 3.3 Hardness The variation of hardness with increased weight % of reinforcement in the matrix alloy in as cast condition without heat treatment is shown in figure.6. It is observed that with increased weight % of reinforcement in the matrix alloy, there is a significant improvement in the hardness of the composites. D ensit y v/s weigh t % of reinforcemen t 2.66 2.665 2.67 2.675 2.68 2.685 2.69 2.695 2.7 2.705 0 24 6810 Weight % of reinforcement Th eor etical Density Ex p er im en tal Densit y Fig.5. Effect of reinforcement on density of the composites.  360 D.Ramesh, R.P.Swamy, T.K.Chandrashekar Vol.11, No.4 Weight % of reinforcement Fig. 6.Variation of hardness with increase in weight % of reinforcement for as cast Al6061 matrix alloy and Al 6061-Frit particulate composites Fig. 7.Variation of hardness with increase in ageing time for Al6061 matrix alloy and Al 6061-Frit particulate composites under heat treatment 0 wt.%. 2 wt.% 4 wt.% 6 wt.% 8 wt.% 10 wt.% o 0 wt.%. 2 wt.% 4 wt.% 6 wt.% 8 wt.% 10 wt.% Solutionizing temp.:530oC Quenching media: Water o Figure 8.Variation of hardness with increase in ageing time for Al6061 matrix alloy and Al 6061-Frit particulate composites under heat treatment conditions.  Vol.11, No .4 Role of Heat Treatment on Al6061- Frit 361 An improvement around 42% is observed in Al6061-10 Wt% frit particulate composites when compared with unreinforced Al6061 alloy. This trend is similar to the results of other researchers [25]. The variation of hardness with increased weight % of reinforcement in the Al6061matrix alloy and Al6061-frit particulate composites with heat are shown in figures.7, 8, and 9. On air quenching and ageing for 8 h, the matrix a lloy displa yed a maximum improvement in hardness around 33%, while Al6061-10 wt % frit composites displayed a maximum improvement in hardness around 11%.On water quenching and ageing for 6 h, the matrix alloy displayed a maximum improvement in hardness around 52%, while Al6061-10 wt% fri t composites displayed a maximum improvement in hardness around 33%. Ice quenching and ageing for 6 h, the matrix alloy displayed a maximum improvement in hardness around 58%, while Al6061-10 wt% frit composite displayed a maximum improvement in hardness around 38%. 4. CONCLUSIONS Microstructural studies reveal a fairly uniform distribution of frit particles in the matrix alloy with a good bond between the matrix alloy and reinforcement. Densit y measur ement studi es reveals as th e weight percenta ge of reinforc ement in creases the density of the composites decreases. Hardness increases with ageing duration, reaches a peak value at 6 h, and with further increase in ageing duration, there is a decrease in hardness. REFERENCES [1] A.R.Answar khan, C.S.Ramesh and A.Ramachandra, 2002, “Heat treatment of Al6061-SiC composites”, proceedings of international companies on manufacturing (Dhaka ICM) pp 21-28. Fig. 9.Variation of hardness with increase in ageing time for Al6061 matrix alloy and Al 6061-Frit particulate composites under heat treatment conditions. 0 wt.%. 2 wt.% 4 wt.% 6 wt.% 8 wt.% 10 wt.% Solutionizing temp.:530oC Quenching media: ICE o  362 D.Ramesh, R.P.Swamy, T.K.Chandrashekar Vol.11, No.4 [2] C.S.Ramesh, A.R.Answar khan, Ravikumar and Savanprabhu, “Prediction of wear co- efficient of Al6061-TiO2 composites”, Wear 259, (2003), 602-608. [3] Appendino.P, Badini.C, Marino.F, and Tomari.A, 1991. J. Mater. Sic & Eng. A 135. 275, [4] Salvo and Surey.M, 1924. J. Mater. Sic & Eng. A 34.709. [5] M.Gupta, and M.K.Surappa, “Effect of wt% of SiC particulates on the ageing behaviour of Al6061/SiC MMC`s”, Journal of Material Science, 14(1995), 1283- 1285. [6] B.N. Pramila Bai ,B.S.Ramasesh , and M.K. Surappa , “Dry sliding wear of A356-Al- SiC”p, Wear 157, ( 1992), 295-304 , [7] Doel T.J.A and Bowen P, 1996, composites A27, 655. [8] Gui.M.C, Wang D.B, W.J.J. Yana G.J and Gli.C 2000 J. Mater. Sic & Techno, 16, 556. [9] Rajan.T.V, Sharma C.P, Ashok Sharma, 1998, Heat treatment principles Techniques, Rajkamal Electric Press, India, Page 142-149. [10] Davis.J.R, 1993, Aluminium and aluminium alloys, in ASM specially Hand book, ASM international, Metal Parts, Ohio. [11] W.D.Callister , Journal Material Science & Engineering, 1997, 511-531. [12] Rollanson E.C, 1998, Metallurgy for engineers, Edward Arnold Ltd, London. [13] H.Ribes, M.Surey, Sci metal 23 (1989) 705-709, [14] G.M.Janoswki, B.J.Pletka, metal mater. A 26 (1995) 3027-3034. [15] P.Appendino, C.Badini, Mater. Sci& Eng. A 135 (1991). 275-279. [16] Z.M.El-Baradie, O.A.El-Shah at, A.N. Abd El-Ajim, J.Mater. Process. Technology 79 (1998) 1-8. [17] V.Amigo, J.L.Ortiz, M.O.Salvador, Serim 12(2000) 383-388. [18] L.Sulvo, G.L.Esperance, M.Surey, J.G. legoux. Mater.Sci.Eng A 177 (1994) 173-183. [19] M.Ramachandra, K.Radhakrishna,”Sliding wear, slurry erosive wear, and corrosive wear of aluminium/SiC composite, Materials Science-Poland, Vol.24, No 2/1, 2006. [20] M.D.Bermudeza, G. Martinez-Niccol as , F.J.Carrion, I. Martin-Mateo, J.A.Rodriguez, E.J.Herrera,”Dry and lubricated wear resistance of mechanically-alloyed aluminium- base sintered composites”, Wear 248,178-186, 2001. [21] S.N.Ahmad, J.Hashim, and M.T.Ghazali, ”The effect of porosity on Mechanical Properties of Cast Discontinuous Reinforced Metal-Matrix composites”, Journal of composite Materials, Vol.39, No 5/2005, pp 451-466. [22] V.S.Aigbodin and S.B. Hassan, “Effects of Silicon carbide reinforcement on Microstructure and properties of cast Al – Si – Fe / SiC particulate composites”, Journal of material sciences and Engineering A, 2007,447,355-360. [23] I. A. Ogucha, “Characterization of Aluminium alloy 2618 and its composites containing alumina particles”, Ph.D. Dissertation, Department of mechanical Engineering, University of Saskatchewan, Saskanoon, 1997, 1-200. [24] V.S.Aigbodion, J.O.Agunsoye,V.Kalu,F.asuke,S.Ola, “Microstructure and Mechanical properties of ceramic composites”,JMMCE,Vol.9,No.6,pp527-538,2010.  Vol.11, No .4 Role of Heat Treatment on Al6061- Frit 363 [25] N.R.Prabhu Swamy, C.S.Ramesh and T.Chandrashekar, “Effect of heat treatment on strength and abrasive wear behaviour of Al6061-SiCp composites”, Bull Mater. Sci., Vol 33, No 1, February 2010, pp 49-54.

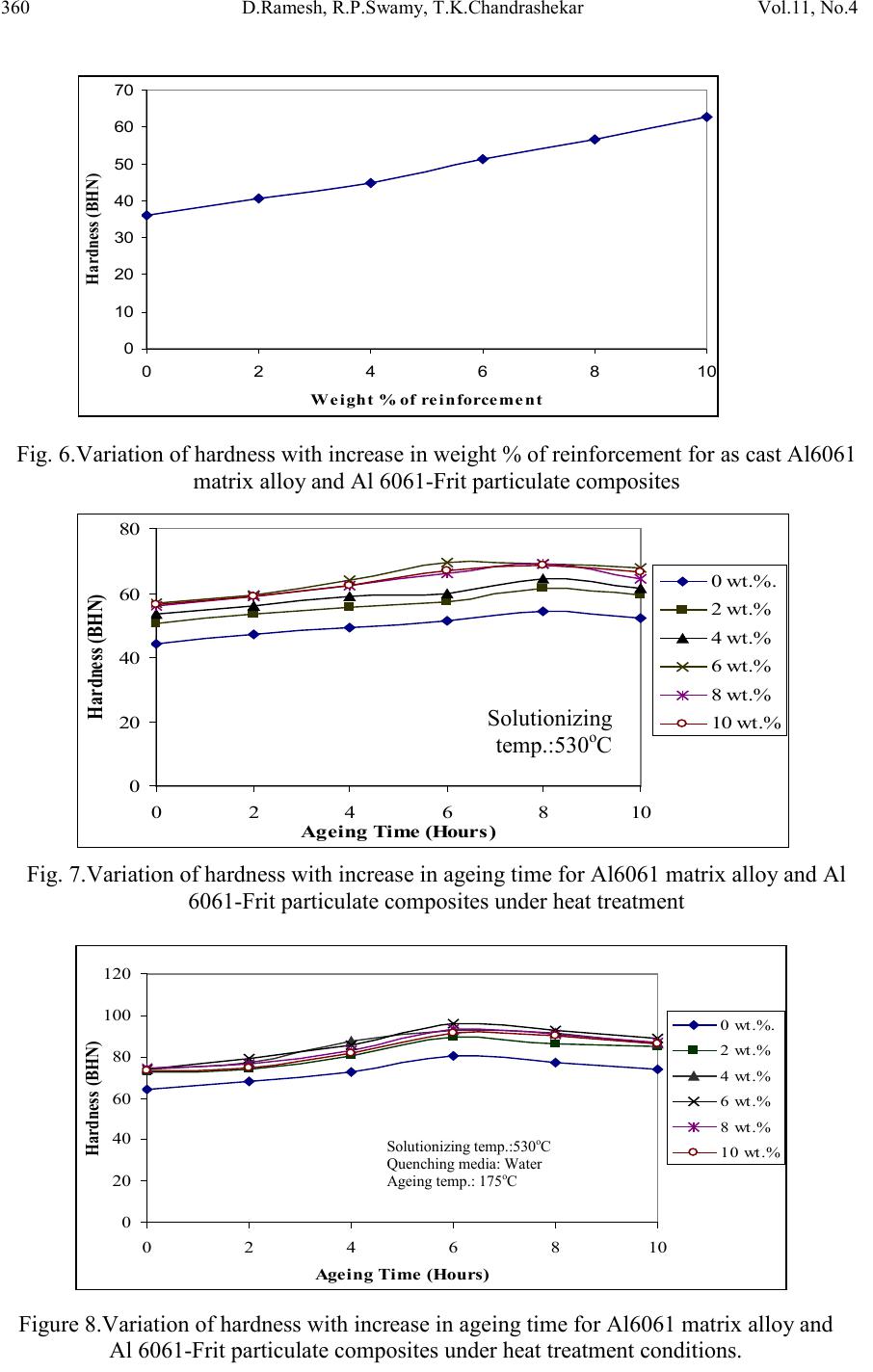

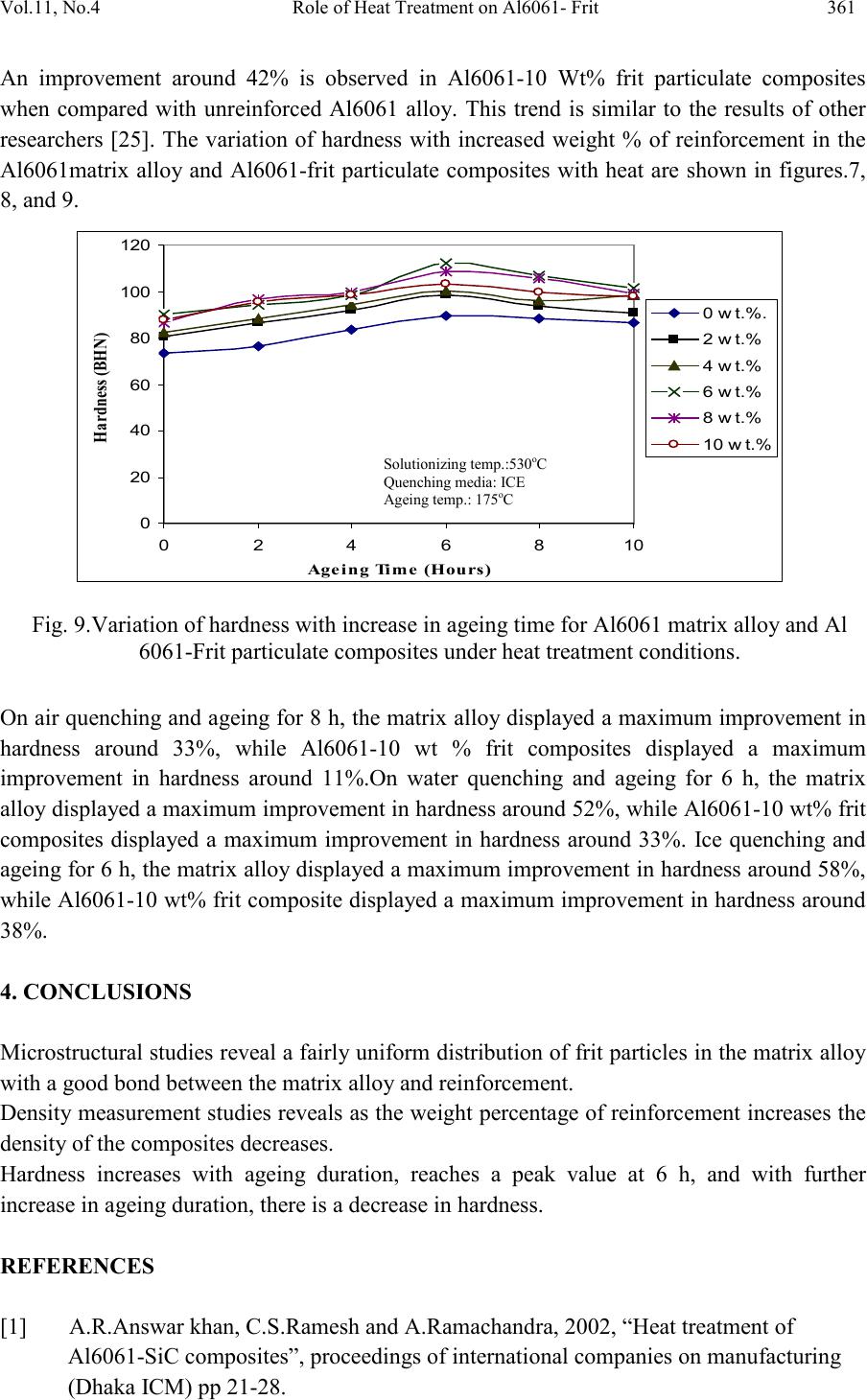

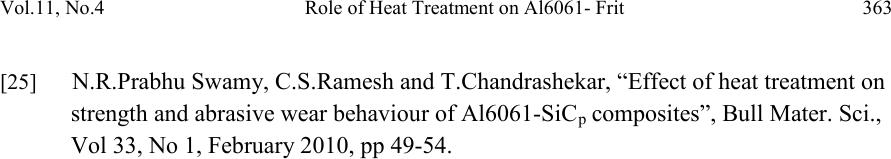

|