Agricultural Sciences

Vol.4 No.12(2013), Article ID:41178,6 pages DOI:10.4236/as.2013.412103

Practical handling skills during road transport of fattening pigs from farm to slaughterhouse: A brief review

![]()

1Department of Bioengineering Technology, KU Leuven | Thomas More, Geel, Belgium; *Corresponding Author: bert.driessen@kuleuven.be

2Department of Animal Welfare, Federal Government Service, Brussels, Belgium

Copyright © 2013 Bert Driessen et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received 24 October 2013; revised 25 November 2013; accepted 17 December 2013

Keywords: Handling; Pigs; Transport; Slaughterhouse; Training

ABSTRACT

The transport of fattening pigs is characterized by a strong human-animal interaction. Consequent handling is important because of animal welfare, meat quality and matching economic consequences. During road transport, human impact can be divided in different steps: 1) driving pigs from the pens via an alley to the trailer, 2) loading, 3) actual transport, 4) unloading to the lairage, and 5) the final phase driving pigs to the stunning. An inadequate design and a poor condition of the facilities will negatively affect the ease of handling pigs. Because of the consequences, acute stress during transport and slaughter should be minimized by acting on the education of people, on equipment and on preparation of animals for the journey. Education programs have to be repeated regularly so that knowledge can be refreshed.

1. INTRODUCTION

After a raising period of several months under specific housing conditions, pigs are transported on road from the farm to the slaughterhouse. The transport phase to the slaughterhouse has been identified as a stressful event for fattening pigs [1,2], mainly because the transport procedure is characterized by an intensive contact between animals and humans, in contrast with the fattening period. The handling of animals should be done with care because it can cause a fear reaction in pigs that are unacquainted with humans. Fear can make handling difficult and potentially causes a dangerous situation to both animal and handler. Only after repeated (friendly) handling in combination with appropriate equipment, these fear responses will be minimized [3].

Because of the combination of several stressors in a very short period of time, the transport procedure may have a large effect on the welfare of pigs. Physical exercise during the loading of animals into the transport vehicle is one of these stressors. Furthermore, moving pigs from their familiar environment into unknown, novel surroundings can cause psychological stress. Therefore, the manner of handling pigs is very important because of the impact on animal stress, welfare, meat quality and the economic implications that come with it. The glycolysis rate of meat increases in acutely stressed pigs which can result in poor meat quality after slaughter, namely pale, soft and exudative (PSE) meat [4]. On the other hand, chronic stress depletes body energy reserves before slaughtering which results in a high final pH value 24 h after slaughter and dark, firm, and dry (DFD) meat [5].

Although the human impact on the ease of handling pigs and pork quality is well known, it is still an ongoing research topic. Nowadays, the emphasis is on training drivers and handlers to reduce rough handling, optimize animal welfare, and reduce deterioration of meat quality and the financial losses that are associated with it. The next step will be the evaluation and optimization of the training programs [6].

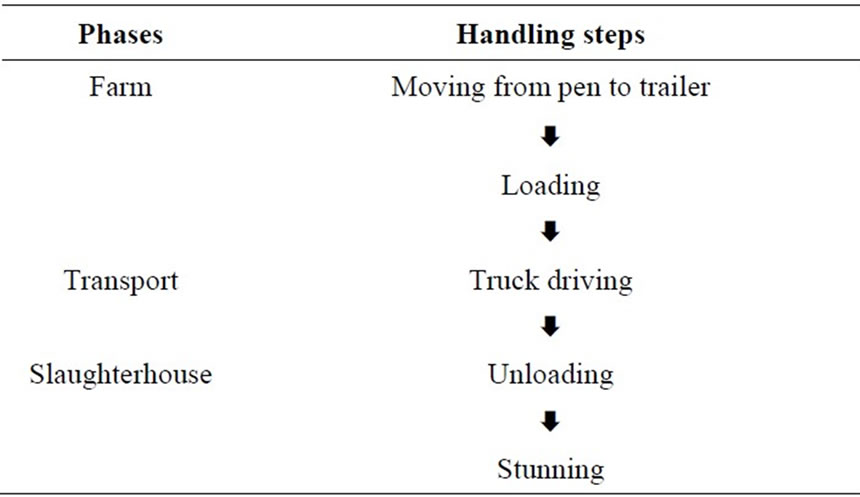

This review summarizes the interactions between humans and pigs during all phases of the transport procedure, focusing on practical handling skills (Table 1).

2. MOVING FROM PEN TO TRAILER

Loading can cause fear in animals that are not habituated to human contact. Pigs exposed to management pro-

Table 1. A summary of the handling steps during the transport of fattening pigs from farm to slaughterhouse.

cedures, prior to loading and transportation, are easier to handle [7]. For example, pigs that have been walked in the alley during finishing will be easier to drive [7-9]. Pigs that have never walked on concrete before, may balk and be more difficult to move. Grandin [10] recommends that every day the producer should walk through both grower and finishing pens to teach the pigs to quietly get up, and to habituate them to human contact. However, the calm and consistent way to get in contact with the animals is important. The fear and stress reactions are greater in pigs managed inconsistently or managed by low self-esteem handlers than in pigs that were handled in a positive and consistent manner and by high self-esteem handlers [11,12]. Grandin [13] noticed that pigs from certain lean genetic lines may be more excitable and difficult to drive. Shea-Moore [14] found that high lean pigs were more fearful than a fatter line of pigs [15]. Also playing a radio in the rooms of the farm in the last weeks before slaughtering helps pigs to cope with novel impressions during the transport procedure, such as loading and transport noises [16].

Grandin [17] emphasizes the importance of stockpersons being familiar with the principles of animal behavior, such as flight zones and visual fields. Moving the pigs will be easier if they are given an opportunity to explore the new floor surface of the alleys than pigs being driven over it. Pigs should be encouraged to move forward by pushing the group from behind with light weight driving boards. The use of electric prods leads to agitated animals which are more difficult to handle [18] and to an increased time necessary to load a trailer. Handling of pigs can also be made easier by keeping them in smaller groups [19]. According to [20], moving 5 or 6 pigs at a time is an optimum for both time savings and handling easiness. Dalla Costa et al. [21] noticed that pigs were more difficult to handle in winter and needed more coercion to load, probably due to the differences in temperature and light, factors considered to influence pig handling [22].

Alleys must be free of equipment and other objects. Pigs may balk if they see shadows and may refuse to move further. Even subtle changes in floor texture may distract pigs. Quiet handling of pigs will be impossible until all distractions (shadows and reflections) are found and eliminated.

3. LOADING

Berry et al. [23] focused on the importance of appropriate loading facilities. They found a relation between the design of the loading gantry and the use of electric prods, slips and falls. A non-slippery floor on the ramp, the lift and in the trailer is an essential condition to handle pigs calmly. The risk of slipping and falling increases on a slippery floor. Gouman et al. [24] showed that using a 90˚ angle of entrance to the ramp had detrimental effects on ease of handling. A 30˚ angle of entrance with the use of boards allows the handlers to direct pigs to the ramp without any possibility for the animals to hide in a corner. Ritter et al. [25] reported that in large plants (length > 100 m), loading distance from pen to trailer can affect the loading rate of non-ambulatory pigs at the farm.

The transfer from the familiar fattening pen to the novelty of the trailer interior combined with the strong physical activity induced by the coercion to walk through sloped ramps, make pigs nervous and more difficult to handle, especially in overcoming ramps at angles higher than 20˚ [26]. The animals may refuse and even turn their sides towards the ramp [27]. In addition, because pigs balk on these steep ramps, handlers may become frustrated by the hesitation leading to harsher handling and increased use of the electric prod [28]. Pigs that are difficult to handle tend to receive “harsher” treatment during loading than pigs that are easy to handle [29] and it has been demonstrated that harsh handling compromises meat quality [30]. McGlone et al. [31] recommend a light weight board rather than a paddle to drive pigs. Because of the detrimental effects electric prods should not be used. Evidently, it is not allowed to strike or kick the animals.

The use of a lift makes the pigs easier to handle and prevents the handlers from using coercion on them. However, if the ramp is necessary, like in the case the truck is not equipped with hydraulic lift or there is a height difference between the loading quay and the truck level, it should have an angle of less than 20˚, should be of a stair-step type and covered by rubber to prevent pigs from slipping and producing disquieting noise by walking on the steel floor of the ramp [2,5].

4. TRUCK DRIVING

The driving style of the trucker influences the behavior of the pigs during transport. During short journeys pigs are standing and sitting most of the time, while during a rough journey a higher number of pigs remain standing compared to a smooth journey [1]. The first kilometers usually generate panic because in most of the roads the conditions in the beginning (often rural roads) are bad, causing a higher frequency of stops, accelerations and de-accelerations [32]. When animal trailers are driven badly, animals are subjected to substantial lateral movement which results from driving too fast around corners, too high accelerations, or too violent braking. This may cause toppling, sliding and excessive corrective muscular action, resulting in bruising, muscular fatigue, fear and injuries to the animals [33,34]. Also the ability of the pigs to rest during the journey will be reduced [35]. The best practice is to drive well so pigs can adapt the standing or lying position in order to cope with the high level of vibrations [36].

Of course, driving the vehicle is related to the driving style of the trucker, but also to the truck type, the suspension characteristics and the quality of the road surface [37].

5. UNLOADING

Although unloading is considered less stressful than loading, a few attention points must be taken into account. To avoid jamming and panic in the unloading group, the truck should be emptied gradually by unloading pigs by transport pen group rather than by deck [38].

Handling problems due to hesitation and refusals of pigs to go forward can also be caused by poor lighting (dark area) and inappropriate design and location of the unloading area. Different colors and shadows may frighten the animals and they preferably walk form a dark to a lighter place [18,27]. A plane level ramp or a hydraulic ramp should be used to unload the pigs. Abbott et al. [7] reported a longer unloading time and more slips and falls in winter due to the unloading facility design, where the unloading ramp had an aluminum base that became slippery when temperatures dropped below zero. The unloading area should not have corners to negotiate, pigs should walk straight into the lairage pen in their truck-group, a solid-gate should be dropped behind the group in order to encourage pigs to walk forward and thus be locked into position allowing an adequate space for the size of the group [38]. Height differences exceeding 20 cm between the truck and unloading ramp can cause handling problems due to refusal or hesitation of the pigs [24]. Narrow passages [39] and noise [8,40] also negatively affect the unloading process.

Smooth unloading of pigs by the handlers should be standard. Rabaste et al. [41] reported that pigs being handled gently (with boards) at unloading were less stressed and adapted faster to the lairage pen environment than pigs being handled with electric prods. Frequent use of electric prods while encouraging the animal to move to the target location results in fear and stress [28].

6. STUNNING

Moving pigs forward to the stunning point is an important source of stress in slaughtering pigs. The number of turns and corners should be minimal and the route the animals take should encourage forward movement. Oneway gates, run-through lairage pens and elimination of right-angled corners in the system have a positive impact on the efficiency of guiding pigs to the stunning area. Moreover, using automatic push gates to move animals reduces the interaction with the handlers and minimizes the use of electrical prods in the slaughterhouse. The handling method is characterized by the stunning system. In a CO2 gas system the pigs are handled in groups. In contrast, a few pigs are moved up the single-file chute into the restrainer of the electrical stunning system which requires the use of electric prods [42]. The use of prods increases mounting behavior between pigs in group, results in more fatigued pigs and a higher proportion of bruised carcasses and PSE pork [41]. Grandin [42] recommends stiff scrub brushes on the end of a stick as an electric prod alternative for moving pigs up a single-file race. However, a total ban on electric prods used on animals that refuse to move at the entrance of the stun box or restrainer, is not recommended because of the probable increase of the frequency of beating, tail twisting and poking sensitive areas of the animals by the handlers after such a ban [42].

Pigs will be encouraged to move forward by lighting that gradually becomes brighter towards the stunning point, without shining directly into the pigs’ eyes. Where a restrainer conveyor is used, there must be a system to reduce groups into single files, e.g. a labyrinth system. The conveyor should be tight enough to prevent excessive movement but not so tight that it causes pain or discomfort [43].

7. TRAINING PROGRAMS

The consequences of acute stress during transport and slaughter should be minimized by acting on the education of people, on equipment and on preparation of animals for the journey [44]. The education includes training, evaluation of achieved knowledge and skills certification for the people involved, as planned, for instance, by the Regulation EC 1/2005 since the 1st of January 2007. The latter have to follow special training courses which include several items related to the human-animal relationship, such as animal behavior, practical aspects of animal handling and the impact of driving behavior on the welfare of the transported animals and on the quality of meat. After a successful examination they achieve a certificate of competence to transport animals. As shown by Grandin [45], the improvement of handling and stunning practices after the audit programs can be relevant. Also shown by [45], there is only a short effect of an education program. Therefore, education programs have to be repeated regularly so that knowledge can be refreshed.

In the light of Regulation (EC) 1/2005, each EU member state has to organize a training course for drivers and handlers of animal transports. There are large differences (speed of implementation, animal species, purpose of transport, training course, type of examination, validity duration of the transport certificate) between Member States in how the Regulation has been implemented and enforced [6]. Given the fact that implementation and enforcement of Regulation (EC) 1/2005 varies among Member States and its implementation and enforcement is still in progress, the impact of the Regulation may not become clear for a number of years.

Council Regulation (EC) No 1099/2009 came into force on 1 January 2013 in all EU Member States. The Regulation covers all aspects of the operations of slaughterhouses from the arrival of animals at the lairage area through to the animals’ death. It also introduces new requirements relating to the training of all slaughterhouse staff involved in the handling of live animals, and in the appointment of Animal Welfare Officers. A successful examination after an appropriate course leads to a certificate of competence for the slaughterhouse staff.

8. CONCLUSION

Despite decennia of research and recommendations, handling is still an important topic and a major cause of distress for slaughter pigs. Animal transport has a high importance for the pork chain economy, as mistakes made at this level have irreversible effects on carcass and meat quality. Also, the efforts made by the producers to improve animal welfare are lost. An adequate handling of fattening pigs should be a point of attention during the transport procedure. All actors must realize that there is an important interaction between handling and the infrastructure. The ease of handling pigs starts with a good infrastructure. Also, training programs for caretakers to handle animals correctly and to understand the basic behavioral principles are necessary. However, for an optimal result the contents and the concept (theory, practice or a combination of it) of the training programs are important. Therefore the existing programs should be evaluated and, if necessary, optimized.

REFERENCES

- Bradshaw, R.H., Parrott, R.F., Good, J.A., Lloyd, D.M. Rodway, R.G. and Broom, D.M. (1996) Effects of mixing and duration of journey on the welfare of pigs during transport. Proceedings EU-Seminar: New Information on Welfare and Meat Quality of Pigs as Related to Handling, Transport and Lairage Conditions, Mariensee, 29-30 June 1995, 95-100.

- Christensen, L. and Barton-Gade, P. (1996) Design of experimental vehicle for transport of pigs and some preliminary results of environmental measurements. Proceedings EU-Seminar: New Information on Welfare and Meat Quality of Pigs as Related to Handling, Transport and Lairage Conditions, Mariensee, 29-30 June 1995, 47- 68.

- Rushen, J., Munksgaard, L., Marnet, P.G. and DePassillé, A.M. (2001) Human contact and the effects of acute stress on cows at milking. Applied Animal Behaviour Science, 73, 1-14. http://dx.doi.org/10.1016/S0168-1591(01)00105-8

- Jensen, J., Aslesen, R., Jebens, E. and Skrondal, A. (1999) Adrenaline-mediated glycogen phosphorylase activation is enhanced in rat soleus muscle with increased glycogen content. Biochimica et Biophysica Acta, 1472, 215-221. http://dx.doi.org/10.1016/S0304-4165(99)00122-1

- Tarrant, P.V. (1989) The effects of handling, transport, slaughter and chilling on meat quality and yield in pigs— A review. Irish Journal of Food Science and Technology, 13, 70-107.

- Baltussen, W., Gebresenbet, G. and De Roest, K. (2011) Study on the impact of Regulation (EC) No 1/2005 on the protection of animals during transport. Specific Contract N° SANCO/2010/D5/S12.574298, European Commission Funded Project, Directorate-General for Health and Consumers, 116.

- Abbott, T.A., Hunter, E.J., Guise, H.J. and Penny, R.H.C. (1997) The effect of experience of handling on pigs willingness to move. Applied Animal Behaviour Science, 54, 371-375. http://dx.doi.org/10.1016/S0168-1591(97)00045-2

- Geverink, N.A., Bühnemann, A., Van de Burgwal, J.A., Lambooij, E., Blokhuis, H.J. and Wiegant, V.M. (1998) Responses of slaughter pigs to transport and lairage sounds. Physiology & Behaviour, 4, 667-673. http://dx.doi.org/10.1016/S0031-9384(97)00513-1

- Lewis, C.R.G., Hulbert, L.E. and McGlone, J.J. (2008) Novelty causes elevated heart rate and immune changes in pigs exposed to handling, alleys, and ramps. Livestock Science, 116, 338-341. http://dx.doi.org/10.1016/j.livsci.2008.02.014

- Grandin, T., Curtis, S.E. and Widowski, T. (1984) Rearing environment affects pig’s time to walk through test chute. Journal of Animal Science, 61, 88.

- Hemsworth, P.H., Barnett, J.L. and Hansen, C. (1987) The influence of inconsistent handling by humans on the behaviour, growth and corticosteroids of young pigs. Applied Animal Behaviour Science, 17, 245-252. http://dx.doi.org/10.1016/0168-1591(87)90149-3

- Gemus, M., Bartlet, P., Nachreiner, R. and Zanella, A.J. (1998) Human Characteristics and handling strategies: Effects on the physiological and behavioural responses of juvenile pigs. Proceedings of the International Pig Veterinary Society, 5-9 July 1998, Birmingham.

- Grandin, T. (1987) Animal handling. Veterinary Clinics of North America, 3, 323-338.

- Shea-Moore, M. (1998) The effect of genotype on behaviour in segregated early weaned pigs in an open field. Journal of Animal Science, 76, 100.

- Busse, C.S. and Shea-Moore, M.M. (1999) Behavioral and physiological responses to transportation stress. Journal of Animal Science, 77, 147.

- Grandin, T. (1989) Behavioral principles of livestock handling. The Professional Animal Scientist, 5, 1-11.

- Grandin, T. (2000) Handling and welfare of livestock in slaughter plants. In: Grandin, T., Ed., Livestock Handling and Transport, CAB International, Wallingford (UK), 409-439. http://dx.doi.org/10.1079/9780851994093.0409

- Gregory, N.G. (1998) Animal welfare and meat science. CAB International, Wallingford (UK).

- Christensen, L. and Barton-Gade, P. (1997) New Danish developments in pig handling at abattoirs. Fleischwfirtschaft, 77, 604-607.

- Lewis, C.R.G. and McGlone, J.J. (2007) Moving finishing pigs in different group sizes: Cardiovascular responses, time, and ease of handling. Livestock Science, 107, 86-90. http://dx.doi.org/10.1016/j.livsci.2006.10.011

- Dalla Costa, O.A., Faucitano, L., Coldebella, A., Ludke, V.A., Peloso, V., Dalla Roza, D. and Paranhos da Costa, M.J.R. (2007) Effects of season of the year, truck type and location on truck on skin bruises and meat quality in pigs. Livestock Science, 107, 29-36. http://dx.doi.org/10.1016/j.livsci.2006.08.015

- Hemsworth, P.H. (2000) Behavioural principles in pig handling. In: Grandin, T., Ed., Livestock Handling and Transport, CAB International, Wallingford (UK), 255- 274. http://dx.doi.org/10.1079/9780851994093.0255

- Berry, N.L., Johnson, A.K., Hill, J., Lonergan, S., Karriker, L.A. and Stalder, K.J. (2012) Loading gantry versus traditional chute for the finisher pig: Effect on welfare at the time of loading and performance measures and transport losses at the harvest facility. Journal of Animal Science, 90, 4028-4036. http://dx.doi.org/10.2527/jas.2011-4973

- Gouman, S., Faucitano, L., Bergeron, R., Crowe, T., Connor, M.L. and Gonyou, H.W. (2013) Effect of ramp configuration on easiness of handling, heart rate, and behaviour of near-market weight pigs at loading. Journal of Animal Science, 91, 3889-3898. http://dx.doi.org/10.2527/jas.2012-6083

- Ritter, M.J., Ellis, M., Bertelsen, C.R., Bowman, R., Brinkmann, J., Dedecker, J.M., Keffaber, K.K., Murphy, C.M., Peterson, B.A., Schlipf, J.M. and Woltert, B.F. (2007) Effects of distance moved during loading and floor space on the trailer during transport on losses of market weight pigs on arrival at the packing plant. Journal of Animal Science, 85, 3454-3461. http://dx.doi.org/10.2527/jas.2007-0232

- Lambooij, E. and Van Putten, G. (1993) Transport of pigs. In: Grandin, T., Ed., Livestock Handling and Transport, CAB International, Wallingford (UK), 213-239.

- Lambooij, E., Geverink, N.A., Broom, D.M. and Bradshaw, R.H. (1996) Quantification of pig’s welfare by behavioural parameters. Proceedings EU-Seminar: New Information on Welfare and Meat Quality of Pigs as Related to Handling, Transport and Lairage Conditions, Mariensee, 29-30 June 1995, 13-19.

- Brundige, L., Oleas, T., Doumit, M. and Zanella, A.J. (1998) Loading techniques and their effect on behavioral and physical responses of market weight pigs. Journal of Animal Science, 76, 99.

- Weeding, C.M., Hunter, E.J., Guise, H.J. and Penny, R.H. (1993) Effects of abattoir and slaughter handling systems on stress indicators in pig blood. The Veterinary Record, 133, 10-13. http://dx.doi.org/10.1136/vr.133.1.10

- Weeding, C.M., Guise, H.J. and Penny, R.H.C. (1993) Factors influencing the welfare and carcass and meat quality of pigs: The use of water sprays in lairage. Animal Production, 56, 393-397. http://dx.doi.org/10.1017/S0003356100006449

- McGlone, J.J., McPherson, R.L. and Anderson, D.L. (2004) Moving devices for finishing pigs: Efficacy of electric prod, board, paddle, or flag. The Professional Animal Scientist, 20, 518-523.

- Chevillon, P. (2000) Pig Welfare during pre-slaughter and stunning. Proceedings of 1st International Virtual Conference on Pork Quality, Welfare, Transport, Slaughter and Consumer, Concordia, 16 November-16 December 2000, 145-158.

- Randall, J.M., Duggan, J.A. and Alami, M.A. (1995) Influence of motion and vibration on animals. Fleischwirtschaft, 75, 158-160.

- Randall, J.M., Stiles, M.A., Geers, R., Schütte, A., Christensen, L. and Bradshaw, R.H. (1995) Transport of pigs: Vibration and discomfort. Proceedings of the United Kingdom Informal Group Meeting on Human Response to Vibration, Silsoe, 18-20 September, 45-50.

- Cockram, M.S., Baxter, E.M., Smith, L.A., Bell, S., Howard, C.M., Prescott, R.J. and Mitchell, M.A. (2004) Effect of driver behaviour, driving events and road type on the stability and resting behaviour of sheep in transit. Animal Science, 79, 165-176.

- Randall, J.M. (1993) Environmental parameters necessary to define comfort for pigs, cattle and sheep in livestock transporters. Animal Production, 57, 299-307. http://dx.doi.org/10.1017/S0003356100006929

- Torrey, S., Bergeron, R., Widowski, T., Lewis, N., Crowe, T., Correa, J.A., Brown, J., Gonyou, H.W. and Faucitano, L. (2013) Transportation of market-weight pigs: I. Effect of season, truck type, and location within truck on behaviour with a two-hour transport. Journal of Animal Science, 91, 2863-2871. http://dx.doi.org/10.2527/jas.2012-6005

- Jones, T. (1999) An investigation and assessment of the handling-systems of twelve abattoirs in Great Britain and four in Ital. In: Improved Handling Systems for Pigs at Slaughter. PhD Thesis, University of London, London.

- Lambooij, E. (2000) Transport of pigs. In: Grandin, T., Ed., Livestock Handling and Transport, CAB International, Wallingford (UK), 275-296. http://dx.doi.org/10.1079/9780851994093.0275

- Lippmann, J., Schaffer, D. and Laube, R.B. (1999) Noise at slaughter plants—Behavioural adaption of slaughter pigs to different noise situations. KTBL-Schrift, 382, 181- 188.

- Rabaste, C., Faucitano, L., Saucier, L., Mormède, P., Correa, J.A., Giguère, A. and Bergeron, R. (2007) The effects of handling and group size on welfare of pigs in lairage and their influence on stomach weight, carcass microbial contamination and meat quality. Canadian Journal of Animal Science, 87, 3-12. http://dx.doi.org/10.4141/A06-041

- Grandin, T. (2013) Making slaughterhouses more humane for cattle, pigs, and sheep. The Annual Review of Animal Biosciences, 1, 491-512. http://dx.doi.org/10.1146/annurev-animal-031412-103713

- Grandin, T., Dodman, N. and Shuster, L. (1989) Effect of Naltrexone on Relaxation Induced by Flank Pressure in Pigs. Pharmacology Biochemistry & Behavior, 33, 839- 842. http://dx.doi.org/10.1016/0091-3057(89)90479-6

- Peeters, E., Deprez, K., Beckers, F., De Baerdemaeker, J., Aubert, A.E. and Geers, R. (2008) Effect of driver and driving style on the stress responses of pigs during a short journey by trailer. Animal Welfare, 17, 189-196.

- Grandin, T. (2007) Effect of customer requirements, international standards and marketing structure on the handling and transport of livestock and poultry. In: Grandin, T., Ed., Livestock Handling and Transport, CABI Publishing, Wallingford (UK), 1-18. http://dx.doi.org/10.1079/9781845932190.0001