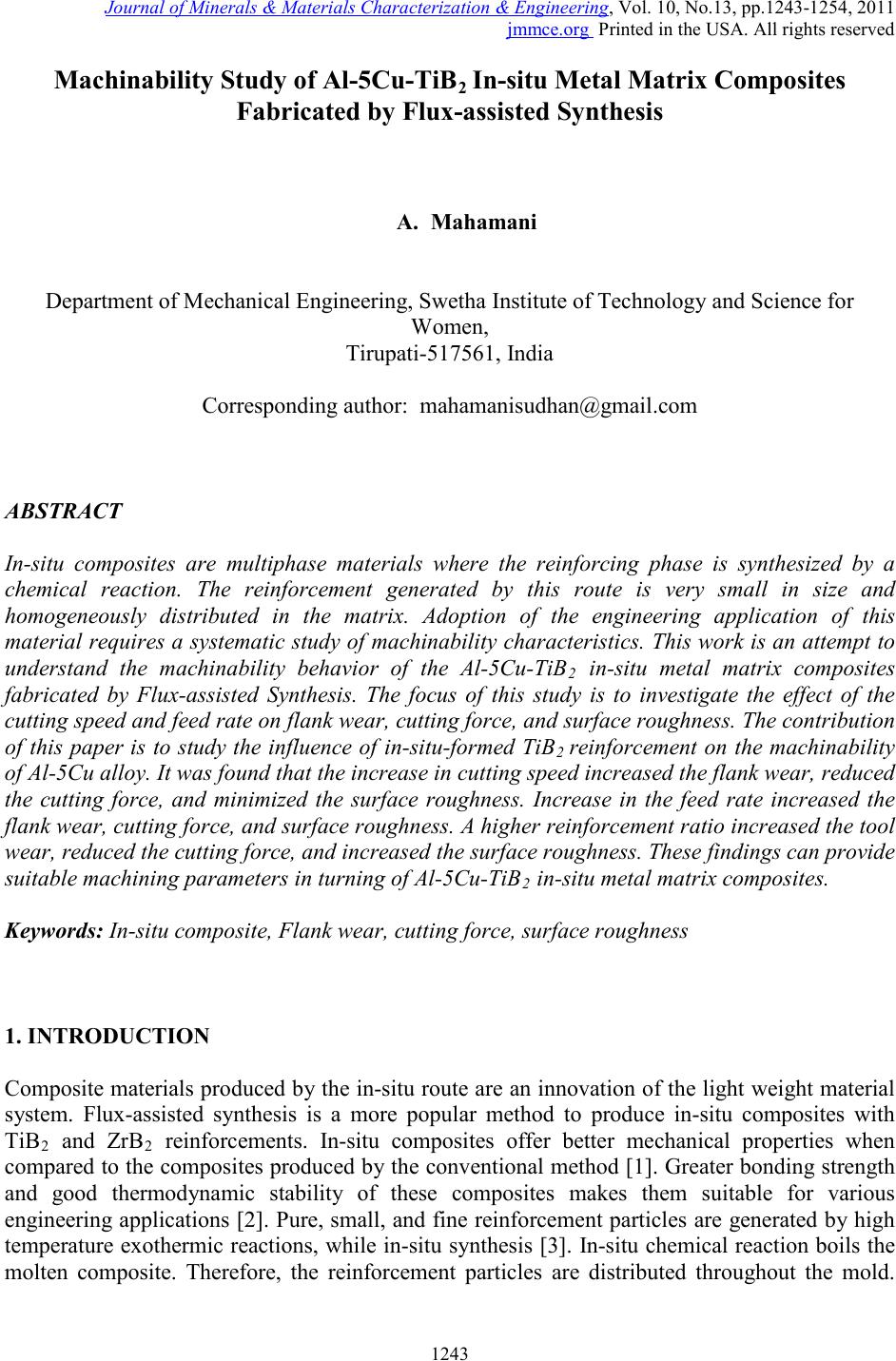

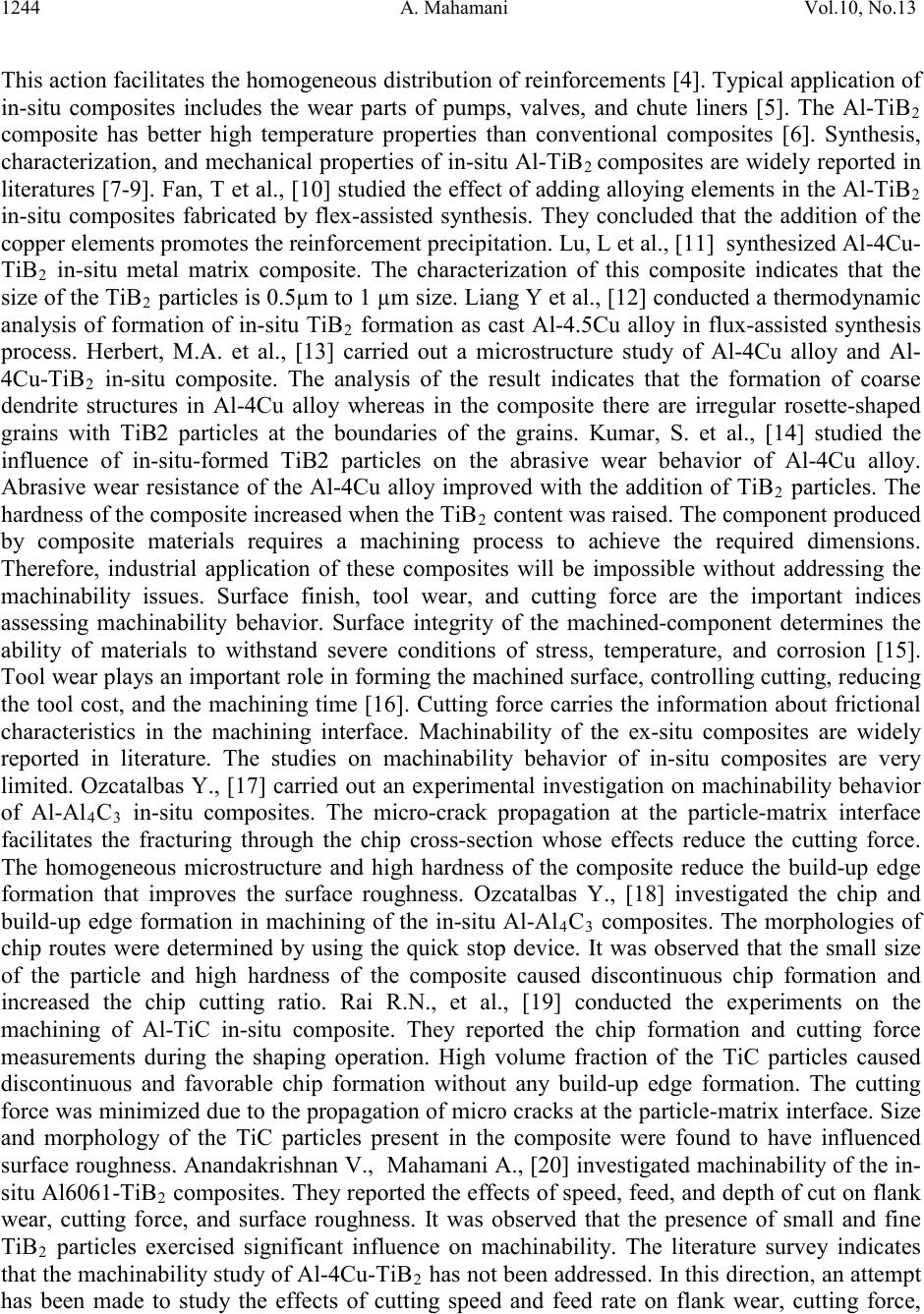

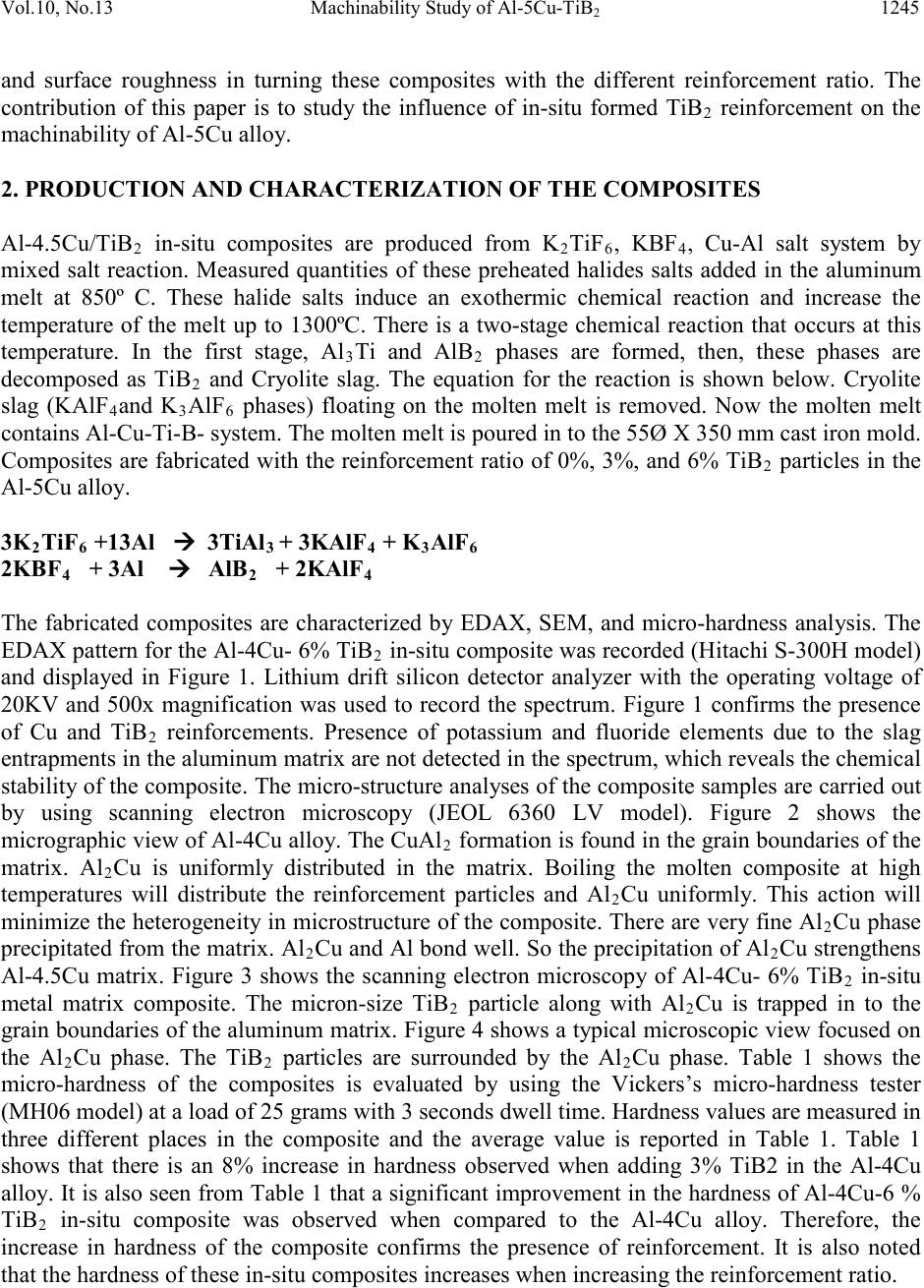

Journal of Minerals & Materials Characterization & Engineering, Vol. 10, No.13, pp.1243-1254, 2011 jmmce.org Printed in the USA. All rights reserved 1243 Machinability Study of Al-5Cu-TiB2 In-situ Met al Matrix C omposites Fabricated by Flux-assisted Synthesis A. Mahamani Department of Mechanical Engineering, Swetha Institute of Technology and S cience for Women , Tirupati-517561, India Corresponding author: mahamanisudhan@gmail.com ABSTRACT In-situ composites are multiphase materials where the reinforcing phase is synthesized by a chemical reaction. The reinforcement generated by this route is very small in size and homogeneously distributed in the matrix. Adoption of the engineering application of this material requires a systematic study of machinability characteristics. This work is an attempt to understand the machinability behavior of the Al-5Cu-TiB2 in-situ metal matrix composites fabricated by Flux-assisted Synthesis. The focus of this study is to investigate the effect of the cutting speed and feed rate on flank wear, cutting force, and surface roughness. The contribution of this paper is to study the influence of in-situ-formed TiB 2 reinfor cement on the machinability of Al-5Cu alloy. It was found that the increase in cutting speed increased the flank wear, reduced the cutting force, and minimized the surface roughness. Increase in the feed rate increased the flank wear, cutting force, and surface roughness. A higher reinforcement ratio increased the t ool wear, reduced the cutting force, and increased the surface roughness. These findings can provide suitable machining parameters in turning of Al-5Cu-TiB2 in-situ metal matrix composites. Keywor d s: In-situ composite, Flank wear, cutting force, surface roughness 1. INTRODUCTION Composite materials produced by the in-situ route are an innovation of th e light weight material system. Flux-assisted synthesis is a more popular method to produce in-situ composites with TiB2 and ZrB2 reinforcements. In-situ composites offer better mechanical properties when compared to the composites produced b y the conv entional method [1]. Greater bonding strength and good thermodynamic stability of these composites makes them suitable for various engineering applications [2]. Pure, small, and fine reinforcement particl es are generated b y high temperature exothermic reactions, while in-situ synthesis [3]. In-situ chemical reaction boils the molten composite. Therefore, the reinforcement particles are distributed throughout the mold.  1244 A. Mahamani Vol.10, No.13 This action facilitates the homogeneous distribution of reinforcements [4]. Typical application of in-situ composites includes the wear parts of pumps, valves, and chute liners [5]. The Al-TiB2 composite has better high temperature properties than conventional composites [6]. Synthesis, charact erizati o n , and mechanical properties of in-situ Al-TiB2 composites are widel y reported in literatures [7-9]. Fan, T et al., [10] s tudied the eff ect of adding alloying elements in the Al-TiB2 in-situ composites fabricated by flex-assisted synthesis. They concluded that the addition of the copper elements promotes the reinforcement precipitation. Lu, L et al., [11] synthesized Al-4Cu- TiB2 in-situ metal matrix composite. The characterization of this composite indicates that the size of the TiB2 particles is 0.5µm to 1 µm size. Lia ng Y et al., [12] conducted a thermod ynamic analysis of formation of in-situ TiB 2 formation as cast Al-4.5Cu alloy in flux-assisted synthesis process. Herbert, M.A. et al., [13] carried out a microstructure study of Al-4Cu alloy and Al- 4Cu-TiB2 in-situ composite. The analysis of the result indicates that the formation of coarse dendrite structures in Al-4Cu alloy whereas in the composite there are irregular rosette-shaped grains with TiB2 particles at the boundaries of the grains. Kumar, S. et al., [14] studied the influence of in-situ-formed TiB2 particles on the abrasive wear behavior of Al-4Cu alloy. Abrasive wear resistance of the Al-4Cu alloy improved with the addition of TiB2 particles. The hardness of the composite increased wh en the TiB2 content was rai sed . The component produced by composite materials requires a machining process to achieve the required dimensions. Therefore, industrial application of these composites will be impossible without addressing the machinability issues. Surface finish, tool wear, and cutting force are the important indices assessing machinability behavior. Surface integrity of the machined-component determines the ability of materials to withstand severe conditions of stress, temperature, and corrosion [15]. Tool wear plays an important role in forming the machined surface, controlling cutting, reducing the tool cost, and the machining time [16]. Cutting force carries the information about frictional characteristics in the machining interface. Machinability of the ex-situ composites are widely reported in literature. The studies on machinability behavior of in-situ composites are very limited. Ozcatalbas Y., [17] carried out an experimental investigation on machinability behavior of Al-Al4C3 in-situ composites. The micro-crack propagation at the particle-matrix interface facilitates the fracturing through the chip cross-section whose effects reduce the cutting force. The homogeneous microstructure and high hardness of the composite reduce the build-up edge formation that improves the surface roughness. Ozcatalbas Y., [18] investigated the chip and build-up edge formation in machining of the in-situ Al-Al4C3 composites. The morphologies of chip routes were determined by using the quick stop device. It was observed that the small size of the particle and high hardness of the composite caused discontinuous chip formation and increased the chip cutting ratio. Rai R.N., et al., [19] conducted the experiments on the machining of Al-TiC in-situ composite. They reported the chip formation and cutting force measurements during the shaping operation. High volume fraction of the TiC particles caused discontinuous and favorable chip formation without any build-up edge formation. The cutting force was minimized due to the propa gation of micro cracks at the particle-matrix i nterface. S iz e and morphology of the TiC particles present in the composite were found to have influenced surface roughness. Anandakrishnan V., Mahamani A., [20] investigated machinability of the in- situ Al6061-TiB2 composi tes. The y reported th e e ffects of speed , feed , and depth of cut on flank wear, cutting force, and surface roughness. It was observed that the presence of small and fine TiB2 particles exercised significant influence on machinability. The literature survey indicates that the machinability study of Al-4Cu-TiB2 has not been addressed. In this direction, an attempt has been made to study the effects of cutting speed and feed rate on flank wear, cutting force,  Vol.10, No.13 Machinability Stud y of Al-5Cu-TiB2 1245 and surface roughness in turning these composites with the different reinforcement ratio. The contribution of this paper is to study the influence of in-situ formed TiB2 reinforcement on the machinability of Al-5Cu alloy. 2. PRODUCTION AND CHARACTERIZATION OF THE COMPOSITES Al-4.5Cu/TiB2 in-situ composites are produced from K2TiF6, KBF4, Cu-Al salt system by mixed salt reaction. Measured quantities of these preheated halides salts added in the aluminum melt at 850º C. These halide salts induce an exothermic chemical reaction and increase the temperature of the melt up to 1300ºC. There is a two-stage chemical reaction that occurs at this temperature. In the first stage, Al3Ti and AlB2 phases are formed, then, these phases are decomposed as TiB2 and Cryolite slag. The equation for the reaction is shown below. Cryolite slag (KAlF4and K3AlF6 phases) floating on the molten melt is removed. Now the molten melt contains Al-Cu-Ti-B- system. The molten melt is poured in to the 55Ø X 350 mm cast iron mold. Composites are fabricated with the reinforcement ratio of 0%, 3%, and 6% TiB 2 particles in the Al-5Cu alloy. 3K2TiF6 +13Al 3TiAl3 + 3KAlF4 + K3AlF6 2KBF4 + 3Al AlB2 + 2KAlF4 The fabricated composites are characterized by EDAX, SEM, and micro-hardness analysis. The EDAX pattern for the Al -4Cu- 6% TiB2 in-situ compos ite was r ecorded (H itach i S-300H model) and displayed in Figure 1. Lithium drift silicon detector analyzer with the operating voltage of 20KV and 500x magnification was used to record the spectrum. Figure 1 confirms the presence of Cu and TiB2 reinforcements. Presence of potassium and fluoride elements due to the slag entrapments in the aluminum matrix are not detected in th e spect ru m, whi ch rev eals th e chem ic al stability of the composite. The micro-structure an alyses of t he compos ite sam ples are car ried out by using scanning electron microscopy (JEOL 6360 LV model). Figure 2 shows the micrographic view of Al-4Cu alloy. The CuAl 2 f ormation is found in the grain boundaries of the matrix. Al2Cu is uniformly distributed in the matrix. Boiling the molten composite at high temperat u res will distribute the reinforcement particles and Al2Cu uniformly. This action will minimize the heterogeneity in microstructure of the composite. There are very fine Al2Cu phase precipitated from the matrix. Al 2Cu and Al bond well. So the precipitation of Al2Cu strengthens Al-4.5Cu matrix. Figure 3 shows the scanning electron microscopy of Al-4Cu- 6% TiB 2 in-situ metal matrix composite. The micron-size TiB2 particle along with Al2Cu is trapped in to the grain boundaries of the aluminum matrix. Figure 4 shows a typical microscopic view focused on the Al2Cu phase. The TiB2 particles are surrounded by the Al2Cu phase. Table 1 shows the micro-hardness of the composites is evaluated by using the Vickers’s micro-hardness tester (MH06 model) at a load of 25 grams with 3 seconds dwell time. Hardness values are measured in three different places in the composite and the average value is reported in Table 1. Table 1 shows that there is an 8% increase in hardness observed when adding 3% TiB2 in the Al-4Cu alloy. It is also seen from Table 1 that a significant improvement in the hardness of Al-4Cu-6 % TiB2 in-situ composite was observed when compared to the Al-4Cu alloy. Therefore, the increase in hardness of the composite confirms the presence of reinforcement. It is also noted that the hardness of these in-situ composites increases when increasing the reinforcement ratio.  1246 A. Mahamani Vol.10, No.13 Table 1 Micro hardness analysis of the composites V Figure 1 EDAX spectrum of Al –Cu-6 % TiB2  Vol.10, No.13 Machinability Stud y of Al-5Cu-TiB2 1247 Figure 2 Microstructure of Al –Cu alloy Figure 3 Microstructure of Al –Cu-3% TiB2 in-situ metal matrix composite Figure 4 Microstructure of Al –Cu-6 % TiB2 in-situ metal matrix composite 3. MACHINING TEST A machinability study was carried out on T urn m aster-35 lathe supplied b y Kirloskar, India. The experimental setup for machining test is shown in Figure-5. Uncoated tungsten carbide insert with the specification of SNMG120408 MTTT5100 was clamped in a rigid tool holder. The insert has clearance angle 7o, cutting edge angle75 o, and nose radius 0.8 mm. Specification of  1248 A. Mahamani Vol.10, No.13 the tool holder was PSBNR-2525M12. The length of turning is 110mm. No chip breaker was used in the experiment. The average flank wear was measured using Mitutoya microscope with 30× magnification. SJ210 stylus type roughness tester (Mitutoya make, 0.001 µm) was used for measuring surface roughness. The cut of length of roughness measurement was 25mm. The cutting force was measured using a Kistler Dynamometer (model 9257B). Data acquisition was carried out by appropriate software Dynaware Kistler. Machining test was conducted in dry cutting condition. During experiments, only one parameter was varied while others were held constant to observe the effects of variation of an individual input parameter on the output parameter. The selected machining parameters and their ranges are given in Table-2. Table 2 Experimental conditions Paramet ers Uni ts Ranges Cutting speed m/min 50,75,100,125 and 150 Feed rate mm/rev 0.1,0.15, 0.2 , 0.25and 0.3 Cutting depth mm 0.5,0.75,1,1.25 and 1.5 Figure 5 photographic view of experimental set up with kistler dynamometer 4. RESULT AND DISCUSSION 4.1 Mechanism of In-Situ Formation Al-5Cu-TiB2 in-situ composite was successfully produced by flux-assisted synthesis. The material characterization confirmed the presence of ZrB2 indicating the purity of materials. Formation of ZrB 2 occurred at 950oC, in the melt during the exothermic reaction. Therefore, no oxide layer formation occurred on the surfaces of TiB2. The pure and active reinforcement  Vol.10, No.13 Machinability Stud y of Al-5Cu-TiB2 1249 promoted the thermodynamic stability of the composite. Fine size reinforcements of ZrB2 formed in the Al matrix due to phase nucleation, which facilitated the wetting and bonding of the interface between the reinforcements and the matrix. The melt boiling at the high temperature distributed the particles throughout the mold and ensured homogeneous distribution. 4.2 Flank Wear Abrasion is the main wear mechanism in fl ank wear during machining. Flank wear i s one of the major factors contributing to the geometric error and thermal damage in a machined work piece [21]. The presence of fine TiB2 particles in the composites causes less damage when engaging the cutting tool with the reinforcements. The Al 2C u formation surrounded b y the reinforcements reduces the abrasive action at the flank face of the tool. Figure 6 shows the effects of cutting speed on flank wear when machining the composites at 0.2 mm/rev feed rate and 1 mm depth of cut. Figure 6 reveals that the increase in cutting speed, increases the flank wear under the same machining conditions. At higher cutting speeds, the material passes away within a short interval of time, which facilitates the machining interface to become the adiabatic system. Increase in temperature softens the cutting tool and causes more tool wear. The effect of feed rate on flank wear was recorded by keeping the cutting speed as 125 m/min and depth of cut as 1mm. Figure 7 shows that hi gher feed rate increases the flank wear. A rise in the federate increases the friction between work p iece and hikes up heat generation which causes greater flank wear. It is observed from Figure 7 that the flank wear increases through an increase in the reinforcement ratio. The presence of small and fine reinforcement particles reduces the tool wear because of the absence of coarseness. Al 2Cu phase surrounded by the TiB 2 particles acts as a lubricant and reduces the effect of reinforcements. Ef fect of c u tting speed on flank wear (0. 2mm/rev & 1 mm DOC) 0 0.05 0.1 0.15 5075100 125 150 Figure 6 Effect of cutting speed on flank wear 4.3 Cutting Force Cutting force signals are highly sensitive carriers of information about the status of the machining process. The influence of cutting speed on cutting force is shown in Figure 8. This shows that an increase in cutting speed decreases the cutting force. An inc rease in cuttin g speed increases the temperature of the work piece, which reduces the hardness of the work piece. Therefore, the cutting force is reduced when this softened work piece is machined. The effect of  1250 A. Mahamani Vol.10, No.13 the feed rate on the cutting force was measured by keeping the cutting speed constant at 125 m/min and the cut at 1 mm depth. As seen from Figure 9, an increase in feed rate increases the cutting force. Generally, the cutting force along the horizontal axis increases when the feed rate is in creased . An incr ease in fe ed rate i ncreas es t he max im um chi p thi cknes s, whi ch inc reas es th e cutti ng for ce. A s s een from Figu res 8 and 9, as t he rei nfo r cemen t r at i o i ncre as es t he cu tt ing forc e is reduced due to a reduction in strain. Effect of feed rate on flank wear (125 m/min & 1 mm DOC) 0 0.05 0.1 0.15 0.05 0.1 0.15 0.2 0.25 Figure 7 Effect of feed rate on flank wear Ef f ect of cutt ing speed o n cutt ing f or ce ( 0.2m m/r ev & 1 mm DOC) 0 20 40 60 80 100 120 140 5075100 125 150 Figure 8 Effect of cutting speed on cutting force  Vol.10, No.13 Machinability Stud y of Al-5Cu-TiB2 1251 Effec t o f feed rate on cutting fo rce (1 25 m/min & 1 mm DOC) 0 50 100 150 0.05 0.1 0.150.2 0.25 Figure 9 Effect of feed rate on cutting force 4.4 Surface Roughness The machined surface qualit y of the composite is one of the most im portant facto rs aff ecting th e actual application. Figure 8 shows the influence of cutting speed on surface roughness. The surface roughness was evaluated under different cutting speeds, at a constant feed rate of (0.2 mm/rev) and a depth of cut (1 mm). As seen from Figure 8, an inc rease i n cutti ng speed reduces the surface roughness. Higher cutting speeds are associated with an increase in the cutting temperature which leads to the formation of suited-up edge formations and minimizing the deposition of build-up edge formation. A higher cutt ing speed can howeve r, improve the surface finish. As the cutting speed increases, the strain rate will also increase. This action facilitates particle fracture and crack-minimizes particle pulling. Therefore, the amount of pin formation is reduced and good surface finish can be achieved. The effect of feed rate on the surface roughness exami ned by keepin g the cut ting speed at 125 mm/m and depth of cut as 1 mm is observed from Figure 9. An increase in feed rate increases the surface roughness. An increase in feed rate increases the pit and crack formation, and causes lar ger tool feed mark s. At higher f eed rates, the tool has more vibration when shifting the cutting from Particle to matrix. This could be the reason for larger feed marks at higher feed rates. The increase in feed rate increases the temperat ure, which en ables particle pulling, and pits and crack form ation. These eff ects incre ase the surface roughness at higher feed rates. These small sized TiB2 particles and improved wettability minimize the possibility of particle pulling, de-bonding of the matrix – reinforcement. The uniform distribution of the particles undergoes uniform plastic deformation which reduces subsurface damage. These effects minimize surface roughness in machining the composites. Figures 8 and 9 show that the surface roughness has been increased by increasing the volume fraction of the composite.  1252 A. Mahamani Vol.10, No.13 Ef fect of c u tting speed on surfa ce roughness (0.2mm/rev & 1 mm DOC) Figure 10 Effect of cutting speed on surface roughness Effe ct of fe ed rate on surfa ce roughne ss (125 m/m i n & 1 mm DOC) 0 0.5 1 1.5 2 2.5 3 3.5 4 0.05 0.1 0.150.2 0.25 Figure 11 Effect of feed rate on surface roughness 5. CONCLUSION The flank wear, cutting force, and surface roughness of the experimental study of machining the Al-5Cu-TiB2 in-situ metal matrix composites indicated the following conclusions: Al-5Cu-TiB2 in-situ metal matrix composite has been synthesized successfully with different reinforcement ratio using flux -assisted synthesis. The presence of TiB2 and ZrB2 phases in the Al-5Cu alloy is confirmed by EDAX analysis. A significant improvement in the hardness was observed by adding reinforcements in t he A l-5Cu alloy. The incre ase in cut ting sp eed increas ed the flank wear, reduced the cutting force, and minimized the surface roughness. An increase in feed rate increased the flank wear, cutting force, and surface roughness.  Vol.10, No.13 Machinability Stud y of Al-5Cu-TiB2 1253 An increase in reinforcement ratio increased the tool wear, reduced the cutting force, and increased the surface roughness. The machinability behavior of Al-5Cu-TiB2 is entirely different from the conventional composites because of the presence of Al2Cu phase, TiB2, and ZrB2 p ar t icles . This detailed of study of machining characteristics would be helpful for the economic and efficient machining of this material. ACKNOWLEDGEME NT S The Author acknowledges the encouragement and support provided by the management of Swetha Institute of Technology and Science for Women, Tirupati. Author also grateful to the AICTE, India for the provision of grant (8024/RID/BOR/MOD/831/9/10) to carry out this experimental work. REFERENCES [1] Kuruvilla A.K., Prasad K.S., Bhanuprasad V.V., Mahajan Y.R., “Microstructure-property correlation in Al–TiB2 (XD) composites” Scripta Metall., vol. 24, 1990,pp. 873-878. [2] Cui C., Shen Y., Meng, F., “Review on fabrication methods of in-situ metal matrix composites” J. Mater. Sci. Tech., vol.16, 2000, pp.619-626. [3] Ramesh C.S., Ahamed A., Channabasappa B.H.,Keshavamurthy R., “Development of Al 6063–TiB2 in situ composites” Mater.D es., vol.31, 2010, pp. 2230- 2236. [4] Feng C.F., Froyen L., “Microstructures of in-situ Al/TiB2 MMCs prepared by a casting route” J. Mater. Sci., vol.35, 2000, pp.837-850. [5] Lewis D., “In-situ reinforcement of metal matrix composites: processing and interface” Academic Press, London, 1991, pp 121-150. [6] Janghorban K., “Processing of ceramic matrix SiC-Al composite” J. Mater. Proc. Techno., vol. 38, 1993, pp. 361-368. [7] Lakshmi S., Lu L.,Gupta M., “In-situ preparation of TiB2 reinforced aluminum based composites” J. Mater. Proc. Techno., vol. 73, 1998, pp.160-166. [8] Lee K.T., Lu L., Lai M.O., “Synthesis of in-situ Al–TiB2 composite using stir cast route” Compo. Struct., vol. 47, 1999, pp. 589-593. [9] Emamy M., Mahta, M., Rasizadeh, J., “Formation of TiB2 particles during dissolution of TiAl3 in Al–TiB2 metal matrix composite using an in-situ technique” Compo. Sci. Techno., vol.66, 2006, pp.1063-1066. [10] Fan T., Yang G., Zhang D., “Thermodynamic effect of alloying addition on in-situ reinforced TiB2/Al composites” Metallur.Mater. Trans.A, vol.36, pp225-233. [11] Lu L., Lai M.O., Chen F.L., “Al-4 wt% Cu composite reinforced with in-situ TiB2 particles” Acta Materialia, Vol.10, 1997, pp. 4297-4309. [12] Li ang Y., Zhou J., Dong S., Y an g T ., “Thermod ynamic anal ysis of the formation of In-situ reinforced phases in cast Al-4.5Cu alloy” J. Wuhan University of Techno. Mater. Sci. Ed, vol. 23, 2008,pp.342-345.  1254 A. Mahamani Vol.10, No.13 [13] Herbert M.A., Sark ar C., Mitra R., Chakraborty M., “Microstructural evolution, hardness, and alligatoring in the mushy state rolled cast Al-4.5Cu alloy and in-situ Al4.5Cu-5TiB2 composite” Metall. Mater. Trans. A, vol. 38, 2007, pp. 2110-2126. 14] Kumar S., Subramanyasarma V., Murty B.S., “High temperature wear behavior of Al–4Cu– TiB2 in-situ composites” Wear, vol. 268, 2010, pp. 1266-1274. [15] Dabade U.A., Joshi S.S., “Analysis of chip formation mechanism in machining of Al/SiCp metal matrix composites” J.Mater. Proc. Techno., vol. 209,2009,pp. 4704-4710. [16] Quan Y.M.., Zhou Z.H.,Ye B.Y., “Cutting process and chip appearance of aluminum matrix composites reinforced by SiC particle” J. Mater. Process. Technol.,vol.91,1997, pp.231-235. [17] Ozcatalbas Y., “Chip and built-up edge formation in the machining of in situ Al4C3–Al composite”. Mater. Des., vol.24, 2003a, pp.215–221. [18]OzcatalbasY., “Investigation of the machinability behavior of Al4C3 reinforced Al-based composite produced by mechanical alloying technique” Compo. Sci. Technol., vol.63,2003, pp.53–61. [19] Rai R.N., Datta G.L., Chakraborty M., Chattopadhyay A.B., “A study on the machinability behavior of Al-TiC composite prepared by in-situ technique” Mater. Sci. Eng.: A, vol. 428, 2006, pp.34-40. [20] Anandakrishnan V., Mahamani A., “Investigations of flank wear, cutting force, and surface roughness in the machining of Al-6061–TiB2 in situ metal matrix composites produced by flux -assisted synthesis” Int J Adv Manuf Technol., vol. 55, 2010,pp.65-73. [21] Yanming Q., Zehua Z, “Tool wear and its mechanism for cutting SiC particle-reinforced aluminium matrix composites” J. Mater. Proc. Techno., vol. 100, 2000, pp.194-199.

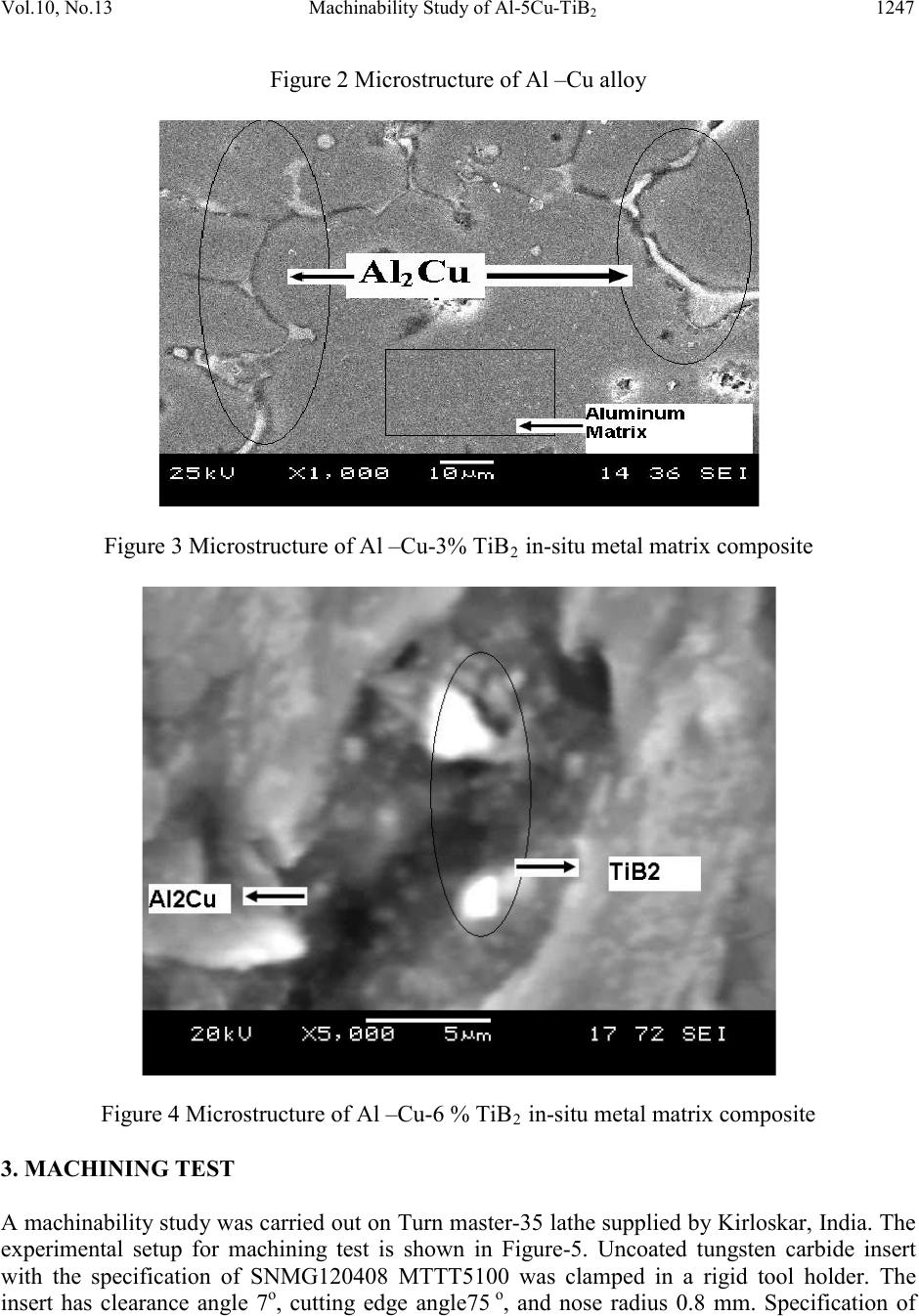

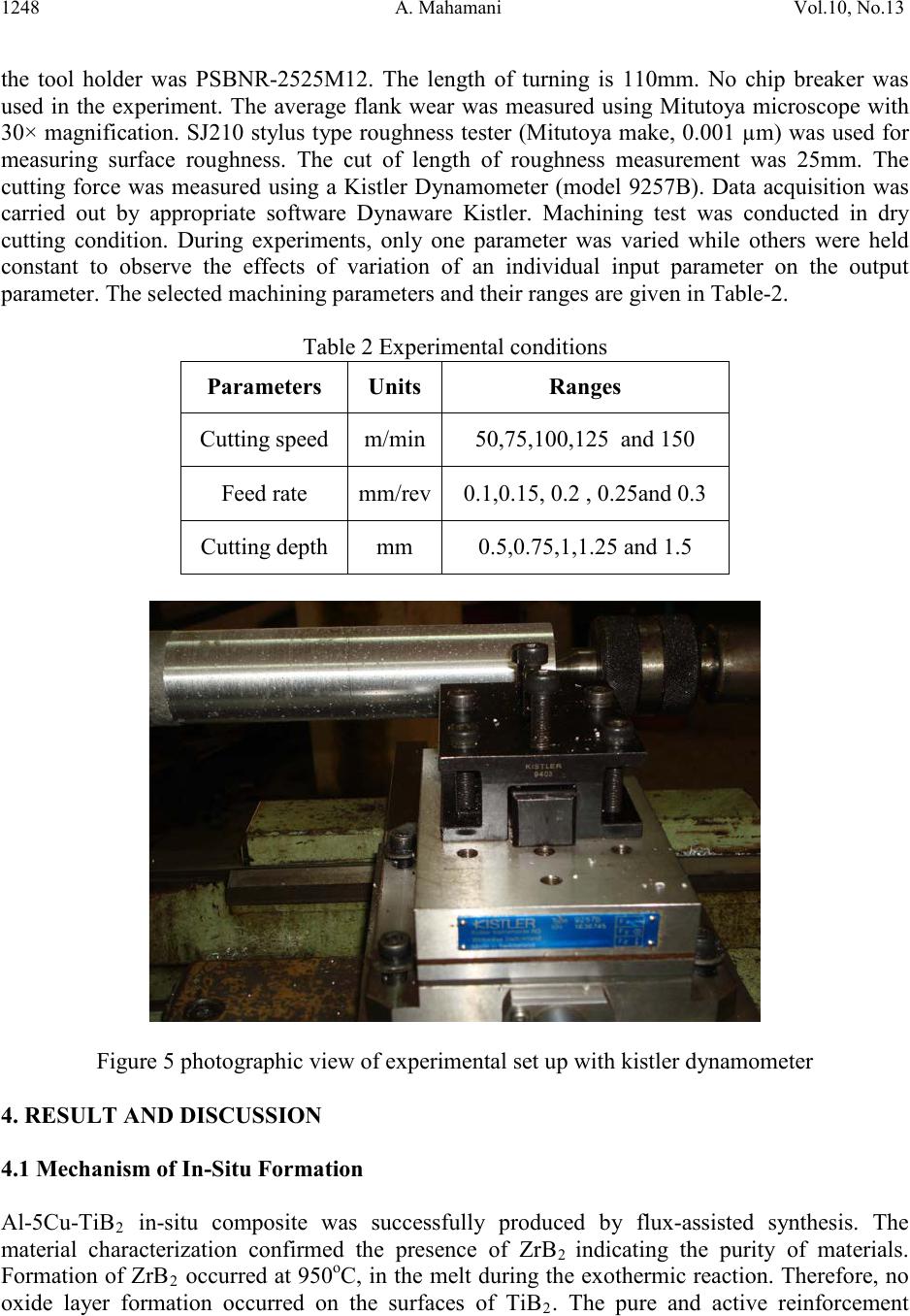

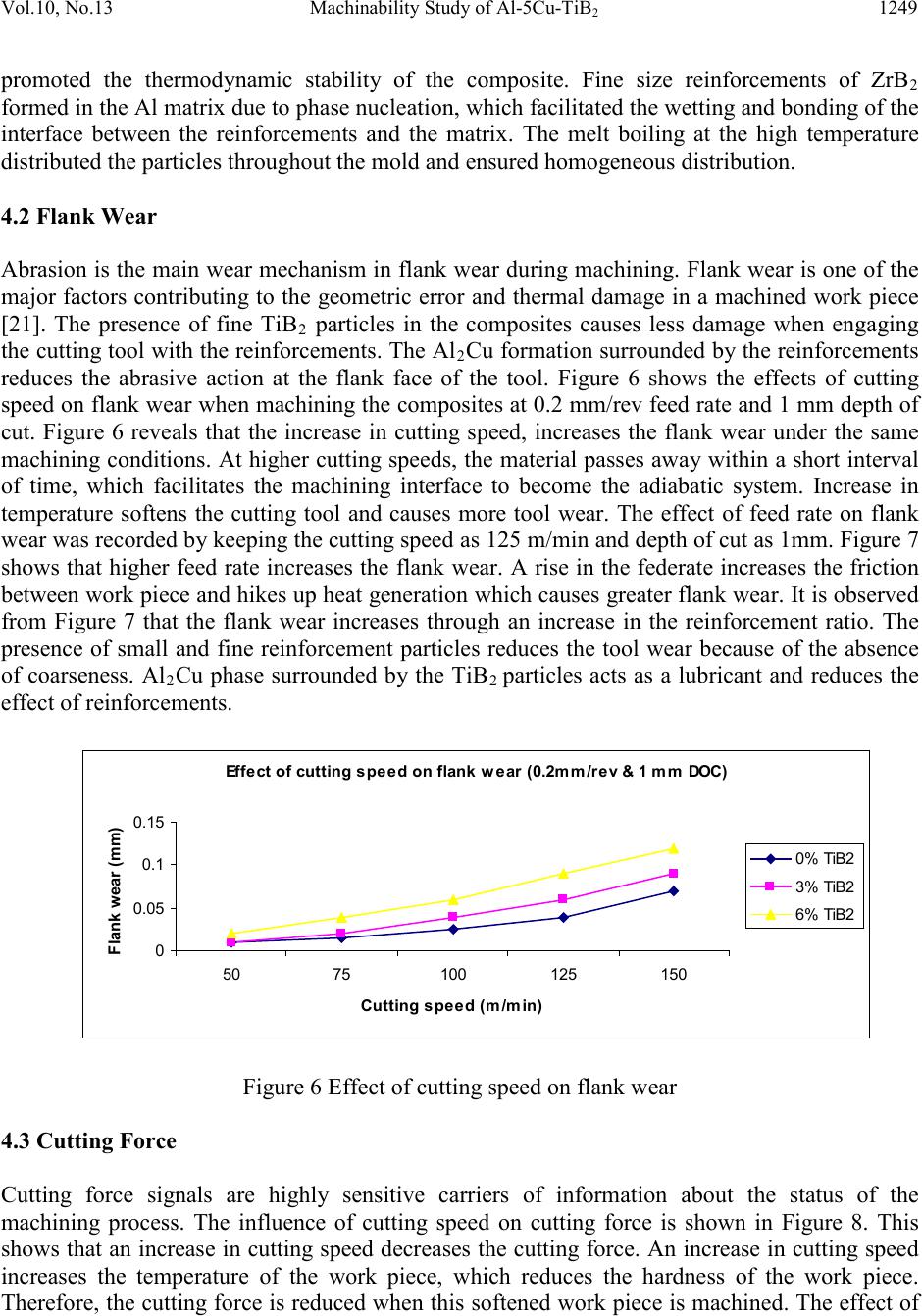

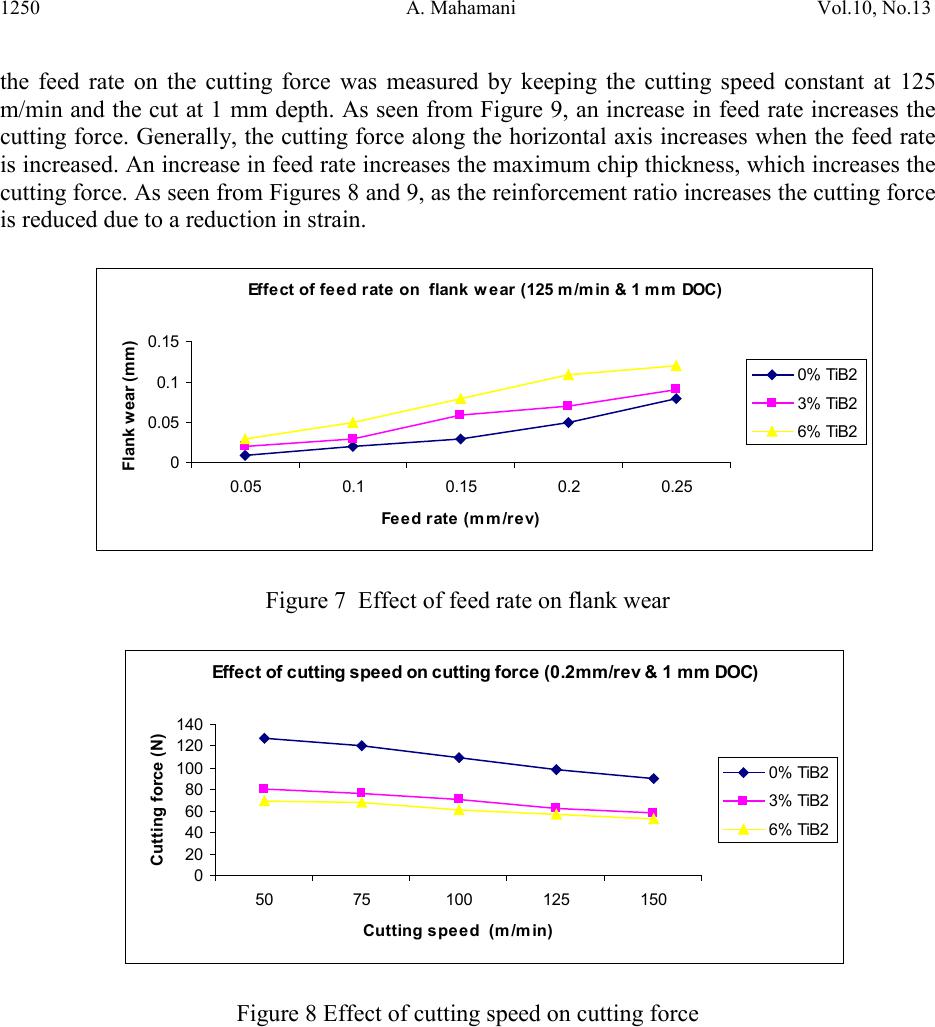

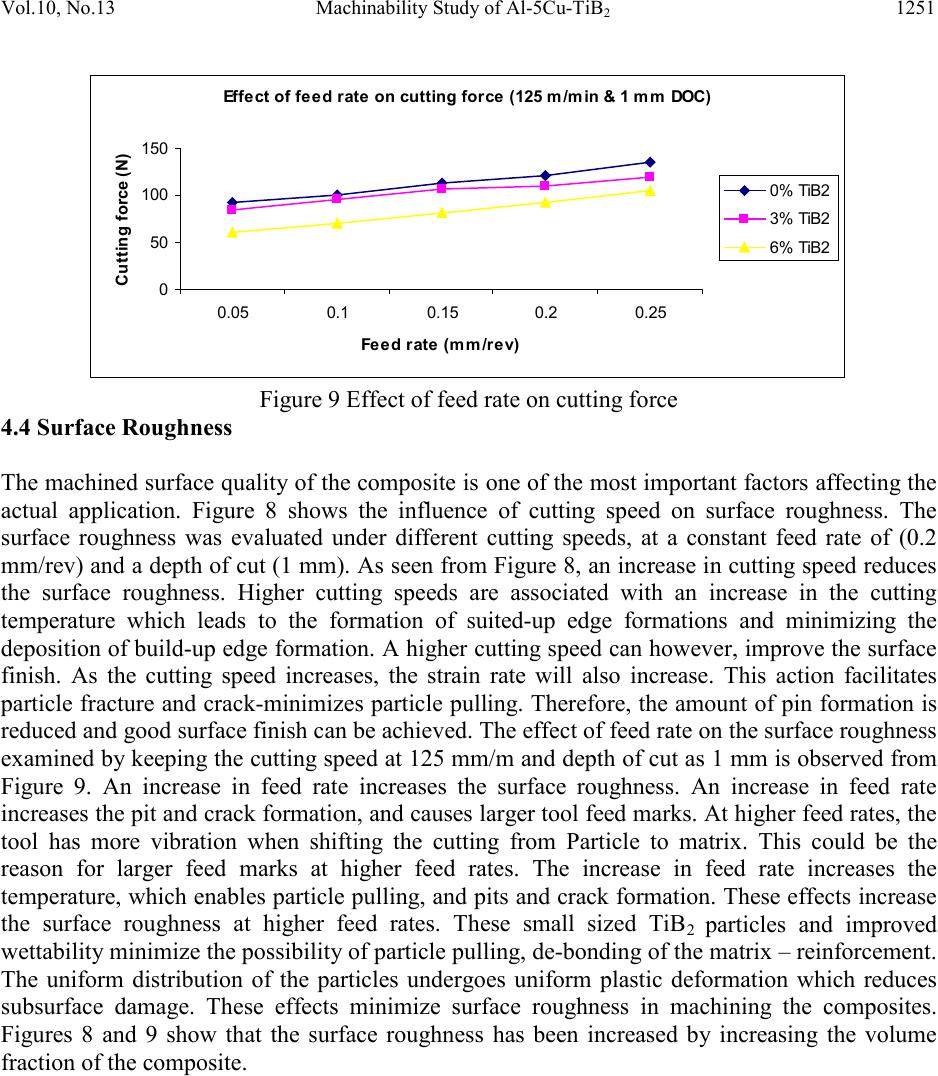

|