Paper Menu >>

Journal Menu >>

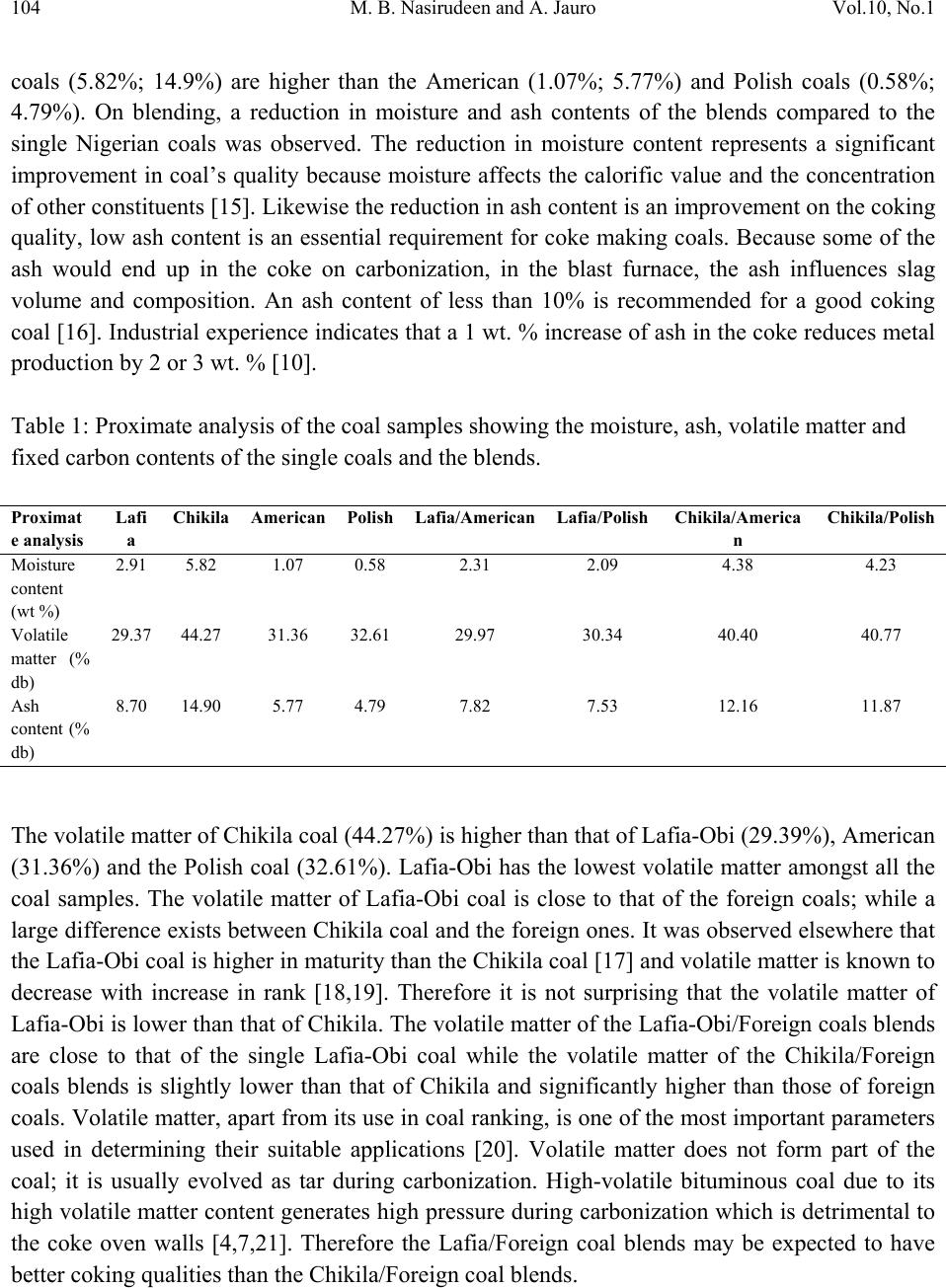

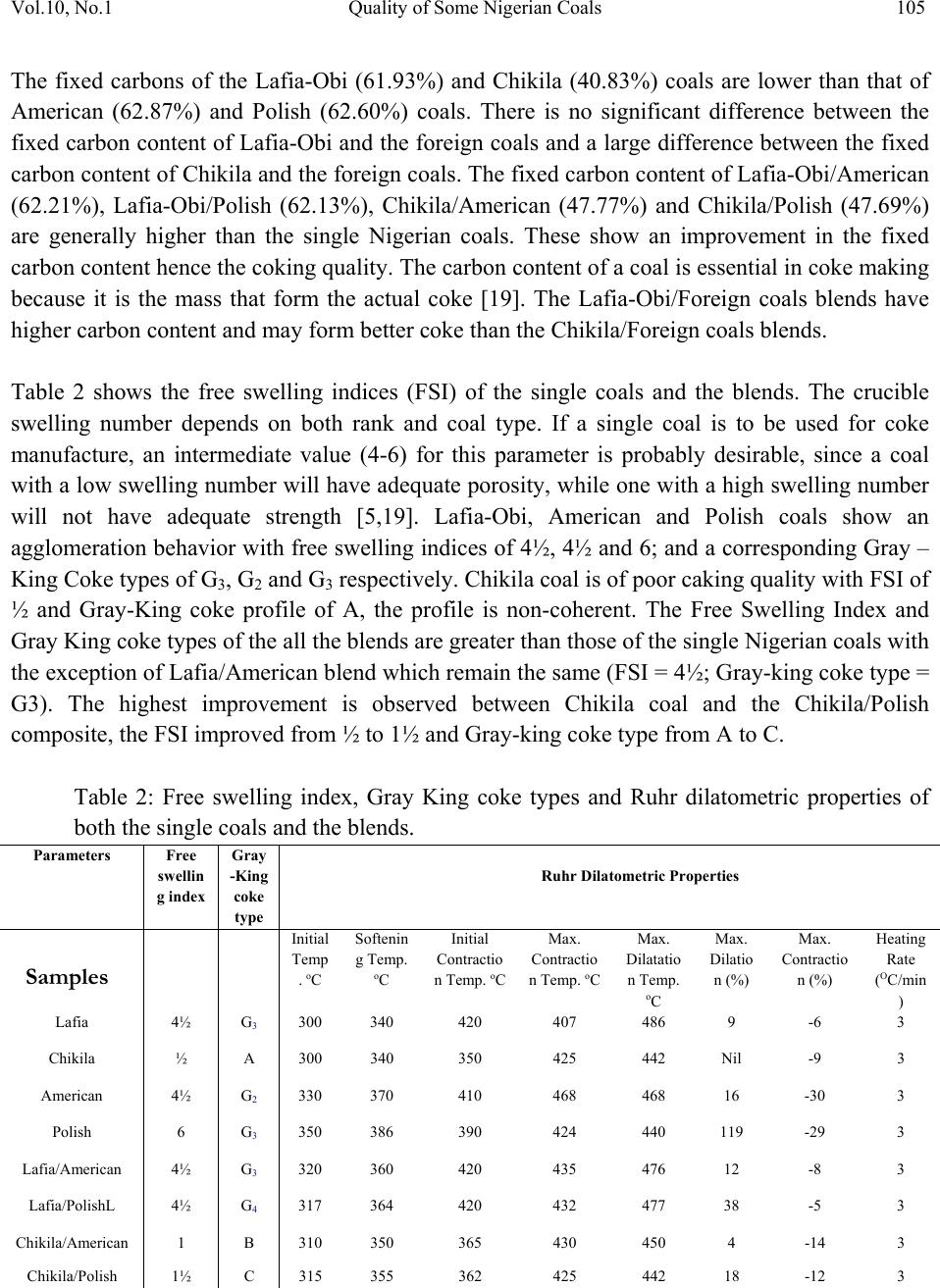

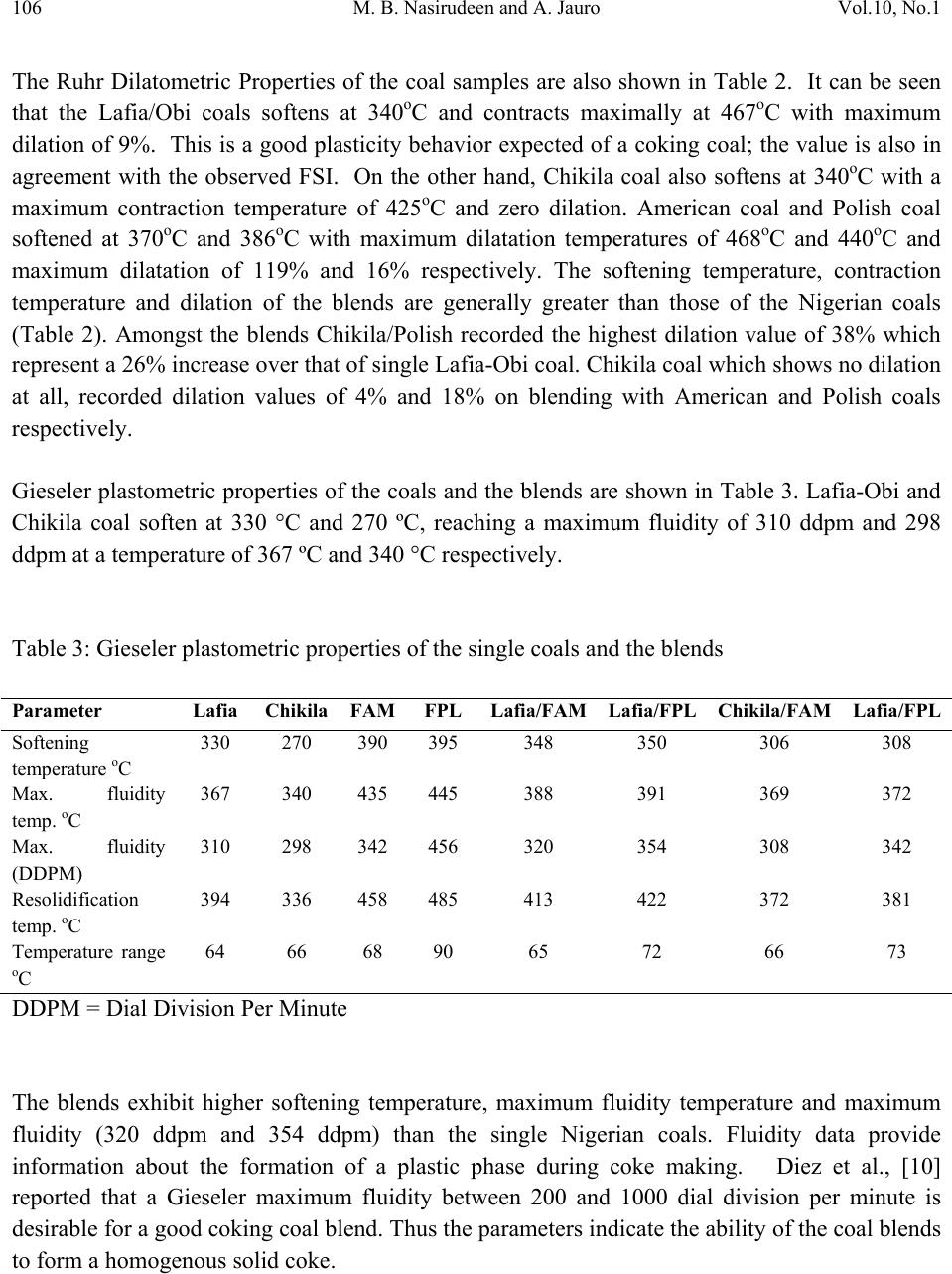

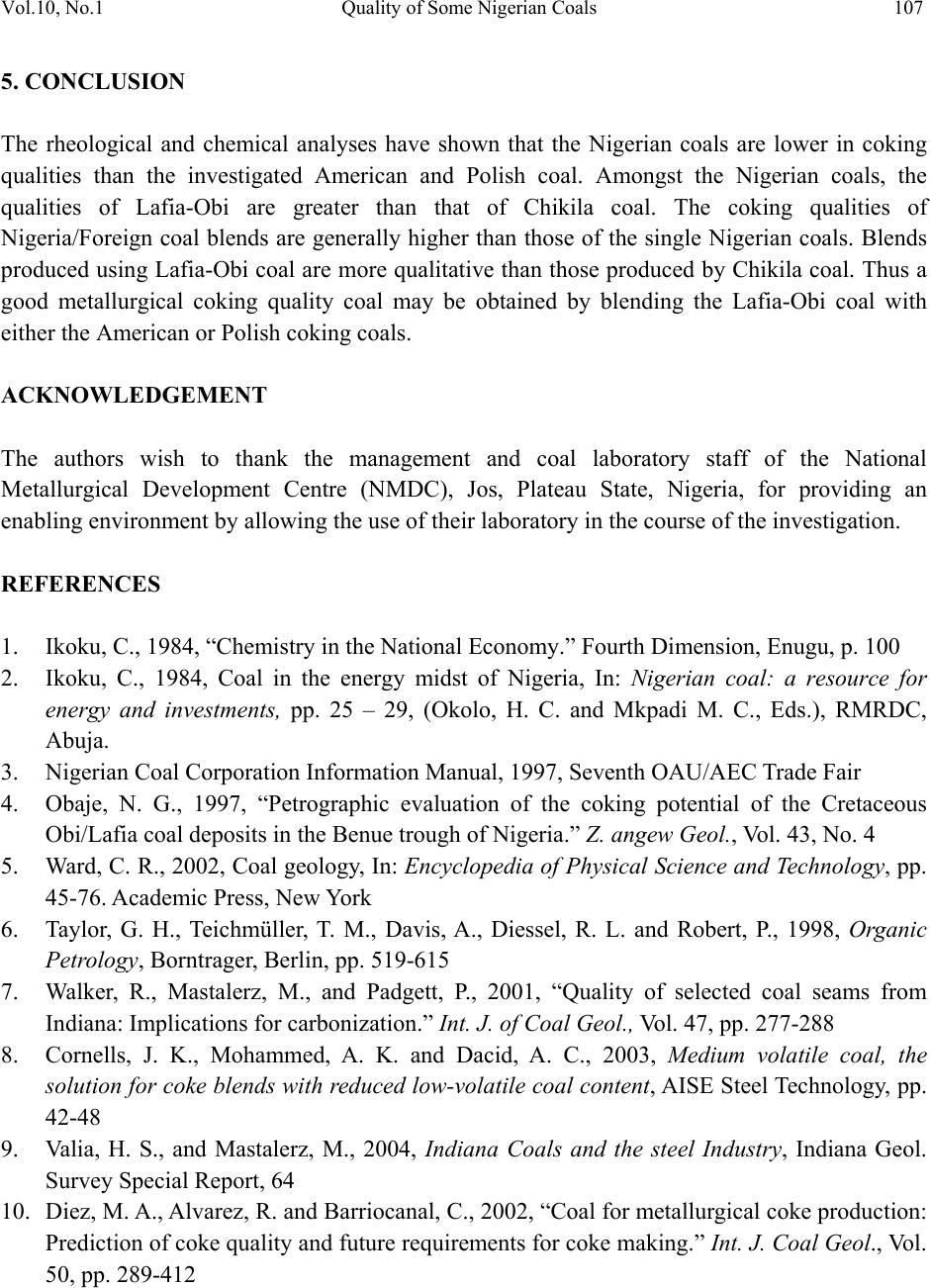

Journal of Minerals & Materials Characterization & Engineering, Vol. 10, No.1, pp.101-1 09, 2011 jmmce.org Printed in the USA. All rights reserved 101 Quality of Some Nigerian Coals as Blending Stock in Metallurgical Coke Production 1M. B. Nasirudeen, 2A. Jauro* 1Department of Chemistry, Kaduna State University, P.M.B 2339, Kaduna, Nigeria 2Chemistry Programme, Abubakar Tafawa Balewa University, PMB 248, Bauchi, Nigeria *Corresponding Author: alijauro@daad-alumni.de ABSTRACT Two Nigerian coals, Lafia-Obi and Chikila were blended in the mass ratio of 70:30 with imported American and Polish coking coals. Proximate analysis, free swelling index, Ruhr dilatometer and Gieseler plastometer were used in assessing the coking qualities of both the single coals and the blends. The results show that the blends are lower in moisture and ash contents; higher in volatile matter and fixed carbon than the single Nigerian coals. The rheological parameters revealed superiority in thermo-plastic properties of the blends over the unblended local coals. Lafia-Obi/Foreign coals blends possess lower ash and better rheological properties compared to Chikila/Foreign coal composites which have high ash and poor rheological properties. These together suggest that amongst the two Nigerian coals, Lafia-Obi is superior for blending w it h t h e f o r ei g n ones in metallurgical coke production. Keywords: coking coals; blending; Nigeria 1. INTRODUCTION The importance of coal in the energy mix of Nigeria and the entire world cannot be underestimated. Coal was first discovered in Nigeria near Udi, by the Mineral Survey of Southern Nigeria in 1909 and its belt spans through a considerable part of the country [1]. The actual production commenced in 1916 with 24 000 tons for that year and recorded a cumulative output of 22.9 million tons by 1967 when production ceased as a result of the Nigerian Civil War [2]. Since then production has been epileptic. Presently the only exploited coal deposits are those of Okaba, Onyeama, Okpara and Okwukpa which are mainly used for combustion purposes [3].  102 M. B. Nasirudeen and A. Jauro Vol.10, No.1 Coking coal is required for coke and can serve the blast furnace of Ajaokuta Steel Company. But most of the Nigerian coals are non-coking types [4]. As part of the Nigerian government economic reform, the Federal Ministry of Solid Minerals Development was established and coal was listed as one of the priority minerals targeted for exploration and exploitation, for export and domestic consumption. Coal can transform into coke only if it softens to a plastic mass on carbonization, followed by decomposition, swelling and evolution of gas and finally resolidification while gas is still being evolved [5]. The quality of coal determines to a large extent the quality of the resulting coke. Some coals possessing some of the coking properties may be lacking in others, and even detrimental to the coke ovens. In the past coke-makers relied on medium-volatile bituminous coals [6], but due to their scarcity and high price, coking coals of this rank are typically used as a ‘base’ in blends, to which coals of differing rank and chemical properties are added, such that, overall, the blend achieves the required coke quality [7,8,9]. Impurities present in coal would end of in coke and this would affect its performance in the blast furnace. This is by decreasing its role as a fuel in terms of amount of carbon available for direct and indirect reduction roles and also its role as a permeable support. Such impurities are moisture, volatile matter, ash, sulfur, phosphorous, and alkali contents [10]. Their desired contents can be achieved easily by suitably proportioning different coals in the blend. Impurities like sulfur, phosphorous and alkalis in coke can be minimized by limiting these constituents in the individual coals. One measure of coal’s ability to make quality coke is fluidity, a test which measures the rheological properties [11]. These properties can be studied during coke formation by monitoring the length of a pressed specimen of powdered coal in a dilatometer, such as the Audibert-Arnu or the Ruhr dilatometer, or by measuring the viscosity, or fluidity, of a pressed coal powder in a Gieseler or Hoehne plastometer as the coal is heated over its carbonization range. Note is taken of the temperature at which critical stages of the carbonization process are reached and of the degree of change, such as contraction, expansion, or fluidity, which develops in the material as the coke is formed. These data can then be used in various ways to assess the suitability of a coal or blend of coals for coke manufacture. In the search for a Nigerian coking coal, Aderonpe [12] carried out the assessment of blends of high volatile (30% - 36%) bituminous coals with low volatile (<20%) bituminous. In another investigation, Onyeama and Okaba coals were reported to be poorly caking, while Lafia/Obi as weakly caking [13]. The Cakability of Enugu coal blended with some imported coals was also studied [13]. This paper reports the blending and quality assessment of some Nigerian coals with American and Polish coking coals. Some parameters that determined coking quality like the proximate analysis, free swelling index, Ruhr dilatometer and Gieseler plastometer were used in accessing the suitability of the blends for metallurgical coke production.  Vol.10, No.1 Quality of Some Nigerian Coals 103 2. MATERIALS The coal samples were obtained from the National Metallurgical Development Centre (NMDC), Jos, Nigeria. The local coals were Chikila and Lafia-Obi (Lafia); while the foreign ones were American and Polish coking coals. The samples were pulverized and sieved using a 200 mesh British standard. A 70:30 mass ratio of foreign to a local coal were used in the blends. The major instruments used for the analysis were Leco Digital Balance LECO 250, Gray King Furnace 11/81/1085, Ruhr Dilat ometer 205DIG, G ieseler Plastometer 42000/A4 and a Phoenix furnace. 3. METHODS 3.1 Proximate Analysis Proximate analyses of the coals were performed based on ASTM Standards [14]. All runs were repeated to check the instrument’s results repeatability and reproducibility. 3.2 Free Swelling Index Determination 1g of coal sample was taken into a porcelain crucible; it was covered and heated for seven (7) minutes on a Bunsen burner. After cooling, the bottom cake was compared with a standard profile. 3.3 Gray King (Coke Type) Determination 10g of the sample was spread over a 15cm length horizontally placed retort tube. The tube’s end was sealed with cotton wool and transferred into a furnace set at an initial temperature of 325oC. The temperature was gradually increased to 600oC. The retort was removed after 15 minutes and allowed to cool. The carbonized coal in the retort was compared with the standard Gray King profiles. 3.4 Ruhr Dilatometric and Gieseler Plastometric Properties The Ruhr Dilatometric and Gieseler Plastometric Properties were determined based on ASTM standards14. 4. RESULTS AND DISCUSSIO N The results obtained from the proximate analysis of the individual coals and those of the blends are shown on Table 1. The moisture and ash contents of Lafia-Obi (2.91%; 8.7%) and Chikila  104 M. B. Nasirudeen and A. Jauro Vol.10, No.1 coals (5.82%; 14.9%) are higher than the American (1.07%; 5.77%) and Polish coals (0.58%; 4.79%). On blending, a reduction in moisture and ash contents of the blends compared to the single Nigerian coals was observed. The reduction in moisture content represents a significant improvement in coal’s quality because moisture affects the calorific value and the concentration of other constituents [15]. Likewise the reduction in ash content is an improvement on the coking quality, low ash content is an essential requirement for coke making coals. Because some of the ash would end up in the coke on carbonization, in the blast furnace, the ash influences slag volume and composition. An ash content of less than 10% is recommended for a good coking coal [16]. Industrial experience indicates that a 1 wt. % increase of ash in the coke reduces metal production by 2 or 3 wt. % [10]. Table 1: Proximate analysis of the coal samples showing the mo is t ur e, ash, volatile matter and fixed carbon contents of the single coals and the blends. Proximat e analysis Lafi a Chikila American Polish Lafia/American Lafia/Polish Chikila/America n Chikila/Polish Moisture content (wt %) 2.91 5.82 1.07 0.58 2.31 2.09 4.38 4.23 Volatile matter (% db) 29.37 44.27 31.36 32.61 29.97 30.34 40.40 40.77 Ash content (% db) 8.70 14.90 5.77 4.79 7.82 7.53 12.16 11.87 The volatile matter of Chikila coal (44.27%) is higher than that of Lafia-Obi (29.39%), American (31.36%) and the Polish coal (32.61%). Lafia-Obi has the lowest volatile matter amongst all the coal samples. The volatile matter of Lafia-Obi coal is close to that of the foreign coals; while a large difference exists between Chikila coal and the foreign ones. It was observed elsewhere that the Lafia-Obi coal is higher in maturity than the Chikila coal [17] and volatile matter is known to decrease with increase in rank [18,19]. Therefore it is not surprising that the volatile matter of Lafia-Obi is lower than that of Chikila. The volatile matter of the Lafia-Obi/Foreign coals blends are close to that of the single Lafia-Obi coal while the volatile matter of the Chikila/Foreign coals blends is slightly lower than that of Chikila and significantly higher than those of foreign coals. Volatile matter, apart from its use in coal ranking, is one of the most important parameters used in determining their suitable applications [20]. Volatile matter does not form part of the coal; it is usually evolved as tar during carbonization. High-volatile bituminous coal due to its high volatile matter content generates high pressure during carbonization which is detrimental to the coke oven walls [4,7,21]. Therefore the Lafia/Foreign coal blends may be expected to have better coking qualities than the Chikila/Foreign coal blends.  Vol.10, No.1 Quality of Some Nigerian Coals 105 The fixed carbons of the Lafia-Obi (61.93%) and Chikila (40.83%) coals are lower than that of American (62.87%) and Polish (62.60%) coals. There is no significant difference between the fixed carbon content of Lafia-Obi and the foreign coals and a large difference between the fixed carbon content of Chikila and the foreign coals. The fixed carbon content of Lafia-Obi/American (62.21%), Lafia-Obi/Polish (62.13%), Chikila/American (47.77%) and Chikila/Polish (47.69%) are generally higher than the single Nigerian coals. These show an improvement in the fixed carbon content hence the coking quality. The carbon content of a coal is essential in coke making because it is the mass that form the actual coke [19]. The Lafia-Obi/Foreign coals blends have higher carbon content and may form better coke than the Chikila/Foreign coals blends. Table 2 shows the free swelling indices (FSI) of the single coals and the blends. The crucible swelling number depends on both rank and coal type. If a single coal is to be used for coke manufacture, an intermediate value (4-6) for this parameter is probably desirable, since a coal with a low swelling number will have adequate porosity, while one with a high swelling number will not have adequate strength [5,19]. Lafia-Obi, American and Polish coals show an agglomeration behavior with free swelling indices of 4½, 4½ and 6; and a corresponding Gray – King Coke types of G3, G2 and G3 respectively. Chikila coal is of poor caking quality with FSI of ½ and Gray-King coke profile of A, the profile is non-coherent. The Free Swelling Index and Gray King coke types of the all the blends are greater than those of the single Nigerian coals with the exception of Lafia/American blend which remain the same (FSI = 4½; Gray-king coke type = G3). The highest improvement is observed between Chikila coal and the Chikila/Polish composite, the FSI improved from ½ to 1½ and Gray-king coke type from A to C. Table 2: Free swelling index, Gray King coke types and Ruhr dilatometric properties of both the single coals and the blends. Parameters Free swellin g index Gray -King coke type Ruhr Dilatometric Properties Initial Temp . oC Softenin g Temp. oC Initial Contractio n Temp. oC Max. Contractio n Temp. oC Max. Dilatatio n Temp. oC Max. Dilatio n (%) Max. Contractio n (%) Heating Rate (OC/min ) Lafia 4½ G3 300 340 420 407 486 9 -6 3 Chikila ½ A 300 340 350 425 442 Nil -9 3 American 4½ G2 330 370 410 468 468 16 -30 3 Polish 6 G3 350 386 390 424 440 119 -29 3 Lafia/American 4½ G3 320 360 420 435 476 12 -8 3 Lafia/PolishL 4½ G4 317 364 420 432 477 38 -5 3 Chikila/American 1 B 310 350 365 430 450 4 -14 3 Chikila/Polish 1½ C 315 355 362 425 442 18 -12 3 Samples  106 M. B. Nasirudeen and A. Jauro Vol.10, No.1 The Ruhr Dilatometric Properties of the coal samples are also shown in Table 2. It can be seen that the Lafia/Obi coals softens at 340oC and contracts maximally at 467oC with maximum dilation of 9%. This is a good plasticity behavior expected of a coking coal; the value is also in agreement with the observed FSI. On the other hand, Chikila coal also softens at 340oC with a maximum contraction temperature of 425oC and zero dilation. American coal and Polish coal softened at 370oC and 386oC with maximum dilatation temperatures of 468oC and 440oC and maximum dilatation of 119% and 16% respectively. The softening temperature, contraction temperature and dilation of the blends are generally greater than those of the Nigerian coals (Table 2). Amongst the blends Chikila/Polish recorded the highest dilation value of 38% which represent a 26% increase over that of single Lafia-Obi coal. Chikila coal which shows no dilation at all, recorded dilation values of 4% and 18% on blending with American and Polish coals respectively. Gieseler plastometric properties of the coals and the blends are shown in Table 3. Lafia-Obi and Chikila coal soften at 330 °C and 270 ºC, reaching a maximum fluidity of 310 ddpm and 298 ddpm at a temperature of 367 ºC and 340 °C respectively. Table 3: Gieseler plastometric properties of the single coals and the blends Parameter Lafia Chikila FAM FPL Lafia/FAM Lafia/FPL Chikila/FAM Lafia/FPL Softening temperature oC 330 270 390 395 348 350 306 308 Max. fluidity temp. oC 367 340 435 445 388 391 369 372 Max. fluidity (DDPM) 310 298 342 456 320 354 308 342 Resolidification temp. oC 394 336 458 485 413 422 372 381 Temperature range oC 64 66 68 90 65 72 66 73 DDPM = Dial Division Per Minute The blends exhibit higher softening temperature, maximum fluidity temperature and maximum fluidity (320 ddpm and 354 ddpm) than the single Nigerian coals. Fluidity data provide information about the formation of a plastic phase during coke making. Diez et al., [10] reported that a Gieseler maximum fluidity between 200 and 1000 dial division per minute is desirable for a good coking coal blend. Thus the parameters indicate the ability of the coal blends to form a homogenous solid coke.  Vol.10, No.1 Quality of Some Nigerian Coals 107 5. CONCLUSION The rheological and chemical analyses have shown that the Nigerian coals are lower in coking qualities than the investigated American and Polish coal. Amongst the Nigerian coals, the qualities of Lafia-Obi are greater than that of Chikila coal. The coking qualities of Nigeria/Foreign coal blends are generally higher than those of the single Nigerian coals. Blends produced using Lafia-Obi coal are more qualitative than those produced by Chikila coal. Thus a good metallurgical coking quality coal may be obtained by blending the Lafia-Obi coal with either the American or Polish coking coals. ACKNOWLEDGEMENT The authors wish to thank the management and coal laboratory staff of the National Metallurgical Development Centre (NMDC), Jos, Plateau State, Nigeria, for providing an enabling environment by allowing the use of their laboratory in the course of the investigation. REFERENCES 1. Ikoku, C., 1984, “Chemistry in the National Economy.” Fourth Dimension, Enugu, p. 100 2. Ikoku, C., 1984, Coal in the energy midst of Nigeria, In: Nigerian coal: a resource for energy and investments, pp. 25 – 29, (Okolo, H. C. and Mkpadi M. C., Eds.), RMRDC, Abuja. 3. Nigerian Coal Corporation Information Manual, 1997, Seventh OAU/AEC Trade Fair 4. Obaje, N. G., 1997, “Petrographic evaluation of the coking potential of the Cretaceous Obi/Lafia coal deposits in the Benue trough of Nigeria.” Z. angew Geol., Vol. 43, No. 4 5. Ward, C. R., 2002, Coal geology, In: Encyclopedia of Physical Science and Technology, pp. 45-76. Academic Press, New York 6. Taylor, G. H., Teichmüller, T. M., Davis, A., Diessel, R. L. and Robert, P., 1998, Organic Petrology, Borntrager, Berlin, pp. 519-615 7. Walker, R., Mastalerz, M., and Padgett, P., 2001, “Quality of selected coal seams from Indiana: Implications for carbonization.” Int. J. of Coal Geol., Vol. 47, pp. 277-288 8. Cornells, J. K., Mohammed, A. K. and Dacid, A. C., 2003, Medium volatile coal, the solution for coke blends with reduced low-volatile coal content, AISE Steel Technology, pp. 42-48 9. Valia, H. S., and Mastalerz, M., 2004, Indiana Coals and the steel Industry, Indiana Geol. Survey Special Report, 64 10. Diez, M. A., Alvarez, R. and Barriocanal, C., 2002, “Coal for metallurgical coke production: Prediction of coke quality and future requirements for coke making.” Int. J. Coal Geol., Vol. 50, pp. 289-412  108 M. B. Nasirudeen and A. Jauro Vol.10, No.1 11. Gransden, J, Price, J., 1997, Geological Fieldwork, British Columbia Geological Survey Branch, paper 1998-1 12. Aderonpe, W. I. A., 1996, Coal Blending: application to Nigerian coals for the iron and steel industries, In: Nigerian Coal: A resource for energy and investments, pp. 125 – 137, (Okolo, H. C. and Mkpadi, M. C., Eds), RMRDC, Abuja 13. Afonja, A. A., 1996, Production of metallurgical coke from non–coking coals, In: , In: Nigerian Coal: A resource for energy and investments, pp. 89 – 105, (Okolo, H. C. and Mkpadi, M. C., Eds), RMRDC, Abuja 14. American Society for Testing and Materials. Annual Book of ASTM Standards, 1992, Section 5: Petroleum Products, Lubricants and Fossil Fuels. 5.05: Gaseous Fuels; Coal and Coke 15. International Energy Agency (IEA)/Organization for Energy Co-operation and Development (OECD), 2002, Coal in the energy supply of India, Paris, p. 28 16. Bustin, R. M., Cameron, A. R., Greve, D. A. and Kalkreuth, W. D., 1985, Coal Petrology: Its Principles, methods and applications. Geological Association of Canada. Course Notes 3, 230 17. Jauro, A., Agho, M. O., Abayeh, O. J., Obaje, N. G., and Abubakar, M. B., 2008, “Petrographic Studies and Coking Properties of Lamza, Chikila and Lafia-Obi Coals of the Benue Trough.” Journal of Mining and Geology, Vol. 44, pp. 11-18 18. Akpabio, I. O., 1998, “Thermal properties of some Nigerian coals.” Journal of Pure and Applied Science Vol. 1, pp. 87 – 92 19. Price, J., Gransden, J., and Hampel, K., 1997, Microscopy, Chemistry and Rheology tools to determine Coal and Coke Characteristics. 1st McMaster’s cokemaking course. McMaster’s University Hamilton, Ontario, Canada, 4.1-4.74 20. Peng Chen., 2002, “Petrographic Characteristics of Chinese coals and their applications in coal Utilization Processes.” Fuel, Vol. 81, pp. 11-12 21. Barriocanal, C., Patrick, J. W., and Walker, A., 1997, “The laboratory identification of dangerously coking coals.” Fuel, Vol. 77, pp. 881-884 |