Paper Menu >>

Journal Menu >>

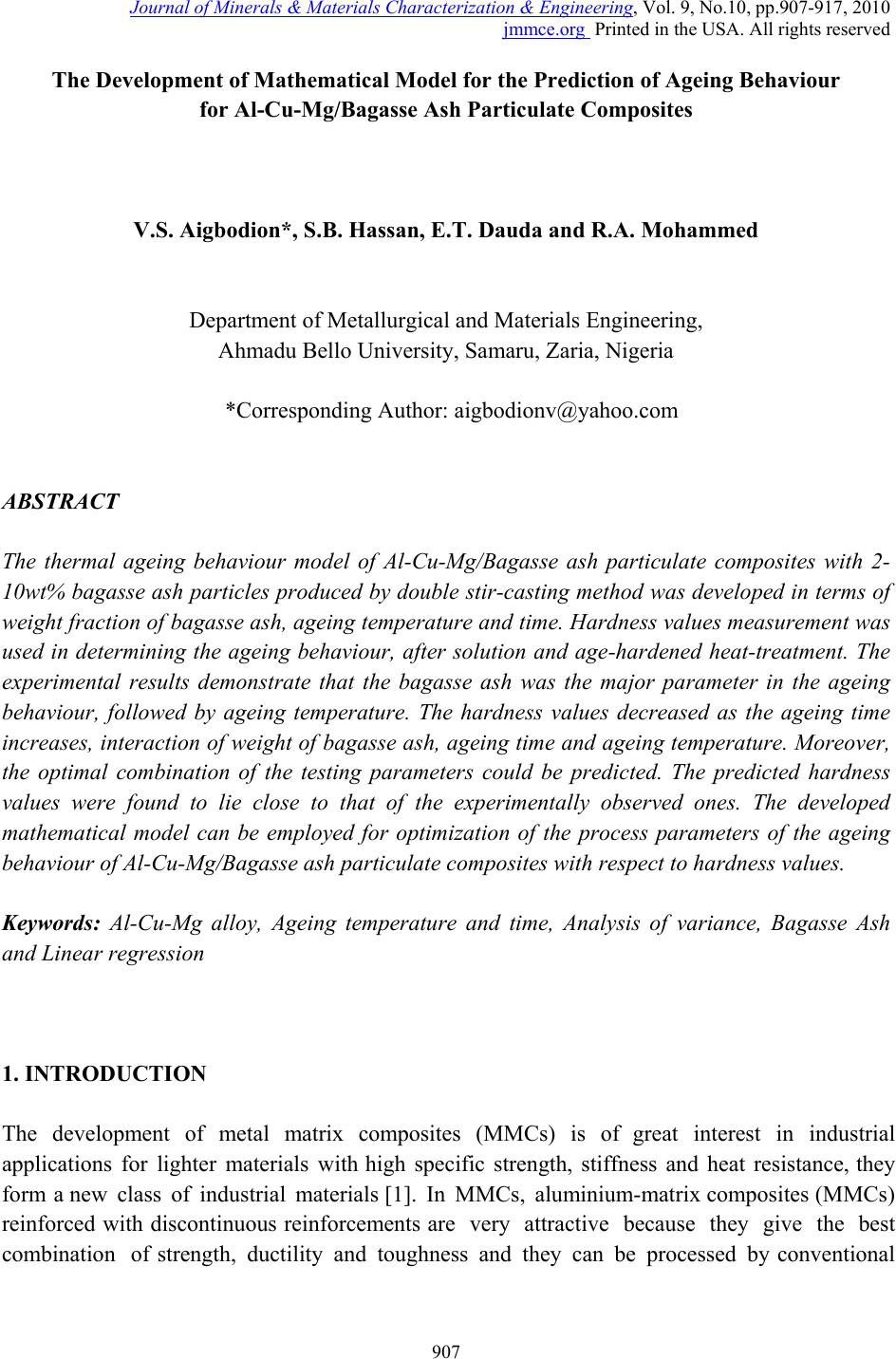

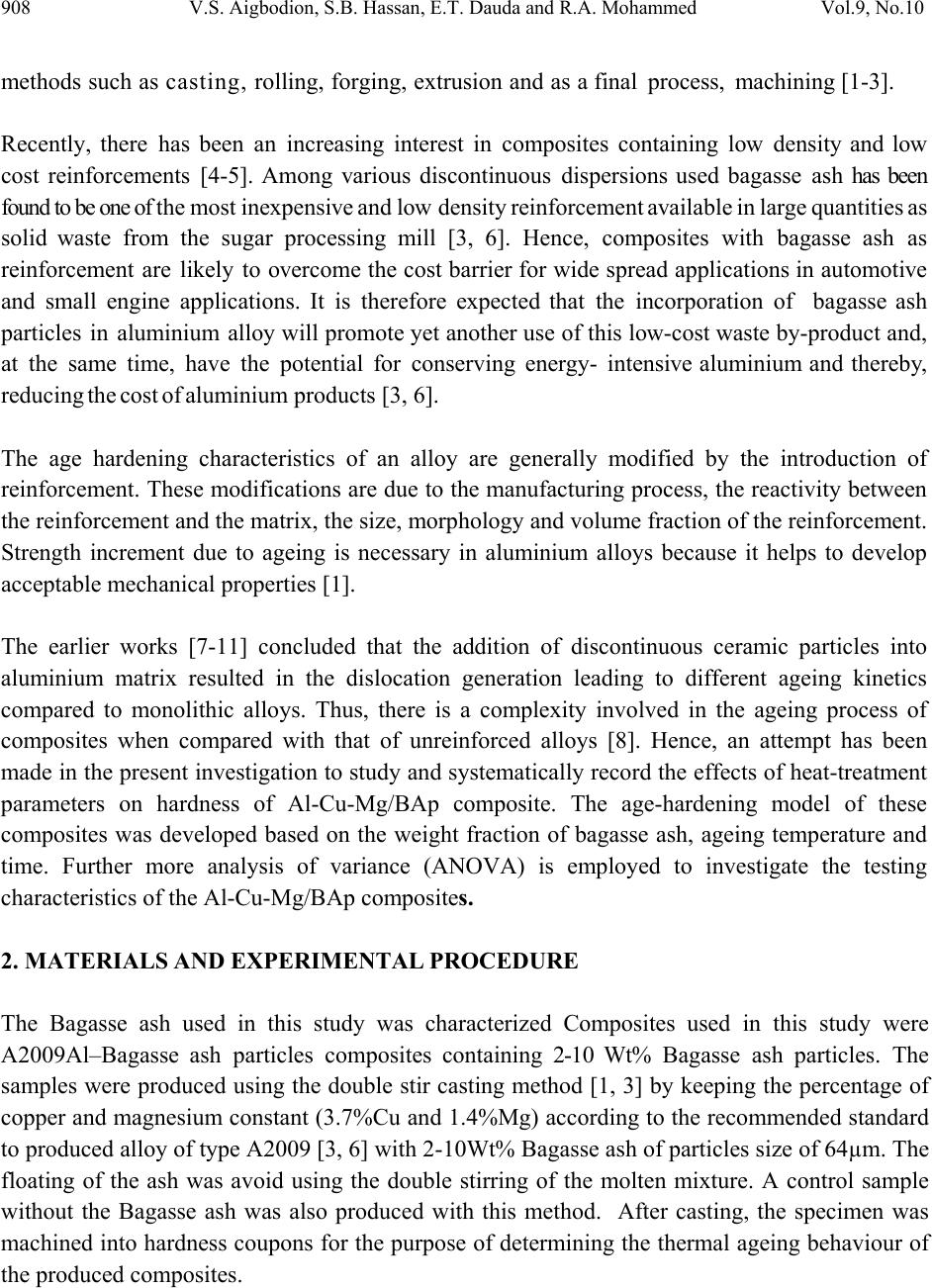

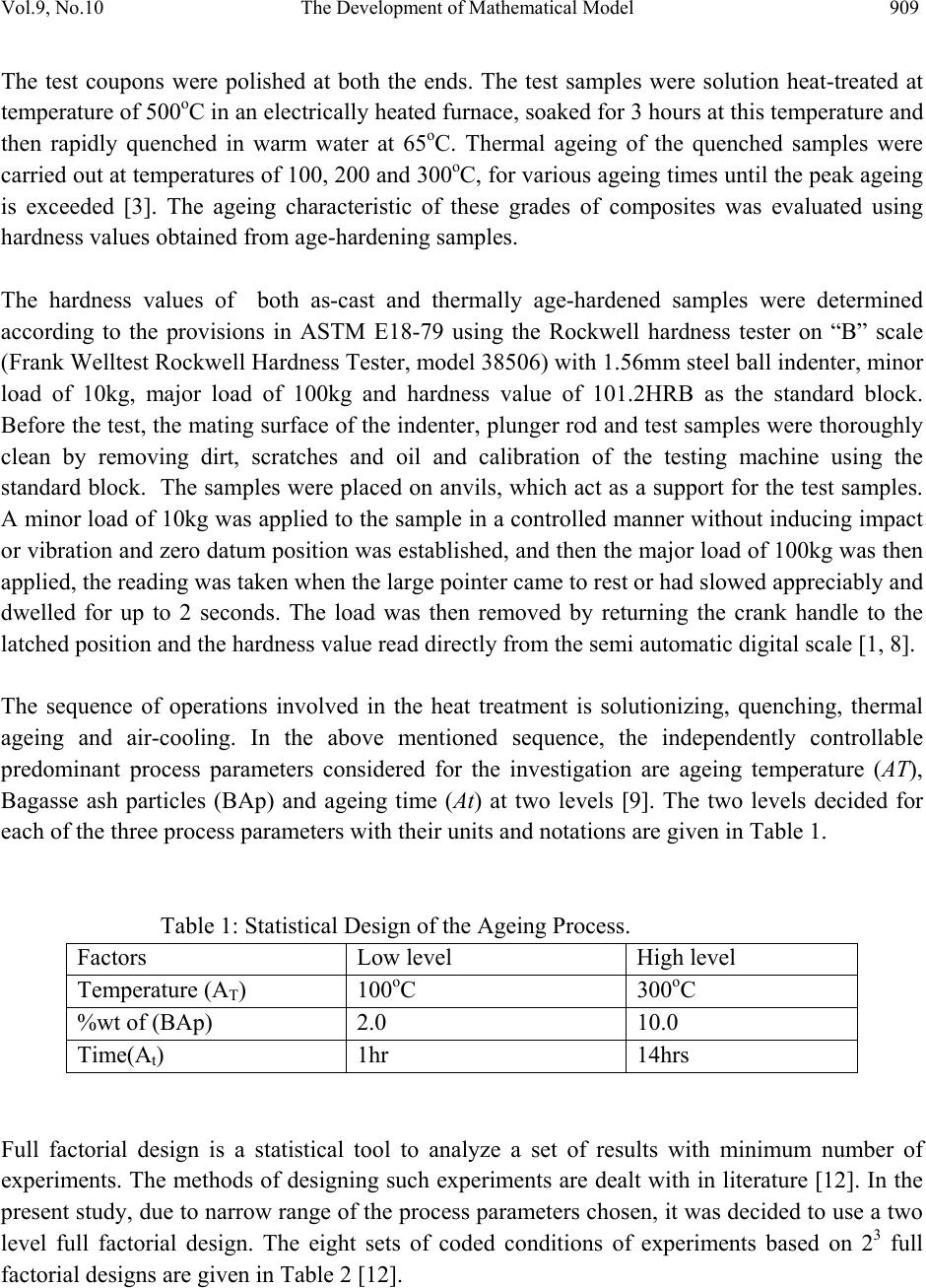

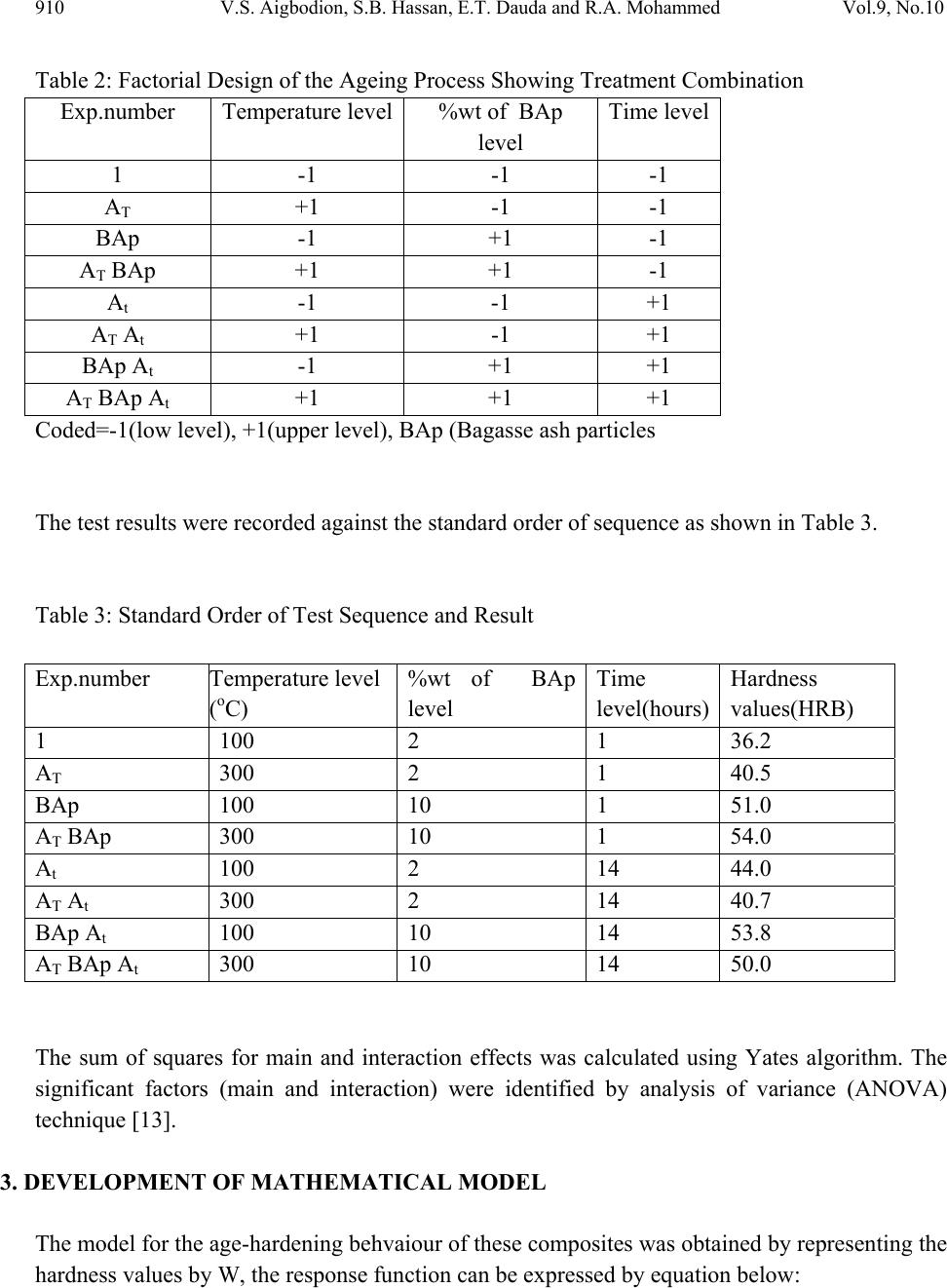

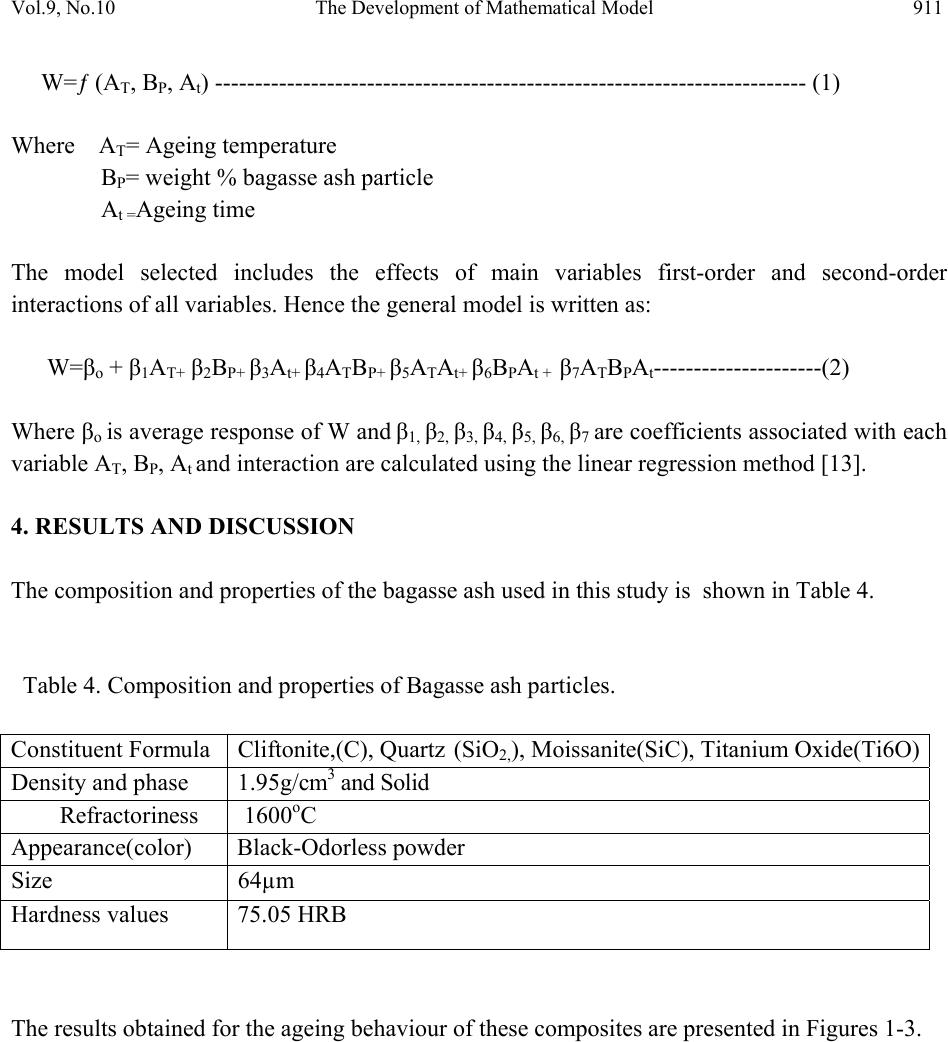

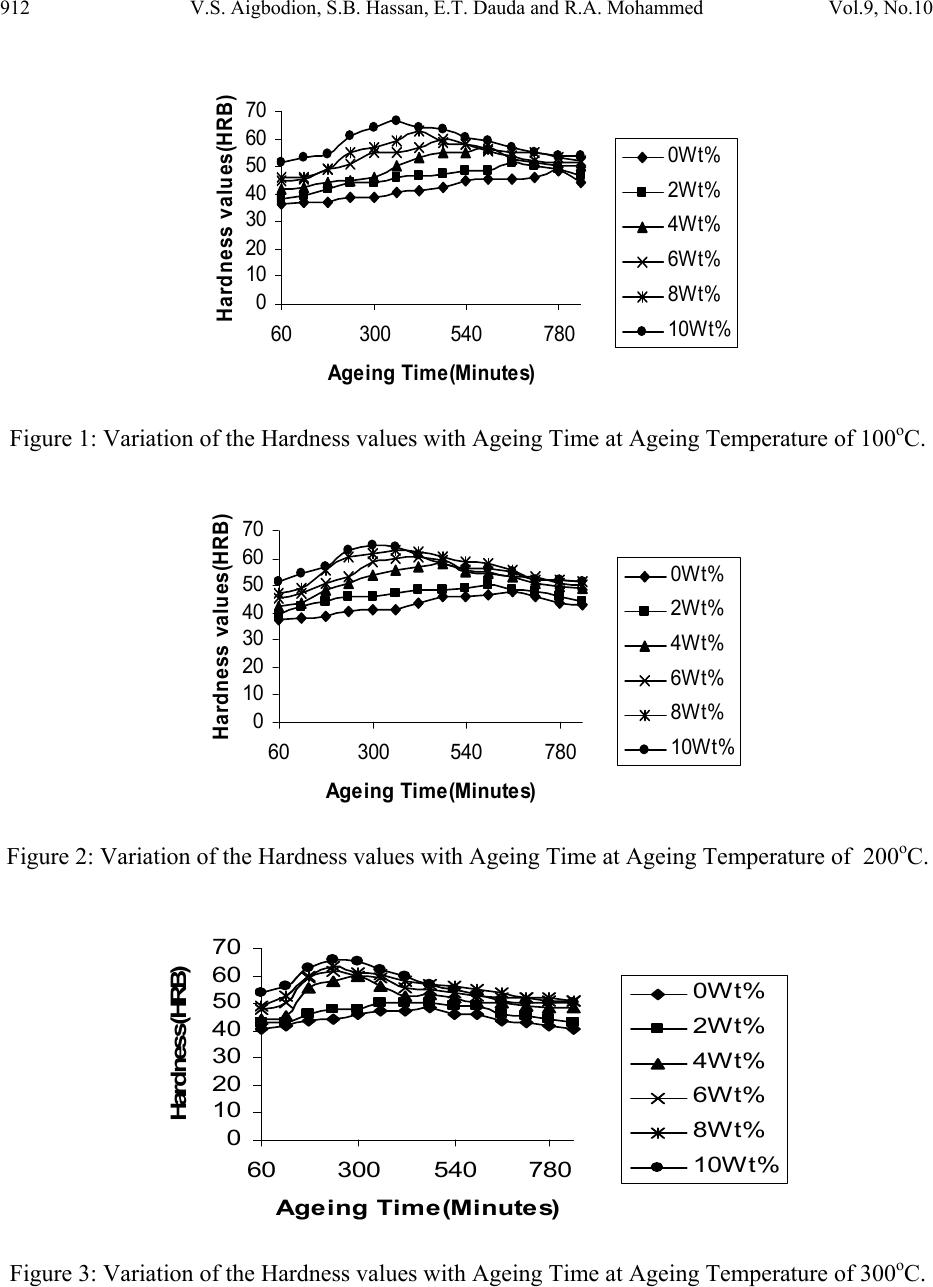

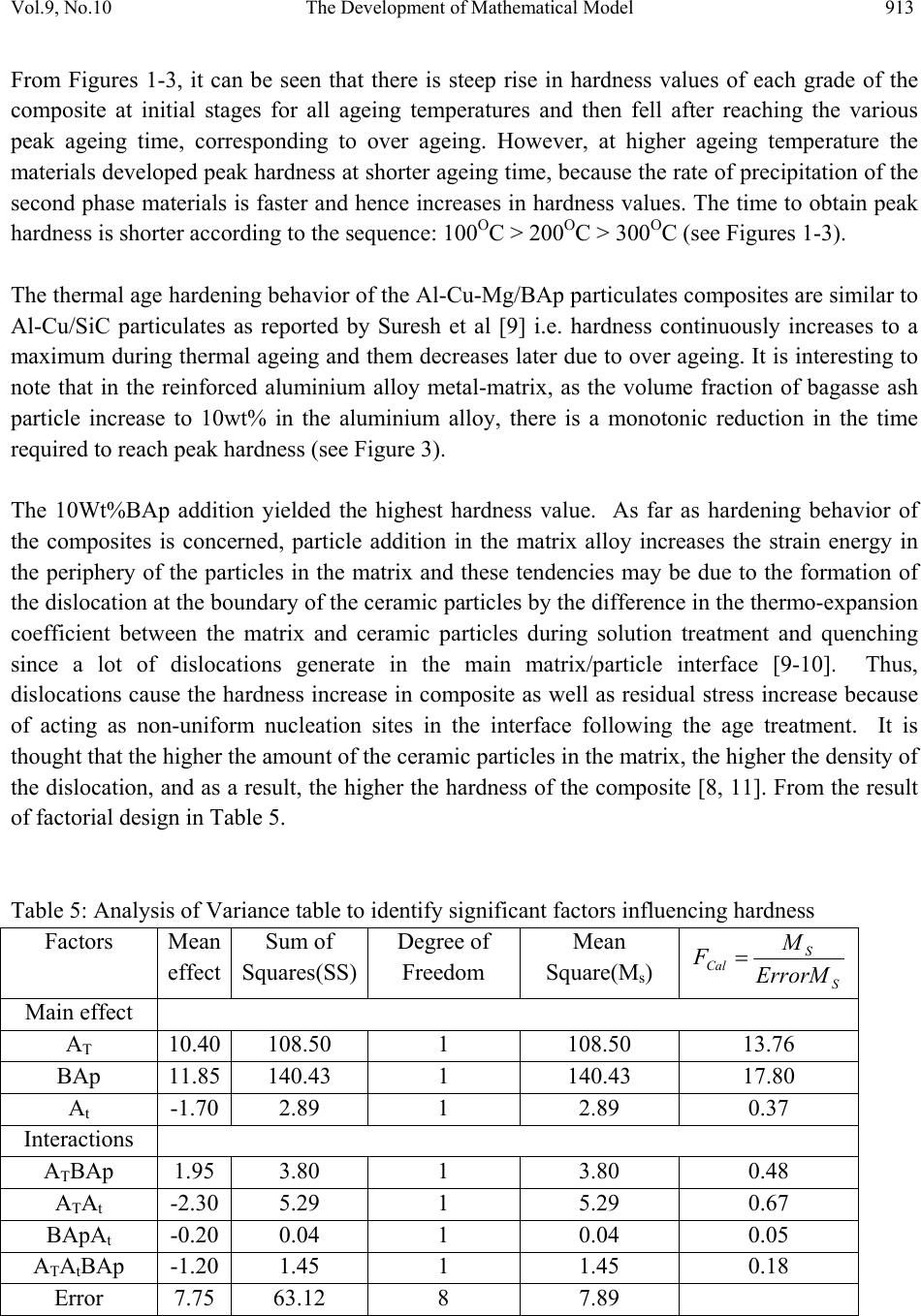

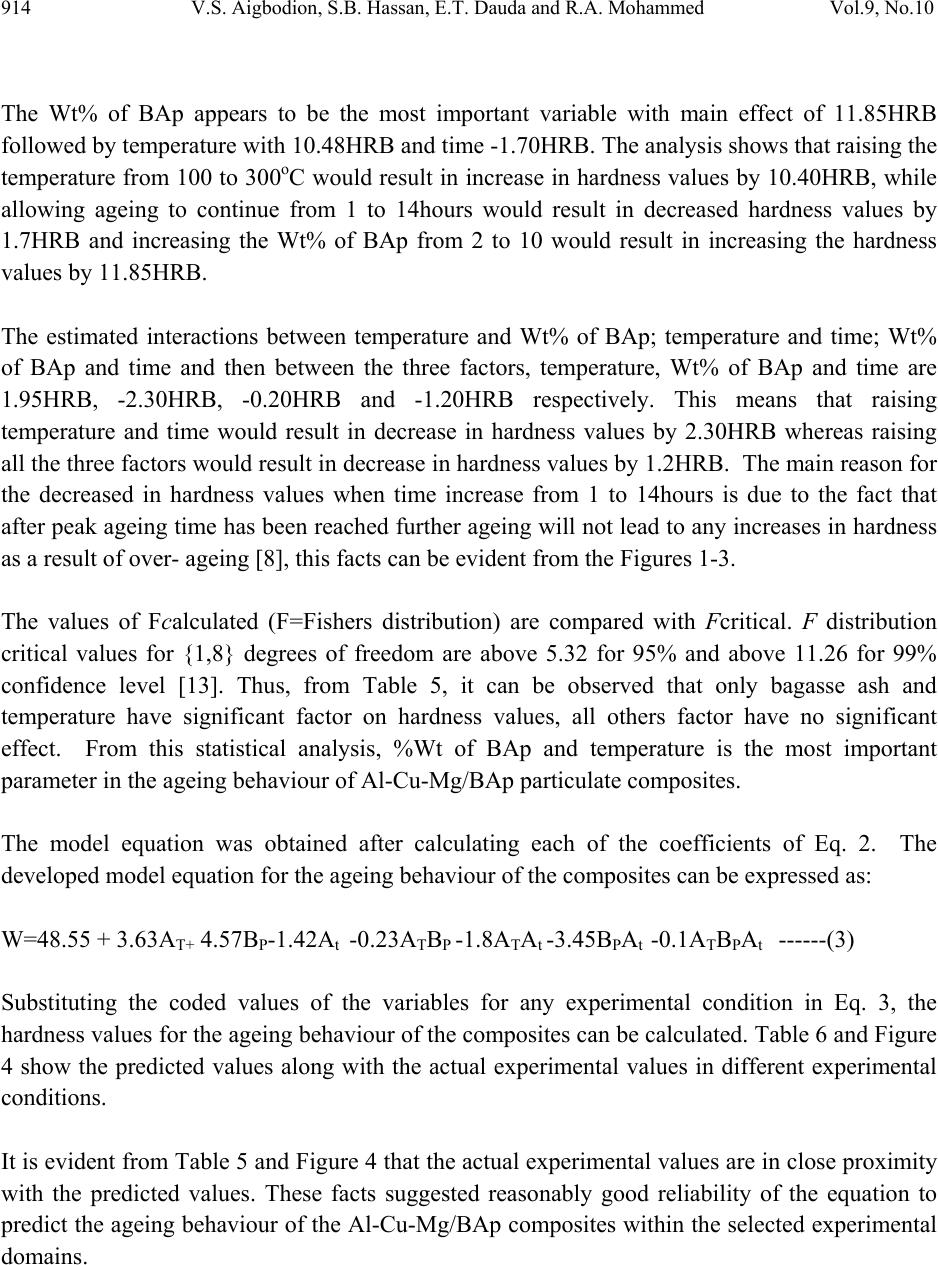

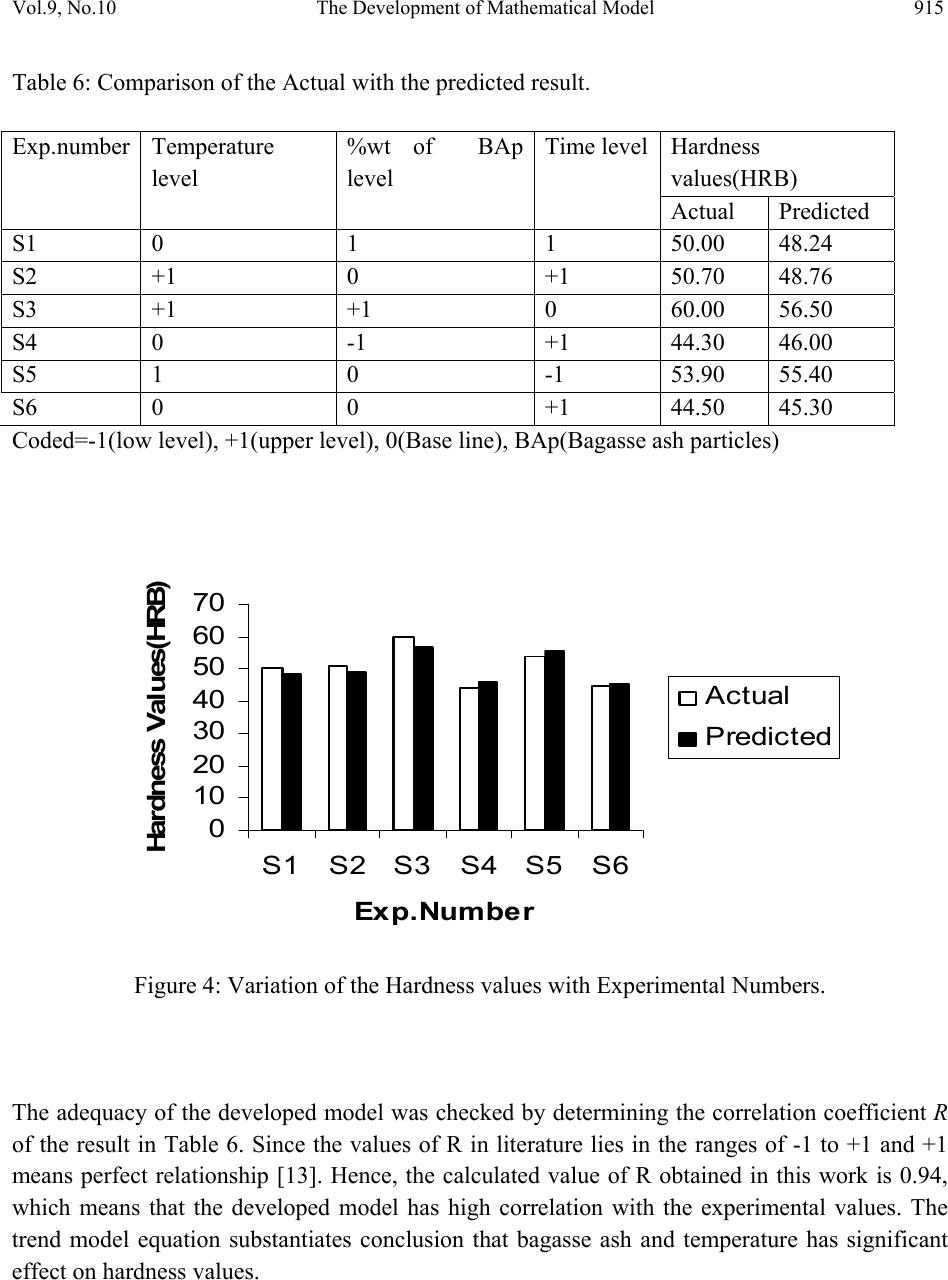

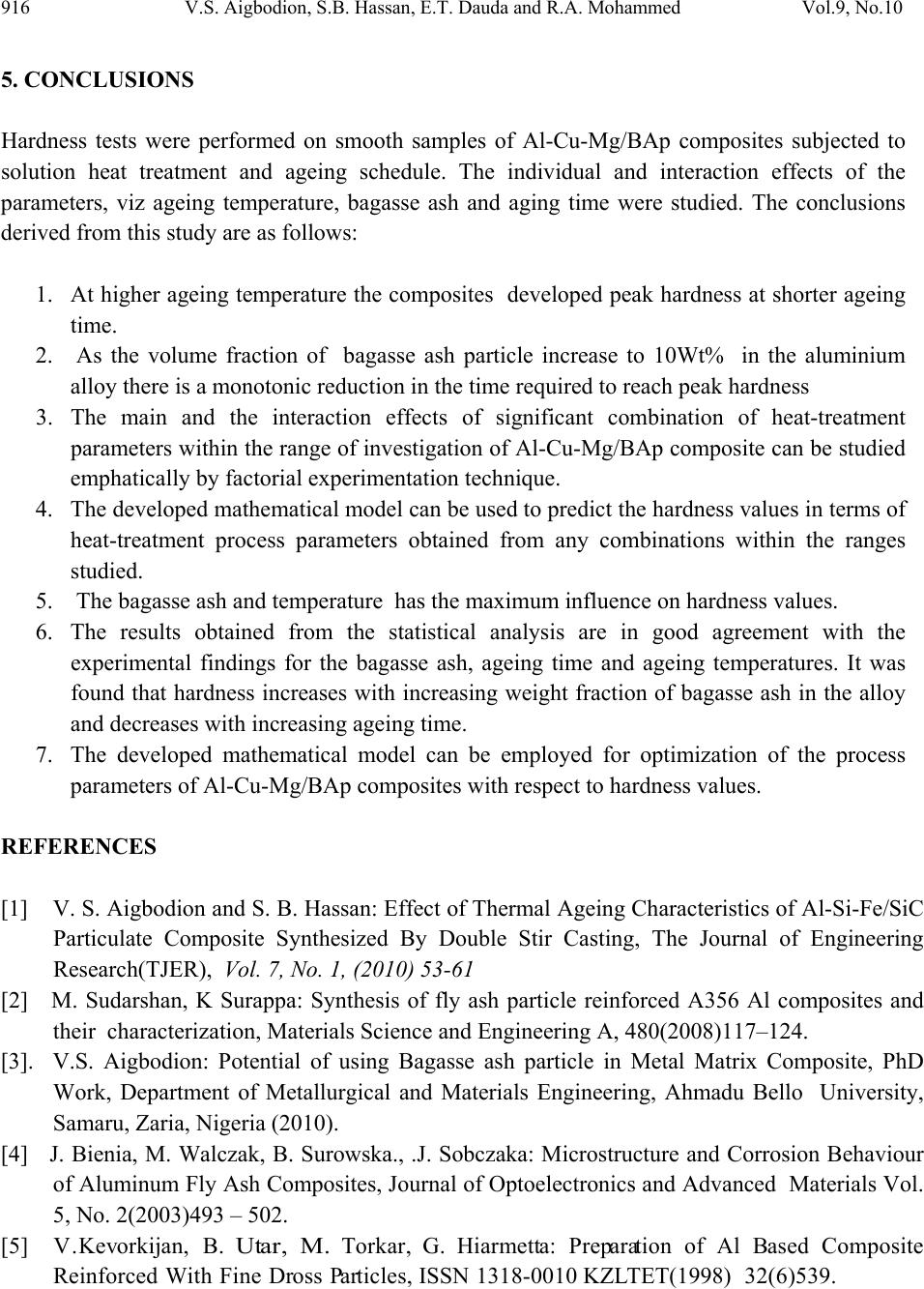

Journal of Minerals & Materials Characterization & Engineering, Vol. 9, No.10, pp.907-917, 2010 jmmce.org Printed in the USA. All rights reserved 907 The Development of Mathematical Model for the Prediction of Ageing Behaviour for Al-Cu-Mg/Bagasse Ash Particulate Composites V.S. Aigbodion*, S.B. Hassan, E.T. Dauda and R.A. Mohammed Department of Metallurgical and Materials Engineering, Ahmadu Bello University, Samaru, Zaria, Nigeria *Corresponding Author: aigbodionv@yahoo.com ABSTRACT The thermal ageing behaviour model of Al-Cu-Mg/Bagasse ash particulate composites with 2- 10wt% bagasse ash particles produced by double stir-casting method was developed in terms of weight fraction of bagasse ash, ageing temperature and time. Hardness values measurement was used in determining the ageing behaviour, after solution and age-hardened heat-treatment. The experimental results demonstrate that the bagasse ash was the major parameter in the ageing behaviour, followed by ageing temperature. The hardness values decreased as the ageing time increases, interaction of weight of bagasse ash, ageing time and ageing temperature. Moreover, the optimal combination of the testing parameters could be predicted. The predicted hardness values were found to lie close to that of the experimentally observed ones. The developed mathematical model can be employed for optimization of the process parameters of the ageing behaviour of Al-Cu-Mg/Bagasse ash particulate composites with respect to har dness val ues. Keywords: Al-Cu-Mg alloy, Ageing temperature and time, Analysis of variance, Bagasse Ash and Linear regression 1. INTRODUCTION The development of metal matrix composites (MMCs) is of great interest in industrial applications for lighter materials with high specific strength, stiffness and heat resistance, they form a new class of industrial materials [1]. In MMCs, aluminium-matrix composites (MMCs) reinforced with discontinuous reinforcements are very attractive because they give the best combination of strength, ductility and toughness and they can be processed by conventional  908 V.S. Aigbodion, S.B. Hassan, E.T. Dauda and R.A. Mohammed Vol.9, No.10 methods such as casting, rolling, forging, extrusion and as a final process, machining [1-3]. Recently, there has been an increasing interest in composites containing low density and low cost reinforcements [4-5]. Among various discontinuous dispersions used bagasse ash has been found to be one of the most inexpensive and low density reinforcement available in large quantities as solid waste from the sugar processing mill [3, 6]. Hence, composites with bagasse ash as reinforcement are likely to overcome the cost barrier for wide spread applications in automotive and small engine applications. It is therefore expected that the incorporation of bagasse ash particles in aluminium alloy will promote yet another use of this low-cost waste by-product and, at the same time, have the potential for conserving energy- intensive aluminium and thereby, reducing the cost of aluminium products [3, 6]. The age hardening characteristics of an alloy are generally modified by the introduction of reinforcement. These modifications are due to the manufacturing process, the reactivity between the reinforcement and the matrix, the size, morphology and volume fraction of the reinforcement. Strength increment due to ageing is necessary in aluminium alloys because it helps to develop acceptable mechanical properties [1]. The earlier works [7-11] concluded that the addition of discontinuous ceramic particles into aluminium matrix resulted in the dislocation generation leading to different ageing kinetics compared to monolithic alloys. Thus, there is a complexity involved in the ageing process of composites when compared with that of unreinforced alloys [8]. Hence, an attempt has been made in the present investigation to study and systematically record the effects of heat-treatment parameters on hardness of Al-Cu-Mg/BAp composite. The age-hardening model of these composites was developed based on the weight fraction of bagasse ash, ageing temperature and time. Further more analysis of variance (ANOVA) is employed to investigate the testing characteristics of the Al-Cu-Mg/BAp composites. 2. MATERIALS AND EXPERIMENTAL PROCEDURE The Bagasse ash used in this study was characterized Composites used in this study were A2009Al–Bagasse ash particles composites containing 2-10 Wt% Bagasse ash particles. The samples were produced using the double stir casting method [1, 3] by keeping the percentage of copper and magnesium constant (3.7%Cu and 1.4%Mg) according to the recommended standard to produced alloy of type A2009 [3, 6] with 2-10Wt% Bagasse ash of particles size of 64µm. The floating of the ash was avoid using the double stirring of the molten mixture. A control sample without the Bagasse ash was also produced with this method. After casting, the specimen was machined into hardness coupons for the purpose of determining the thermal ageing behaviour of the produced composites.  Vol.9, No.10 The Development of Mathematical Model 909 The test coupons were polished at both the ends. The test samples were solution heat-treated at temperature of 500oC in an electrically heated furnace, soaked for 3 hours at this temperature and then rapidly quenched in warm water at 65oC. Thermal ageing of the quenched samples were carried out at temperatures of 100, 200 and 300oC, for various ageing times until the peak ageing is exceeded [3]. The ageing characteristic of these grades of composites was evaluated using hardness values obtained from age-hardening samples. The hardness values of both as-cast and thermally age-hardened samples were determined according to the provisions in ASTM E18-79 using the Rockwell hardness tester on “B” scale (Frank Welltest Rockwell Hardness Tester, model 38506) with 1.56mm steel ball indenter, minor load of 10kg, major load of 100kg and hardness value of 101.2HRB as the standard block. Before the test, the mating surface of the indenter, plunger rod and test samples were thoroughly clean by removing dirt, scratches and oil and calibration of the testing machine using the standard block. The samples were placed on anvils, which act as a support for the test samples. A minor load of 10kg was applied to the sample in a controlled manner without inducing impact or vibration and zero datum position was established, and then the major load of 100kg was then applied, the reading was taken when the large pointer came to rest or had slowed appreciably and dwelled for up to 2 seconds. The load was then removed by returning the crank handle to the latched position and the hardness value read directly from the semi automatic digital scale [1, 8]. The sequence of operations involved in the heat treatment is solutionizing, quenching, thermal ageing and air-cooling. In the above mentioned sequence, the independently controllable predominant process parameters considered for the investigation are ageing temperature (AT), Bagasse ash particles (BAp) and ageing time (At) at two levels [9]. The two levels decided for each of the three process parameters with their units and notations are given in Table 1. Table 1: Statistical Design of the Ageing Process. Factors Low level High level Temperature (AT) 100oC 300oC %wt of (BAp) 2.0 10.0 Time(At) 1hr 14hrs Full factorial design is a statistical tool to analyze a set of results with minimum number of experiments. The methods of designing such experiments are dealt with in literature [12]. In the present study, due to narrow range of the process parameters chosen, it was decided to use a two level full factorial design. The eight sets of coded conditions of experiments based on 23 full factorial designs are given in Table 2 [12].  910 V.S. Aigbodion, S.B. Hassan, E.T. Dauda and R.A. Mohammed Vol.9, No.10 Table 2: Factorial Design of the Ageing Process Showing Treatment Combination Exp.number Temperature level%wt of BAp level Time level 1 -1 -1 -1 AT +1 -1 -1 BAp -1 +1 -1 AT BAp +1 +1 -1 At -1 -1 +1 AT At +1 -1 +1 BAp At -1 +1 +1 AT BAp At +1 +1 +1 Coded=-1(low level), +1(upper level), BAp (Bagasse ash particles The test results were recorded against the standard order of sequence as shown in Table 3. Table 3: Standard Order of Test Sequence and Result Exp.number Temperature level (oC) %wt of BAp level Time level(hours) Hardness values(HRB) 1 100 2 1 36.2 AT 300 2 1 40.5 BAp 100 10 1 51.0 AT BAp 300 10 1 54.0 At 100 2 14 44.0 AT At 300 2 14 40.7 BAp At 100 10 14 53.8 AT BAp At 300 10 14 50.0 The sum of squares for main and interaction effects was calculated using Yates algorithm. The significant factors (main and interaction) were identified by analysis of variance (ANOVA) technique [13]. 3. DEVELOPMENT OF MATHEMATICAL MODEL The model for the age-hardening behvaiour of these composites was obtained by representing the hardness values by W, the response function can be expressed by equation below:  Vol.9, No.10 The Development of Mathematical Model 911 W=ƒ (AT, BP, At) -------------------------------------------------------------------------- (1) Where AT= Ageing temperature BP= weight % bagasse ash particle At =Ageing time The model selected includes the effects of main variables first-order and second-order interactions of all variables. Hence the general model is written as: W=βo + β1AT+ β2BP+ β3At+ β4ATBP+ β5ATAt+ β6BPAt + β7ATBPAt---------------------(2) Where βo is average response of W and β1, β2, β3, β4, β5, β6, β7 are coefficients associated with each variable AT, BP, At and interaction are calculated using the linear regression method [13]. 4. RESULTS AND DISCUSSION The composition and properties of the bagasse ash used in this study is shown in Table 4. Table 4. Composition and properties of Bagasse ash particles. Constituent Formula Cliftonite,(C), Quartz (SiO2,), Moissanite(SiC), Titanium Oxide(Ti6O) Density and phase 1.95g/cm3 and Solid Refractoriness 1600oC Appearance(color) Black-Odorless powder Size 64µm Hardness values 75.05 HRB The results obtained for the ageing behaviour of these composites are presented in Figures 1-3.  912 V.S. Aigbodion, S.B. Hassan, E.T. Dauda and R.A. Mohammed Vol.9, No.10 0 10 20 30 40 50 60 70 60300 540780 Age i ng Ti m e(Mi nute s) Hardness valu es(HRB) 0Wt% 2Wt% 4Wt% 6Wt% 8Wt% 10Wt% Figure 1: Variation of the Hardness values with Ageing Time at Ageing Temperature of 100oC. 0 10 20 30 40 50 60 70 60300 540780 Age i ng Ti m e(Min ute s) Hardness values(HRB) 0Wt% 2Wt% 4Wt% 6Wt% 8Wt% 10Wt% Figure 2: Variation of the Hardness values with Ageing Time at Ageing Temperature of 200oC. 0 10 20 30 40 50 60 70 60300540780 Age i ng Ti m e (Minute s) Hardness(HRB) 0Wt% 2Wt% 4Wt% 6Wt% 8Wt% 10Wt% Figure 3: Variation of the Hardness values with Ageing Time at Ageing Temperature of 300oC.  Vol.9, No.10 The Development of Mathematical Model 913 From Figures 1-3, it can be seen that there is steep rise in hardness values of each grade of the composite at initial stages for all ageing temperatures and then fell after reaching the various peak ageing time, corresponding to over ageing. However, at higher ageing temperature the materials developed peak hardness at shorter ageing time, because the rate of precipitation of the second phase materials is faster and hence increases in hardness values. The time to obtain peak hardness is shorter according to the sequence: 100OC > 200OC > 300OC (see Figures 1-3). The thermal age hardening behavior of the Al-Cu-Mg/BAp particulates composites are similar to Al-Cu/SiC particulates as reported by Suresh et al [9] i.e. hardness continuously increases to a maximum during thermal ageing and them decreases later due to over ageing. It is interesting to note that in the reinforced aluminium alloy metal-matrix, as the volume fraction of bagasse ash particle increase to 10wt% in the aluminium alloy, there is a monotonic reduction in the time required to reach peak hardness (see Figure 3). The 10Wt%BAp addition yielded the highest hardness value. As far as hardening behavior of the composites is concerned, particle addition in the matrix alloy increases the strain energy in the periphery of the particles in the matrix and these tendencies may be due to the formation of the dislocation at the boundary of the ceramic particles by the difference in the thermo-expansion coefficient between the matrix and ceramic particles during solution treatment and quenching since a lot of dislocations generate in the main matrix/particle interface [9-10]. Thus, dislocations cause the hardness increase in composite as well as residual stress increase because of acting as non-uniform nucleation sites in the interface following the age treatment. It is thought that the higher the amount of the ceramic particles in the matrix, the higher the density of the dislocation, and as a result, the higher the hardness of the composite [8, 11]. From the result of factorial design in Table 5. Table 5: Analysis of Variance table to identify significant factors influencing hardness Factors Mean effect Sum of Squares(SS) Degree of Freedom Mean Square(Ms) S S Cal ErrorM M F Main effect AT 10.40 108.50 1 108.50 13.76 BAp 11.85 140.43 1 140.43 17.80 At -1.70 2.89 1 2.89 0.37 Interactions ATBAp 1.95 3.80 1 3.80 0.48 ATAt -2.30 5.29 1 5.29 0.67 BApAt -0.20 0.04 1 0.04 0.05 ATAtBAp -1.20 1.45 1 1.45 0.18 Error 7.75 63.12 8 7.89  914 V.S. Aigbodion, S.B. Hassan, E.T. Dauda and R.A. Mohammed Vol.9, No.10 The Wt% of BAp appears to be the most important variable with main effect of 11.85HRB followed by temperature with 10.48HRB and time -1.70HRB. The analysis shows that raising the temperature from 100 to 300oC would result in increase in hardness values by 10.40HRB, while allowing ageing to continue from 1 to 14hours would result in decreased hardness values by 1.7HRB and increasing the Wt% of BAp from 2 to 10 would result in increasing the hardness values by 11.85HRB. The estimated interactions between temperature and Wt% of BAp; temperature and time; Wt% of BAp and time and then between the three factors, temperature, Wt% of BAp and time are 1.95HRB, -2.30HRB, -0.20HRB and -1.20HRB respectively. This means that raising temperature and time would result in decrease in hardness values by 2.30HRB whereas raising all the three factors would result in decrease in hardness values by 1.2HRB. The main reason for the decreased in hardness values when time increase from 1 to 14hours is due to the fact that after peak ageing time has been reached further ageing will not lead to any increases in hardness as a result of over- ageing [8], this facts can be evident from the Figures 1-3. The values of Fcalculated (F=Fishers distribution) are compared with Fcritical. F distribution critical values for {1,8} degrees of freedom are above 5.32 for 95% and above 11.26 for 99% confidence level [13]. Thus, from Table 5, it can be observed that only bagasse ash and temperature have significant factor on hardness values, all others factor have no significant effect. From this statistical analysis, %Wt of BAp and temperature is the most important parameter in the ageing behaviour of Al-Cu-Mg/BAp particulate composites. The model equation was obtained after calculating each of the coefficients of Eq. 2. The developed model equation for the ageing behaviour of the composites can be expressed as: W=48.55 + 3.63AT+ 4.57BP-1.42At -0.23ATBP -1.8ATAt -3.45BPAt -0.1ATBPAt ------(3) Substituting the coded values of the variables for any experimental condition in Eq. 3, the hardness values for the ageing behaviour of the composites can be calculated. Table 6 and Figure 4 show the predicted values along with the actual experimental values in different experimental conditions. It is evident from Table 5 and Figure 4 that the actual experimental values are in close proximity with the predicted values. These facts suggested reasonably good reliability of the equation to predict the ageing behaviour of the Al-Cu-Mg/BAp composites within the selected experimental domains.  Vol.9, No.10 The Development of Mathematical Model 915 Table 6: Comparison of the Actual with the predicted result. Exp.number Temperature level %wt of BAp level Time levelHardness values(HRB) Actual Predicted S1 0 1 1 50.00 48.24 S2 +1 0 +1 50.70 48.76 S3 +1 +1 0 60.00 56.50 S4 0 -1 +1 44.30 46.00 S5 1 0 -1 53.90 55.40 S6 0 0 +1 44.50 45.30 Coded=-1(low level), +1(upper level), 0(Base line), BAp(Bagasse ash particles) 0 10 20 30 40 50 60 70 S1 S2S3 S4S5 S6 Exp.Numb er Hardness Valu es(H RB) Actual Predicted Figure 4: Variation of the Hardness values with Experimental Numbers. The adequacy of the developed model was checked by determining the correlation coefficient R of the result in Table 6. Since the values of R in literature lies in the ranges of -1 to +1 and +1 means perfect relationship [13]. Hence, the calculated value of R obtained in this work is 0.94, which means that the developed model has high correlation with the experimental values. The trend model equation substantiates conclusion that bagasse ash and temperature has significant effect on hardness values.  916 V.S. Aigbodion, S.B. Hassan, E.T. Dauda and R.A. Mohammed Vol.9, No.10 5. CONCLUSIONS Hardness tests were performed on smooth samples of Al-Cu-Mg/BAp composites subjected to solution heat treatment and ageing schedule. The individual and interaction effects of the parameters, viz ageing temperature, bagasse ash and aging time were studied. The conclusions derived from this study are as follows: 1. At higher ageing temperature the composites developed peak hardness at shorter ageing time. 2. As the volume fraction of bagasse ash particle increase to 10Wt% in the aluminium alloy there is a monotonic reduction in the time required to reach peak hardness 3. The main and the interaction effects of significant combination of heat-treatment parameters within the range of investigation of Al-Cu-Mg/BAp composite can be studied emphatically by factorial experimentation technique. 4. The developed mathematical model can be used to predict the hardness values in terms of heat-treatment process parameters obtained from any combinations within the ranges studied. 5. The bagasse ash and temperature has the maximum influence on hardness values. 6. The results obtained from the statistical analysis are in good agreement with the experimental findings for the bagasse ash, ageing time and ageing temperatures. It was found that hardness increases with increasing weight fraction of bagasse ash in the alloy and decreases with increasing ageing time. 7. The developed mathematical model can be employed for optimization of the process parameters of Al-Cu-Mg/BAp composites with respect to hardness values. REFERENCES [1] V. S. Aigbodion and S. B. Hassan: Effect of Thermal Ageing Characteristics of Al-Si-Fe/SiC Particulate Composite Synthesized By Double Stir Casting, The Journal of Engineering Research(TJER), Vol. 7, No. 1, (2010) 53-61 [2] M. Sudarshan, K Surappa: Synthesis of fly ash particle reinforced A356 Al composites and their characterization, Materials Science and Engineering A, 480(2008)117–124. [3]. V.S. Aigbodion: Potential of using Bagasse ash particle in Metal Matrix Composite, PhD Work, Department of Metallurgical and Materials Engineering, Ahmadu Bello University, Samaru, Zaria, Nigeria (2010). [4] J. Bienia, M. Walczak, B. Surowska., .J. Sobczaka: Microstructure and Corrosion Behaviour of Aluminum Fly Ash Composites, Journal of Optoelectronics and Advanced Materials Vol. 5, No. 2(2003)493 – 502. [5] V.Kevorkijan, B. Utar, M. Torkar, G. Hiarmetta: Preparation of Al Based Composite Reinforced With Fine Dross Particles, ISSN 1318-0010 KZLTET(1998) 32(6)539.  Vol.9, No.10 The Development of Mathematical Model 917 [6] S. B. Hassan and V. S. Aigbodion: The study of the Microstructure and Interfacial Reaction of Al-Cu-Mg/Bagasse Ash Particulate Composite, Journal of Alloy & Compounds, 491 (2010) 571–574. [7] S. Valdez, B. Campillo, R. Pérez, L. Martínez, H. García: Synthesis and microstructural characterization of Al–Mg alloy–SiC particle composite, Materials Letters 62(2008)2623– 2625. [8] S.B. Hassan, O. Aponbiede and V.S. Aigbodion: Precipitation hardening characteristics of Al- Si-Fe/SiC particulate composites Journal of alloys & compounds 466(2008), 268-272 [9] S. Suresh, T. Christman, Y. Sugimura, Accelerated aging in cast Al alloy—SiC particulate Composite, Scr. Metall. 23 (1989) 1599– 1602. [10] P. Appendino, C. Badini, F. Marino, A. Tomasi, 6061 Aluminium alloy—SiC particulate Composite: a comparison between aging behaviour in T4 and T6 treatments, J. Mater. Sci. Eng. A.135 (1991) 275–279. [11] L. Salvo, M. Svery, Effect of reinforcement on age-hardening of cast 6061-AlSiC and 6061 Al-Al2O3 particulate composite, Metall. Trans. A 22A (1996) 2553–2653. [12] Y. Sahin.: The prediction of wear resistance model for the metal matrix composites, Wear 258 (2005) 1717–1722. [13] I. Miller, J.E. Freund: Probability and Statistics for Engineers, Prentice Hall India Ltd., India (2001), 125-140. |