Paper Menu >>

Journal Menu >>

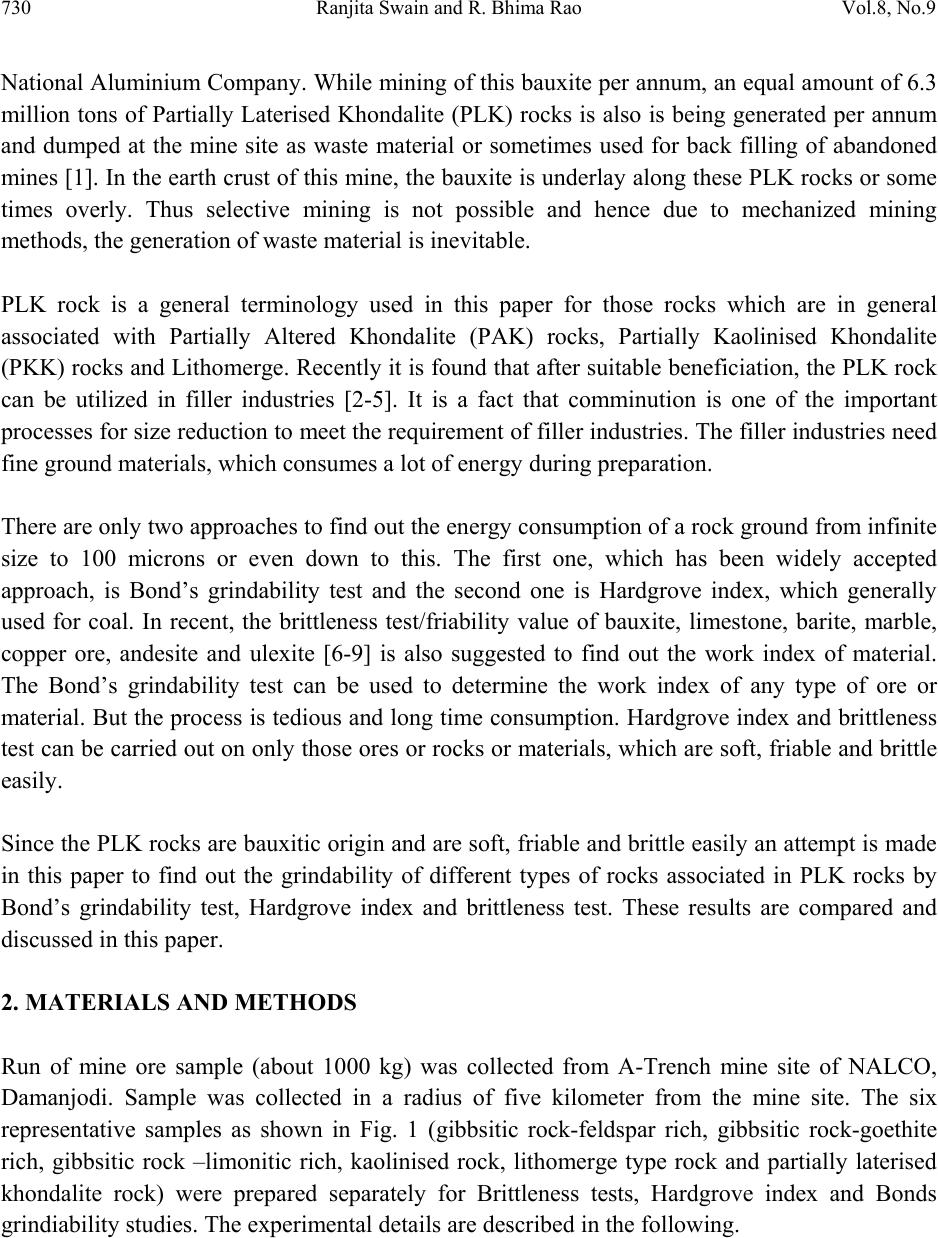

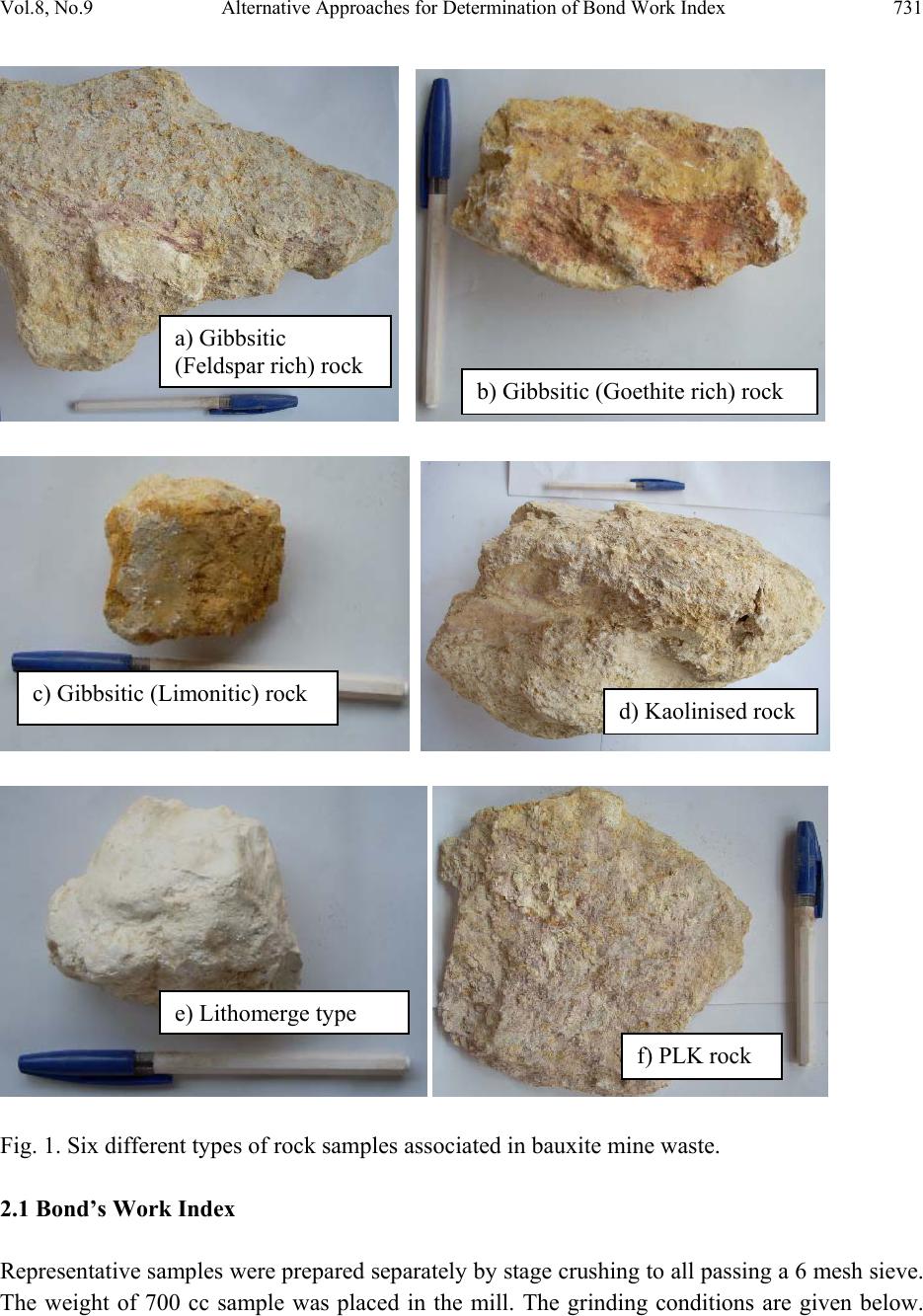

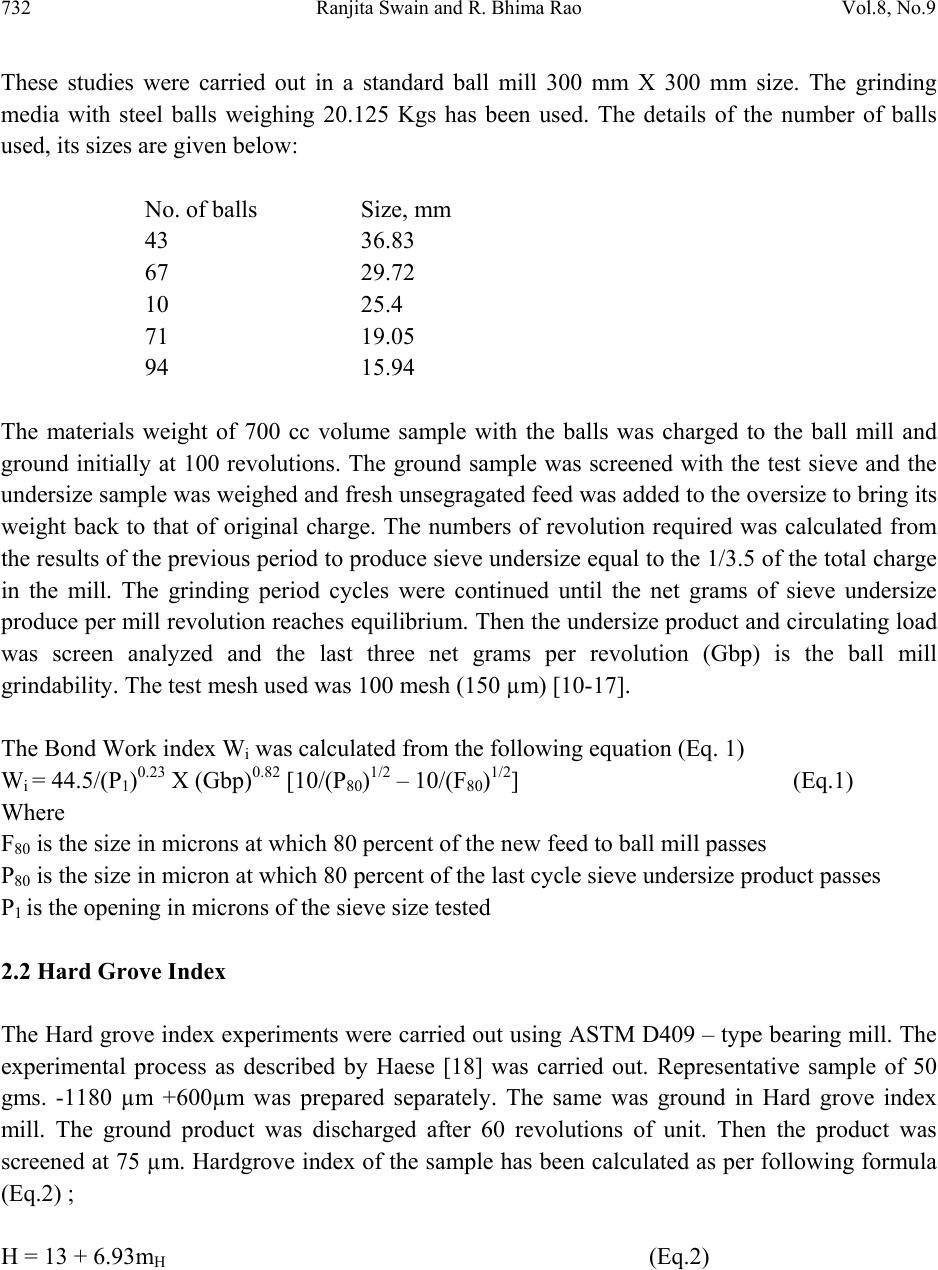

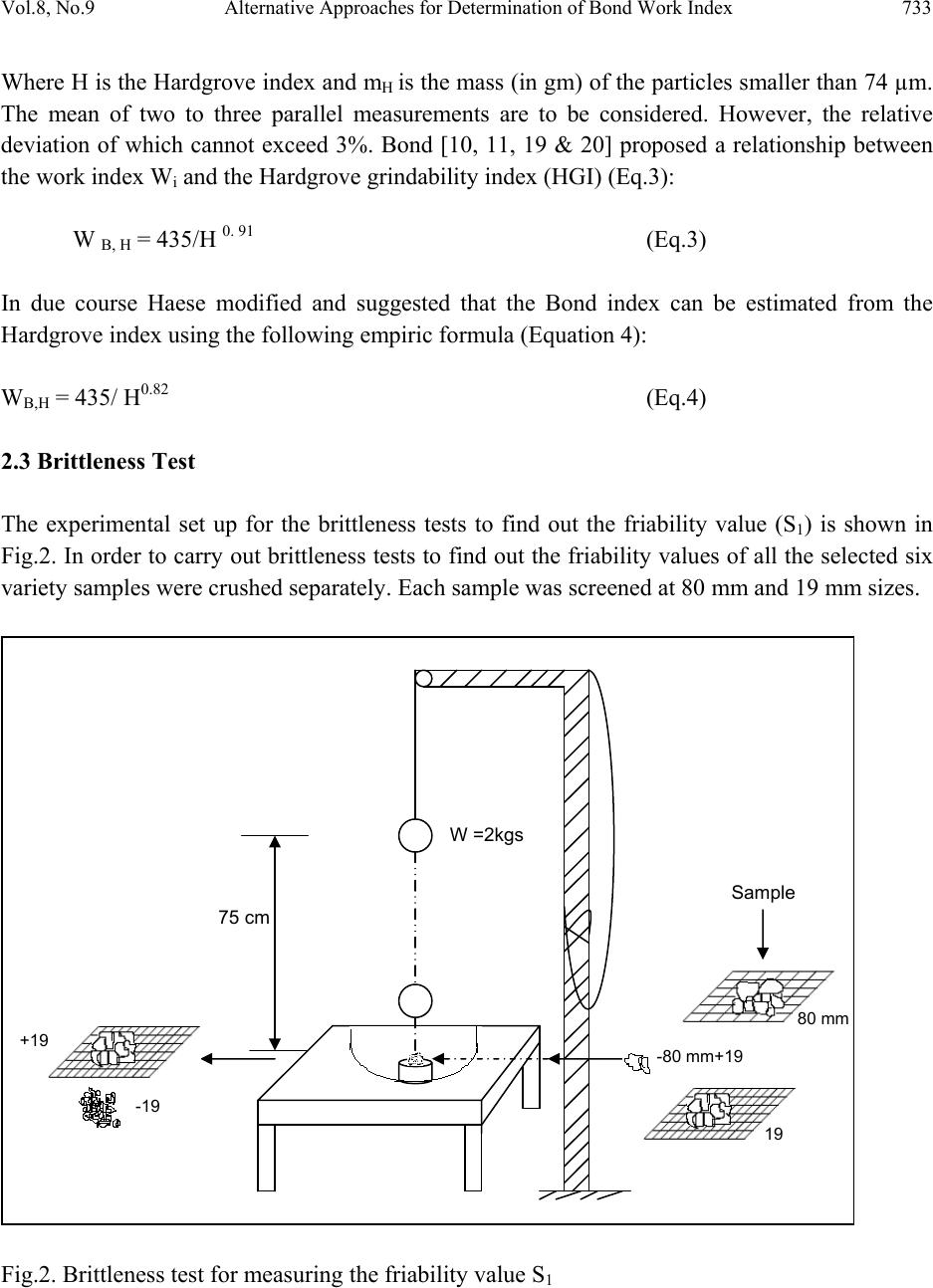

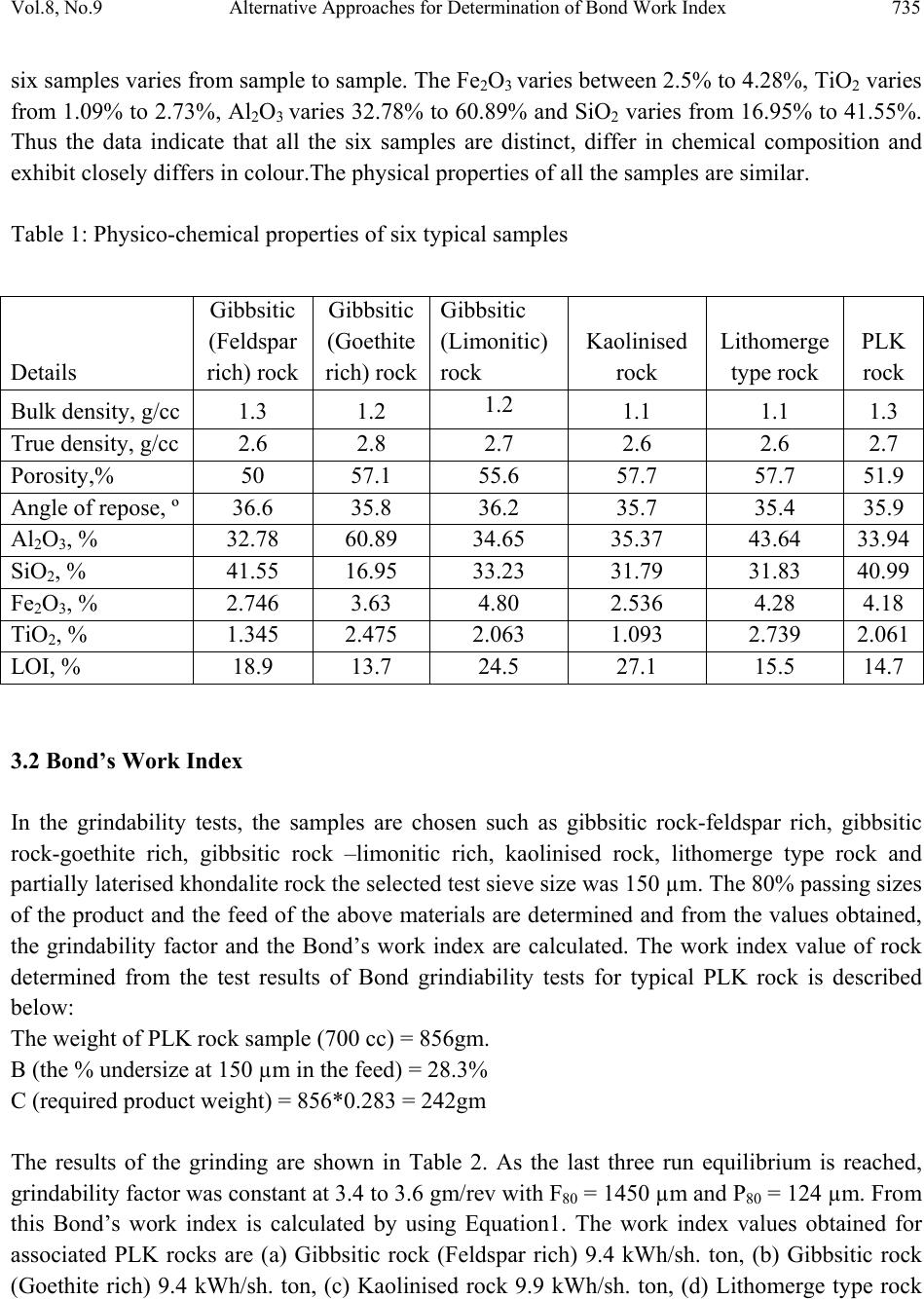

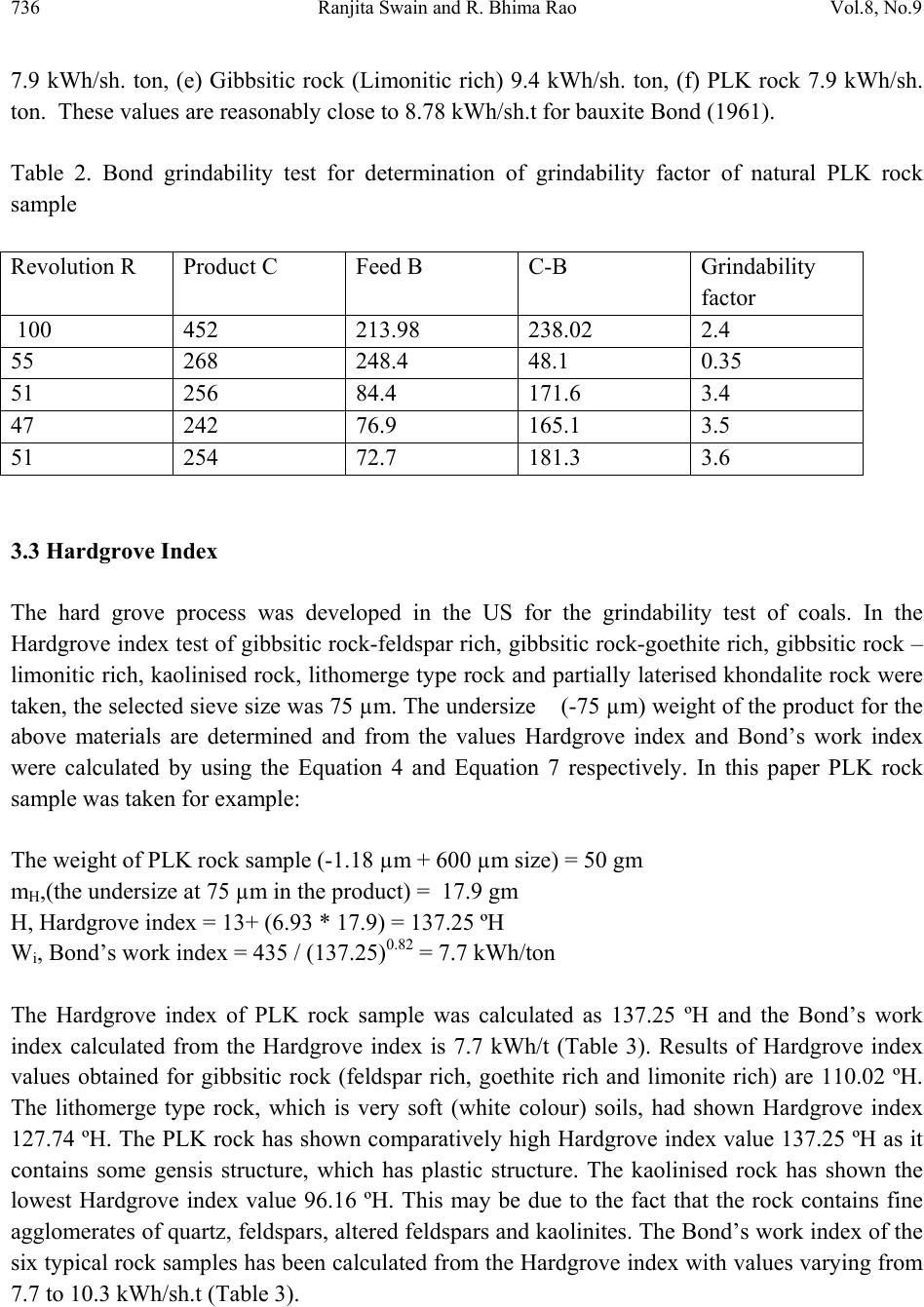

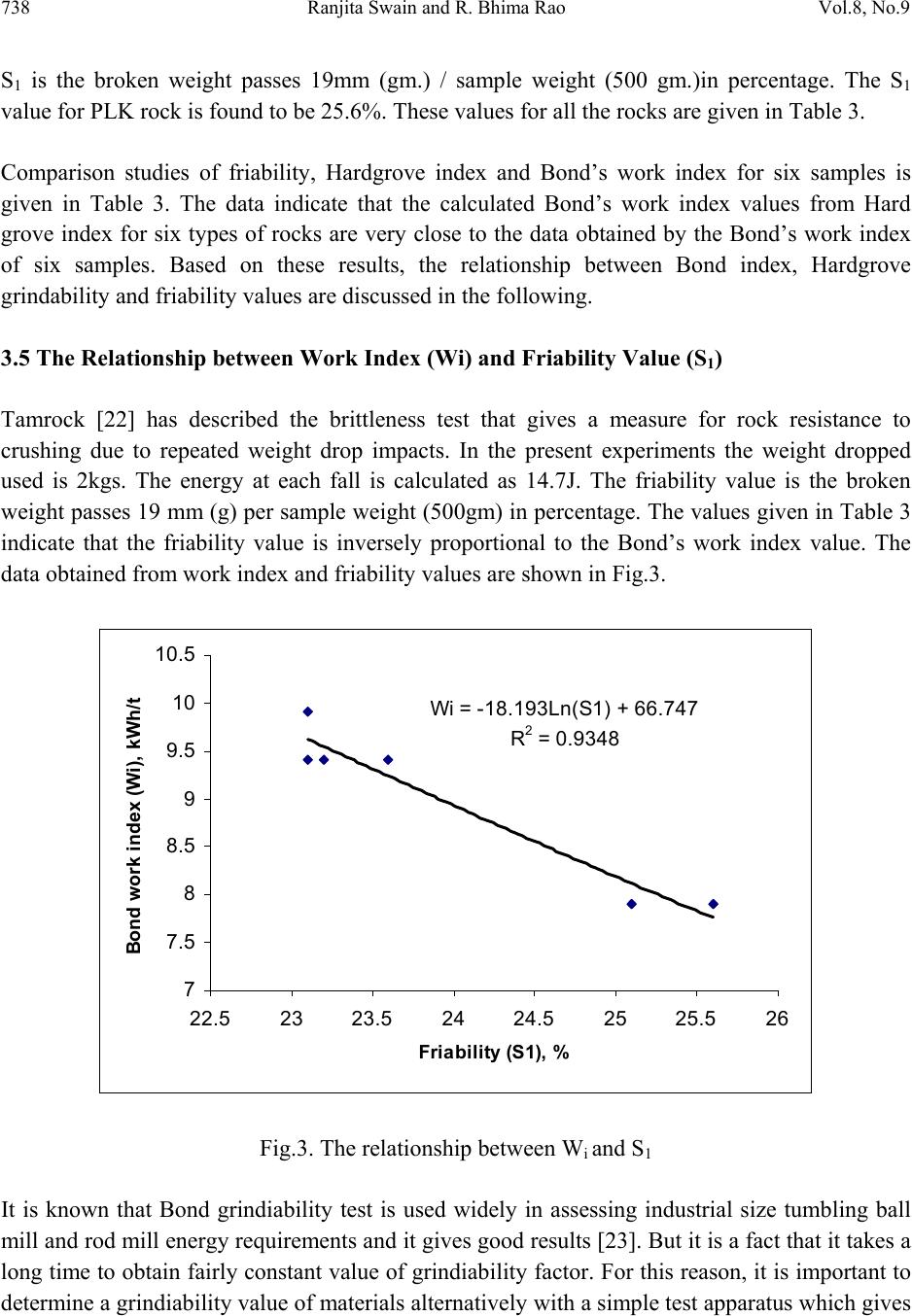

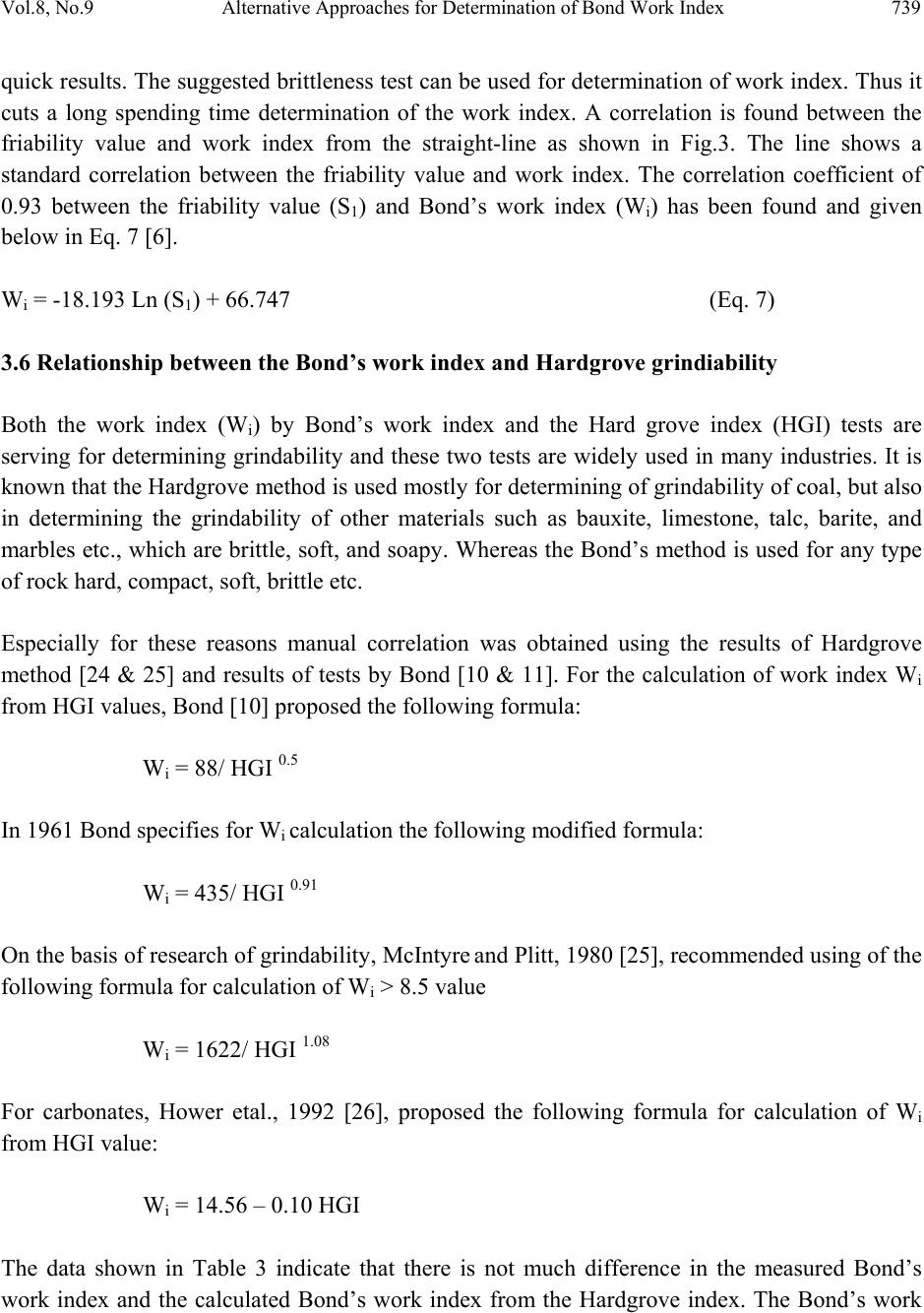

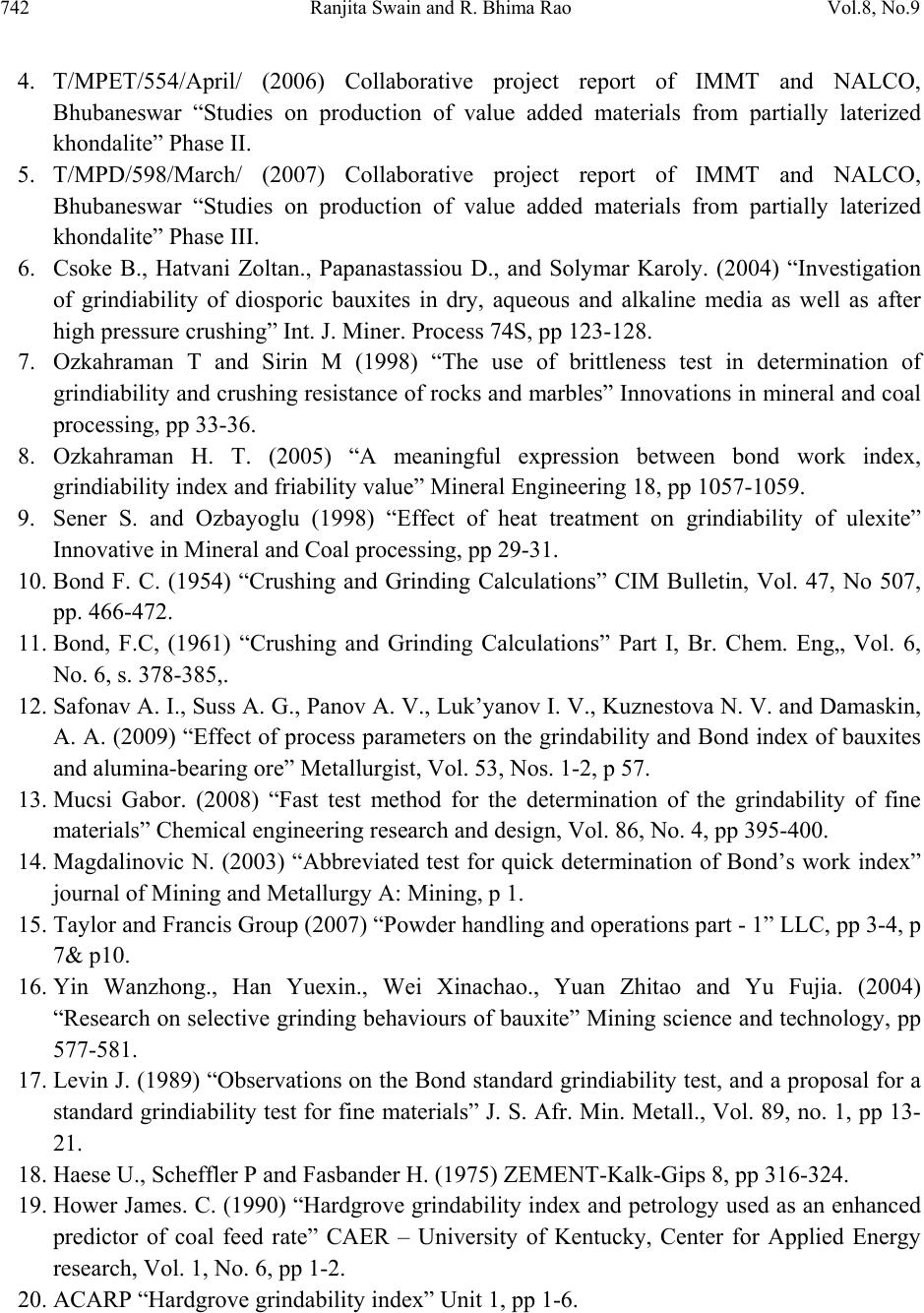

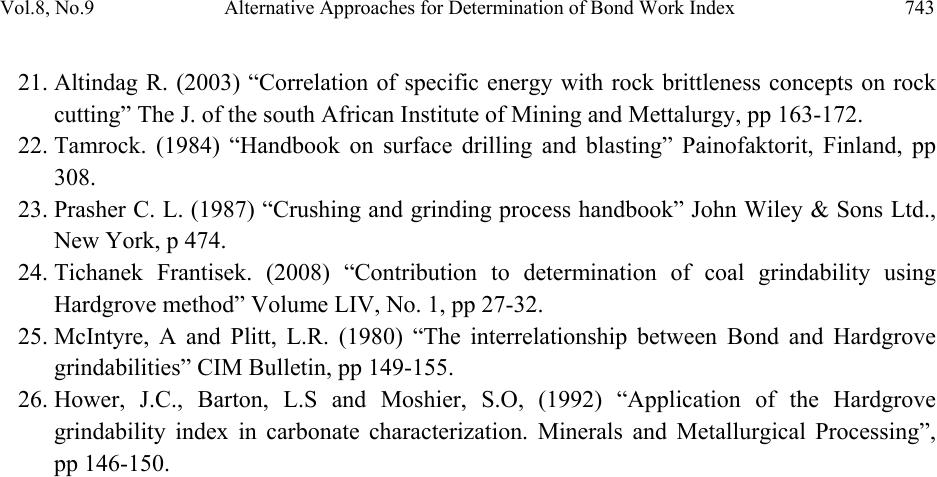

Journal of Minerals & Materials Characterization & Engineering, Vol. 8, No. 9, pp 729-743, 2009 jmmce.org Printed in the USA. All rights reserved 729 Alternative Approaches for Determination of Bond Work Index on Soft and Friable Partially Laterised Khondalite Rocks of Bauxite Mine Waste Materials Ranjita Swain and R. Bhima Rao* Institute of Mineral s and Materials Technology (Council of Scientific & I n d u s t r i a l Research) Bhubaneswar 751 013 *Corresponding Author: bhimarao@immt.res.in, bhimarao@gmail.com ABSTRACT PLK (Partially Laterised Khondalite) rock is a general terminology used in this paper for those rocks which are in general associated in bauxite mining such as Partially Altered Khondalite (PAK) rocks, Partially Kaolinised Khondalite (PKK) rocks and Lithomerge. This paper deals with the Bond’s work index, Hardgrove index and Brittleness tests on six typical rock samples and its correlation. As a fast method, the determination of the Bond index from the Hardgrove index (by calculation) is almost matching with measured Bond’s work index. The Bond’s work index of the above rock samples calculated from the Hardgrove index value has shown a variation from 7.7 to 10.3 kWh/sh.t. A correlation is found between the friability value and work index. The correlation coefficient of 0.93 between the friability value (S1) and Bond’s work index, Wi = -18.193 Ln (S1) + 66.747 has been found. The brittleness test results may not be very close to the work index values, as in brittleness tests relatively large grains are ground, whereas the HGI values, grinding of fine –grain samples involved. Thus the grindability of PLK rocks or bauxite can be determi ne d b y t h e simple test performance, HGI. Keywords: Brittleness, Friability value, Hardgrove index, Bond’s work index, PLK rocks, Bauxite mine waste. 1. INTRODUCTION Khondalite rocks of Easternghats containing bauxite is being mined about 6.3 million tons per annum in the state of Orissa, India to produce around 2.1 million tons of alumina per year by  730 Ranjita Swain and R. Bhima Rao Vol.8, No.9 National Aluminium Company. While mining of this bauxite per annum, an equal amount of 6.3 million tons of Partially Laterised Khondalite (PLK) rocks is also is being generated per annum and dumped at the mine site as waste material or sometimes used for back filling of abandoned mines [1]. In the earth crust of this mine, the bauxite is underlay along these PLK rocks or some times overly. Thus selective mining is not possible and hence due to mechanized mining methods, the generation of waste material is inevitable. PLK rock is a general terminology used in this paper for those rocks which are in general associated with Partially Altered Khondalite (PAK) rocks, Partially Kaolinised Khondalite (PKK) rocks and Lithomerge. Recently it is found that after suitable beneficiation, the PLK rock can be utilized in filler industries [2-5]. It is a fact that comminution is one of the important processes for size reduction to meet the requirement of filler industries. The filler industries need fine ground materials, which consumes a lot of energy during preparation. There are only two approa ches to find out the en ergy consumption of a rock ground from infinite size to 100 microns or even down to this. The first one, which has been widely accepted approach, is Bond’s grindability test and the second one is Hardgrove index, which generally used for coal. In recent, the brittleness test/friability value of bauxite, limestone, barite, marble, copper ore, andesite and ulexite [6-9] is also suggested to find out the work index of material. The Bond’s grindability test can be used to determine the work index of any type of ore or material. But the process is tedious and long ti me consumption. Hardgrove index and brittleness test can be carried out on only those ores or rocks or materials, which are soft, friable and brittle easily. Since the P LK rocks are bauxi tic origin and are sof t, friable and brittle easily an attempt is made in this paper to find out the grindability of different types of rocks associated in PLK rocks by Bond’s grindability test, Hardgrove index and brittleness test. These results are compared and discussed in this paper. 2. MATERIALS AND METHODS Run of mine ore sample (about 1000 kg) was collected from A-Trench mine site of NALCO, Damanjodi. Sample was collected in a radius of five kilometer from the mine site. The six representative samples as shown in Fig. 1 (gibbsitic rock-feldspar rich, gibbsitic rock-goethite rich, gibbsitic rock –limonitic rich, kaolinised rock, lithomerge type rock and partially laterised khondalite rock) were prepared separately for Brittleness tests, Hardgrove index and Bonds grindiability studies. The experimental details are described in the following.  Vol.8, No.9 Alternative Approaches for Determination of Bond Work Index 731 Fig. 1. Six different types of rock samples associated in baux ite mine waste. 2.1 Bond’s Work Index Representati ve samples w ere prepared sep aratel y by stage crushing to all passing a 6 mesh sieve. The weight of 700 cc sample was placed in the mill. The grinding conditions are given below. a) Gibbsitic (Feldspar rich) rock b) Gibbsitic (Goethite rich) rock c) Gibbsitic (Limonitic) rock d) Kaolinised rock e ) Lithomer g e t yp e f) PLK rock  732 Ranjita Swain and R. Bhima Rao Vol.8, No.9 These studies were carried out in a standard ball mill 300 mm X 300 mm size. The grinding media with steel balls weighing 20.125 Kgs has been used. The details of the number of balls used, its sizes are given below: No. of balls Size, mm 43 36.83 67 29.72 10 25.4 71 19.05 94 15.94 The materials weight of 700 cc volume sample with the balls was charged to the ball mill and ground initially at 100 revolutions. The ground sample was screened with the test sieve and the undersize sample was weighed and fresh unsegragated feed was added to the oversize to bring its weight back to that of original charge. The numbers of revolution required was calculated from the results of the previous period to produce sieve undersize equal to the 1/3.5 of the total charge in the mill. The grinding period cycles were continued until the net grams of sieve undersize produce per mill revolution reaches equilibrium. Then the undersize product and circulating load was screen analyzed and the last three net grams per revolution (Gbp) is the ball mill grindability. The test mesh used was 100 mesh (150 µm) [10-17]. The Bond Work index Wi was calculated from the following equation (Eq. 1) Wi = 44.5/(P1)0.23 X (Gbp)0.82 [10/(P80)1/2 – 10/(F80)1/2] (Eq.1) Where F80 is the size in microns at which 80 percent of the new f eed to ball mill passes P80 is the size in micron at which 80 percent of the last cycle sieve undersize product passes P1 is the opening in microns of the sieve size tested 2.2 Hard Grove Index The Hard grove index experiments were carried out using ASTM D409 – type bearing mill. The experimental process as described by Haese [18] was carried out. Representative sample of 50 gms. -1180 µm +600µm was prepared separately. The same was ground in Hard grove index mill. The ground product was discharged after 60 revolutions of unit. Then the product was screened at 75 µm. Hardgrove index of the sample has been calculated as per following formula (Eq.2) ; H = 13 + 6.93mH (Eq.2)  Vol.8, No.9 Alternative Approaches for Determination of Bond Work Index 733 Where H is the Hardgrove index and mH is the mass (in g m) of the particles smaller than 74 µm. The mean of two to three parallel measurements are to be considered. However, the relative deviation of which cannot exceed 3%. Bond [10, 11, 19 & 20] proposed a relationship between the work index Wi and the Hardgrove grindability index (HGI) (Eq.3): W B, H = 435/H 0. 91 (Eq.3) In due course Haese modified and suggested that the Bond index can be estimated from the Hardgrove index using the following empiric formula (Equation 4): WB,H = 435/ H0.82 (Eq.4) 2.3 Brittleness Test The experimental set up for the brittleness tests to find out the friability value (S1) is shown in Fig.2. In order to carry out brittleness tests to find out the friability values of all the selected six variety samples were crushed separately. Each sample was screened at 80 mm and 19 mm sizes. Fig.2. Brittleness test for measuring the friability value S1 W =2kgs 75 cm 80 mm 19 +19 Sample -19 -80 mm+19  734 Ranjita Swain and R. Bhima Rao Vol.8, No.9 The selected rock sample of -80+19 mm size fraction was subjected to impact crushing for brittleness tests. In this connection a test apparatus has been designed as shown in Fig.2. to suit bauxite strength characteristics used in alumina production. The weight dropped is 2kgs from a height of 75cm. In general the drop weight tests of minimum three or four parallel tests are to be carried out and the mean value to be consid ered for deter mination of friability values . But in the present investigation, all the rock types, subjected to brittleness tests, under the 2kg drop weight, were produced fine powder (by single drop weight) and hence there was no scope to repeat second drop weight test on the same sample. The friability (S1) is calculated as given below: F = the broken weight passes 19 mm (gms)/ Sample weight X 100 (Eq.5) Thus the friability value S1 equals the percentage of undersized material, which passes through the 19 mm size after crushing. The energy calculation for drop weight at each fall is given below. E = m * g* h (Eq.6) Where m = mass of the weight drop on the sample E = Energy of each fall, J g = gravitational force, m/s2 h = height from where the falls on the sample, m 3. RESULTS AND DISCUSSION 3.1 Physicochemical Characteristics Six chosen typical samples have posses a wide range of colours (Fig.1). The colours vary from white, yellow, grey, brown, red and pinkish or of mixed varieties. Their brightness also varies from sample to sample. The light brownish varieties are gibbsitic rock with feldspars and occasionally have white clayey patches (kaolinite) or vug/cavity filled quartz (Fig. 1a). The dark brownish varieties are also gibbsitic with goethite rich content (Fig 1b). Similarly the brown rock associated with light to dark yellow colour limonite (Fig 1c). The white variety samples which are soft, friable to semi-friable and clayey are mostly kaolinised or lithomerge rocks (Fig.1d and 1e). Many of the white varieties of the samples are soapy to hand. Some of the hand specimen samples show the gneissic structure that of a fresh khondalite. The samples are partially lateritised to fully lateritised khondalites (Fig 1f). The physical properties and complete chemical analysis (Table 1) indicate that the physical properties of all thes e samples are almos t similar. It is observed that the bulk density varies from 1.1 to 1.4 g/cc, true density varies fro m 2.6 to 2.8 g/cc. However, the chemical analysis of these  Vol.8, No.9 Alternative Approaches for Determination of Bond Work Index 735 six samples varies from sample to samp le. The F e2O3 varies betw een 2.5% to 4.28%, TiO2 varies from 1.09% to 2.73%, Al2O3 varies 32.78% to 60.89% and SiO2 varies from 16.95% to 41.55%. Thus the data indicate that all the six samples are distinct, differ in chemical composition and exhibit closely differs in colour.The physical properties of all the samples are similar. Table 1: Physico-chemical properties of six typical samples 3.2 Bond’s Work Index In the grindability tests, the samples are chosen such as gibbsitic rock-feldspar rich, gibbsitic rock-goethite rich, gibbsitic rock –limonitic rich, kaolinised rock, lithomerge type rock and partially laterised khondalite rock the selected test sieve size was 150 µm. The 80% passing sizes of the product and the feed of the above materials are determined and from the values obtained, the grindability factor and the Bond’s work index are calculated. The work index value of rock determined from the test results of Bond grindiability tests for typical PLK rock is described below: The weight of PLK rock sample (700 cc) = 856gm. B (the % undersize at 150 µm in the feed) = 28.3% C (required product weight) = 856*0.283 = 242gm The results of the grinding are shown in Table 2. As the last three run equilibrium is reached, grindability factor was constant at 3.4 to 3.6 gm/rev with F80 = 1450 µm and P80 = 124 µm. From this Bond’s work index is calculated by using Equation1. The work index values obtained for associated PLK rocks are (a) Gibbsitic rock (Feldspar rich) 9.4 kWh/sh. ton, (b) Gibbsitic rock (Goethite rich) 9.4 kWh/sh. ton, (c) Kaolinised rock 9.9 kWh/sh. ton, (d) Lithomerge type rock Details Gibbsitic (Feldspar rich) rock Gibbsitic (Goethite rich) rock Gibbsitic (Limonitic) rock Kaolinised rock Lithomerge type rock PLK rock Bulk density, g/cc 1.3 1.2 1.2 1.1 1.1 1.3 True density, g/cc 2.6 2.8 2.7 2.6 2.6 2.7 Porosity,% 50 57.1 55.6 57.7 57.7 51.9 Angle of repose, º 36.6 35.8 36.2 35.7 35.4 35.9 Al2O3, % 32.78 60.89 34.65 35.37 43.64 33.94 SiO2, % 41.55 16.95 33.23 31.79 31.83 40.99 Fe2O3, % 2.746 3.63 4.80 2.536 4.28 4.18 TiO2, % 1.345 2.475 2.063 1.093 2.739 2.061 LOI, % 18.9 13.7 24.5 27.1 15.5 14.7  736 Ranjita Swain and R. Bhima Rao Vol.8, No.9 7.9 kWh/sh. ton, (e) Gibbsitic rock (Limonitic rich) 9.4 kWh/sh. ton, (f) PLK rock 7.9 kWh/sh. ton. These values are reasonably close to 8.78 kWh/sh.t for bauxite Bond (1961). Table 2. Bond grindability test for determination of grindability factor of natural PLK rock sample Revolution R Product C Feed B C-B Grindability factor 100 452 213.98 238.02 2.4 55 268 248.4 48.1 0.35 51 256 84.4 171.6 3.4 47 242 76.9 165.1 3.5 51 254 72.7 181.3 3.6 3.3 Hardgrove Index The hard grove process was developed in the US for the grindability test of coals. In the Hardgrove index test of gibbsitic rock-feldspar rich, gibbsitic rock-goethite rich, gibbsitic rock – limonitic rich, kaolinised rock, lithomerge type rock and partially laterised khondalite rock were taken, the selected si eve size was 75 µm. The undersize (-75 µm) weight of the product for the above materials are determined and from the values Hardgrove index and Bond’s work index were calculated by using the Equation 4 and Equation 7 respectively. In this paper PLK rock sample was taken for example: The weight of PLK rock sample (-1.18 µm + 600 µm size) = 50 gm mH,(the undersize at 75 µm in the product) = 17.9 gm H, Hardgrove index = 13+ (6.93 * 17.9) = 137.25 ºH Wi, Bond’s work index = 435 / (137.25)0.82 = 7.7 kWh/ton The Hardgrove index of PLK rock sample was calculated as 137.25 ºH and the Bond’s work index calculated from the Hardgrove index is 7.7 kWh/t (Table 3). Results of Hardgrove index values obtained for gibbsitic rock (feldspar rich, goethite rich and limonite rich) are 110.02 ºH. The lithomerge type rock, which is very soft (white colour) soils, had shown Hardgrove index 127.74 ºH. The PLK rock has shown comparatively high Hardgrove index value 137.25 ºH as it contains some gensis structure, which has plastic structure. The kaolinised rock has shown the lowest Hardgrove index value 96.16 ºH. This may be due to the fact that the rock contains fine agglomerates of quartz, feldspars, altered feldspars and kaolinites. The Bond’s work index of the six typical rock sa mples has been calculated fr om the Hardgrove index with values varying from 7.7 to 10.3 kWh/sh.t (Table 3).  Vol.8, No.9 Alternative Approaches for Determination of Bond Work Index 737 Table 3. Comparison studies of friability, Hardgrove index and Bond’s work index Details Bond index Wi (KW h/t) Hardgrove index (ºH) *Calculated Bond index Wi,h (KW h/t) Friability value,% Gibbsitic rock (Feldspar rich) 9.4 110.02 9.2 23.1 Gibbsitic rock (Goethite rich) 9.4 110.02 9.2 23.2 Gibbsitic (Limonitic) rock 9.4 110.02 9.2 23.6 Kaolinised rock 9.9 96.16 10.3 23.1 Lithomerge type rock 7.9 127.74 8.2 25.1 PLK rock 7.9 137.25 7.7 25.6 Bond’s work index calculated from Hardgrove index 3.4 Brittleness Test It is mentioned earlier that friability value is measured from the brittleness test. Brittleness, defined differently from author to author, is an important me chani cal property of rocks, but ther e is no universally accepted brittleness concept or measurement method in mechanical excavation [6]. Many studies can be seen of the relationship between brittleness and the other performance parameters of machines and rock properties in literatures [21]. The results of the friability values determined from the brittleness tests for six different type rocks of same geological source are given in Table 3. The data indicate that these is significant change observed in the friability values expressed in terms of percentage of -19 mm particles produced for each rock type. The typical PLK rock and lithomerge type rock samples have shown friability value around 25% and the rest four type rocks are shown around 23% average. The tested PLK rock sample aggregate volume corresponds to that of a 500 gm in the fraction - 80mm+19 mm size. The friability value S1 equals the percentage of undersized material, which passes through 19 mm size after crushing on the base mortar by one weight drop. The mean value for a minimum of four to five tests is chosen as the rock sample S1 value. The weight dropped is 2kgs. Therefore the energy at each fall is 2kgf x 0.75m x 9.81 m/sec2 = 14.7 J (Eq.6).  738 Ranjita Swain and R. Bhima Rao Vol.8, No.9 S1 is the broken weight passes 19mm (gm.) / sample weight (500 gm.)in percentage. The S1 value for PLK rock is found to be 25.6%. These values for all the rocks are given in Table 3. Comparison studies of friability, Hardgrove index and Bond’s work index for six samples is given in Table 3. The data indicate that the calculated Bond’s work index values from Hard grove index for six types of rocks are very close to the data obtained by the Bond’s work index of six samples. Based on these results, the relationship between Bond index, Hardgrove grindability and fri ability values are discussed in the following. 3.5 The Relationship between Work Index (Wi) and Friability Value (S1) Tamrock [22] has described the brittleness test that gives a measure for rock resistance to crushing due to repeated weight drop impacts. In the present experiments the weight dropped used is 2kgs. The energy at each fall is calculated as 14.7J. The friability value is the broken weight passes 19 mm (g) per sample weight (500gm) in percentage. The values given in Table 3 indicate that the friability value is inversely proportional to the Bond’s work index value. The data obtained from work index and friability values are shown in Fig.3. Wi = -18.193Ln(S1) + 66.747 R 2 = 0.9348 7 7.5 8 8.5 9 9.5 10 10.5 22.5 2323.5 2424.5 2525.5 26 Friability (S1), % Bond work index (Wi), kWh/t Fig.3. The relationship between Wi and S1 It is known that Bond grindiability test is used widely in assessing industrial size tumbling ball mill and rod mill energy requirements and it gives good results [23]. But it is a fact that it takes a long time to obtain fairly constant value of grindiability factor. For this reason, it is important to determine a grindiability value of materials alternatively with a simple test apparatus which gives  Vol.8, No.9 Alternative Approaches for Determination of Bond Work Index 739 quick results. The suggested brittleness test can be used for determination of work index. Thus it cuts a long spending time determination of the work index. A correlation is found between the friability value and work index from the straight-line as shown in Fig.3. The line shows a standard correlation between the friability value and work index. The correlation coefficient of 0.93 between the friability value (S1) and Bond’s work index (Wi) has been found and given below in Eq. 7 [6]. Wi = -18.193 Ln (S1) + 66.747 (Eq. 7) 3.6 Relationship between the Bond’s work index and Hardgrove grindiability Both the work index (Wi) by Bond’s work index and the Hard grove index (HGI) tests are serving for determining grindability and these two tests are widely used in many industries. It is known that the Hardgrove method is used mostly for deter mining of grindability of coal, but also in determining the grindability of other materials such as bauxite, limestone, talc, barite, and marbles etc., which are brittle, soft, and soapy. Whereas the Bond’s method is used for any type of rock hard, compact, soft, brittle etc. Especially for these reasons manual correlation was obtained using the results of Hardgrove method [24 & 25] and results of tests by Bond [10 & 11]. For the calculation of work index Wi from HGI values, Bond [10] proposed the following formula: Wi = 88/ HGI 0.5 In 1961 Bond specifies for Wi calculation the following modified formula: Wi = 435/ HGI 0.91 On the basis of resear ch of grindability, McIntyre and Plitt, 1980 [25], recommended using of the following formula for calculation of Wi > 8.5 value W i = 1622/ HGI 1.08 For carbonates, Hower etal., 1992 [26], proposed the following formula for calculation of Wi from HGI value: W i = 14.56 – 0.10 HGI The data shown in Table 3 indicate that there is not much difference in the measured Bond’s work index and the calculated Bond’s work index from the Hardgrove index. The Bond’s work  740 Ranjita Swain and R. Bhima Rao Vol.8, No.9 index varies from 7.9 to 9.9 kWh/t whereas the calculated Bond’s work index from Hardgrove index varies from 7.7 to 10.3 kWh/t. Fig. 4 shows the comparison of the measured Bond work index estimated from the Hardgrove grindability using the relation given in Equation 4. The data show that under the investigated conditions there is tight relationship between the Bond index and the Hardgrove grindability. y = 0.9982x R 2 = 0.9944 0 2 4 6 8 10 12 024681012 Me asure d Bond w ork inde x, kW h/t Bond work index calculated from Hardgrove grindiability, kWh/t Fig.4. Comparison of the measured Bond work index and the Bond work index estimated from the Hardgrove grindability using the relation (Eq.5) The Bond method of grindability determination is time consuming and a constant value of material grindability is only achieved after several grinding periods, where as for determination of the HGI, the experimental procedure takes few minutes. In contrast the brittleness test is very rapid and friability value is obtained still in a much shorter time. However, the Wi values obtained by calculation from HGI not always precisely correspond to the values of work index specified by sample brittleness testing. This is associated with the fact that in brittleness tests relatively large grains are ground, whereas the HGI values is discovered by grinding of fine – grain samples [24]. Brittleness test is performed on impact testing device. Hence, the brittleness test results may not be very close to the work index values. Thus in view of the above observations, the grindability of PLK rocks or bauxite can be determined by the simple test performance, HGI.  Vol.8, No.9 Alternative Approaches for Determination of Bond Work Index 741 4. CONCLUSIONS The following conclusions are drawn from the Bond’s work index, Hardgrove index and Brittleness tests on six typical rock samples. The work index values obtained for associated PLK rocks in the bauxite mine vary from 7.9 kWh/sh.t to 9.9 kWh/sh.t. These values are reasonably close to 8.78 kWh/sh.t for bauxite as estimated by Bond. As a fast method, the determination of the Bond index from the Hardgrove index (by calculation) is almost matching with measured Bond’s work index. The Bond’s work index of the above rock samples calculated from the Hardgrove index value has shown a variation from 7.7 to 10.3 kWh/sh.t. A correlation is found between the friability value and work index. The correlation coefficient of 0.93 between the friability value (S1) and Bond’s work index, Wi = -18.193 Ln (S1) + 66.747 has been found. However, the brittleness test results may not be very clos e to the work index values for other types of rock samples determined by Bond. The Wi values obtained by calculation from HGI is very close to the Bond work index values, since the HGI values is discovered by grinding of even fine –grain samples. Thus the grindability of PLK rocks or bauxite can be determined by the simple test performance, HGI. ACKNOWLEDGEMENTS The authors are thankful to Prof. B.K. Mishra, Director for his kind permission to publish this paper. Thanks also due to Sri P. S. R. Reddy, HOD, MPD, for his constant suggestions. One of the authors Ms. Ranjita Swain is thankful to CSIR for granting CSIR SRF. REFERENCES 1. NALCO brocher (2008) “A profile on National Aluminium Company” Bhubaneswar. 2. Rao R. Bhima., Swain Ranjita., Prasad A. R., Prakash S., Rao K.K., Das S.K., Das B., Reddy P.S.R., Mishra C.R and Pani B.S. (2006) “Utilization of partially laterised khondalite rocks for refractory applications” 60th NMD-ATM, pp 6-7. 3. T/MPET/515/July/ (2005) Collaborative project report of IMMT and NALCO, Bhubaneswar “Studies on production of value added materials from partially laterized khondalite” Phase I.  742 Ranjita Swain and R. Bhima Rao Vol.8, No.9 4. T/MPET/554/April/ (2006) Collaborative project report of IMMT and NALCO, Bhubaneswar “Studies on production of value added materials from partially laterized khondalite” Phase II. 5. T/MPD/598/March/ (2007) Collaborative project report of IMMT and NALCO, Bhubaneswar “Studies on production of value added materials from partially laterized khondalite” Phase III. 6. Csoke B., Hatvani Zoltan., Papanastassiou D., and Solymar Karoly. (2004) “Investigation of grindiability of diosporic bauxites in dry, aqueous and alkaline media as well as after high pressure crushing” Int. J. Miner. Process 74S, pp 123-128. 7. Ozkahraman T and Sirin M (1998) “The use of brittleness test in determination of grindiability and crushing resistance of rocks and marbles” Innovations in mineral and coal processing, pp 33-36. 8. Ozkahraman H. T. (2005) “A meaningful expression between bond work index, grindiability index and friability value” Mineral Engineering 18, pp 1057-1059. 9. Sener S. and Ozbayoglu (1998) “Effect of heat treatment on grindiability of ulexite” Innovative in Mineral and Coal processing, pp 29-31. 10. Bond F. C. (1954) “Crushing and Grinding Calculations” CIM Bulletin, Vol. 47, No 507, pp. 466-472. 11. Bond, F.C, (1961) “Crushing and Grinding Calculations” Part I, Br. Chem. Eng„ Vol. 6, No. 6, s. 378-385,. 12. Safonav A. I., Suss A. G., Panov A. V., Luk’yanov I. V., Kuznestova N. V. and Damaskin, A. A. (2009) “Effect of process parameters on the grindability and Bond index of bauxites and alumina-bearing ore” Metallurgist, Vol. 53, Nos. 1-2, p 57. 13. Mucsi Gabor. (2008) “Fast test method for the determination of the grindability of fine materials” Chemical engineering research and design, Vol. 86, No. 4, pp 395-400. 14. Magdalinovic N. (2003) “Abbreviated test for quick determination of Bond’s work index” journal of Mining and Metallurgy A: Mining, p 1. 15. Taylor and Francis Group (2007) “Powder handling and operations part - 1” LLC, pp 3-4, p 7& p10. 16. Yin Wanzhong., Han Yuexin., Wei Xinachao., Yuan Zhitao and Yu Fujia. (2004) “Research on selective grinding behaviours of bauxite” Mining scienc e and technology, pp 577-581. 17. Levin J. (1989) “Observations on the Bond standard grindiability test, and a proposal for a standard grindiability test for fine materials” J. S. Afr. Min. Metall., Vol. 89, no. 1, pp 13- 21. 18. Haese U., Scheffler P and Fasbander H. (1975) ZEMENT-Kalk-Gips 8, pp 316-324. 19. Hower James. C. (1990) “Hardgrove grindability index and petrology used as an enhanced predictor of coal feed rate” CAER – University of Kentucky, Center for Applied Energy research, Vol. 1, No. 6, pp 1-2. 20. ACARP “Hardgrove grindability index” Unit 1, pp 1-6.  Vol.8, No.9 Alternative Approaches for Determination of Bond Work Index 743 21. Altindag R. (2003) “Correlation of specific energy with rock brittleness concepts on rock cutting” The J. of the south African Institute of Mining and Mettalurgy, pp 163-172. 22. Tamrock. (1984) “Handbook on surface drilling and blasting” Painofaktorit, Finland, pp 308. 23. Prasher C. L. (1987) “Crushing and grinding process handbook” John Wiley & Sons Ltd., New York, p 474. 24. Tichanek Frantisek. (2008) “Contribution to determination of coal grindability using Hardgrove method” Volume LIV, No. 1, pp 27-32. 25. McIntyre, A and Plitt, L.R. (1980) “The interrelationship between Bond and Hardgrove grindabilities” CIM Bulletin, pp 149-155. 26. Hower, J.C., Barton, L.S and Moshier, S.O, (1992) “Application of the Hardgrove grindability index in carbonate characterization. Minerals and Metallurgical Processing”, pp 146-150. |