Paper Menu >>

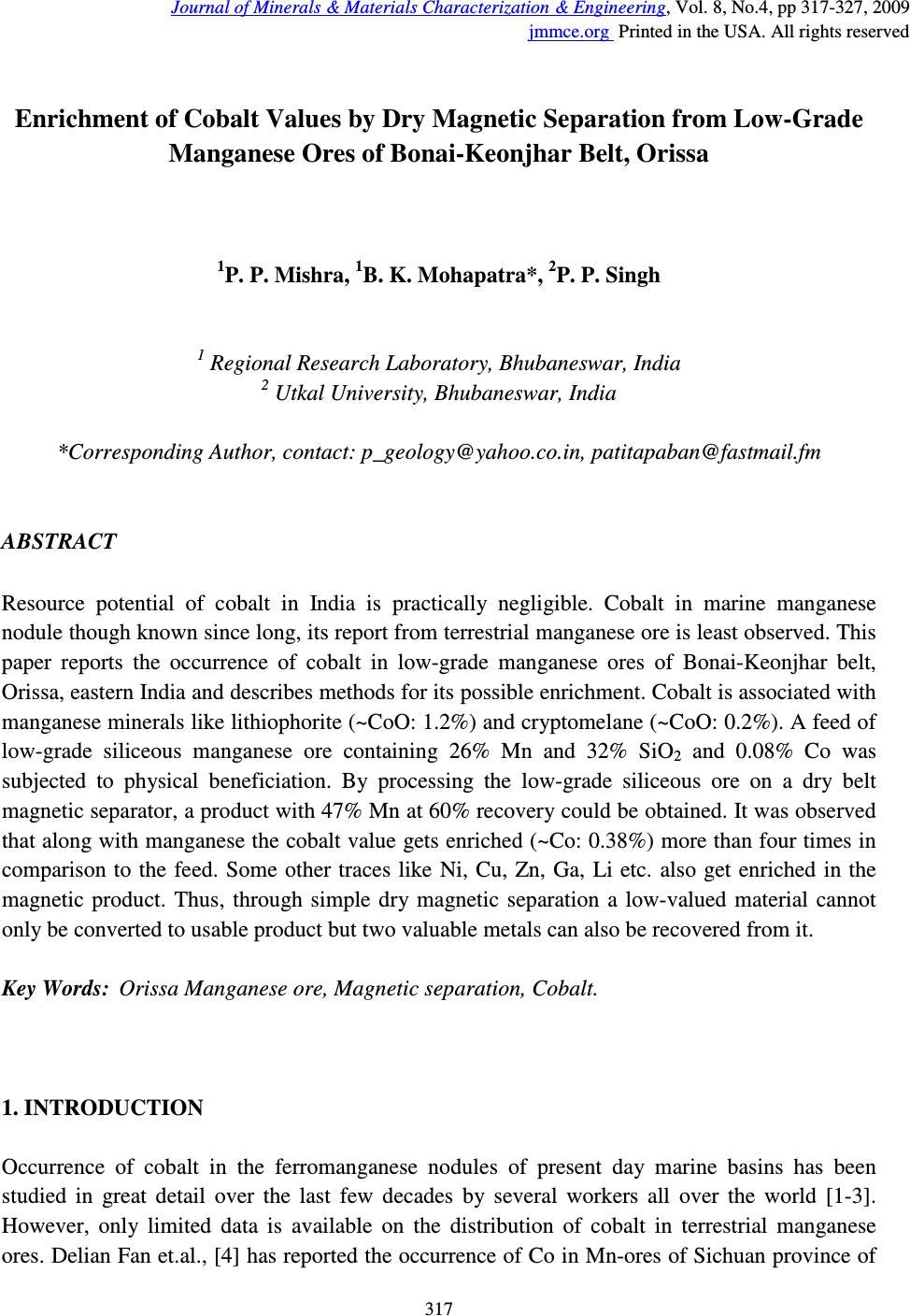

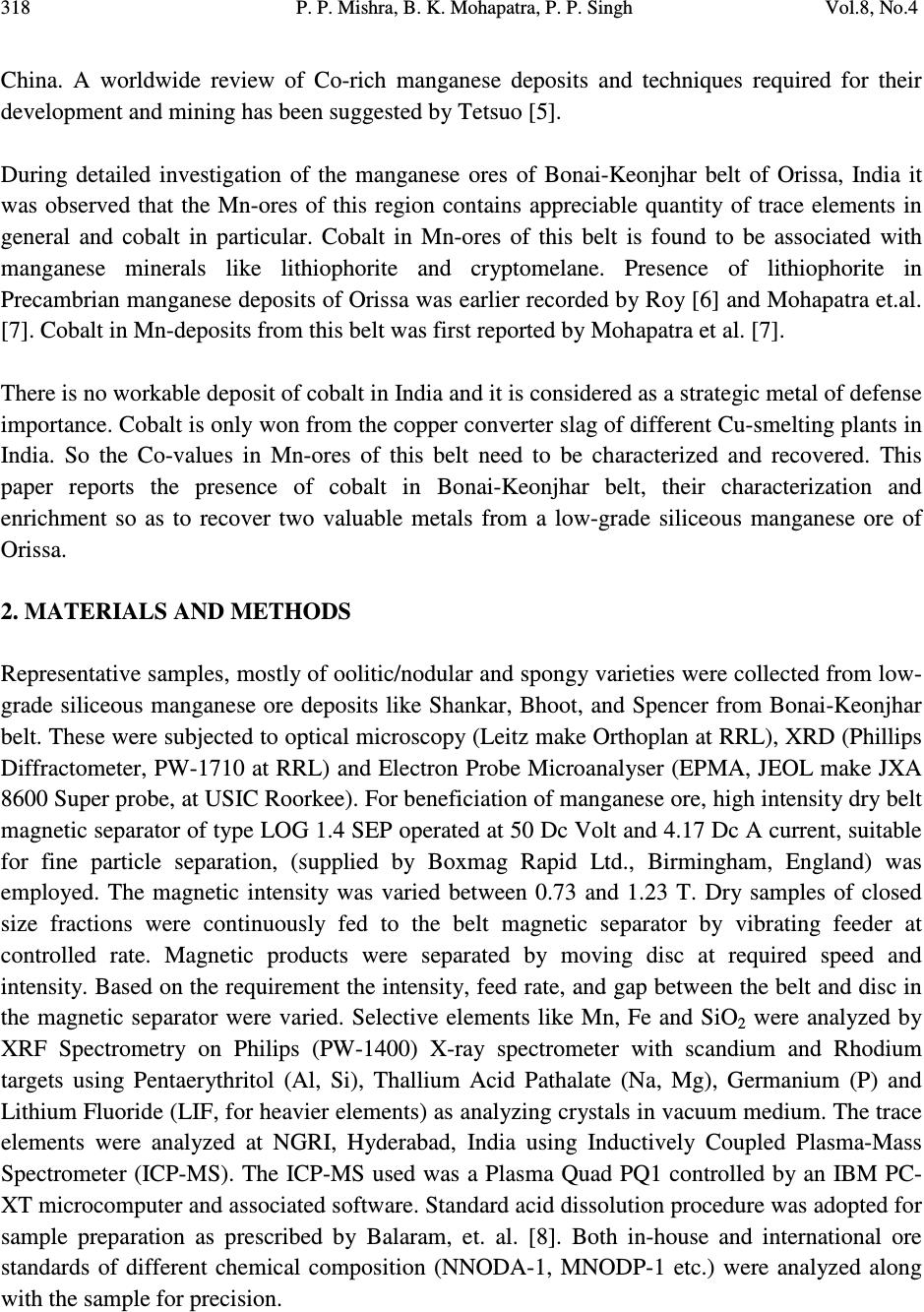

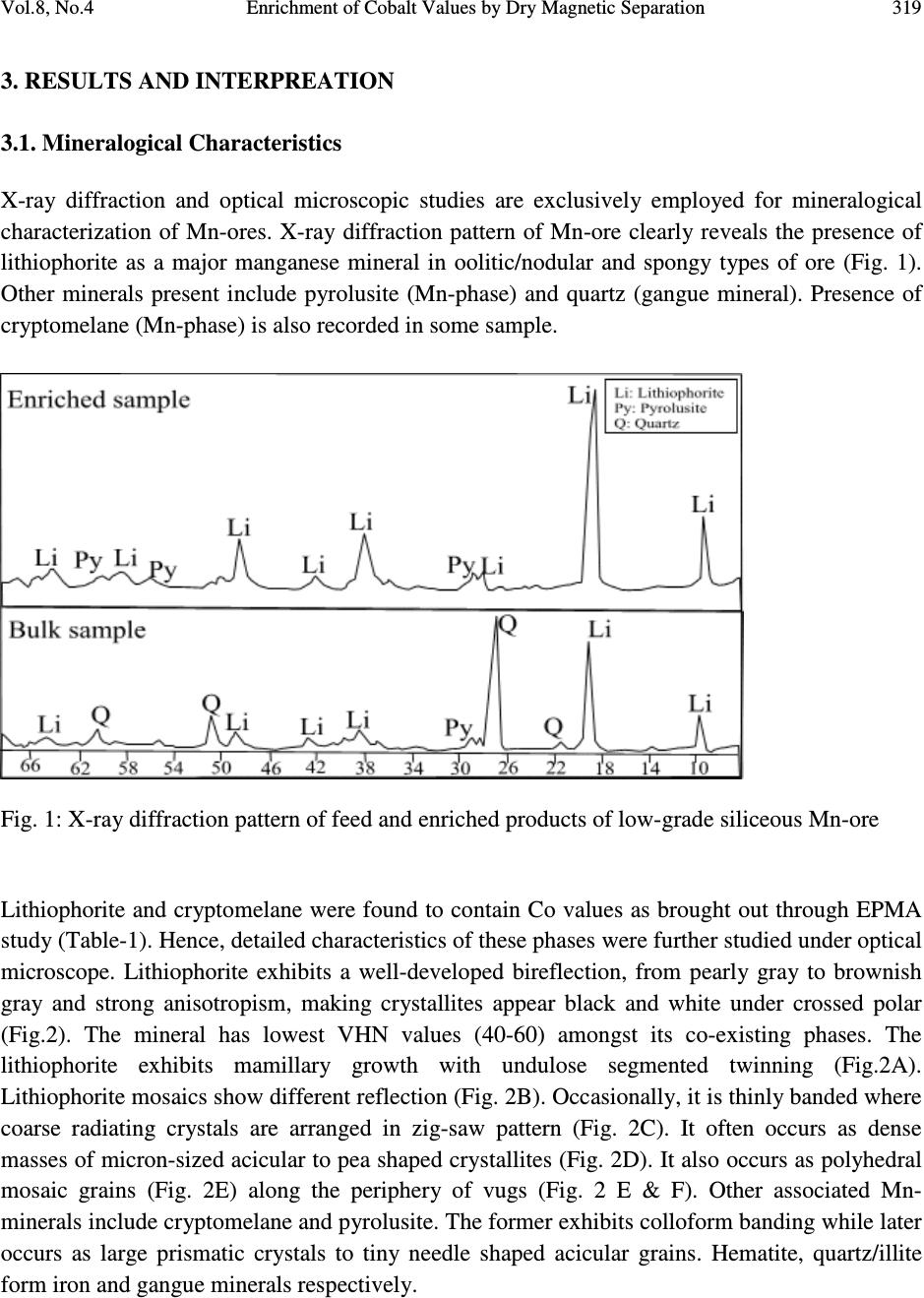

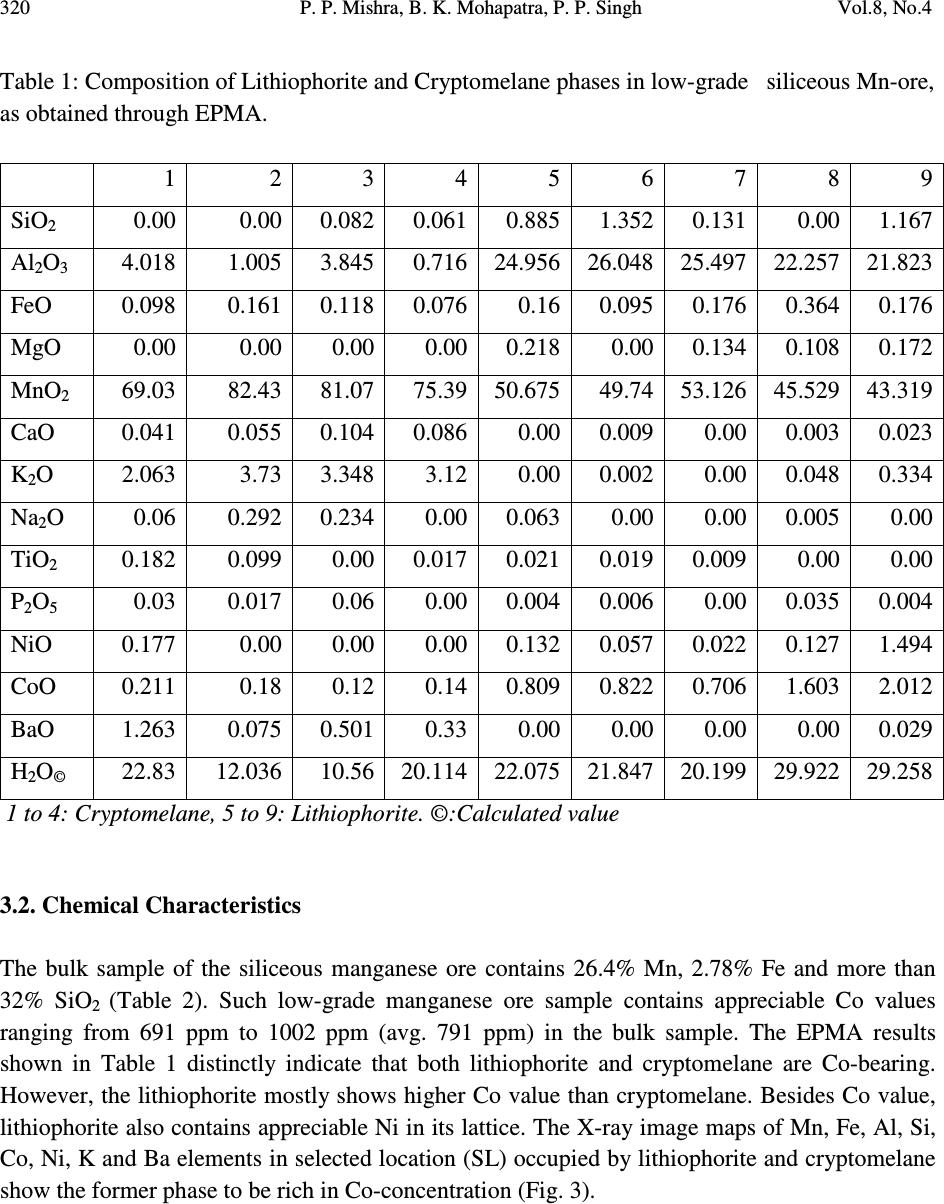

Journal Menu >>

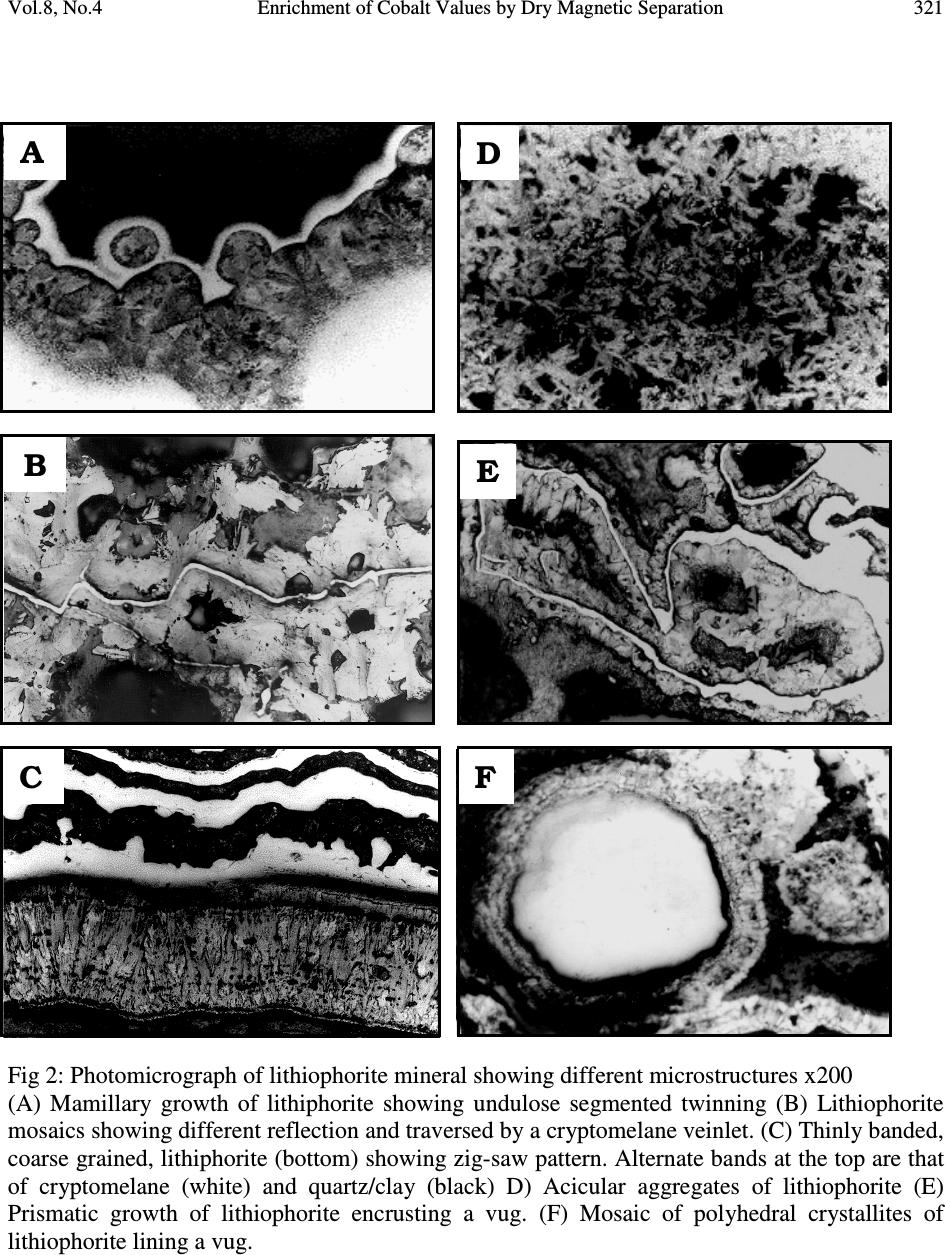

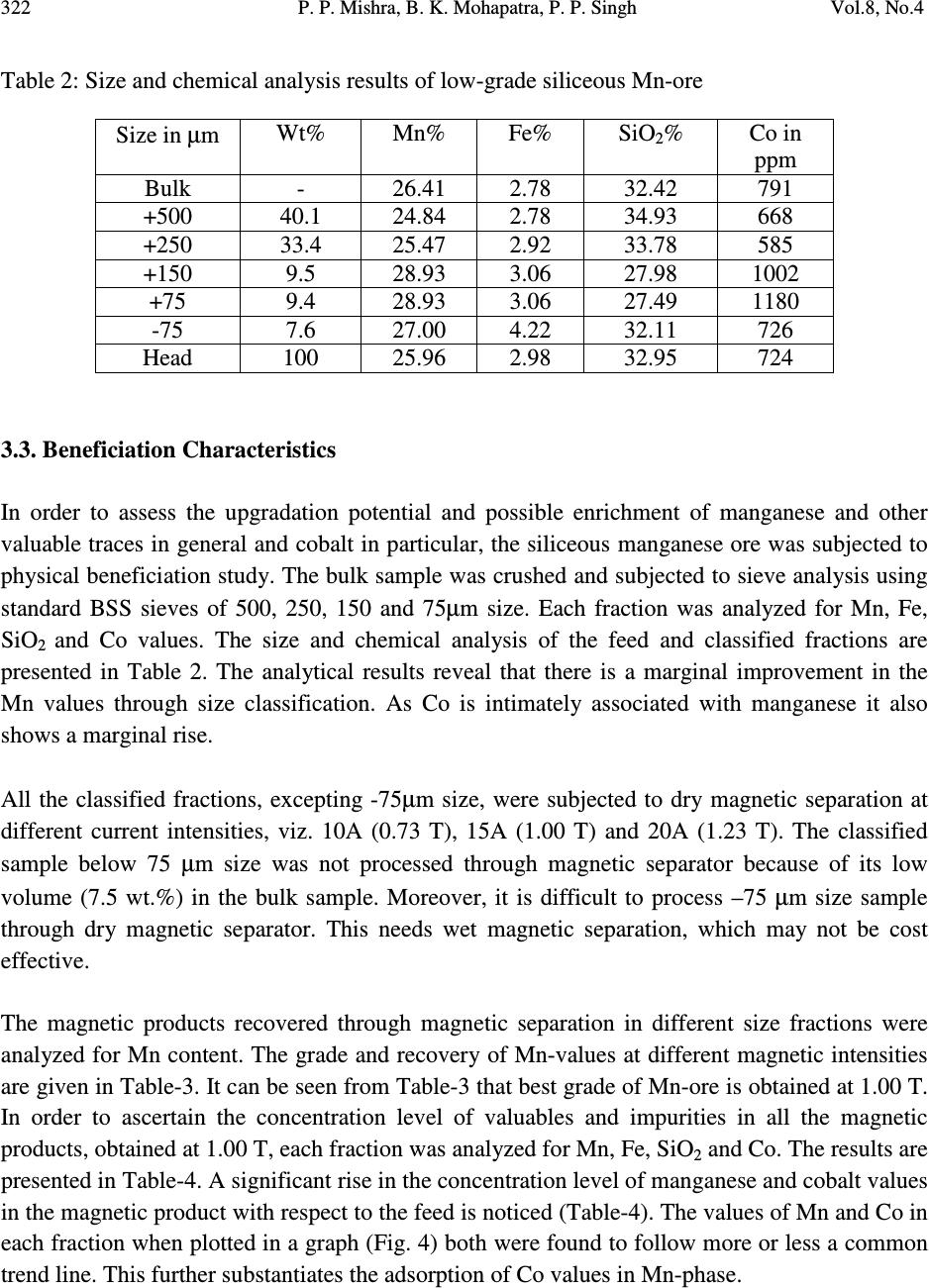

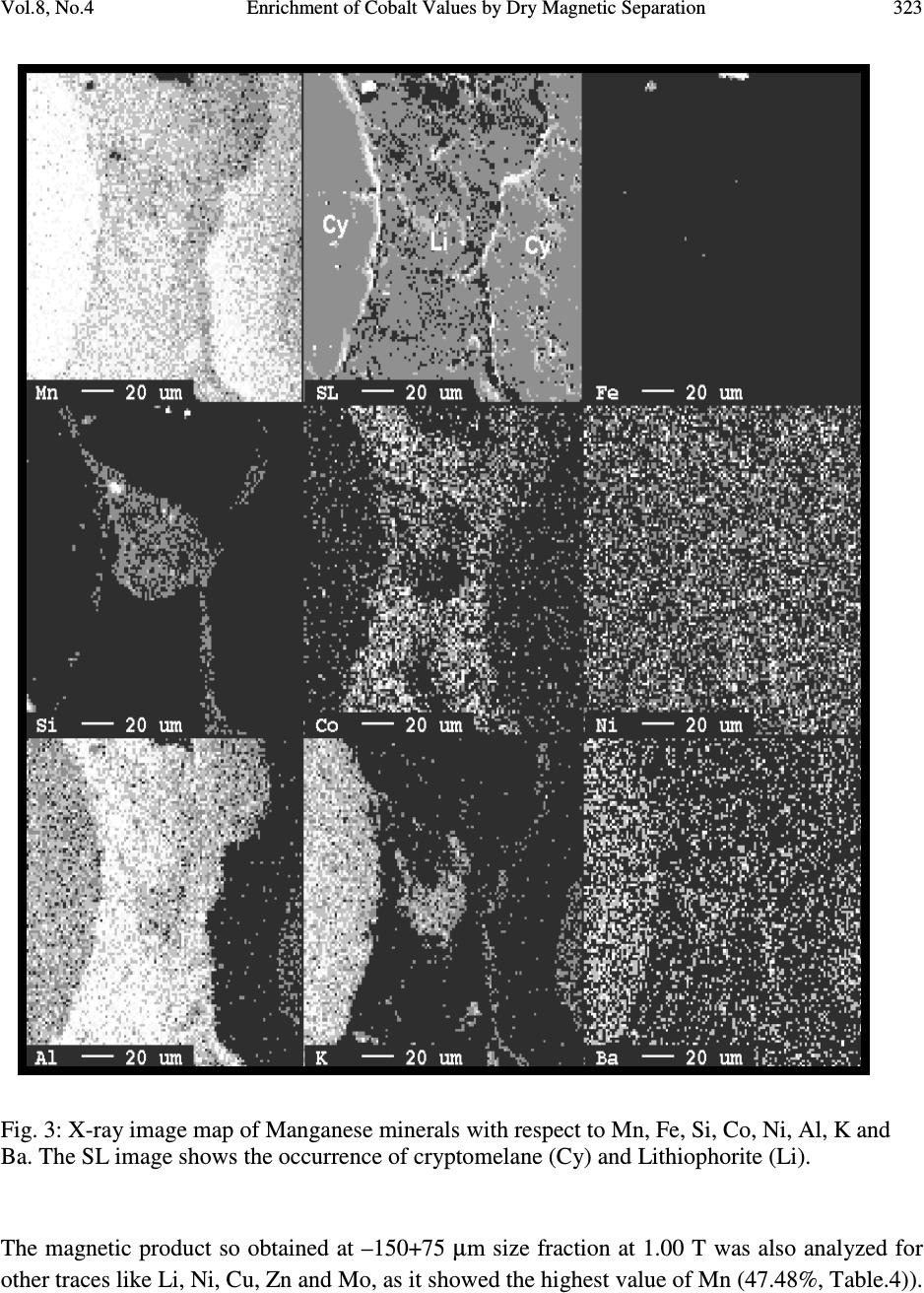

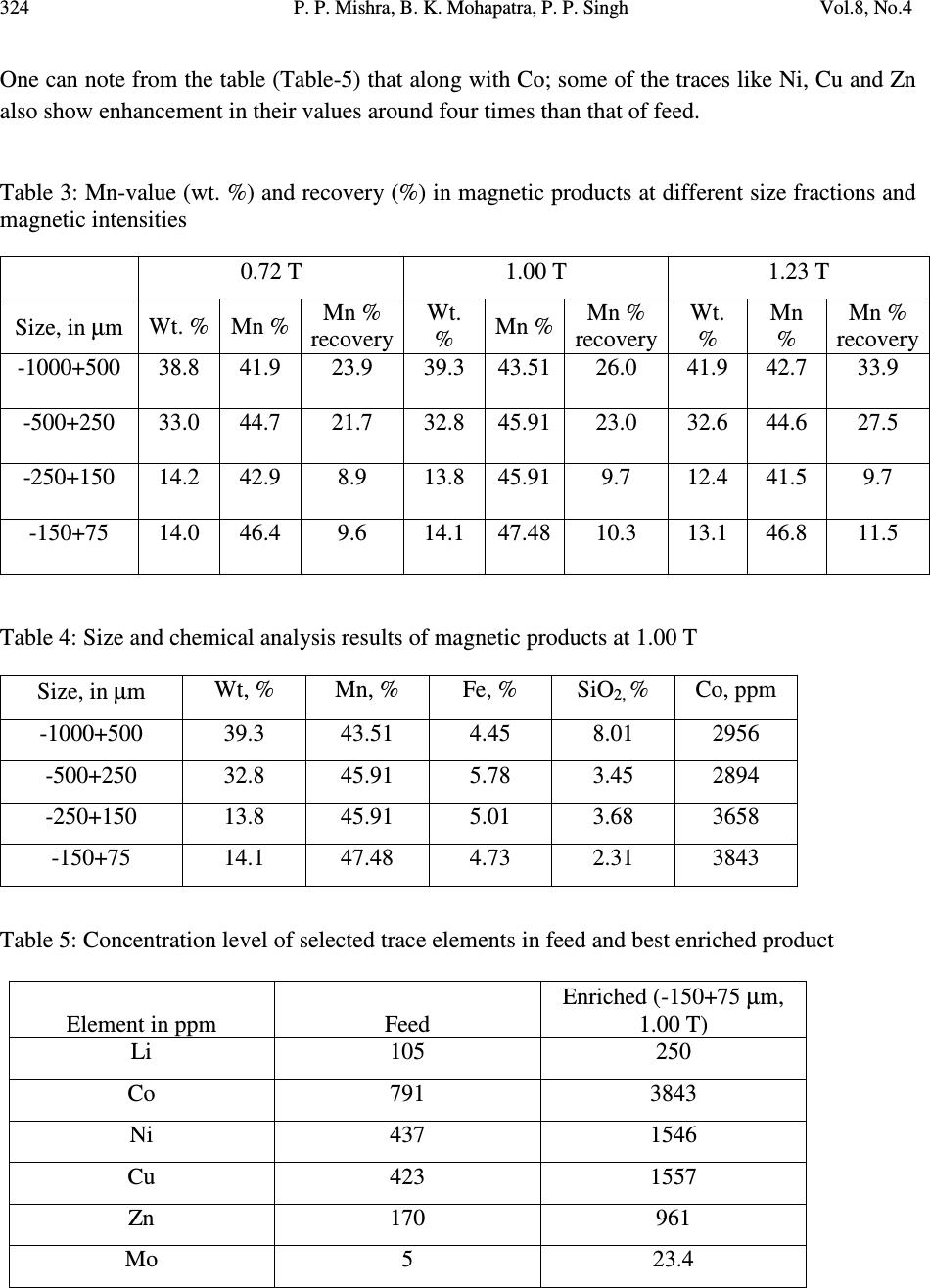

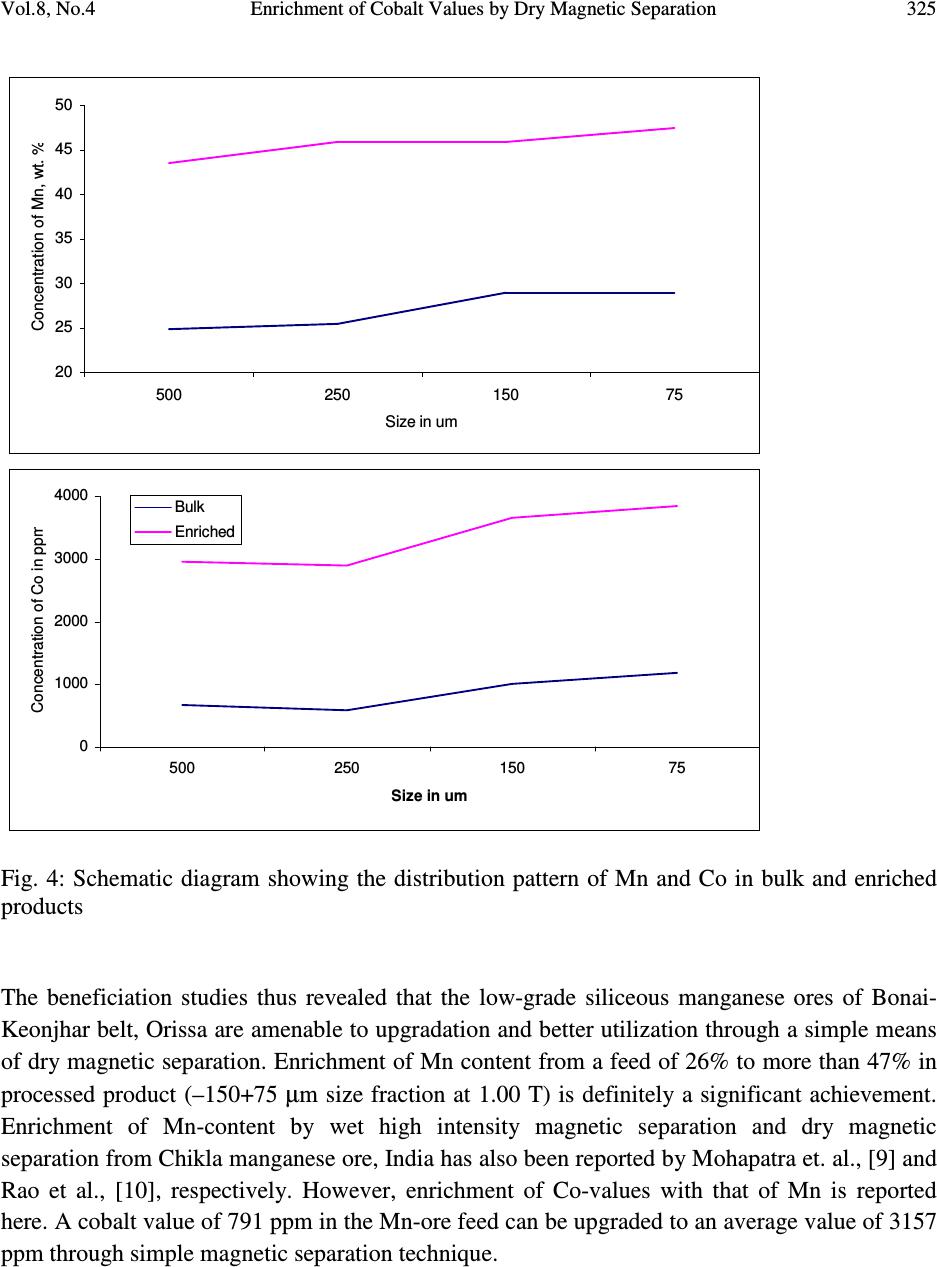

Journal of Minerals & Materials Characterization & Engineering, Vol. 8, No.4, pp 317-327, 2009 jmmce.org Printed in the USA. All rights reserved 317 Enrichment of Cobalt Values by Dry Magnetic Separation from Low-Grade Manganese Ores of Bonai-Keonjhar Belt, Orissa 1 P. P. Mishra, 1 B. K. Mohapatra*, 2 P. P. Singh 1 Regional Research Laboratory, Bhubaneswar, India 2 Utkal University, Bhubaneswar, India *Corresponding Author, contact: p_geology@yahoo.co.in, patitapaban@fastmail.fm ABSTRACT Resource potential of cobalt in India is practically negligible. Cobalt in marine manganese nodule though known since long, its report from terrestrial manganese ore is least observed. This paper reports the occurrence of cobalt in low-grade manganese ores of Bonai-Keonjhar belt, Orissa, eastern India and describes methods for its possible enrichment. Cobalt is associated with manganese minerals like lithiophorite (~CoO: 1.2%) and cryptomelane (~CoO: 0.2%). A feed of low-grade siliceous manganese ore containing 26% Mn and 32% SiO 2 and 0.08% Co was subjected to physical beneficiation. By processing the low-grade siliceous ore on a dry belt magnetic separator, a product with 47% Mn at 60% recovery could be obtained. It was observed that along with manganese the cobalt value gets enriched (~Co: 0.38%) more than four times in comparison to the feed. Some other traces like Ni, Cu, Zn, Ga, Li etc. also get enriched in the magnetic product. Thus, through simple dry magnetic separation a low-valued material cannot only be converted to usable product but two valuable metals can also be recovered from it. Key Words: Orissa Manganese ore, Magnetic separation, Cobalt. 1. INTRODUCTION Occurrence of cobalt in the ferromanganese nodules of present day marine basins has been studied in great detail over the last few decades by several workers all over the world [1-3]. However, only limited data is available on the distribution of cobalt in terrestrial manganese ores. Delian Fan et.al., [4] has reported the occurrence of Co in Mn-ores of Sichuan province of  318 P. P. Mishra, B. K. Mohapatra, P. P. Singh Vol.8, No.4 China. A worldwide review of Co-rich manganese deposits and techniques required for their development and mining has been suggested by Tetsuo [5]. During detailed investigation of the manganese ores of Bonai-Keonjhar belt of Orissa, India it was observed that the Mn-ores of this region contains appreciable quantity of trace elements in general and cobalt in particular. Cobalt in Mn-ores of this belt is found to be associated with manganese minerals like lithiophorite and cryptomelane. Presence of lithiophorite in Precambrian manganese deposits of Orissa was earlier recorded by Roy [6] and Mohapatra et.al. [7]. Cobalt in Mn-deposits from this belt was first reported by Mohapatra et al. [7]. There is no workable deposit of cobalt in India and it is considered as a strategic metal of defense importance. Cobalt is only won from the copper converter slag of different Cu-smelting plants in India. So the Co-values in Mn-ores of this belt need to be characterized and recovered. This paper reports the presence of cobalt in Bonai-Keonjhar belt, their characterization and enrichment so as to recover two valuable metals from a low-grade siliceous manganese ore of Orissa. 2. MATERIALS AND METHODS Representative samples, mostly of oolitic/nodular and spongy varieties were collected from low- grade siliceous manganese ore deposits like Shankar, Bhoot, and Spencer from Bonai-Keonjhar belt. These were subjected to optical microscopy (Leitz make Orthoplan at RRL), XRD (Phillips Diffractometer, PW-1710 at RRL) and Electron Probe Microanalyser (EPMA, JEOL make JXA 8600 Super probe, at USIC Roorkee). For beneficiation of manganese ore, high intensity dry belt magnetic separator of type LOG 1.4 SEP operated at 50 Dc Volt and 4.17 Dc A current, suitable for fine particle separation, (supplied by Boxmag Rapid Ltd., Birmingham, England) was employed. The magnetic intensity was varied between 0.73 and 1.23 T. Dry samples of closed size fractions were continuously fed to the belt magnetic separator by vibrating feeder at controlled rate. Magnetic products were separated by moving disc at required speed and intensity. Based on the requirement the intensity, feed rate, and gap between the belt and disc in the magnetic separator were varied. Selective elements like Mn, Fe and SiO 2 were analyzed by XRF Spectrometry on Philips (PW-1400) X-ray spectrometer with scandium and Rhodium targets using Pentaerythritol (Al, Si), Thallium Acid Pathalate (Na, Mg), Germanium (P) and Lithium Fluoride (LIF, for heavier elements) as analyzing crystals in vacuum medium. The trace elements were analyzed at NGRI, Hyderabad, India using Inductively Coupled Plasma-Mass Spectrometer (ICP-MS). The ICP-MS used was a Plasma Quad PQ1 controlled by an IBM PC- XT microcomputer and associated software. Standard acid dissolution procedure was adopted for sample preparation as prescribed by Balaram, et. al. [8]. Both in-house and international ore standards of different chemical composition (NNODA-1, MNODP-1 etc.) were analyzed along with the sample for precision.  Vol.8, No.4 Enrichment of Cobalt Values by Dry Magnetic Separation 319 3. RESULTS AND INTERPREATION 3.1. Mineralogical Characteristics X-ray diffraction and optical microscopic studies are exclusively employed for mineralogical characterization of Mn-ores. X-ray diffraction pattern of Mn-ore clearly reveals the presence of lithiophorite as a major manganese mineral in oolitic/nodular and spongy types of ore (Fig. 1). Other minerals present include pyrolusite (Mn-phase) and quartz (gangue mineral). Presence of cryptomelane (Mn-phase) is also recorded in some sample. Fig. 1: X-ray diffraction pattern of feed and enriched products of low-grade siliceous Mn-ore Lithiophorite and cryptomelane were found to contain Co values as brought out through EPMA study (Table-1). Hence, detailed characteristics of these phases were further studied under optical microscope. Lithiophorite exhibits a well-developed bireflection, from pearly gray to brownish gray and strong anisotropism, making crystallites appear black and white under crossed polar (Fig.2). The mineral has lowest VHN values (40-60) amongst its co-existing phases. The lithiophorite exhibits mamillary growth with undulose segmented twinning (Fig.2A). Lithiophorite mosaics show different reflection (Fig. 2B). Occasionally, it is thinly banded where coarse radiating crystals are arranged in zig-saw pattern (Fig. 2C). It often occurs as dense masses of micron-sized acicular to pea shaped crystallites (Fig. 2D). It also occurs as polyhedral mosaic grains (Fig. 2E) along the periphery of vugs (Fig. 2 E & F). Other associated Mn- minerals include cryptomelane and pyrolusite. The former exhibits colloform banding while later occurs as large prismatic crystals to tiny needle shaped acicular grains. Hematite, quartz/illite form iron and gangue minerals respectively.  320 P. P. Mishra, B. K. Mohapatra, P. P. Singh Vol.8, No.4 Table 1: Composition of Lithiophorite and Cryptomelane phases in low-grade siliceous Mn-ore, as obtained through EPMA. 1 2 3 4 5 6 7 8 9 SiO 2 0.00 0.00 0.082 0.061 0.885 1.352 0.131 0.00 1.167 Al 2 O 3 4.018 1.005 3.845 0.716 24.956 26.048 25.497 22.257 21.823 FeO 0.098 0.161 0.118 0.076 0.16 0.095 0.176 0.364 0.176 MgO 0.00 0.00 0.00 0.00 0.218 0.00 0.134 0.108 0.172 MnO 2 69.03 82.43 81.07 75.39 50.675 49.74 53.126 45.529 43.319 CaO 0.041 0.055 0.104 0.086 0.00 0.009 0.00 0.003 0.023 K 2 O 2.063 3.73 3.348 3.12 0.00 0.002 0.00 0.048 0.334 Na 2 O 0.06 0.292 0.234 0.00 0.063 0.00 0.00 0.005 0.00 TiO 2 0.182 0.099 0.00 0.017 0.021 0.019 0.009 0.00 0.00 P 2 O 5 0.03 0.017 0.06 0.00 0.004 0.006 0.00 0.035 0.004 NiO 0.177 0.00 0.00 0.00 0.132 0.057 0.022 0.127 1.494 CoO 0.211 0.18 0.12 0.14 0.809 0.822 0.706 1.603 2.012 BaO 1.263 0.075 0.501 0.33 0.00 0.00 0.00 0.00 0.029 H 2 O © 22.83 12.036 10.56 20.114 22.075 21.847 20.199 29.922 29.258 1 to 4: Cryptomelane, 5 to 9: Lithiophorite. ©:Calculated value 3.2. Chemical Characteristics The bulk sample of the siliceous manganese ore contains 26.4% Mn, 2.78% Fe and more than 32% SiO 2 (Table 2). Such low-grade manganese ore sample contains appreciable Co values ranging from 691 ppm to 1002 ppm (avg. 791 ppm) in the bulk sample. The EPMA results shown in Table 1 distinctly indicate that both lithiophorite and cryptomelane are Co-bearing. However, the lithiophorite mostly shows higher Co value than cryptomelane. Besides Co value, lithiophorite also contains appreciable Ni in its lattice. The X-ray image maps of Mn, Fe, Al, Si, Co, Ni, K and Ba elements in selected location (SL) occupied by lithiophorite and cryptomelane show the former phase to be rich in Co-concentration (Fig. 3).  Vol.8, No.4 Enrichment of Cobalt Values by Dry Magnetic Separation 321 Fig 2: Photomicrograph of lithiophorite mineral showing different microstructures x200 (A) Mamillary growth of lithiphorite showing undulose segmented twinning (B) Lithiophorite mosaics showing different reflection and traversed by a cryptomelane veinlet. (C) Thinly banded, coarse grained, lithiphorite (bottom) showing zig-saw pattern. Alternate bands at the top are that of cryptomelane (white) and quartz/clay (black) D) Acicular aggregates of lithiophorite (E) Prismatic growth of lithiophorite encrusting a vug. (F) Mosaic of polyhedral crystallites of lithiophorite lining a vug. A D B E F C  322 P. P. Mishra, B. K. Mohapatra, P. P. Singh Vol.8, No.4 Table 2: Size and chemical analysis results of low-grade siliceous Mn-ore Size in µ m Wt% Mn% Fe% SiO 2 % Co in ppm Bulk - 26.41 2.78 32.42 791 +500 40.1 24.84 2.78 34.93 668 +250 33.4 25.47 2.92 33.78 585 +150 9.5 28.93 3.06 27.98 1002 +75 9.4 28.93 3.06 27.49 1180 -75 7.6 27.00 4.22 32.11 726 Head 100 25.96 2.98 32.95 724 3.3. Beneficiation Characteristics In order to assess the upgradation potential and possible enrichment of manganese and other valuable traces in general and cobalt in particular, the siliceous manganese ore was subjected to physical beneficiation study. The bulk sample was crushed and subjected to sieve analysis using standard BSS sieves of 500, 250, 150 and 75µm size. Each fraction was analyzed for Mn, Fe, SiO 2 and Co values. The size and chemical analysis of the feed and classified fractions are presented in Table 2. The analytical results reveal that there is a marginal improvement in the Mn values through size classification. As Co is intimately associated with manganese it also shows a marginal rise. All the classified fractions, excepting -75µm size, were subjected to dry magnetic separation at different current intensities, viz. 10A (0.73 T), 15A (1.00 T) and 20A (1.23 T). The classified sample below 75 µm size was not processed through magnetic separator because of its low volume (7.5 wt.%) in the bulk sample. Moreover, it is difficult to process –75 µm size sample through dry magnetic separator. This needs wet magnetic separation, which may not be cost effective. The magnetic products recovered through magnetic separation in different size fractions were analyzed for Mn content. The grade and recovery of Mn-values at different magnetic intensities are given in Table-3. It can be seen from Table-3 that best grade of Mn-ore is obtained at 1.00 T. In order to ascertain the concentration level of valuables and impurities in all the magnetic products, obtained at 1.00 T, each fraction was analyzed for Mn, Fe, SiO 2 and Co. The results are presented in Table-4. A significant rise in the concentration level of manganese and cobalt values in the magnetic product with respect to the feed is noticed (Table-4). The values of Mn and Co in each fraction when plotted in a graph (Fig. 4) both were found to follow more or less a common trend line. This further substantiates the adsorption of Co values in Mn-phase.  Vol.8, No.4 Enrichment of Cobalt Values by Dry Magnetic Separation 323 Fig. 3: X-ray image map of Manganese minerals with respect to Mn, Fe, Si, Co, Ni, Al, K and Ba. The SL image shows the occurrence of cryptomelane (Cy) and Lithiophorite (Li). The magnetic product so obtained at –150+75 µm size fraction at 1.00 T was also analyzed for other traces like Li, Ni, Cu, Zn and Mo, as it showed the highest value of Mn (47.48%, Table.4)).  324 P. P. Mishra, B. K. Mohapatra, P. P. Singh Vol.8, No.4 One can note from the table (Table-5) that along with Co; some of the traces like Ni, Cu and Zn also show enhancement in their values around four times than that of feed. Table 3: Mn-value (wt. %) and recovery (%) in magnetic products at different size fractions and magnetic intensities 0.72 T 1.00 T 1.23 T Size, in µm Wt. % Mn % Mn % recovery Wt. % Mn % Mn % recovery Wt. % Mn % Mn % recovery -1000+500 38.8 41.9 23.9 39.3 43.51 26.0 41.9 42.7 33.9 -500+250 33.0 44.7 21.7 32.8 45.91 23.0 32.6 44.6 27.5 -250+150 14.2 42.9 8.9 13.8 45.91 9.7 12.4 41.5 9.7 -150+75 14.0 46.4 9.6 14.1 47.48 10.3 13.1 46.8 11.5 Table 4: Size and chemical analysis results of magnetic products at 1.00 T Size, in µ m Wt, % Mn, % Fe, % SiO 2, % Co, ppm -1000+500 39.3 43.51 4.45 8.01 2956 -500+250 32.8 45.91 5.78 3.45 2894 -250+150 13.8 45.91 5.01 3.68 3658 -150+75 14.1 47.48 4.73 2.31 3843 Table 5: Concentration level of selected trace elements in feed and best enriched product Element in ppm Feed Enriched (-150+75 µ m, 1.00 T) Li 105 250 Co 791 3843 Ni 437 1546 Cu 423 1557 Zn 170 961 Mo 5 23.4  Vol.8, No.4 Enrichment of Cobalt Values by Dry Magnetic Separation 325 20 25 30 35 40 45 50 500 250 15075 Size in um Concentration of Mn, wt. % 0 1000 2000 3000 4000 500 250 15075 Size in um Concentration of Co in ppm Bulk Enriched Fig. 4: Schematic diagram showing the distribution pattern of Mn and Co in bulk and enriched products The beneficiation studies thus revealed that the low-grade siliceous manganese ores of Bonai- Keonjhar belt, Orissa are amenable to upgradation and better utilization through a simple means of dry magnetic separation. Enrichment of Mn content from a feed of 26% to more than 47% in processed product (–150+75 µm size fraction at 1.00 T) is definitely a significant achievement. Enrichment of Mn-content by wet high intensity magnetic separation and dry magnetic separation from Chikla manganese ore, India has also been reported by Mohapatra et. al., [9] and Rao et al., [10], respectively. However, enrichment of Co-values with that of Mn is reported here. A cobalt value of 791 ppm in the Mn-ore feed can be upgraded to an average value of 3157 ppm through simple magnetic separation technique.  326 P. P. Mishra, B. K. Mohapatra, P. P. Singh Vol.8, No.4 4. DISCUSSION Mineralogical and geochemical characterization of low-grade siliceous manganese ores from Bonai-Keonjhar belt indicated that lithiophorite is the dominant Mn-mineral and quartz is the major gangue. The electron probe microanalysis and X-ray image map of different elements in such an ore clearly reveal that the lithiophorite is cobalt bearing i.e. Co is present in adsorbed state within Mn-phase. The manganese minerals are para-magnetic in nature while quartz is non- magnetic. So the undesired non-magnetic quartz can easily be separated from magnetic manganese phase by simple physical separation process (dry magnetic separation). Thus the trace elements in general and Co in particular present in the lattices of Mn-minerals are upgraded automatically along with the Mn-values. A four-fold increase in the cobalt and other trace values (Ni, Cu & Zn) has been recorded in the enriched product with respect to the feed sample. Following the above simple flow sheet, the low-grade manganese ore (26% Mn), which has negligible market value, can be upgraded to a valuable product (>47% Mn). Co enrichment further adds to the value. Methods have been developed to recover Co and Ni metals associated with marine manganese nodules [11-13] by different leaching processes. Applicability of this method to the Orissa manganese ores needs to be studied. If 50, 000 tonnes of manganese ores with 0.5% of cobalt on an average is smelted electrically, about 250 tonnes of cobalt will be obtained. In view of advantage of recovering Co as a by-product with electro-manganese and the availability of substantial resources of low-grade siliceous manganese ores in Orissa, the feasibility of conversion of a part of manganese ore from this part of India deserves further detail study. 5. CONCLUSION The occurrence of Co with lithiophorite phase in the low-grade siliceous manganese ores of Bonai-Keonjhar belt and their amenability to upgradation through dry magnetic separation is reported. A low-grade siliceous ore containing 26% Mn and 791 ppm Co can be enriched up to a product of 47% Mn and 3843 ppm Co with 69% recovery. Thus a waste can be converted to a wealth at very low cost and minimum unit operations. Sincere efforts are needed to recover these two valuable metals by suitable extractive metallurgical methods like chemical, bio-chemical, biological, electro-metallurgical and hydro-metallurgical process routes. ACKNOWLEDGEMENT The authors are highly thankful to the Director, Institute of Minerals and Materials Technology, Bhubaneswar for his kind permission to publish this paper. Thanks are due to Mr. P.S.R. Reddy, Sct. G for his critical review of the manuscript and Dr. S. Prakash, Sr. Sct. for his assistance in magnetic separation work. The authors are also thankful to the Department of Science &  Vol.8, No.4 Enrichment of Cobalt Values by Dry Magnetic Separation 327 Technology, New Delhi, India for their financial support in the form of a project (ESS/23/VES/043/99). REFERENC ES [1] Glasby, G. P., 1975, “Minor element enrichment in manganese nodules relative to sea-water and marine sediment.” Nature wissenschaften, Vol. 65, pp. 133-135. [2] Glasby, G. P., Keays, R. R., and Rankin, P. C., 1978, “The distribution of rare earth, precious metal and other trace elements in recent and fossil deep sea manganese nodules.” Geochem. J., Vol. 12, pp. 229-248. [3] Mohapatra, B. K. and Sahoo. R. K., 1999, “Characterisation of marine ferromanganese concretions.” Metals Materials and Processes, Vol. 11, pp. 101-116. [4] Delian Fan, Hein James R., and Ye Jie, 1999, “Ordovician reef hosted Jiaodingshan Mn-Co deposit and Dawashan Mn deposit, Sichuan Province, China.” Ore Geology Review, Vol. 15, pp. 135-151. [5] Tetsuo, Yamazaki, 1999, “Cobalt rich Mn deposit and techniques required for the development.” Kagaku Kogyo, Vol. 50, pp. 372-378. [6] Roy, S., 1981, Manganese deposits, Academy Press, London, pp. 451. [7] Mohapatra, B. K., Paul, A. K. and Sahoo, R. K., 1989, “Characterisation of manganese ores of a part of Western Koira valley, Keonjhar Dist., Orissa.” Journal of Geological Society of India, Vol. 34, pp. 632-646. [8] Balaram, V., Manikyamba, C., Ramesh, S. L., and Saxena, V. C., 1989, “Determination of rare earth elements in Japanese rock standards by Inductively Coupled Plasma Mass Spectrometry.” Atomic Spectroscopy, Vol. 2, pp. 19-23. [9] Mohapatra, B. K; Rao, D. S. and Sahoo, R. K, 1995, “Characterisation and magnetic separation studies of Chikla manganese ores, Maharastra.” Ind. Min. Eng. J., July, pp. 37-41. [10] Rao, G. V; Mohapatra, B. K and Tripathy, A. K., 1998, “Enrichment of the manganese content by wet high intensity magnetic separation from chikla manganese ore, India.” Magnetic and Electrical Separation, Vol. 9, pp. 69-82. [11] Mohanty, P. S.; Ghosh, M. K.; Anand, S. and Das, R. P., 1994, “Leaching of manganese nodules in ammoniacal medium with elemental sulphur as reductant.” Trans. Instn. Min. Met., Sec. C, Vol. 143, pp. 151-155. [12] Devi. N. B.; Nathsarma, K. C. and Chakraborty, V., 1998, “Separation of cobalt (II) and nickel (II) from sulphate solutions using sodium salts of D2EHPA, PC88A and Cyanex 272.” Hydrometallurgy, Vol. 49, pp. 47-61. [13] Devi. N. B.; Nathsarma, K. C. and Chakraborty, V., 2000, “Separation of divalent manganese and cobalt ions from sulphate solutions using sodium salts of D2EHPA, PC88A and Cyanex 272.” Hydrometallurgy, Vol. 54, pp. 117-131. |