Paper Menu >>

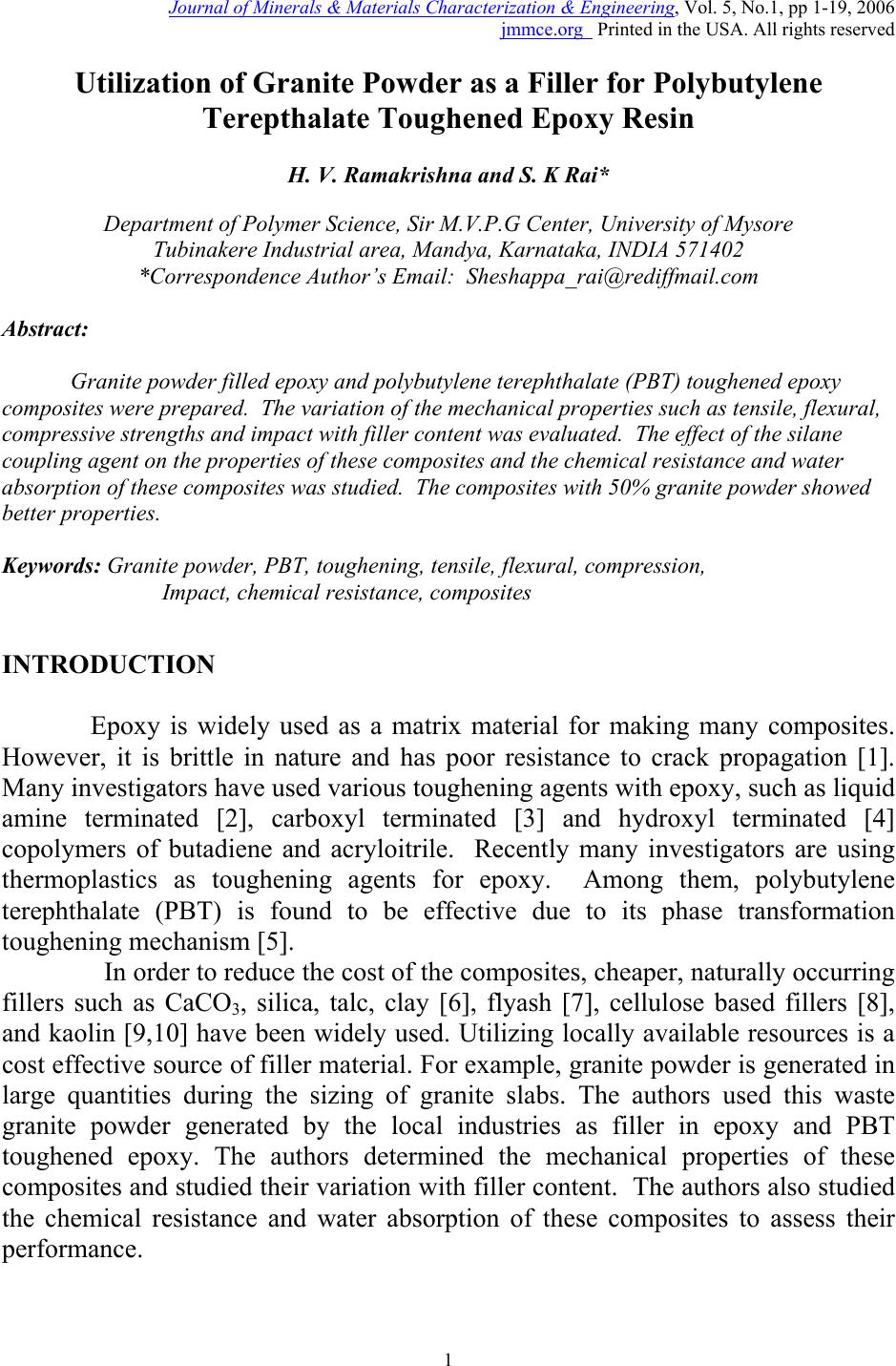

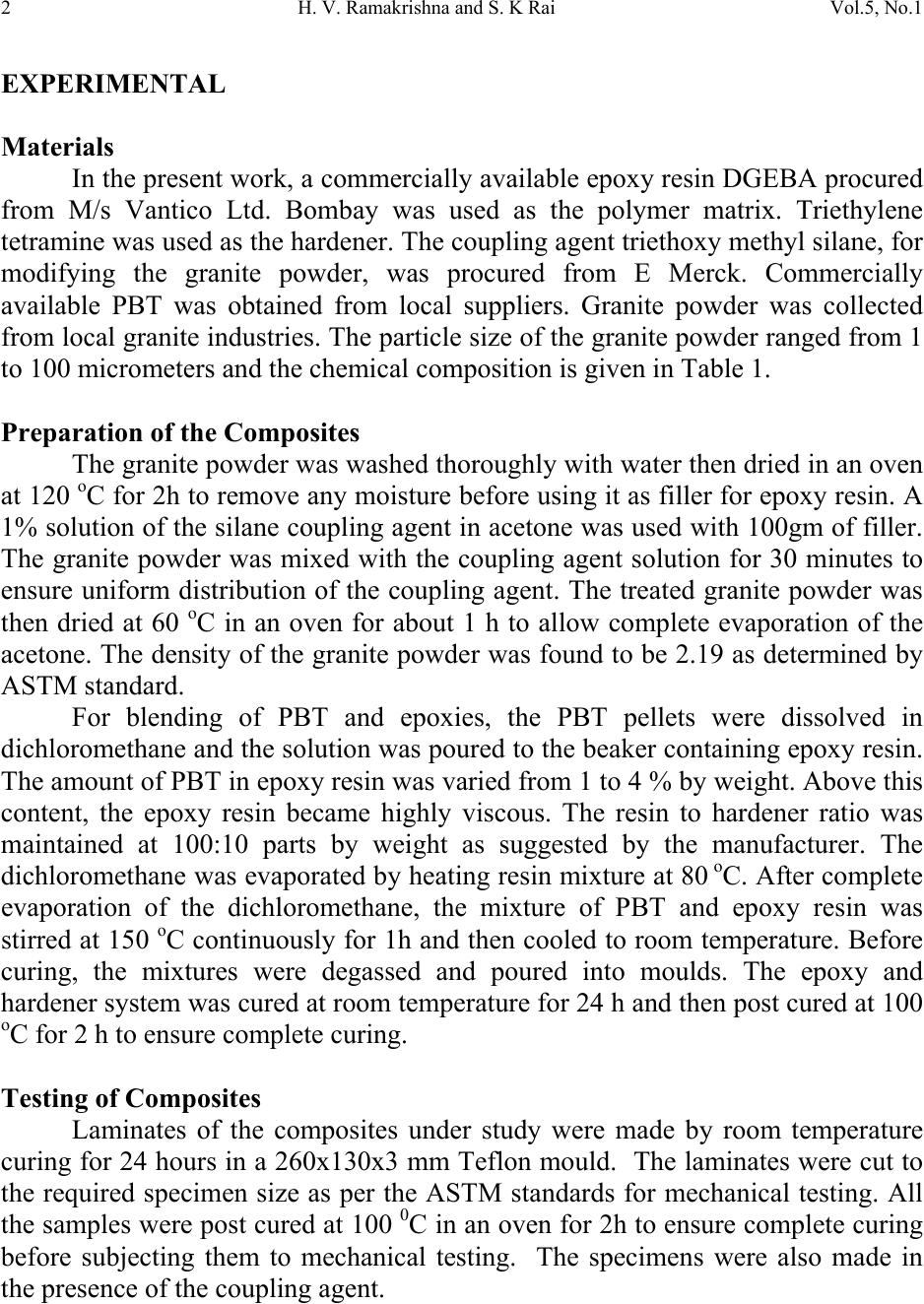

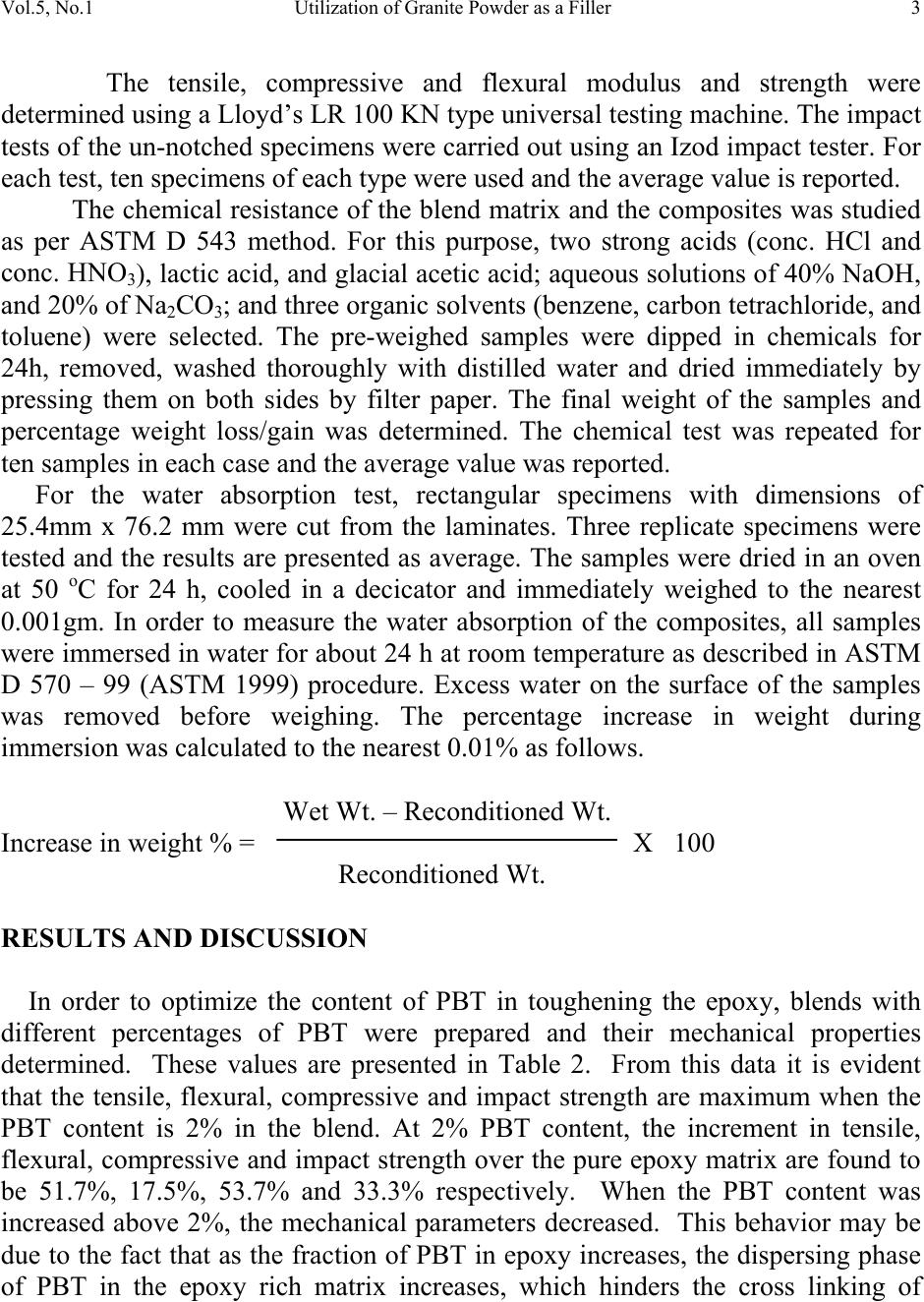

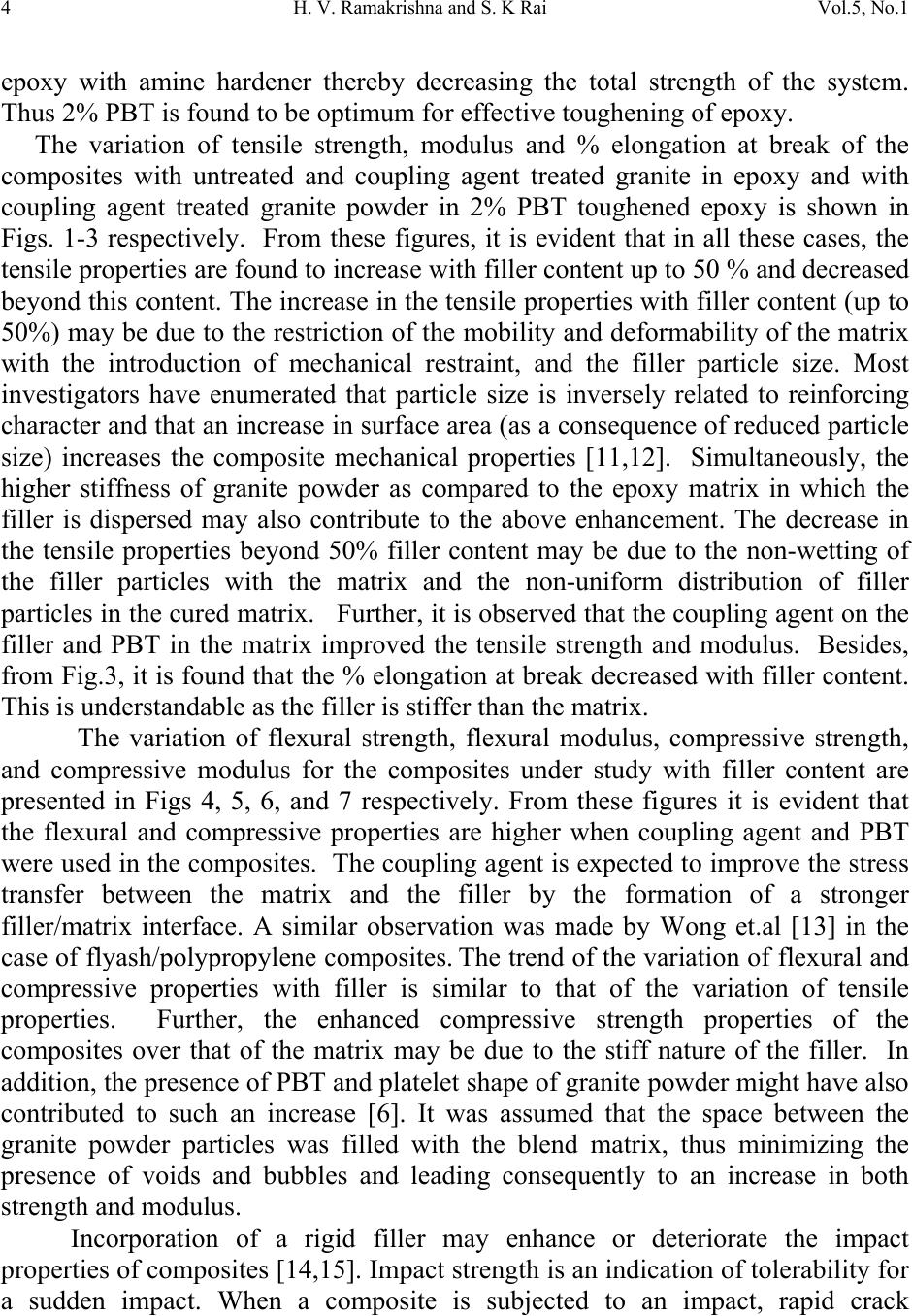

Journal Menu >>

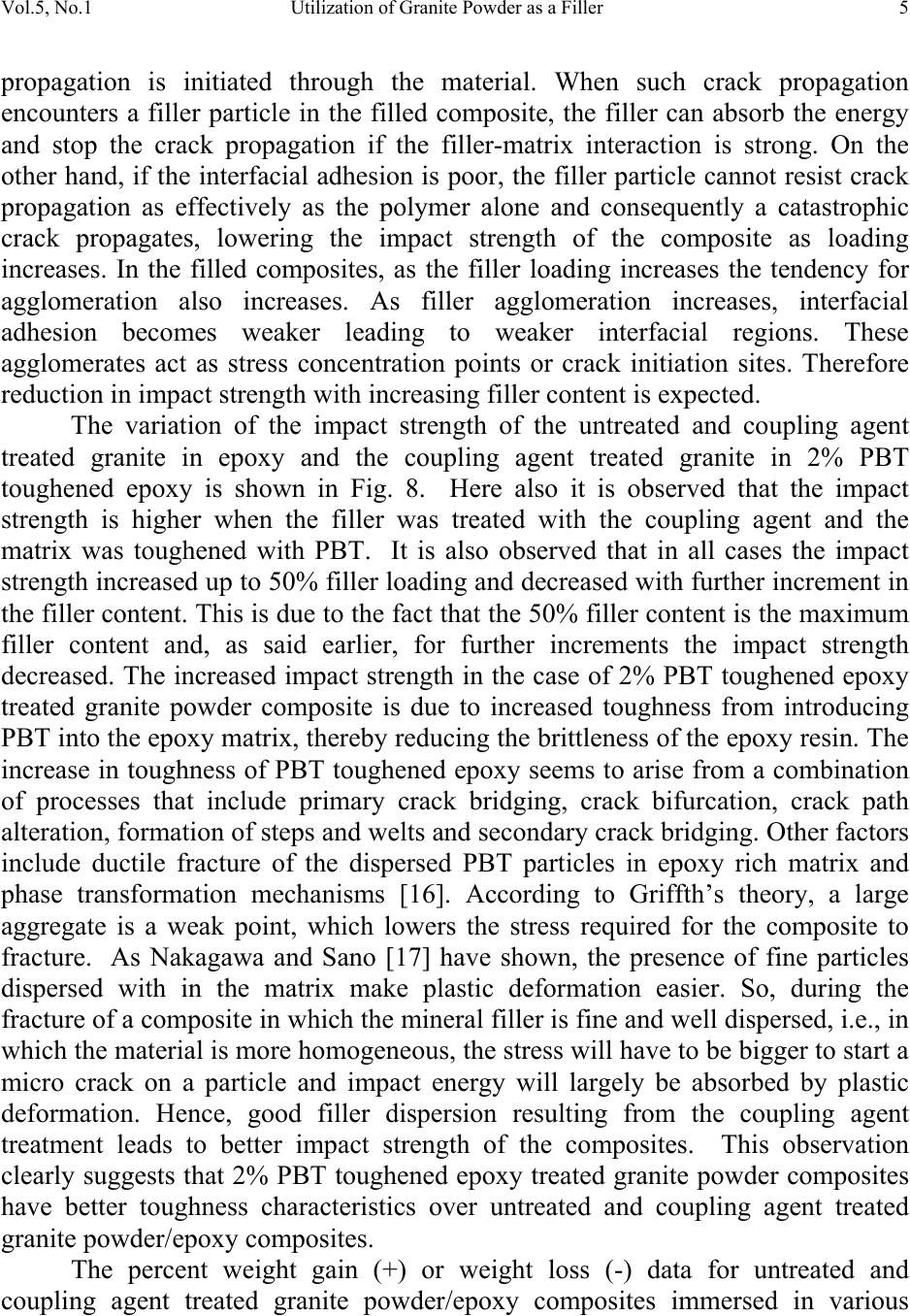

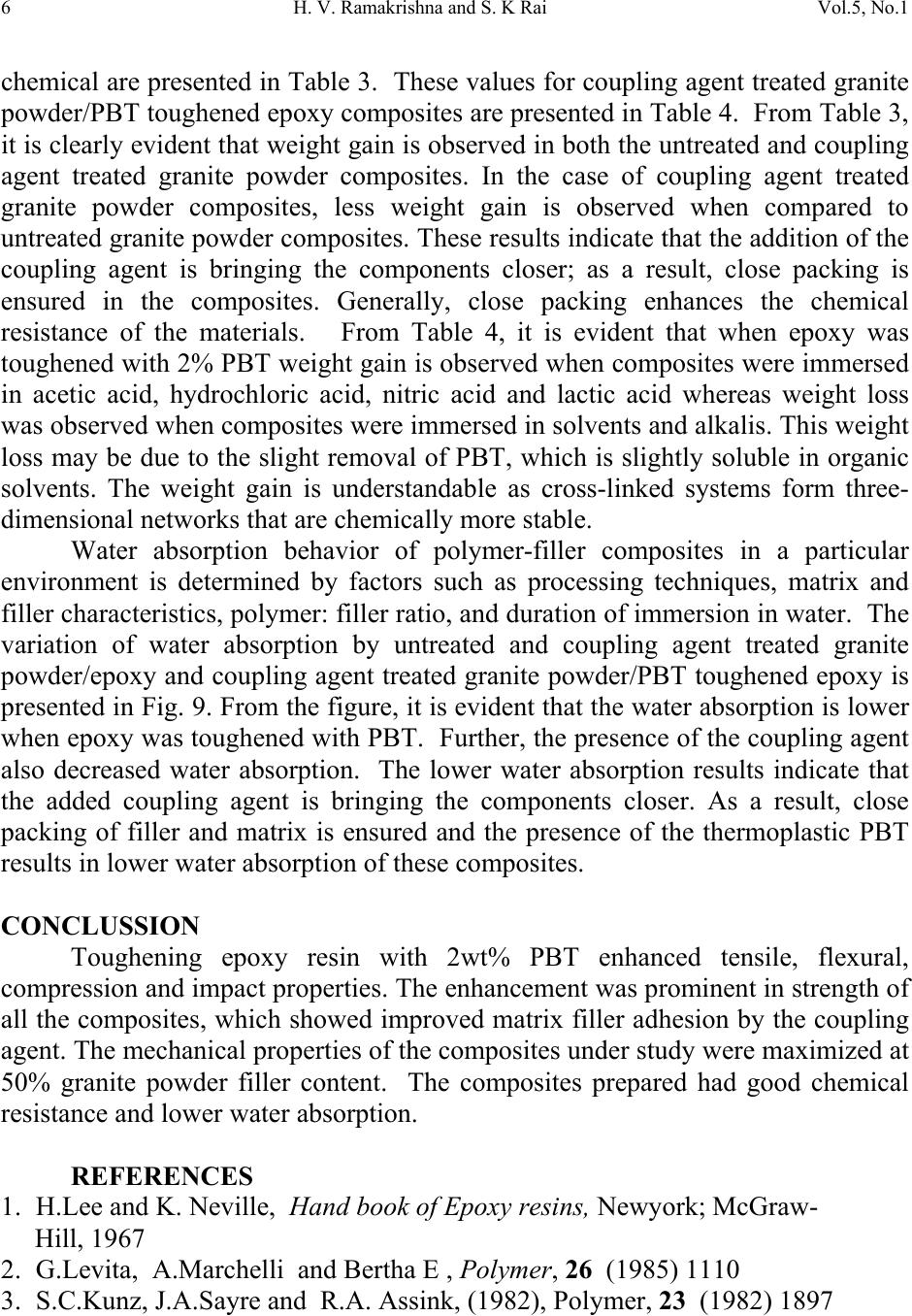

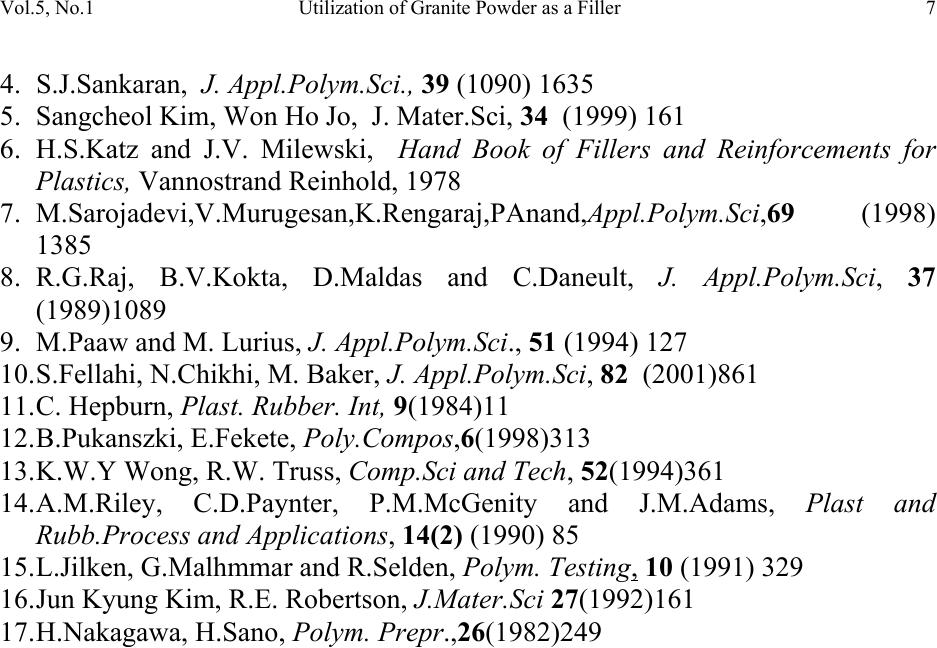

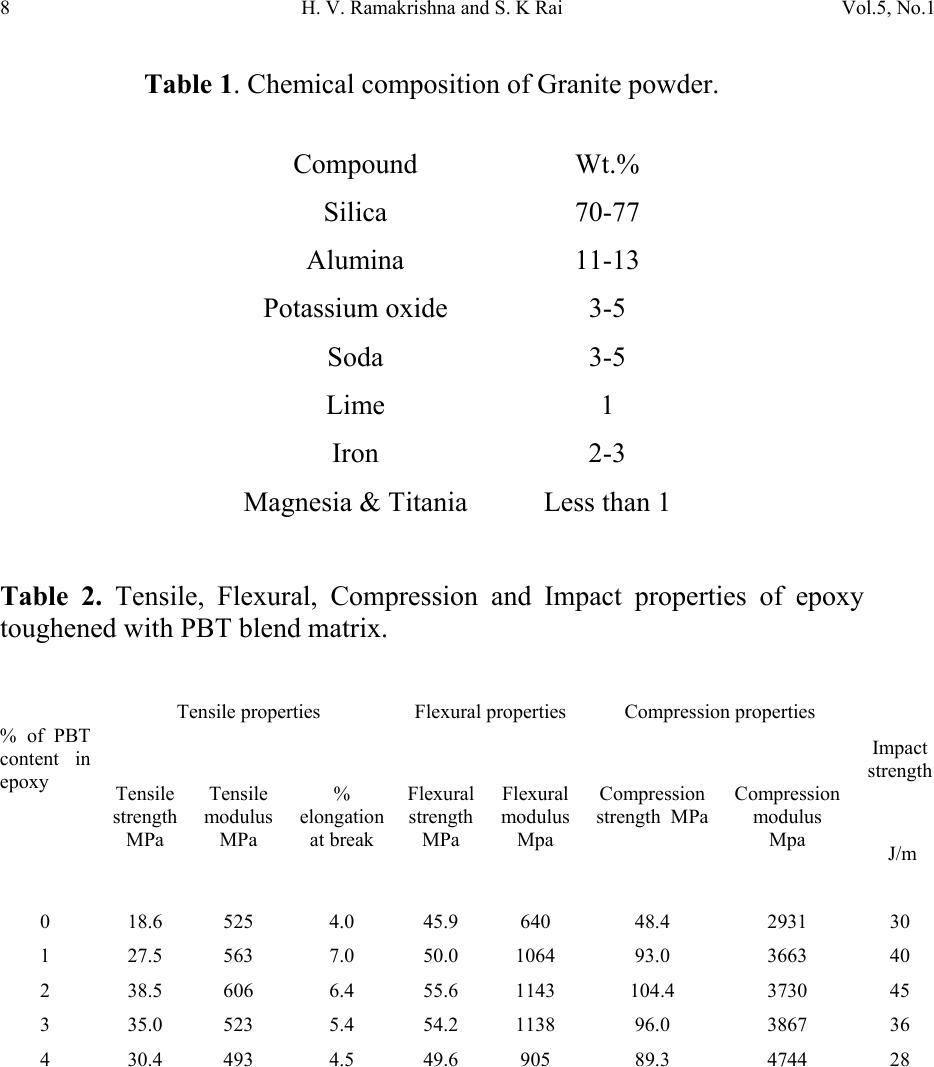

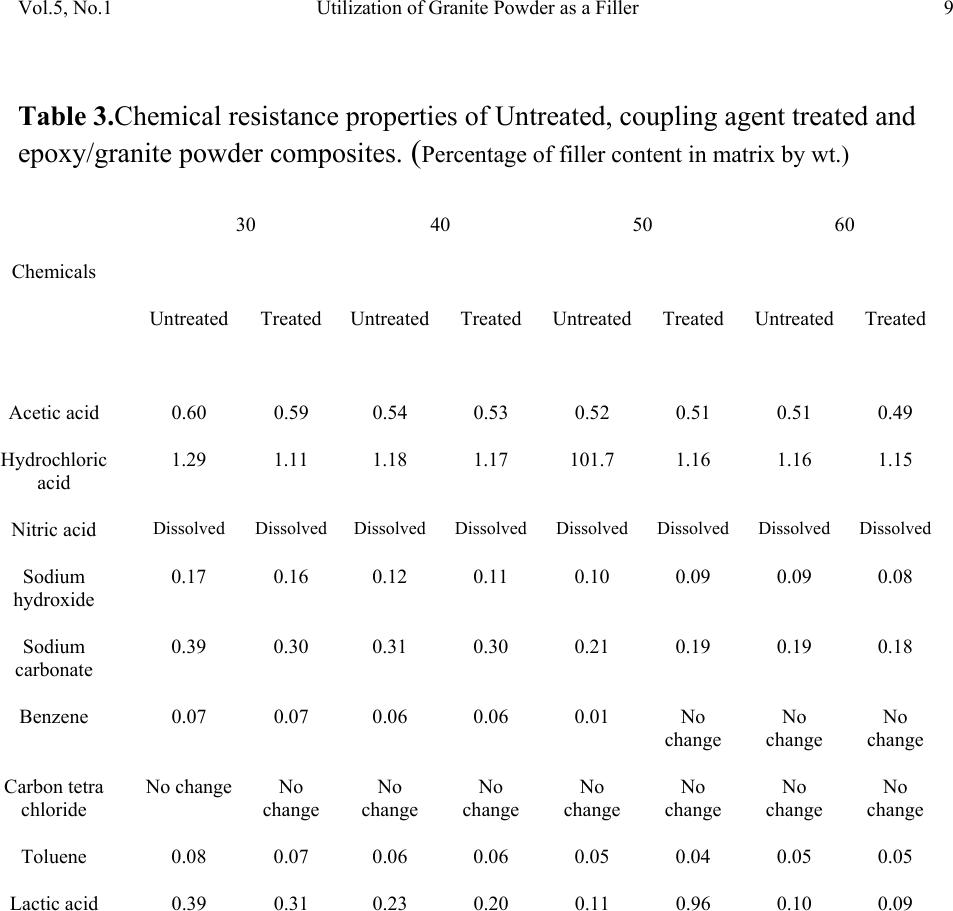

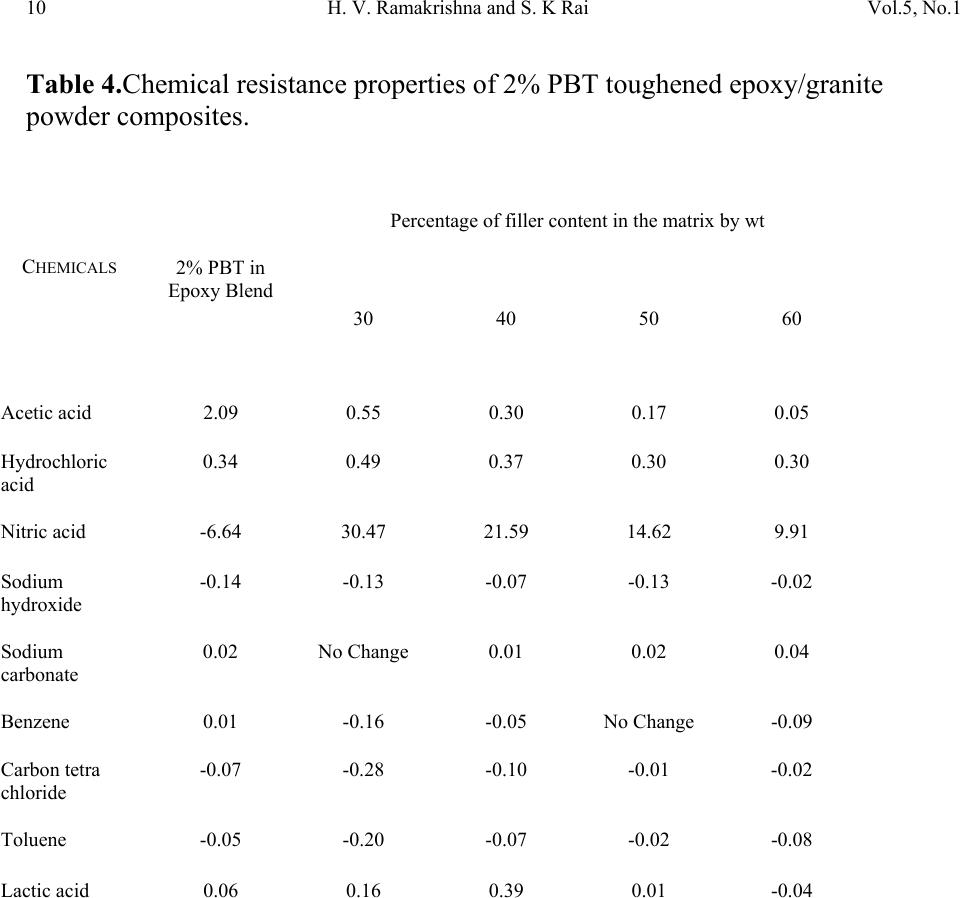

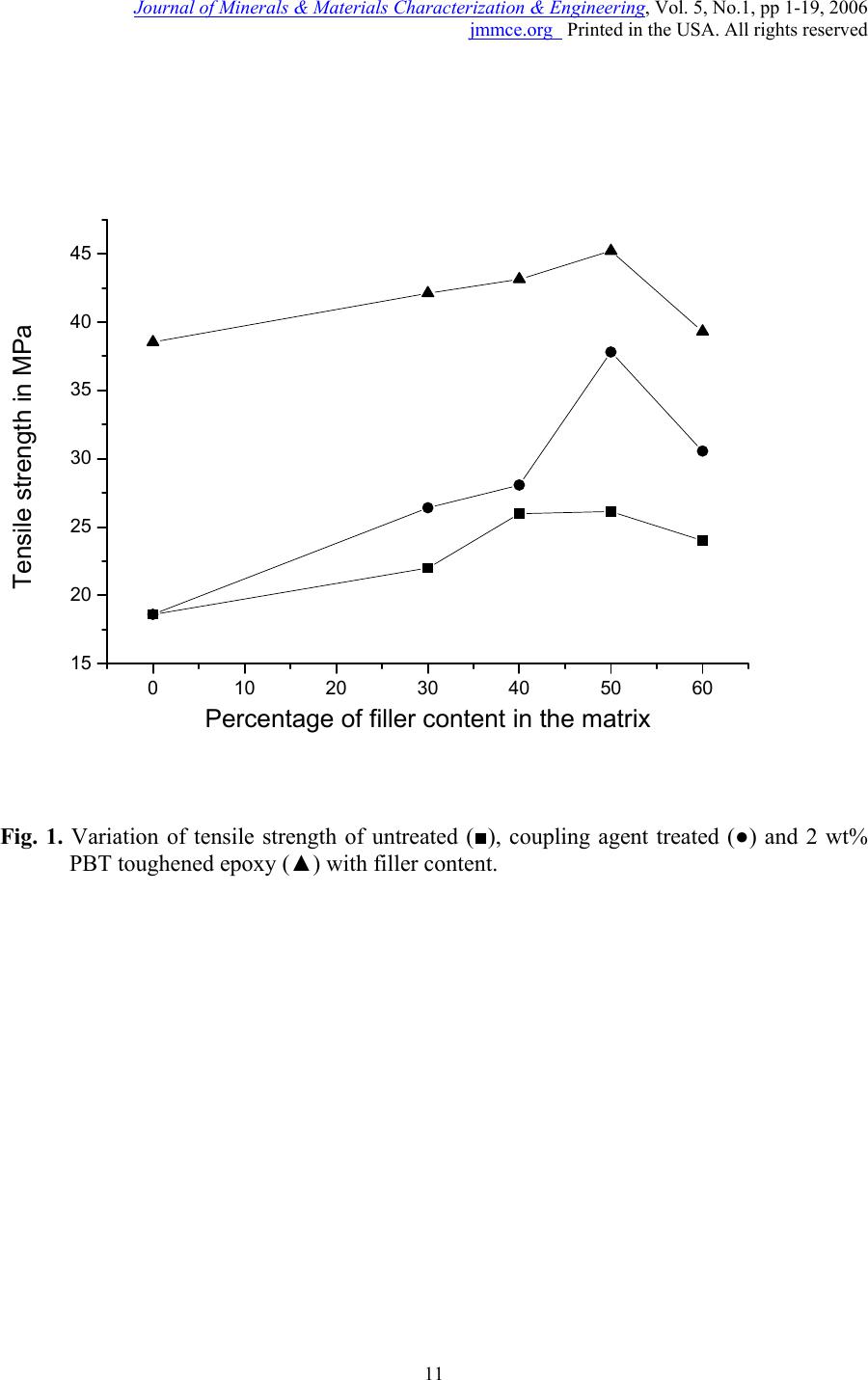

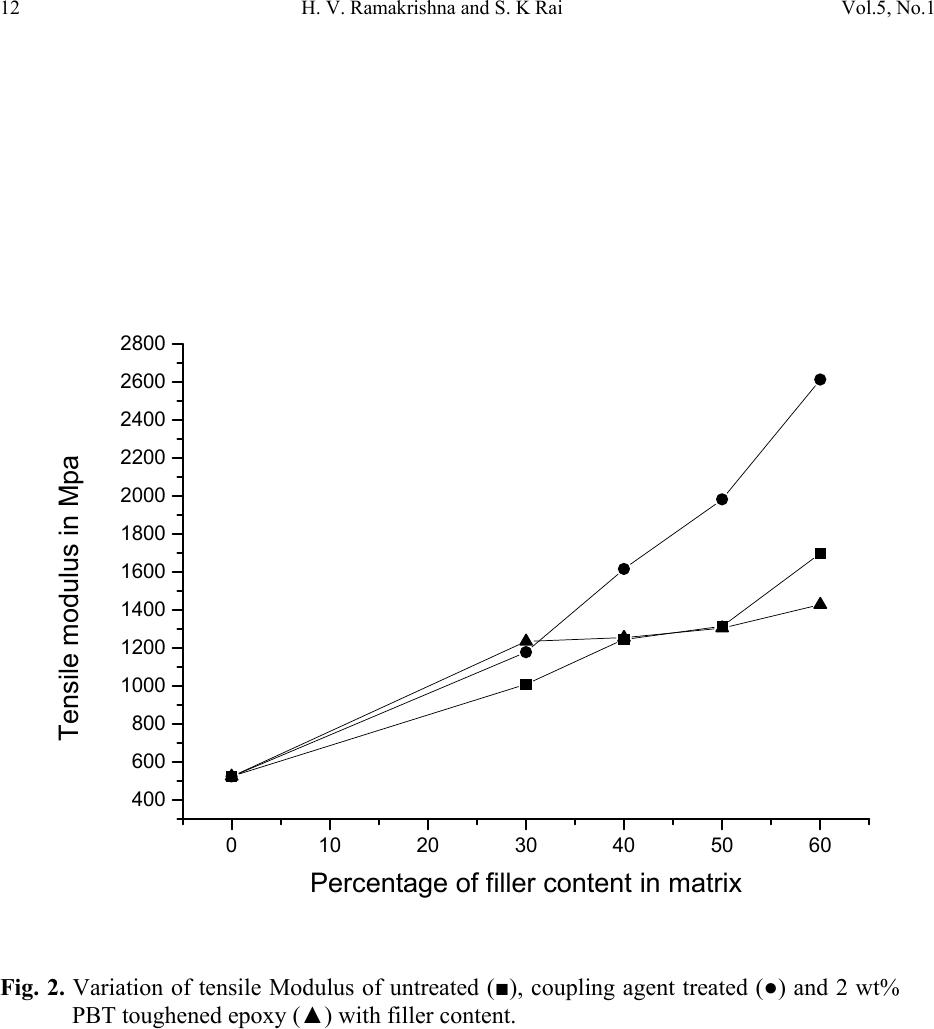

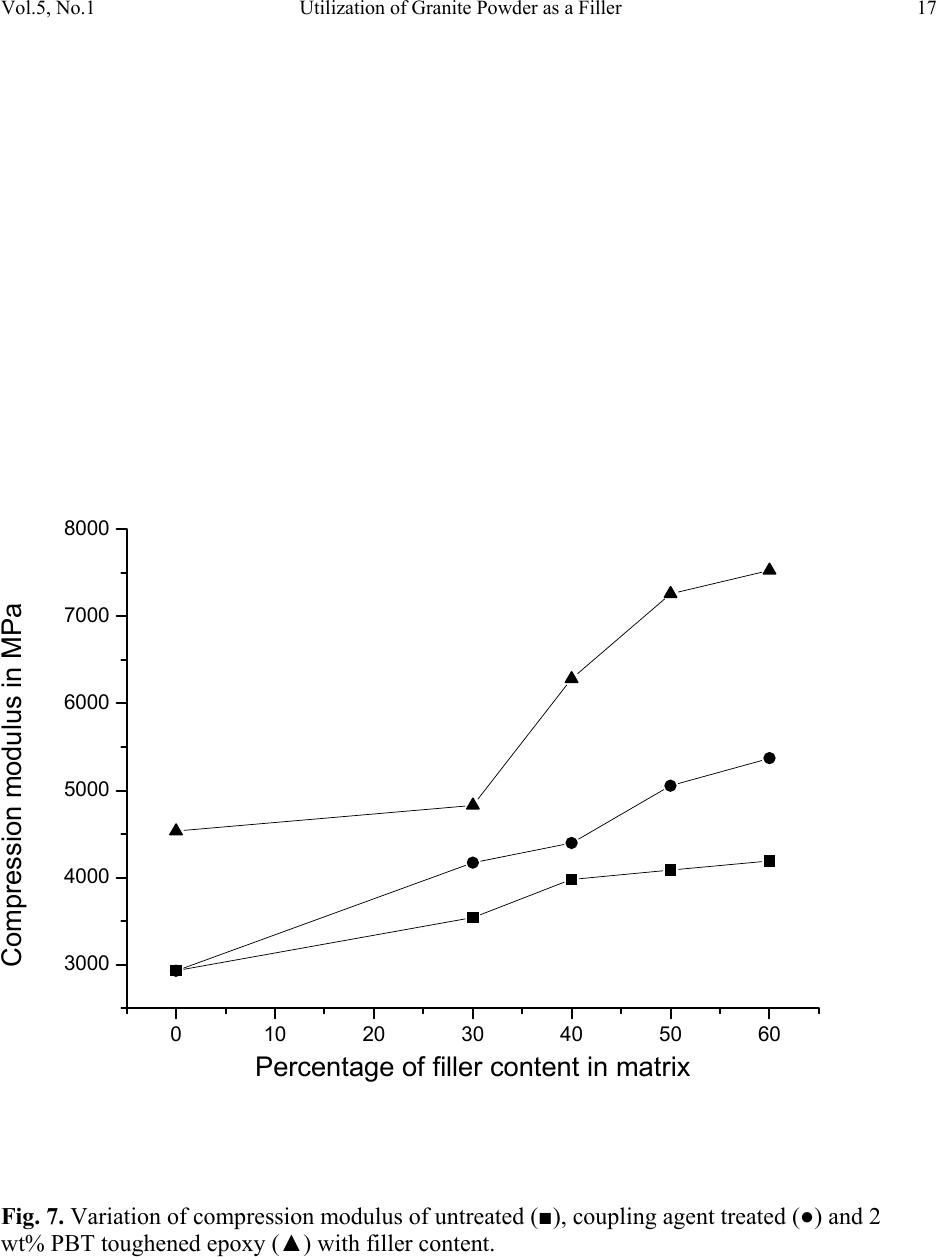

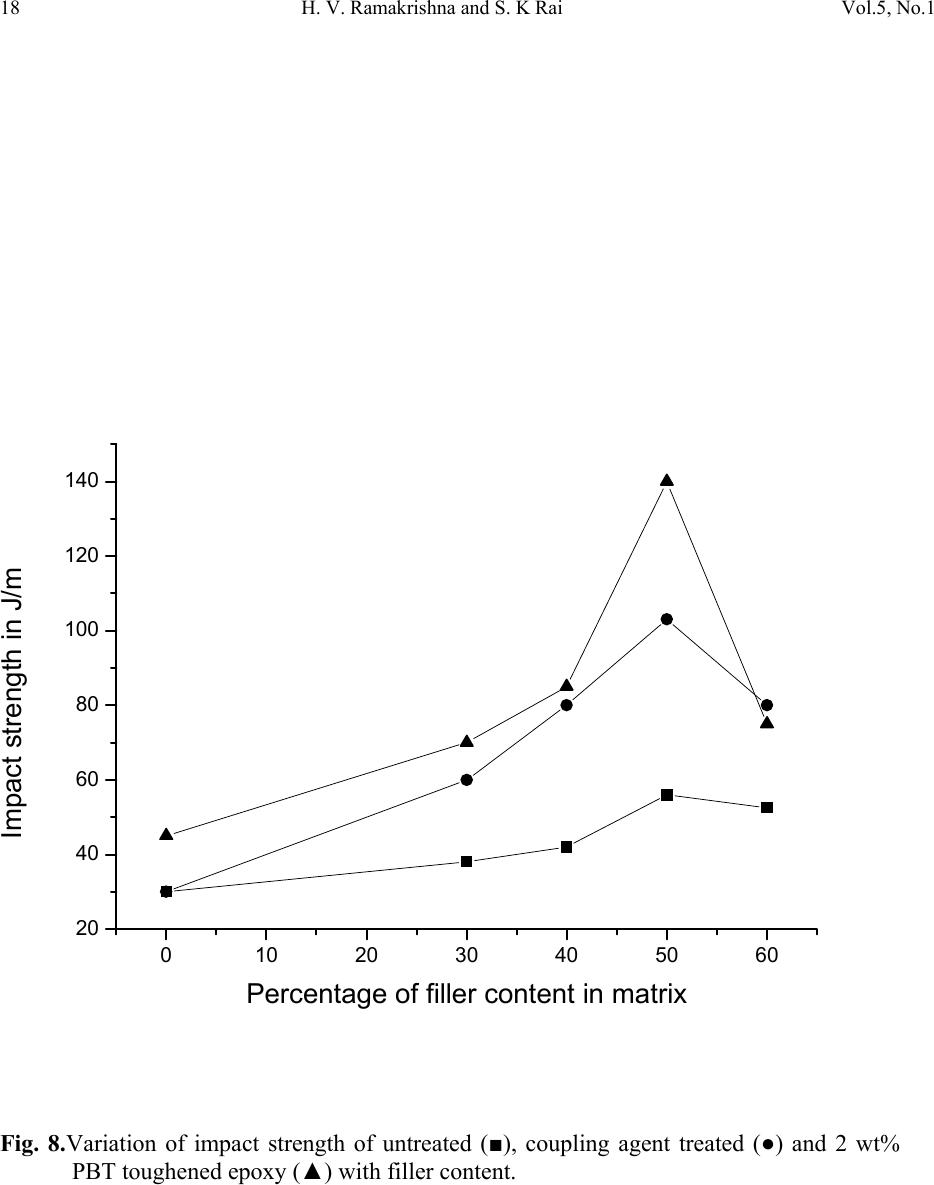

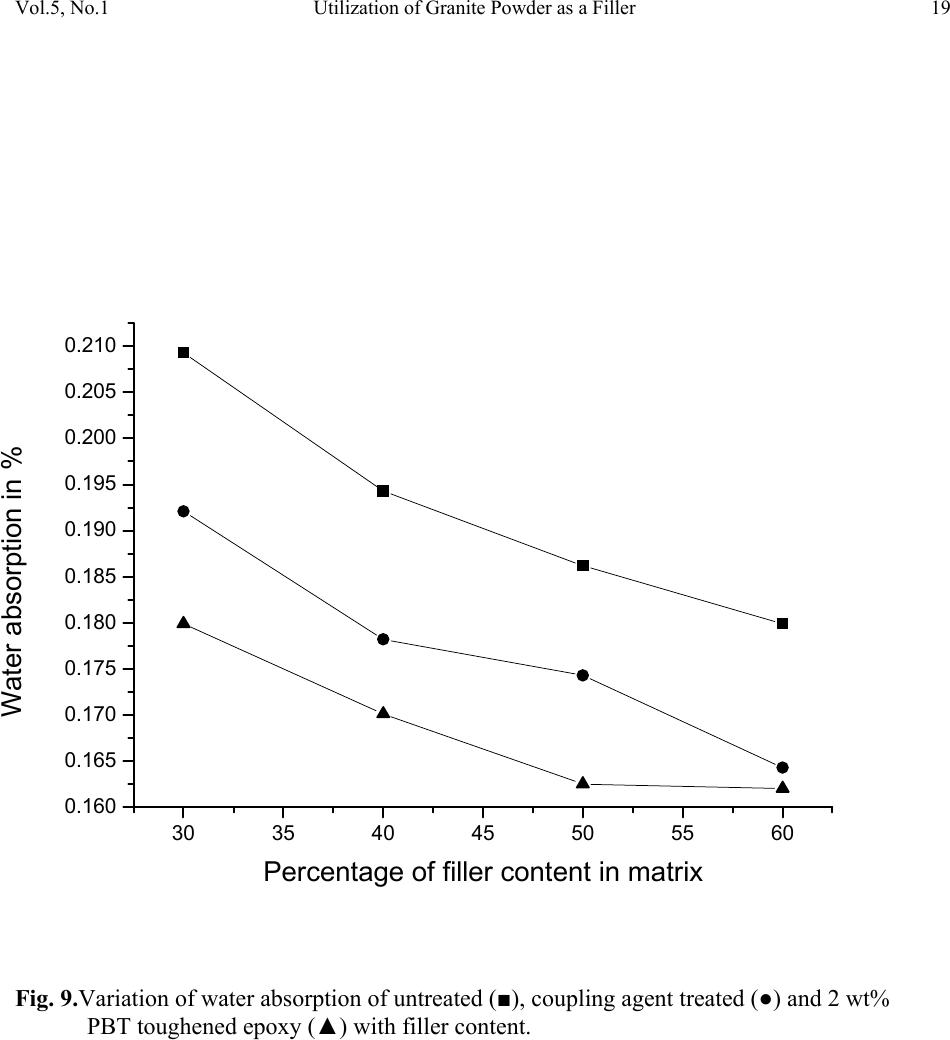

Journal of Minerals & Materials Characterization & Engineering, Vol. 5, No.1, pp 1-19, 2006 jmmce.org Printed in the USA. All rights reserved 1 Utilization of Granite Powder as a Filler for Polybutylene Terepthalate Toughened Epoxy Resin H. V. Ramakrishna and S. K Rai* Department of Polymer Science, Sir M.V.P.G Center, University of Mysore Tubinakere Industrial area, Mandya, Karnataka, INDIA 571402 *Correspondence Author’s Email: Sheshappa_rai@rediffmail.com Abstract: Granite powder filled epoxy and polybutylene terephthalate (PBT) toughened epoxy composites were prepared. The variation of the mechanical properties such as tensile, flexural, compressive strengths and impact with filler content was evaluated. The effect of the silane coupling agent on the properties of these composites and the chemical resistance and water absorption of these composites was studied. The composites with 50% granite powder showed better properties. Keywords: Granite powder, PBT, toughening, tensile, flexural, compression, Impact, chemical resistance, composites INTRODUCTION Epoxy is widely used as a matrix material for making many composites. However, it is brittle in nature and has poor resistance to crack propagation [1]. Many investigators have used various toughening agents with epoxy, such as liquid amine terminated [2], carboxyl terminated [3] and hydroxyl terminated [4] copolymers of butadiene and acryloitrile. Recently many investigators are using thermoplastics as toughening agents for epoxy. Among them, polybutylene terephthalate (PBT) is found to be effective due to its phase transformation toughening mechanism [5]. In order to reduce the cost of the composites, cheaper, naturally occurring fillers such as CaCO 3 , silica, talc, clay [6], flyash [7], cellulose based fillers [8], and kaolin [9,10] have been widely used. Utilizing locally available resources is a cost effective source of filler material. For example, granite powder is generated in large quantities during the sizing of granite slabs. The authors used this waste granite powder generated by the local industries as filler in epoxy and PBT toughened epoxy. The authors determined the mechanical properties of these composites and studied their variation with filler content. The authors also studied the chemical resistance and water absorption of these composites to assess their performance.  2 H. V. Ramakrishna and S. K Rai Vol.5, No.1 EXPERIMENTAL Materials In the present work, a commercially available epoxy resin DGEBA procured from M/s Vantico Ltd. Bombay was used as the polymer matrix. Triethylene tetramine was used as the hardener. The coupling agent triethoxy methyl silane, for modifying the granite powder, was procured from E Merck. Commercially available PBT was obtained from local suppliers. Granite powder was collected from local granite industries. The particle size of the granite powder ranged from 1 to 100 micrometers and the chemical composition is given in Table 1. Preparation of the Composites The granite powder was washed thoroughly with water then dried in an oven at 120 o C for 2h to remove any moisture before using it as filler for epoxy resin. A 1% solution of the silane coupling agent in acetone was used with 100gm of filler. The granite powder was mixed with the coupling agent solution for 30 minutes to ensure uniform distribution of the coupling agent. The treated granite powder was then dried at 60 o C in an oven for about 1 h to allow complete evaporation of the acetone. The density of the granite powder was found to be 2.19 as determined by ASTM standard. For blending of PBT and epoxies, the PBT pellets were dissolved in dichloromethane and the solution was poured to the beaker containing epoxy resin. The amount of PBT in epoxy resin was varied from 1 to 4 % by weight. Above this content, the epoxy resin became highly viscous. The resin to hardener ratio was maintained at 100:10 parts by weight as suggested by the manufacturer. The dichloromethane was evaporated by heating resin mixture at 80 o C. After complete evaporation of the dichloromethane, the mixture of PBT and epoxy resin was stirred at 150 o C continuously for 1h and then cooled to room temperature. Before curing, the mixtures were degassed and poured into moulds. The epoxy and hardener system was cured at room temperature for 24 h and then post cured at 100 o C for 2 h to ensure complete curing. Testing of Composites Laminates of the composites under study were made by room temperature curing for 24 hours in a 260x130x3 mm Teflon mould. The laminates were cut to the required specimen size as per the ASTM standards for mechanical testing. All the samples were post cured at 100 0 C in an oven for 2h to ensure complete curing before subjecting them to mechanical testing. The specimens were also made in the presence of the coupling agent.  Vol.5, No.1 Utilization of Granite Powder as a Filler 3 The tensile, compressive and flexural modulus and strength were determined using a Lloyd’s LR 100 KN type universal testing machine. The impact tests of the un-notched specimens were carried out using an Izod impact tester. For each test, ten specimens of each type were used and the average value is reported. The chemical resistance of the blend matrix and the composites was studied as per ASTM D 543 method. For this purpose, two strong acids (conc. HCl and conc. HNO 3 ), lactic acid, and glacial acetic acid; aqueous solutions of 40% NaOH, and 20% of Na 2 CO 3 ; and three organic solvents (benzene, carbon tetrachloride, and toluene) were selected. The pre-weighed samples were dipped in chemicals for 24h, removed, washed thoroughly with distilled water and dried immediately by pressing them on both sides by filter paper. The final weight of the samples and percentage weight loss/gain was determined. The chemical test was repeated for ten samples in each case and the average value was reported. For the water absorption test, rectangular specimens with dimensions of 25.4mm x 76.2 mm were cut from the laminates. Three replicate specimens were tested and the results are presented as average. The samples were dried in an oven at 50 o C for 24 h, cooled in a decicator and immediately weighed to the nearest 0.001gm. In order to measure the water absorption of the composites, all samples were immersed in water for about 24 h at room temperature as described in ASTM D 570 – 99 (ASTM 1999) procedure. Excess water on the surface of the samples was removed before weighing. The percentage increase in weight during immersion was calculated to the nearest 0.01% as follows. Wet Wt. – Reconditioned Wt. Increase in weight % = X 100 Reconditioned Wt. RESULTS AND DISCUSSION In order to optimize the content of PBT in toughening the epoxy, blends with different percentages of PBT were prepared and their mechanical properties determined. These values are presented in Table 2. From this data it is evident that the tensile, flexural, compressive and impact strength are maximum when the PBT content is 2% in the blend. At 2% PBT content, the increment in tensile, flexural, compressive and impact strength over the pure epoxy matrix are found to be 51.7%, 17.5%, 53.7% and 33.3% respectively. When the PBT content was increased above 2%, the mechanical parameters decreased. This behavior may be due to the fact that as the fraction of PBT in epoxy increases, the dispersing phase of PBT in the epoxy rich matrix increases, which hinders the cross linking of  4 H. V. Ramakrishna and S. K Rai Vol.5, No.1 epoxy with amine hardener thereby decreasing the total strength of the system. Thus 2% PBT is found to be optimum for effective toughening of epoxy. The variation of tensile strength, modulus and % elongation at break of the composites with untreated and coupling agent treated granite in epoxy and with coupling agent treated granite powder in 2% PBT toughened epoxy is shown in Figs. 1-3 respectively. From these figures, it is evident that in all these cases, the tensile properties are found to increase with filler content up to 50 % and decreased beyond this content. The increase in the tensile properties with filler content (up to 50%) may be due to the restriction of the mobility and deformability of the matrix with the introduction of mechanical restraint, and the filler particle size. Most investigators have enumerated that particle size is inversely related to reinforcing character and that an increase in surface area (as a consequence of reduced particle size) increases the composite mechanical properties [11,12]. Simultaneously, the higher stiffness of granite powder as compared to the epoxy matrix in which the filler is dispersed may also contribute to the above enhancement. The decrease in the tensile properties beyond 50% filler content may be due to the non-wetting of the filler particles with the matrix and the non-uniform distribution of filler particles in the cured matrix. Further, it is observed that the coupling agent on the filler and PBT in the matrix improved the tensile strength and modulus. Besides, from Fig.3, it is found that the % elongation at break decreased with filler content. This is understandable as the filler is stiffer than the matrix. The variation of flexural strength, flexural modulus, compressive strength, and compressive modulus for the composites under study with filler content are presented in Figs 4, 5, 6, and 7 respectively. From these figures it is evident that the flexural and compressive properties are higher when coupling agent and PBT were used in the composites. The coupling agent is expected to improve the stress transfer between the matrix and the filler by the formation of a stronger filler/matrix interface. A similar observation was made by Wong et.al [13] in the case of flyash/polypropylene composites. The trend of the variation of flexural and compressive properties with filler is similar to that of the variation of tensile properties. Further, the enhanced compressive strength properties of the composites over that of the matrix may be due to the stiff nature of the filler. In addition, the presence of PBT and platelet shape of granite powder might have also contributed to such an increase [6]. It was assumed that the space between the granite powder particles was filled with the blend matrix, thus minimizing the presence of voids and bubbles and leading consequently to an increase in both strength and modulus. Incorporation of a rigid filler may enhance or deteriorate the impact properties of composites [14,15]. Impact strength is an indication of tolerability for a sudden impact. When a composite is subjected to an impact, rapid crack  Vol.5, No.1 Utilization of Granite Powder as a Filler 5 propagation is initiated through the material. When such crack propagation encounters a filler particle in the filled composite, the filler can absorb the energy and stop the crack propagation if the filler-matrix interaction is strong. On the other hand, if the interfacial adhesion is poor, the filler particle cannot resist crack propagation as effectively as the polymer alone and consequently a catastrophic crack propagates, lowering the impact strength of the composite as loading increases. In the filled composites, as the filler loading increases the tendency for agglomeration also increases. As filler agglomeration increases, interfacial adhesion becomes weaker leading to weaker interfacial regions. These agglomerates act as stress concentration points or crack initiation sites. Therefore reduction in impact strength with increasing filler content is expected. The variation of the impact strength of the untreated and coupling agent treated granite in epoxy and the coupling agent treated granite in 2% PBT toughened epoxy is shown in Fig. 8. Here also it is observed that the impact strength is higher when the filler was treated with the coupling agent and the matrix was toughened with PBT. It is also observed that in all cases the impact strength increased up to 50% filler loading and decreased with further increment in the filler content. This is due to the fact that the 50% filler content is the maximum filler content and, as said earlier, for further increments the impact strength decreased. The increased impact strength in the case of 2% PBT toughened epoxy treated granite powder composite is due to increased toughness from introducing PBT into the epoxy matrix, thereby reducing the brittleness of the epoxy resin. The increase in toughness of PBT toughened epoxy seems to arise from a combination of processes that include primary crack bridging, crack bifurcation, crack path alteration, formation of steps and welts and secondary crack bridging. Other factors include ductile fracture of the dispersed PBT particles in epoxy rich matrix and phase transformation mechanisms [16]. According to Griffth’s theory, a large aggregate is a weak point, which lowers the stress required for the composite to fracture. As Nakagawa and Sano [17] have shown, the presence of fine particles dispersed with in the matrix make plastic deformation easier. So, during the fracture of a composite in which the mineral filler is fine and well dispersed, i.e., in which the material is more homogeneous, the stress will have to be bigger to start a micro crack on a particle and impact energy will largely be absorbed by plastic deformation. Hence, good filler dispersion resulting from the coupling agent treatment leads to better impact strength of the composites. This observation clearly suggests that 2% PBT toughened epoxy treated granite powder composites have better toughness characteristics over untreated and coupling agent treated granite powder/epoxy composites. The percent weight gain (+) or weight loss (-) data for untreated and coupling agent treated granite powder/epoxy composites immersed in various  6 H. V. Ramakrishna and S. K Rai Vol.5, No.1 chemical are presented in Table 3. These values for coupling agent treated granite powder/PBT toughened epoxy composites are presented in Table 4. From Table 3, it is clearly evident that weight gain is observed in both the untreated and coupling agent treated granite powder composites. In the case of coupling agent treated granite powder composites, less weight gain is observed when compared to untreated granite powder composites. These results indicate that the addition of the coupling agent is bringing the components closer; as a result, close packing is ensured in the composites. Generally, close packing enhances the chemical resistance of the materials. From Table 4, it is evident that when epoxy was toughened with 2% PBT weight gain is observed when composites were immersed in acetic acid, hydrochloric acid, nitric acid and lactic acid whereas weight loss was observed when composites were immersed in solvents and alkalis. This weight loss may be due to the slight removal of PBT, which is slightly soluble in organic solvents. The weight gain is understandable as cross-linked systems form three- dimensional networks that are chemically more stable. Water absorption behavior of polymer-filler composites in a particular environment is determined by factors such as processing techniques, matrix and filler characteristics, polymer: filler ratio, and duration of immersion in water. The variation of water absorption by untreated and coupling agent treated granite powder/epoxy and coupling agent treated granite powder/PBT toughened epoxy is presented in Fig. 9. From the figure, it is evident that the water absorption is lower when epoxy was toughened with PBT. Further, the presence of the coupling agent also decreased water absorption. The lower water absorption results indicate that the added coupling agent is bringing the components closer. As a result, close packing of filler and matrix is ensured and the presence of the thermoplastic PBT results in lower water absorption of these composites. CONCLUSSION Toughening epoxy resin with 2wt% PBT enhanced tensile, flexural, compression and impact properties. The enhancement was prominent in strength of all the composites, which showed improved matrix filler adhesion by the coupling agent. The mechanical properties of the composites under study were maximized at 50% granite powder filler content. The composites prepared had good chemical resistance and lower water absorption. REFERENCES 1. H.Lee and K. Neville, Hand book of Epoxy resins, Newyork; McGraw- Hill, 1967 2. G.Levita, A.Marchelli and Bertha E , Polymer, 26 (1985) 1110 3. S.C.Kunz, J.A.Sayre and R.A. Assink, (1982), Polymer, 23 (1982) 1897  Vol.5, No.1 Utilization of Granite Powder as a Filler 7 4. S.J.Sankaran, J. Appl.Polym.Sci., 39 (1090) 1635 5. Sangcheol Kim, Won Ho Jo, J. Mater.Sci, 34 (1999) 161 6. H.S.Katz and J.V. Milewski, Hand Book of Fillers and Reinforcements for Plastics, Vannostrand Reinhold, 1978 7. M.Sarojadevi,V.Murugesan,K.Rengaraj,PAnand,Appl.Polym.Sci,69 (1998) 1385 8. R.G.Raj, B.V.Kokta, D.Maldas and C.Daneult, J. Appl.Polym.Sci, 37 (1989)1089 9. M.Paaw and M. Lurius, J. Appl.Polym.Sci., 51 (1994) 127 10. S.Fellahi, N.Chikhi, M. Baker, J. Appl.Polym.Sci, 82 (2001)861 11. C. Hepburn, Plast. Rubber. Int, 9(1984)11 12. B.Pukanszki, E.Fekete, Poly.Compos,6(1998)313 13. K.W.Y Wong, R.W. Truss, Comp.Sci and Tech, 52(1994)361 14. A.M.Riley, C.D.Paynter, P.M.McGenity and J.M.Adams, Plast and Rubb.Process and Applications, 14(2) (1990) 85 15. L.Jilken, G.Malhmmar and R.Selden, Polym. Testing, 10 (1991) 329 16. Jun Kyung Kim, R.E. Robertson, J.Mater.Sci 27(1992)161 17. H.Nakagawa, H.Sano, Polym. Prepr.,26(1982)249  8 H. V. Ramakrishna and S. K Rai Vol.5, No.1 Table 1. Chemical composition of Granite powder. Compound Wt.% Silica 70-77 Alumina 11-13 Potassium oxide 3-5 Soda 3-5 Lime 1 Iron 2-3 Magnesia & Titania Less than 1 Table 2. Tensile, Flexural, Compression and Impact properties of epoxy toughened with PBT blend matrix. Tensile properties Flexural properties Compression properties % of PBT content in epoxy Tensile strength MPa Tensile modulus MPa % elongation at break Flexural strength MPa Flexural modulus Mpa Compression strength MPa Compression modulus Mpa Impact strength J/m 0 18.6 525 4.0 45.9 640 48.4 2931 30 1 27.5 563 7.0 50.0 1064 93.0 3663 40 2 38.5 606 6.4 55.6 1143 104.4 3730 45 3 35.0 523 5.4 54.2 1138 96.0 3867 36 4 30.4 493 4.5 49.6 905 89.3 4744 28  Vol.5, No.1 Utilization of Granite Powder as a Filler 9 Table 3.Chemical resistance properties of Untreated, coupling agent treated and epoxy/granite powder composites. (Percentage of filler content in matrix by wt.) 30 40 50 60 Chemicals Untreated Treated Untreated Treated Untreated Treated Untreated Treated Acetic acid 0.60 0.59 0.54 0.53 0.52 0.51 0.51 0.49 Hydrochloric acid 1.29 1.11 1.18 1.17 101.7 1.16 1.16 1.15 Nitric acid Dissolved Dissolved Dissolved Dissolved Dissolved Dissolved Dissolved Dissolved Sodium hydroxide 0.17 0.16 0.12 0.11 0.10 0.09 0.09 0.08 Sodium carbonate 0.39 0.30 0.31 0.30 0.21 0.19 0.19 0.18 Benzene 0.07 0.07 0.06 0.06 0.01 No change No change No change Carbon tetra chloride No change No change No change No change No change No change No change No change Toluene 0.08 0.07 0.06 0.06 0.05 0.04 0.05 0.05 Lactic acid 0.39 0.31 0.23 0.20 0.11 0.96 0.10 0.09  10 H. V. Ramakrishna and S. K Rai Vol.5, No.1 Table 4.Chemical resistance properties of 2% PBT toughened epoxy/granite powder composites. Percentage of filler content in the matrix by wt C HEMICALS 2% PBT in Epoxy Blend 30 40 50 60 Acetic acid 2.09 0.55 0.30 0.17 0.05 Hydrochloric acid 0.34 0.49 0.37 0.30 0.30 Nitric acid -6.64 30.47 21.59 14.62 9.91 Sodium hydroxide -0.14 -0.13 -0.07 -0.13 -0.02 Sodium carbonate 0.02 No Change 0.01 0.02 0.04 Benzene 0.01 -0.16 -0.05 No Change -0.09 Carbon tetra chloride -0.07 -0.28 -0.10 -0.01 -0.02 Toluene -0.05 -0.20 -0.07 -0.02 -0.08 Lactic acid 0.06 0.16 0.39 0.01 -0.04  Journal of Minerals & Materials Characterization & Engineering, Vol. 5, No.1, pp 1-19, 2006 jmmce.org Printed in the USA. All rights reserved 11 Fig. 1. Variation of tensile strength of untreated (■), coupling agent treated (●) and 2 wt% PBT toughened epoxy (▲) with filler content. 0102030405060 15 20 25 30 35 40 45 Tensile strength in MPa Percentage of filler content in the matrix  12 H. V. Ramakrishna and S. K Rai Vol.5, No.1 Fig. 2. Variation of tensile Modulus of untreated (■), coupling agent treated (●) and 2 wt% PBT toughened epoxy (▲) with filler content. 0102030405060 400 600 800 1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 Tensile modulus in Mpa Percentage of filler content in matrix  Vol.5, No.1 Utilization of Granite Powder as a Filler 13 Fig. 3. Variation of tensile elongation of untreated (■), coupling agent treated (●) and 2 wt% PBT toughened epoxy (▲) with filler content. 0102030405060 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 % Elongation at break Percentage of filler content in matrix  14 H. V. Ramakrishna and S. K Rai Vol.5, No.1 Fig. 4. Variation of flexural strength of untreated (■), coupling agent treated (●) and 2 wt% PBT toughened epoxy (▲) with filler content. 0102030405060 45 50 55 60 65 70 75 80 85 Flexural strength in MPa Percentage of filler content in matrix  Vol.5, No.1 Utilization of Granite Powder as a Filler 15 Fig. 5. Variation of flexural modulus of untreated (■), coupling agent treated (●) and 2 wt% PBT toughened epoxy (▲) with filler content. 0102030405060 0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000 6500 7000 Flexural modulus in MPa Percentage of filler content in matrix  16 H. V. Ramakrishna and S. K Rai Vol.5, No.1 Fig. 6.Variation of compression strength of untreated (■), coupling agent treated (●) and 2 wt% PBT toughened epoxy (▲) with filler content. 0102030405060 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140 Compression strength in MPa Percentage of filler content in matrix  Vol.5, No.1 Utilization of Granite Powder as a Filler 17 Fig. 7. Variation of compression modulus of untreated (■), coupling agent treated (●) and 2 wt% PBT toughened epoxy (▲) with filler content. 0102030405060 3000 4000 5000 6000 7000 8000 Compression modulus in MPa Percentage of filler content in matrix  18 H. V. Ramakrishna and S. K Rai Vol.5, No.1 Fig. 8.Variation of impact strength of untreated (■), coupling agent treated (●) and 2 wt% PBT toughened epoxy (▲) with filler content. 0102030405060 20 40 60 80 100 120 140 Impact strength in J/m Percentage of filler content in matrix  Vol.5, No.1 Utilization of Granite Powder as a Filler 19 Fig. 9.Variation of water absorption of untreated (■), coupling agent treated (●) and 2 wt% PBT toughened epoxy (▲) with filler content. 30354045505560 0.160 0.165 0.170 0.175 0.180 0.185 0.190 0.195 0.200 0.205 0.210 Water absorption in % Percentage of filler content in matrix |