Paper Menu >>

Journal Menu >>

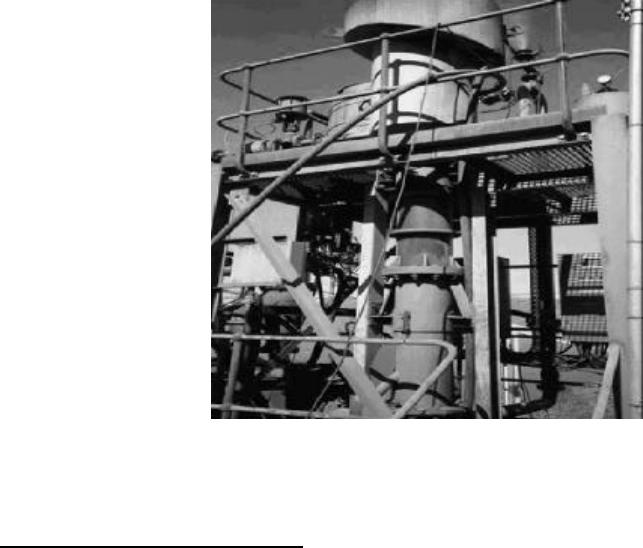

Journal of Minerals & Materials Characterization & Engineering, Vol. 2, No.2, pp 137-144, 2003 http://www.jmmce.org, printed in the USA. All rights reserved 137 Separation of Metals from a Slag Using a Multi-cell Jig David C. Yang1, Ricus van Reenan2, and Vimal Bhimsan3 1Mineral Technologies International, Inc., Morgantown, West Virginia, USA 2Apic Toll Treatment (Pty) Ltd, Parktown, South Africa 3Mintek, Randburg, South Africa The emerging Yang jig technology offers sharp separation of fine particles by the difference in their specific gravity. Mixed particles are fed either wet or dry into an inlet near the top of a column that is packed by corrugated plates, and the pulse water enters near the bottom. Heavy particles migrate downward and light particles move upward with the drag force imparted by a net up-flow stream of liquid being channeled through a large number of jigging cells. The multi-cell design enables repetitive separation actions as the particles travel in opposite vertical directions and allows precise concentration at high capacities with no short-circuiting. When a steady-state condition is reached, particles are stratified in a well-defined density gradient. The concentrated heavy particles discharge from the bottom, while the light particles overflow through a top launder. Scale-up is nearly linear with the separator volume. This paper presents basic principles of the process and its applications for recovery of metals from slag, especially ferroalloys. A commercial jig plant has been installed in South Africa to recover metal concentrate of 97% grade at 76% metal recovery from minus 1mm ferrochrome slag far exceeding conventional gravity methods. Introduction A significant amount of mineral and metal values are lost in fine slimes in the mining and metallurgical industry today because of the lack of an efficient and cost-effective method for their recovery. Most of this fine material is being disposed of as waste in enormous tonnage causing great economic and environmental concerns. The Yang jig technology [1], patented in 1996, has been developed to solve these problems. This technology represents the latest advancement in jigging separation of finely disseminated particulate material. Having many advantages compared to conventional methods, it is capable of separating and recovering high quality products from waste, such as metal values from slag. Thus the industry will benefit by reducing the unit production costs and gain a competitive edge in the market place. During the past three years, a pilot-plant scale Yang jig was built and tested in South Africa for various possible applications. The objectives of the test work were (1) to evaluate the separation efficiency in the processing of different feed materials, especially metal from slag, and (2) to identify the key operating variables, such as feed rate, feed density, upward water flow rate, etc., and determine their effect on the performance, and thereby optimize the operating conditions. The applications and advantages of the technology will be presented including some highlights of the project findings.  138 David C. Yang, Ricus van Reenan , and Vimal Bhimsan Vol.2, No.2 Multi-cell jigging A schematic diagram of the Yang jig used in the study is shown in Figure 1. This jig is unique in its multi-cell design and use of a novel jigging concept. Figure 1. Yang jig Schematic Design. The machine consists of a single column fitted with specially designed packing plates. The packing acts as a partition dividing the unit into a great number of jigging cells and also functions as a riffling system analogous to thin film separators. The velocity profile of the pulsed water provides a mechanism for stratification of solid particles along the vertical direction according to the particle specific gravity. The length and frequency of stroke can be varied to suit the application [2, 3]. During suction (downward water movement), particle beds build on the packing in layers and then cascade down the vessel to the next packing stage as a combined semi-compacted mass. During the pulsion cycle (upward water flow), the downward movement of the particle bed is halted and the upper portions of the particle beds are re-suspended, with a portion being hydraulically lifted up the column and the other fraction being trapped in an eddy zone under the inclined packing above. Particles trapped in the eddy current return to the original packed bed by hindered settling classification and the lighter particles tend to settle near the top of the bed. The fine heavy particles also trickle down into the weakly agitated bed during this phase. The net effect is improved transportation of high-density particles down the column to the concentrate stream (metals or heavy minerals) by virtue of the mass movement of the bed on the suction stroke since the bed helps protect these fines from high upward currents. The  Vol.2, No.2 Separation of Metal s from a Slag Usin g a Multi-cell Jig 139 vertically induced staged cleaning action enhances fine particle density separations. The design of the high-capacity multi-cell machine reduces both floor space requirements and construction costs. Pilot plant and plant applications Several laboratory and pilot scale plants are operating, and a plant study by a South African manufacturer for metal recovery from slag at an operating ferrochrome plant included a Yang jig to treat the finest cut of the slag feed of a 2mm top size. The results indicate commercial viability of the Yang jig column. It is particularly well suited to the processing of iron ore, coal, mineral sands, and other minerals and metals from gangue materials [4, 5, 6]. Potential environmental protection applications include the removal of nitrates and heavy metals and effluent treatment to produce water, which complies with environmental control requirements. Further scope for application exists in the chemical, pharmaceutical, food and petroleum industries. The Yang jig is potentially useful to recover free gold, sulfides, native copper, native silver, tin/tantalum, diamonds and garnet. There is a great potential for its commercial use in metal recovery from slag either as primary and secondary recovery units. Some results obtained from typical tests in these applications are described in the following sections for comparison with other methods. Experimental work Equipment and test procedure The preliminary tests were employed on a wide variety of finely disseminated materials on pilot scale 76mm jig, 19mm and 51mm laboratory units. In a plant site test, a 12-in (300mm) plant column was tested at a plant site for recovery of ferrochrome from slag. The jig column was extended by sections and could vary up to 3m tall. The feed slurry was prepared in a tank with a stirrer and a re-circulation pump to keep the particles in suspension and well mixed. A representative sample stream was tapped from the re-circulation line by a pump to feed the column jig continuously at a controlled rate. If particles were too coarse to avoid a strong segregation in the feed sump, the material, either dry or wet at any practical density, would require gravity feeding to the top of column. High specific gravity particles were drawn into the concentrate hutch during the suction stroke of the bed and were discharged steadily. The lighter gangue was discharged over the top cone. The pulsed water was monitored through an automatic control instrument in connection with a density probe on top of the column. Samples of feed, concentrate and tailings were taken when a steady-state operating condition was reached. Selected samples were then filtered, dried, weighed, and analyzed for metal content using selected light microscopy on the prepared polished sections. Some samples were also sent for chemical analysis.  140 David C. Yang, Ricus van Reenan , and Vimal Bhimsan Vol.2, No.2 Results and discussions Ferrochrome recovery from slag fines Slag/metal/sand slimes This material is the classifier fines from Company A (Phase II expansion plant) in South Africa. The feed sample with a top size of 0.3mm was tested as received using the Yang jig pilot plant unit. The sample was also tested after screening to remove +0.15mm particles. Typical results obtained are shown in Table 1 with the test conditions. Table 1. Results of the Yang jig testing on Company A’s slag slimes as received. Test No. Top Size Sample %Mass %Metal % Rec. %Cr %Fe %Si A1 0.3mm Conc. 5.8 95.0 79.5 44.0 28.9 2.8 Tails 94.2 1.5 20.5 11.5 7.8 20.1 Feed 100.0 6.9 100.0 13.4 9.0 19.1 A2 0.3mm Conc. 5.8 97.0 85.7 45.3 29.8 2.6 Tails 94.2 1.0 14.3 10.8 7.1 19.5 Feed 100.0 6.6 100.0 12.8 8.4 18.5 A3 0.15mm Conc. 47.9 90.8 88.8 Tails 52.1 15.0 13.2 Feed 100.0 54.5 100.0 A4 0.15mm Conc. 54.0 91.8 90.9 Tails 46.0 10.7 9.1 Feed 100.0 54.5 100.0 Operating conditions: Test No. Fee d Rate (kg/h) Feed Wate r (1/h) Feed Solids (%) H ut c h Wa t e r ( 1 /h) A1 246.6 700.0 26.1 456 A2 226.2 500.0 31.1 456 A3 142.0 135.0 28.9 135 A4 140.9 500.0 31.1 456 The results show the metal concentrate yielded 6% by weight containing +95% metal grade at a metal recovery of over 80%. Even though the development work is being continued, the following observations were noted from many series of tests: 1) With metal from slag, it is easy to obtain a high-grade product at the expense of recovery. This is due to higher density and faster settling metal particles than the slag. 2) The amplitude and shape of the pulse also affect the settling rates of the particles. The amplitude determines the degree of fluidity (or porosity) within the bed, and creates more voidage for the particles to move. The amplitude should be such that all the lighter particles are able to move further upwards on the upstroke, while the heavier particles move downward on the downstroke. 3) The hutch water affects both grades and recoveries. Ideally, the upward water velocity in the 3-inch (76mm) section of the jig should be greater than or equal to that in the 6- inch section, to prevent light particles from moving downward (at steady-state  Vol.2, No.2 Separation of Metal s from a Slag Usin g a Multi-cell Jig 141 conditions, the heavy layer is built up to almost the height of the feed point). This ensures good grades. But increasing the hutch water much beyond this limit will result in lower recoveries. These relationships still have to be quantified, but should also be indicated in Figure 2a. 4) Feed pulp density is a very important variable affecting recoveries, as it determines the net upward water velocity in the 6-inch (152mm) section of the column. For a given hutch water flow, the relationship between feed solids and metal recovery is shown in Figure 2b. 5) A feed rate of 250 kg/h (for the pilot unit) can be used as a design estimate. Beyond this limit, metal recoveries decrease drastically. This feed rate translates to 6.2 tph/m3 of jig volume, i.e. a 300mm diameter column (bottom section) could process 4 tph feed. 0 20 40 60 80 100 % 0100200 300 400500 Hutch Water, l/h Metal Grade Metal Recovery (a) 70 75 80 85 90 Metal Recovery,% 15 20 2530 35 Feed Solid s, % (b) Figure 2. Effect of hutch water and feed solids on jig performance  142 David C. Yang, Ricus van Reenan , and Vimal Bhimsan Vol.2, No.2 Ultrafine slag slimes Company B is currently experiencing problems with the slag slimes handling section of their ferrochrome plant. The high percentage of ultrafine material (60% < 38µm) rapidly clogs the belt filter rendering it useless. Yang jig tests were carried out on a sample of unflocculated slimes. The aim was to produce a metal rich concentrate that could be remelted in the existing furnaces; hence metal grade was not as crucial as overall metal recovery. The slimes contained 3.02% metal, 50% of which was present in the -38µm fraction. The concentrate produced an overall grade of 27.9% metal at a recovery of 67%. The feed sample was also processed on a laboratory Falcon Concentrator for comparison. The slimes were processed through one rougher and two scavenger stages, producing 2 concentrates and one tailings sample. The operating conditions of the Falcon and the sample masses are given in Table 2. Each of the samples was examined mineralogically to determine the percentage metal. The concentrate produced contained 15% metal and recovered 67% of the metal present. Comparing the grade versus recovery relationships for the Yang jig and the Falcon, the jig produced much higher grades for similar metal recoveries over much of the curve. Table 2. Performance comparison of the Yang jig vs. Falcon concentrator. Company B’s slag slimes: 65% -38µm Method* Sample %Mass %Metal % Rec. %Cr %Fe %Si Yang 1(f) Conc. 6.7 43.7 31.0 23.5 15.7 8.8 Tails 93.3 2.0 69.0 9.1 7.0 16.7 Yang 1 Conc. 6.7 27.9 67.2 19.5 13.0 10.7 Tails 93.3 1.0 32.8 9.4 7.2 16.6 Feed 100.0 2.8 100.0 10.1 7.6 16.2 Falcon 1 Conc. 23.0 15.0 67.5 15.6 10.6 12.7 Tails 77.0 2.2 32.5 7.9 6.7 16.6 Falcon 1+1 Conc. 41.7 11.9 96.9 13.8 9.4 13.8 Tails 58.3 0.3 14.3 6.8 6.3 17.1 Feed 100.0 5.1 100.0 9.7 7.6 15.7 *Yan g 1 = on e ro u gh e r p r o ce s si n g ; 1 (f ) = o n e r ou g h er fi n e p r od u c t Fal c on 1 = on e ro u gh er p r oc es si n g; 1 +1 = on e r ou gh er + on e s ca ve ng e r Plant Testing A 300mm Yang jig was manufactured under license from MTI by a South African company and installed at an operating ferrochrome plant for recovery of the metal concentrate from – 1mm ferrochrome slag (see the picture in Figure 3). Even though the operation was not extensive, on the average, 7 tons of the metal concentrate were produced per day for recycle to the smelter using a 300mm diameter by 3m tall column jig alone. The concentrate grade was always very high, averaging 97% metal grade at 76% metal recovery. The results are commensurate with that obtained from the 76mm pilot Yang jig on other similar materials.  Vol.2, No.2 Separation of Metal s from a Slag Usin g a Multi-cell Jig 143 Figure 3. Yang jig plant installation. Technical and Economical Potential Design Advantages Continuous and excellent results have been obtained by the Yang jig on a variety of applications. It is particularly suitable to replace a conventional circuit where many stages are required. Good process control is possible as varying the distribution of the mass based on pulp density and pulsation rate can control the extent of dispersion of different phases. The floor space required by the plant is about one tenth that required by alternative systems. Sharp separation is possible at a very high feed rate because the Yang jig enables numerous repeated actions exerted upon the particles. It is characterized by the transient multi-force- field interacting with the packing that produces additional shearing action on the particles to enhance the separation. It is unique in the sense that it combines entirely different separation processes of thin film jigging and thin film concentration. Commercialization efforts Process benefits of the Yang jig are obvious in terms of performance improvements and cost reductions, and ease of scale. Mineral Technologies International, Inc. (MTI) is developing the scale-up of the units leading to commercial applications in the mineral and metal industry. MTI is committed to quality and innovation while fostering strategic alliances in order to bring the technology to the marketplace. Pilot-scale testing can be conducted either on-site or at the MTI test facilities in West Virginia following bench-scale exploratory tests. The availability of different sized test columns allows test work to be done on a scale that best suits the project objectives and the client’s budget. This will be backed up by MTI’s comprehensive support and services. In a time of heightened emphasis on financial performance and competitiveness, MTI provides strategic weapons in the battle for profitability. 144 David C. Yang, Ricus van Reenan , and Vimal Bhimsan Vol.2, No.2 Summary and Conclusions 1) The Yang jig technology incorporates a multi-cell packing idea and number of novel features providing increased capacity in a more robust and compact design. 2) The jig device is mechanically simple, with no agitators or internal moving parts, and it is easy to install and automate. 3) The detailed mechanism of the Yang jig is still under study. Subsequent testing will exemplify the effects and interactions of key operating variables on the jigging separation. 4) This technology offers an excellent opportunity for mineral and metal producers to strengthen their competitive edge. Its effectiveness, simplicity, low initial capital and operating costs will make this unique jigging technology feasible for many applications. 5) MTI is looking for interested parties to participate in the opportunity for increasing their profits through advanced technologies. References [1] D. C. Yang: "Device and Process for Gravitational Separation of Solid Particles," U.S. Patent No. 5,507,393, April 16, 1996. [2] D. C. Yang, and T. P. Meloy: “Gravity Separation of Minus 500 mesh Particles” (Paper presented at the SME Annual Meeting, Denver, Colorado, March 1997). [3] Q. Dai: “Simulation of Packed Column Jigging” (M.S. thesis, West Virginia University, 1999). [4] Private Communication. [5] D. C. Yang, P. Bozzato, and G. Ferrara: “Packed Column Jig sets New Standards in Iron Ore Concentration” Proceedings of the XXI International Mineral Processing Congress, Rome, Italy, 23-27 July 2000. [6] D. D. Yang: “Iron Ore Beneficiation With Packed Column Jig,” Journal of Minerals & Materials Characterization & Engineering, Vol 2 No. 1, 43-512003 |