World Journal of Mechanics

Vol.4 No.5(2014), Article ID:46260,9 pages

DOI:10.4236/wjm.2014.45015

Numerical Simulation of Two-Dimensional Dendritic Growth Using Phase-Field Model

Abdullah Shah1*, Ali Haider1, Said Karim Shah2

1Department of Mathematics, COMSATS Institute of Information Technology, Park Road, Islamabad, Pakistan

2Department of Physics, Abdul Wali Khan University, Mardan, Khyber Pukhtunkhwa, Pakistan

Email: *abdullah_shah@comsats.edu.pk

Copyright © 2014 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 29 January 2014; revised 26 February 2014; accepted 15 March 2014

ABSTRACT

In this article, we study the phase-field model of solidification for numerical simulation of dendritic crystal growth that occurs during the casting of metals and alloys. Phase-field model of solidification describes the physics of dendritic growth in any material during the process of under cooling. The numerical procedure in this work is based on finite difference scheme for space and the 4th-order Runge-Kutta method for time discretization. The effect of each physical parameter on the shape and growth of dendritic crystal is studied and visualized in detail.

Keywords:Dendritic Crystal Growth, Phase-Field Model, 4th-Order Runge-Kutta Method

1. Introduction

The study of dendritic crystal growth has become an important aspect in the field of chemical processing, solid state physics and material sciences. The growth of these crystals is a common phenomenon in metals and alloys. The dendrite morphology is also very important in metallurgy. Material properties like volatility, toughness, corrosiveness and strength to resist stress depend upon the growth and morphology of these dendrite crystals. The growth of dendrites in any material depends upon the system temperature [1] . During the casting and formation of metals and alloys, these tiny microstructures grow due to the phenomenon of solidification. These tiny microstructures have a direct impact on the material properties like the quality of a certain material which is influenced by the presence of these microstructures. When metals are casted, dendrites begin to grow due to the process of under-cooling. These dendrites keep on growing until the whole of the liquid phase transforms into solid phase [2] . The study of these dendrites, their size, shape and growth velocity is very important industrially because they do change the quality of materials. Materials abundant in dendrites are likely to be corrosion and are vulnerable [1] [3] . This work focuses on the factors responsible for the formation of these patterns and the methods to limit the growth of these solidification microstructures. In the visualization of dendritic structures, the branches and side branches are very important, since the temperature factor greatly limits the growth of these dendrites. We studied numerically the parameters responsible for dendritic growth and tried to explain their effects on the growth. We also explained the fact that, when the temperature is very low, the growth of these dendrites accelerates. The tip velocity of the side branches is increased by lowering the temperature, whereas the radius or thickness of these side branches is small. By increasing the temperature, the growth rate is decreased and side branches grows with less speed while having larger radii [2] . Further increasing the temperature of the system beyond melting point melts the structure.

2. Phase-Field Model

Phase-field model of solidification were first introduced by Fix [4] and Langer

[5] for solving the interfacial problems and to handle the discontinuities involved

with the sharp interface model. Phase-field models being numerically simple are

very popular in the field of material sciences, solid state physics and electrochemistry

in recent years. They are commonly used for the simulation of dendritic growth.

This model was first applied for the numerical results of limited diffusion growth

by Collins and Levine [6] and by Kobayashi [7] for the study and growth of dendrite.

The phase-field model is a mathematical model which explains the physics of dendritic

solidification in materials due to undercooling in a natural way. This model has

been used extensively to solve the free boundary problems without tracking of the

interface at every time step. In Phase-field model, the sharp interface model is

replaced by two non-linear equations. The interface between both phases is considered

as a diffusion layer with very small thickness [8] . This diffusion layer is given

by the Phase-field parameter

which is a function of space

which is a function of space

and time

and time . This phase-field

or order parameter

. This phase-field

or order parameter

is also called the level set function which varies from 0 to 1. It has value 0 in

the liquid phase and 1 in the solid phase and the intermediate value between 0 and

1 gives us the phase transition. This Phase-field parameter distinguishes the solid

phase from the liquid phase and the transition layer in between. The problem of

locating the position of interface in sharp interface model is covered by this phase-field

parameter [9] . The main idea behind the phase-field model is that the jump discontinuity

or sharp interface is replaced by a smooth and continuous interface of very small

width due to which the singularities involved in the sharp interface model are removed.

The main purpose of the phase-field parameter

is also called the level set function which varies from 0 to 1. It has value 0 in

the liquid phase and 1 in the solid phase and the intermediate value between 0 and

1 gives us the phase transition. This Phase-field parameter distinguishes the solid

phase from the liquid phase and the transition layer in between. The problem of

locating the position of interface in sharp interface model is covered by this phase-field

parameter [9] . The main idea behind the phase-field model is that the jump discontinuity

or sharp interface is replaced by a smooth and continuous interface of very small

width due to which the singularities involved in the sharp interface model are removed.

The main purpose of the phase-field parameter

is to identify the phase by prescribing a value to each phase. Phase-field model

of solidification comprises of two parabolic non-linear partial differential equations,

the phase-field equation of motion which comprises of the dynamic variable

is to identify the phase by prescribing a value to each phase. Phase-field model

of solidification comprises of two parabolic non-linear partial differential equations,

the phase-field equation of motion which comprises of the dynamic variable

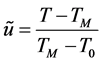

and the thermal diffusion equation which consists of the dimensionless temperature

and the thermal diffusion equation which consists of the dimensionless temperature

with value

with value . Here,

. Here,

is the temperature of the system,

is the temperature of the system,

is the melting temperature and

is the melting temperature and

is the systems initial temperature. The basic equations are:

is the systems initial temperature. The basic equations are:

(2.1)

(2.1)

(2.2)

(2.2)

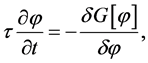

In Equation (2.1),

is the typical relaxation time,

is the typical relaxation time,

is the square-gradient free energy functional

which accounts for the mixing of energy in the interface due to the evacuation of

heat and it describes the solid and liquid phases. The negative sign in Equation

(2.1) ensures that as the total free energy of the transition layer is decreased

followed by the minimization of the square gradient free energy functional, the

phase-field parameter

is the square-gradient free energy functional

which accounts for the mixing of energy in the interface due to the evacuation of

heat and it describes the solid and liquid phases. The negative sign in Equation

(2.1) ensures that as the total free energy of the transition layer is decreased

followed by the minimization of the square gradient free energy functional, the

phase-field parameter

evolves towards the liquid phase, that is the transition layer grows and moves towards

the liquid phase as time increases. Equation (2.1) gives us the relationship between

the free energy of the transition layer and its front tracking and is our basic

phase-field equation which gives us the location and velocity of interface. Since

the tracking of interface is very important and difficult to handle, this problem

can be overcome by Equation (2.1) which accounts for the growth of the solidification

front. The value of the square-gradient free energy functional is given by [10]

:

evolves towards the liquid phase, that is the transition layer grows and moves towards

the liquid phase as time increases. Equation (2.1) gives us the relationship between

the free energy of the transition layer and its front tracking and is our basic

phase-field equation which gives us the location and velocity of interface. Since

the tracking of interface is very important and difficult to handle, this problem

can be overcome by Equation (2.1) which accounts for the growth of the solidification

front. The value of the square-gradient free energy functional is given by [10]

:

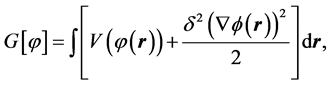

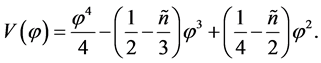

(2.3)

(2.3)

where

is the interfacial width and

is the interfacial width and

is the bulk free energy functional. In this model, we used the double well free

energy functional with prescribed value as:

is the bulk free energy functional. In this model, we used the double well free

energy functional with prescribed value as:

(2.4)

(2.4)

This double well free energy functional ensures the growth of the solid phase at

the expense of liquid phase. When the free energy of the liquid phase decreases

then the liquid phase transforms into solid phase. This free energy functional has

two minima, one at

and the other at

and the other at

corresponding to the liquid and solid phases respectively. In Equation (2.4),

corresponding to the liquid and solid phases respectively. In Equation (2.4),

is a function of dimensionless temperature

is a function of dimensionless temperature

with

with .

.

gives the solid phase i.e.

gives the solid phase i.e.

and

and

gives the liquid phase

gives the liquid phase ,

,

gives us the phase equilibrium. The prescription

chosen for

gives us the phase equilibrium. The prescription

chosen for

is

is

where

and

and

are the material parameters.

are the material parameters.

is the actual temperature of the system and

is the actual temperature of the system and

is the melting temperature. This prescription of

is the melting temperature. This prescription of

ensures the growth of the solid phase since it is a difference between the actual

temperature

ensures the growth of the solid phase since it is a difference between the actual

temperature

of the system and systems melting temperature

of the system and systems melting temperature . Now most of the

phenomenon of dendritic growth occurring are anisotropic in nature. In order to

introduce anisotropy in Phase-field model of solidification, we assumed the interfacial

width

. Now most of the

phenomenon of dendritic growth occurring are anisotropic in nature. In order to

introduce anisotropy in Phase-field model of solidification, we assumed the interfacial

width

as a function of angle

as a function of angle

i.e.

i.e. , where

, where

is the angle between the

is the angle between the

-axis and

-axis and . This angle

is in normal direction to the interface and it gives the direction of the interface

[11] . For isotropic case this interfacial width

. This angle

is in normal direction to the interface and it gives the direction of the interface

[11] . For isotropic case this interfacial width

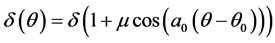

is constant. The function of interfacial width for the anisotropic case is

is constant. The function of interfacial width for the anisotropic case is

where

is the modulation of interfacial width,

is the modulation of interfacial width,

is the orientation of the anisotropy axis.

Changing the value of

is the orientation of the anisotropy axis.

Changing the value of

changes the orientation of the dendrite.

changes the orientation of the dendrite.

is the anisotropic mode number, which gives

us the shape of the dendrites (for octagonal dendritic structure, we choose

is the anisotropic mode number, which gives

us the shape of the dendrites (for octagonal dendritic structure, we choose ). Anisotropy in

the phase-field model is responsible for the development of side branches of dendrites.

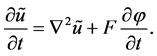

Equation (2.2) is the basic time dependent heat equation or the thermal diffusion

equation with an extra term

). Anisotropy in

the phase-field model is responsible for the development of side branches of dendrites.

Equation (2.2) is the basic time dependent heat equation or the thermal diffusion

equation with an extra term

called the source term, which accounts for the liberation of latent heat at the

interface and maintains the energy balance between both phases. These equations

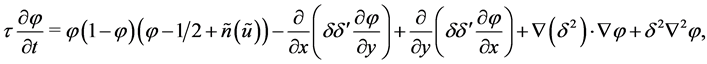

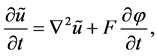

are in their dimensionless units. The final phase-field equations in two dimensions

are:

called the source term, which accounts for the liberation of latent heat at the

interface and maintains the energy balance between both phases. These equations

are in their dimensionless units. The final phase-field equations in two dimensions

are:

(2.5)

(2.5)

(2.6)

(2.6)

The solution of the phase-field Equation (2.5) describes the shape, motion and location of the diffusion layer, while the solution of the thermal-diffusion Equation (2.6) gives the temperature of the interfacial layer.

3. Numerical Method and Results

For space discretization, we applied the method of finite difference (central difference

scheme) and for time discretization, we applied the 4th-order Runge-Kutta method.

The Laplacians

and

and

occurring in phase-field Equation (2.5) and thermal-diffusion Equation (2.6) respectively

are solved by using the nine point finite difference formula for desirable accuracy.

We gave an illustration of the effect of each parameter on the growth and shape

of dendritic crystal. The effect of each parameter on the size, shape and growth

of crystal is analyzed separately and thoroughly. Parameters like relaxation time

occurring in phase-field Equation (2.5) and thermal-diffusion Equation (2.6) respectively

are solved by using the nine point finite difference formula for desirable accuracy.

We gave an illustration of the effect of each parameter on the growth and shape

of dendritic crystal. The effect of each parameter on the size, shape and growth

of crystal is analyzed separately and thoroughly. Parameters like relaxation time , orientation angle

, orientation angle , interfacial

width

, interfacial

width , melting temperature

, melting temperature , time

, time , latent

heat

, latent

heat

and mode number of anisotropy

and mode number of anisotropy

are studied separately and their effects on the dendrite are visualized. Numerical

results for both phase-field

are studied separately and their effects on the dendrite are visualized. Numerical

results for both phase-field

and temperature

and temperature

are presented here for different values of time. We focused in this study, on the

measures of controlling the growth of dendrites. We also presented here the effect

of each parameter on the tip velocity and tip radius of side branches. Since the

side branches in dendritic growth are very important from industrial point of view.

Their presence directly affects the quality of material and they normally occur

due to the presence of impurities in the material. Therefore, we also focused on

the effect of each parameter on the side branches.

are presented here for different values of time. We focused in this study, on the

measures of controlling the growth of dendrites. We also presented here the effect

of each parameter on the tip velocity and tip radius of side branches. Since the

side branches in dendritic growth are very important from industrial point of view.

Their presence directly affects the quality of material and they normally occur

due to the presence of impurities in the material. Therefore, we also focused on

the effect of each parameter on the side branches.

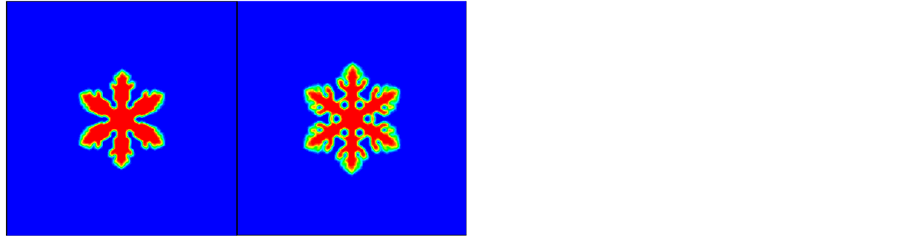

3.1. Effect of Relaxation Time on Dendrite

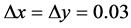

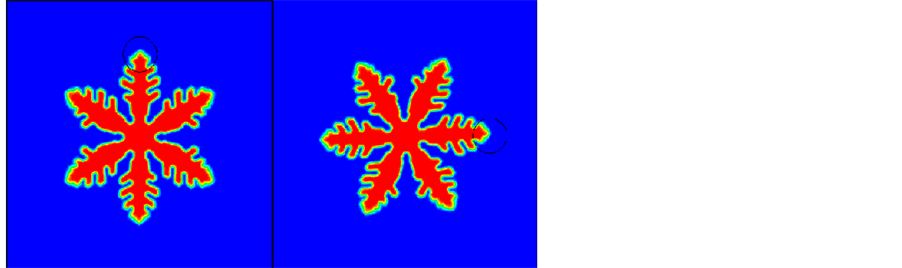

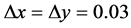

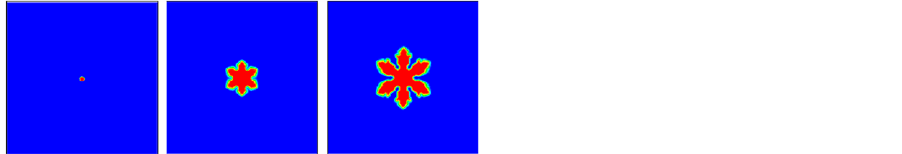

In Figures 1(a)-(c), results are compared using

different values of . For

. For

and

and , we have compared the dendritic growth for

, we have compared the dendritic growth for ,

,

and

and , inside square domain of

size

, inside square domain of

size

with anisotropy

with anisotropy

and at time

and at time . The graphs clearly

shows that for small values of relaxation time i.e., for

. The graphs clearly

shows that for small values of relaxation time i.e., for , the growth process

is much faster as compared to

, the growth process

is much faster as compared to

and

and . This is in agreement to the fact that, for

small values of relaxation time

. This is in agreement to the fact that, for

small values of relaxation time , the atoms takes

less time to retain their equilibrium position and undergo the process of nucleation,

while for large values of relaxation time the equilibrium state is retained lately.

Relaxation time has an indirect effect on the tip velocity and tip radius of side

branches. Note that in Figures 1(a)-(c) both tip

velocity and tip radius of side branches decreases as the relaxation time is increased

from

, the atoms takes

less time to retain their equilibrium position and undergo the process of nucleation,

while for large values of relaxation time the equilibrium state is retained lately.

Relaxation time has an indirect effect on the tip velocity and tip radius of side

branches. Note that in Figures 1(a)-(c) both tip

velocity and tip radius of side branches decreases as the relaxation time is increased

from

to

to .

.

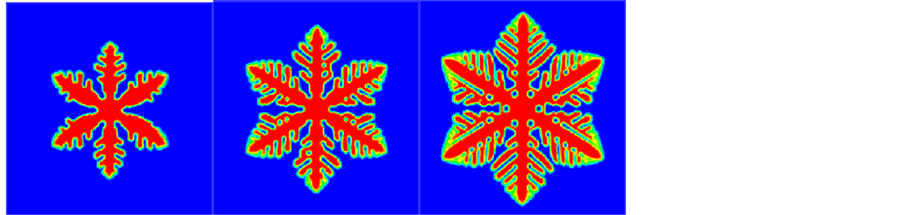

3.2. Effect of Orientation Angle on Dendrite

The angle

is the orientation of anisotropy axis and changing the value of

is the orientation of anisotropy axis and changing the value of

brings changes in the orientation of dendritic crystal. With anisotropy

brings changes in the orientation of dendritic crystal. With anisotropy ,

Figure 2(a) and Figure 2(b) shows the

rotational effect of crystal at an angle of 90˚ which is due to the change

in the value of orientation angle

,

Figure 2(a) and Figure 2(b) shows the

rotational effect of crystal at an angle of 90˚ which is due to the change

in the value of orientation angle

from

from

to

to

respectively. It also shows that

respectively. It also shows that

changes only the orientation of the crystal keeping the shape and growth of dendrite

unaffected.

changes only the orientation of the crystal keeping the shape and growth of dendrite

unaffected.

(a) (b) (c)

(a) (b) (c)

Figure 1. Crystal growth

at (a) ; (b)

; (b) ; and (c)

; and (c) .

.

(a) (b)

(a) (b)

Figure 2. Crystal growth

at (a) ; (b)

; (b) .

.

3.3. Effect of Interfacial Width on Dendrite

In this subsection, for the same values of step size,

and

and , we computed

the problem for two different

, we computed

the problem for two different

and

and

for time

for time

as shown in Figure 3(a) and

Figure 3(b). We observed that when the interfacial width

as shown in Figure 3(a) and

Figure 3(b). We observed that when the interfacial width

is slightly increased from

is slightly increased from

to

to

respectively, the tip velocity and tip radius of side branches also increased. Note

that for interfacial width

respectively, the tip velocity and tip radius of side branches also increased. Note

that for interfacial width

the growth of the crystal almost ceases (the method diverges).

the growth of the crystal almost ceases (the method diverges).

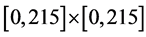

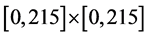

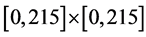

3.4. Effect of Melting Temperature on Dendrite

In this subsection, we gave the numerical simulation for different values of melting

temperature

for phasefield distribution

for phasefield distribution . Using square domain

of size

. Using square domain

of size

with

with ,

,

,

,

, and latent heat

, and latent heat , we compared the results

for

, we compared the results

for

and 1.2 at time

and 1.2 at time .

Figures 4(a)-(c) shows the effect of melting temperature

.

Figures 4(a)-(c) shows the effect of melting temperature

on the size, shape and growth of dendrite for phase-field

on the size, shape and growth of dendrite for phase-field

distribution. Since the dimensionless temperature

distribution. Since the dimensionless temperature

is given by

is given by

where

is the temperature of the system,

is the temperature of the system,

is the melting temperature and

is the melting temperature and

is the system’s initial temperature with value

is the system’s initial temperature with value . As the value of

. As the value of

is increased from 1.0 to 1.2, the dimensionless temperature

is increased from 1.0 to 1.2, the dimensionless temperature

decreases. Therefore, the growth process accelerates by increasing the value of

decreases. Therefore, the growth process accelerates by increasing the value of

(Figures 4(a)-(c)). Note that melting temperature

(Figures 4(a)-(c)). Note that melting temperature

has a direct effect on the growth and shape of dendrite. It is also clear from Figures 4(a)-(c) that increasing the melting temperature

has a direct effect on the growth and shape of dendrite. It is also clear from Figures 4(a)-(c) that increasing the melting temperature , increases the tip velocity of side branches

while the tip radius has an inverse effect. When

, increases the tip velocity of side branches

while the tip radius has an inverse effect. When

is increased, the dimensionless temperature

is increased, the dimensionless temperature

decreases and the tip radius of side branches decreases. When the dimensionless

temperature

decreases and the tip radius of side branches decreases. When the dimensionless

temperature

is very low the growth of these dendrites accelerates, the tip velocity of the side

branches is increased by lowering the temperature, whereas the radius or thickness

of these side branches is small. By increasing the temperature, the growth rate

is decreased, side branches grow with less speed while have larger radii. Further

increasing the temperature of the system beyond melting point melts the structure.

is very low the growth of these dendrites accelerates, the tip velocity of the side

branches is increased by lowering the temperature, whereas the radius or thickness

of these side branches is small. By increasing the temperature, the growth rate

is decreased, side branches grow with less speed while have larger radii. Further

increasing the temperature of the system beyond melting point melts the structure.

(a) (b)

(a) (b)

Figure 3. Crystal growth

at (a) ; (b)

; (b)

(a) (b) (c)

(a) (b) (c)

Figure 4. Crystal growth

at (a) ; (b)

; (b) ; and (c)

; and (c) .

.

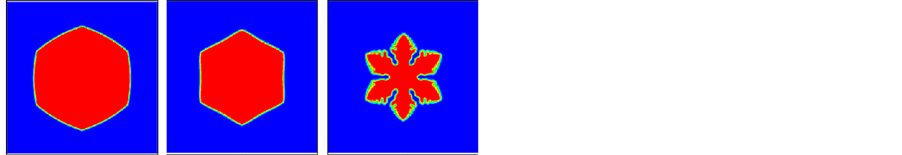

3.5. Effect of Anisotropy on Dendrite

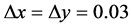

Anisotropy has a direct effect on the shape of dendritic crystal. In Figure 5, we presented the tetragonal shape of dendrite using

mode number of anisotropy , on square mesh

of size

, on square mesh

of size

with

with , latent heat

, latent heat , relaxation time

, relaxation time , orientation

angle

, orientation

angle , interfacial width

, interfacial width

and

and

at time

at time

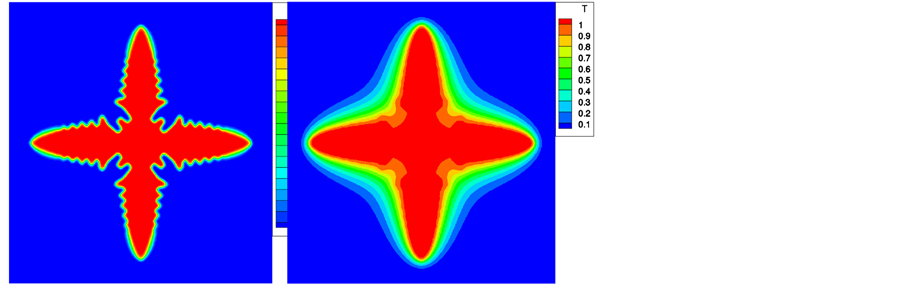

both for phase-field and temperature values respectively. We now present the hexagonal

shape of dendrite in Figure 6, by increasing the

mode number of anisotropy

both for phase-field and temperature values respectively. We now present the hexagonal

shape of dendrite in Figure 6, by increasing the

mode number of anisotropy , on square mesh

of size

, on square mesh

of size

with

with , latent heat

, latent heat , relaxation time

, relaxation time , orientation

angle

, orientation

angle , interfacial width

, interfacial width

and

and , both for phase-field and temperature values

respectively at time

, both for phase-field and temperature values

respectively at time

Note that anisotropy has a direct affect on the side branches. As clear from Figures 5-7, when anisotropy is increased from

Note that anisotropy has a direct affect on the side branches. As clear from Figures 5-7, when anisotropy is increased from

to

to , the side branches appear around the crystal.

Moreover the tip velocity and tip radius of side branches is also increased when

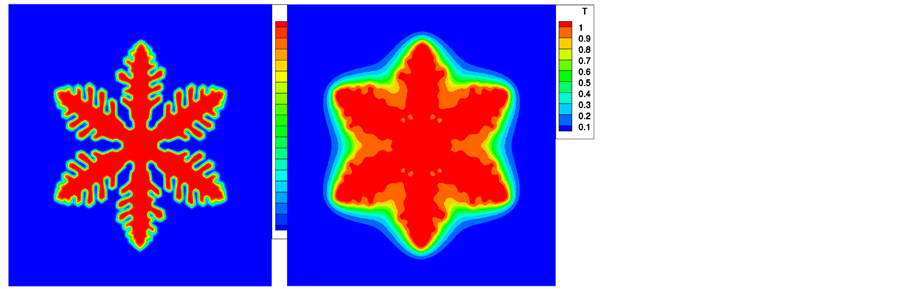

anisotropy is changed from 4 to 6. We now give the octagonal shape of dendrite by

using mode number of anisotropy

, the side branches appear around the crystal.

Moreover the tip velocity and tip radius of side branches is also increased when

anisotropy is changed from 4 to 6. We now give the octagonal shape of dendrite by

using mode number of anisotropy

under the same values of physical parameters at time

under the same values of physical parameters at time

In Figure 7, we have simulated the results for

both phase-field and temperature distribution respectively. The anisotropic mode

number

In Figure 7, we have simulated the results for

both phase-field and temperature distribution respectively. The anisotropic mode

number

tells us about the presence of impurities in a material. Materials abundant in impurities

have large anisotropic mode numbers and therefore a large amount of side branches

grow around the dendritic crystal with larger radii.

tells us about the presence of impurities in a material. Materials abundant in impurities

have large anisotropic mode numbers and therefore a large amount of side branches

grow around the dendritic crystal with larger radii.

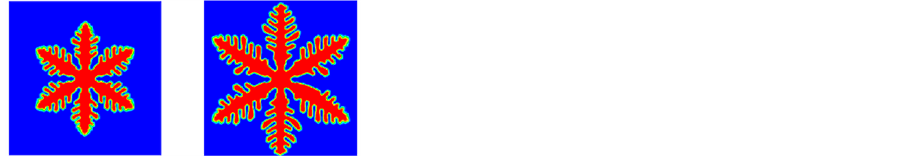

3.6. Effect of Latent Heat on Dendrite

The whole growth process of the dendrite depends mainly upon latent heat F. This auxiliary parameter is the most important physical quantity of the phase-field model. It accounts for the liberation of heat from the solidifi-

(a) (b)

(a) (b)

Figure 5. Dendritic growth

for anisotropy . (a) (Phase-field

distribution); (b) (temperature distribution).

. (a) (Phase-field

distribution); (b) (temperature distribution).

(a) (b)

(a) (b)

Figure 6. Dendritic growth

for anisotropy . (a) (Phase-field

distribution); (b) (temperature distribution).

. (a) (Phase-field

distribution); (b) (temperature distribution).

(a) (b)

(a) (b)

Figure 7. Dendritic growth

for anisotropy . (a) (phase-field

distribution); (b) (temperature distribution).

. (a) (phase-field

distribution); (b) (temperature distribution).

cation front (diffusion layer). Large values of latent heat F accounts for the evacuation

of heat from the interfacial region in a great amount. Therefore, the growth of

dendrite is directly proportional to the value of latent heat F. For small values

of F the growth process is slow, as less amount of heat evacuates from the diffusion

layer and hence the solidification process is slow. Latent heat F is the main parameter

which triggers the solidification process. Figures 8(a)-(e)

shows the dendritic growth for latent heat

and 2.0, inside square domain of size

and 2.0, inside square domain of size

with

with , relaxation time

, relaxation time , orientation

angle

, orientation

angle , interfacial width

, interfacial width , mode number

of anisotropy

, mode number

of anisotropy

and

and

respectively at time

respectively at time .

Figures 8(a)-(e) clearly shows that the shape of dendrite depends upon

the latent heat f, for large values of f the branches and side branches form around

the dendritic crystal. Latent heat f has a direct effect on the tip radius and tip

velocity of side branches. As latent heat f increases from 0.5 to 2.0, the tip radius

and tip velocity of side branches also increases. Therefore, in order to limit the

growth of side branches, latent heat f should be taken small.

.

Figures 8(a)-(e) clearly shows that the shape of dendrite depends upon

the latent heat f, for large values of f the branches and side branches form around

the dendritic crystal. Latent heat f has a direct effect on the tip radius and tip

velocity of side branches. As latent heat f increases from 0.5 to 2.0, the tip radius

and tip velocity of side branches also increases. Therefore, in order to limit the

growth of side branches, latent heat f should be taken small.

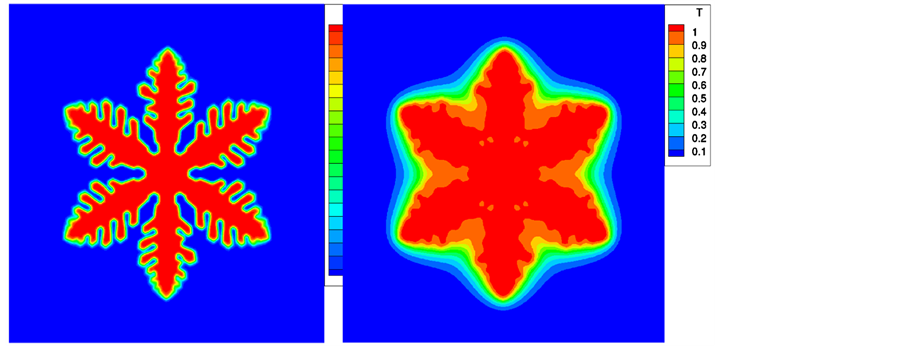

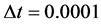

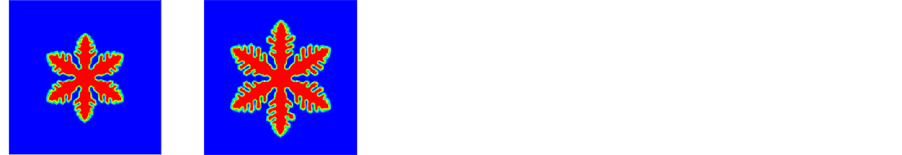

3.7. Effect of Time on Dendrite

Time has a direct effect on the growth as well as on the shape of dendritic crystal.

Figures 9(a)-(e) shows the effect of time on the

dendritic growth for , 0.05, 0.1, 0.15

and 0.2 respectively with relaxation time

, 0.05, 0.1, 0.15

and 0.2 respectively with relaxation time , orientation angle

, orientation angle , interfacial width

, interfacial width , mode number

of anisotropy

, mode number

of anisotropy ,

,

,

,

and latent heat

and latent heat . Figure

9 clearly shows the effect of time on the growth and shape of dendrites.

At time

. Figure

9 clearly shows the effect of time on the growth and shape of dendrites.

At time , we get the central

nucleus while for large values of time the growth process accelerates along with

the shape. The branches and side branches form around the solid grain for large

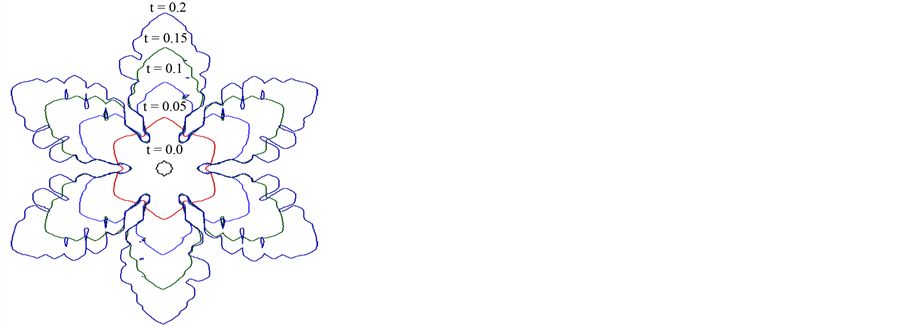

values of time. In Figure 10, we have given contour

plot of dendritic growth for time

, we get the central

nucleus while for large values of time the growth process accelerates along with

the shape. The branches and side branches form around the solid grain for large

values of time. In Figure 10, we have given contour

plot of dendritic growth for time , 0.05, 0.1, 0.15

and 0.2 respectively. It also shows the acceleration of growth phenomenon with the

passage of time. Clearly the interfacial velocity is a function of time. The tip

radius and tip velocity of side branches also increases by increasing the time.

, 0.05, 0.1, 0.15

and 0.2 respectively. It also shows the acceleration of growth phenomenon with the

passage of time. Clearly the interfacial velocity is a function of time. The tip

radius and tip velocity of side branches also increases by increasing the time.

4. Conclusion

In this work, a numerical scheme is developed for the solution of phase-field equation coupled with thermal diffusion equation. The numerical procedure is based on nine point finite difference for spatial discretization and 4th-order Runge-Kutta method for temporal discretization on uniform grids. Both methods are popular for their simplicity, stability and accuracy. The numerical solver is tested and validated by studying each parameter briefly and the effect of every physical parameter on the growth of dendrite is analyzed and justified with the actual phenomenon of dendritic solidification. Effects of relaxation time, interfacial width, mode number of anisotropy, temporal resolution, orientation angle, latent heat, melting temperature and time on the growth and shape of

(a)

(a) (b)

(b)

Figure 8. Dendritic growth

at (a) ; (b)

; (b) ; (c)

; (c) ; (d)

; (d) ; and

(e)

; and

(e) .

.

(a)

(a) (b)

(b)

Figure 9. Dendritic growth

at (a) ; (b)

; (b) ; (c)

; (c) ; (d)

; (d) ; and (e)

; and (e) .

.

Figure 10. Dendritic

growth at ,

,

,

,

,

, ; and

; and .

.

dendritic crystal are simulated and presented. Effects of these parameters on the tip velocity and tip radius of side branches are also presented.

References

- Glicksman, M.E. and Marsh, S.P. (1993) Handbook of Crystal Growth. North-Holland, Amsterdam, 1075-1080.

- Boettinger, W.J., Coriell, S.R., Greer, A.L., Karma, A., Kurz, W., Rappaz, M. and Trivedi, R. (2000) Solidification Microstructures: Recent Developments, Future Directions. Acta Materialia, 48, 43-70. http://dx.doi.org/10.1016/S1359-6454(99)00287-6

- Cahn, J.W. (1967) Crystal Growth. Pergamon Press, Oxford, 681-690.

- Fix, G.J. (1983) Free Boundary Problems. Boston, 115-135.

- Langer, J.S. (1980) Instabilities and Pattern Formation in Crystal Growth. Reviews of Modern Physics, 52, 1-28. http://dx.doi.org/10.1103/RevModPhys.52.1

- Collins, J.B. and Levine, H. (1985) Diffuse Interface Model of Diffusion-Limited Crystal Growth. Physical Review B, 31, 160-195. http://dx.doi.org/10.1103/PhysRevB.31.6119

- Kobayashi, R. (1993) Modeling and Numerical Simulations of Dendritic Crystal Growth. Physica D, 63, 410-423. http://dx.doi.org/10.1016/0167-2789(93)90120-P

- Ying, X., McDonough, J.M. and Tagavi, K.A. (2006) A Numerical Procedure for Solving 2D Phase-Field Model Problems, Journal of Computational Physics, 218, 770-793. http://dx.doi.org/10.1016/j.jcp.2006.03.007

- Wheeler, A.A., Murray, B.T. and Schaefer, R.J. (1993) Computation of Dendrites Using a Phase-Field Model. Physica D, 66, 243-262. http://dx.doi.org/10.1016/0167-2789(93)90242-S

- Biben, T. (2005) Phase-Field Models for Free-Boundary Problems. European Journal of Physics, 26, 47-55. http://dx.doi.org/10.1088/0143-0807/26/5/S06

- McFadden, G.B., Wheeler, A.A., Braun, R.J., Coriell, S.R. and Sekerka, R.F. (1993) Phase-Field Models for Anisotropic Interfaces. Physical Review E, 48, 2016-2024. http://dx.doi.org/10.1103/PhysRevE.48.2016

NOTES

*Corresponding author.