Journal of Transportation Technologies

Vol.4 No.3(2014), Article

ID:48060,9

pages

DOI:10.4236/jtts.2014.43019

Cargo Airships: International Competition

Barry E. Prentice1, Robert Knotts2

1I.H. Asper School of Business, University of Manitoba, Winnipeg, Canada 2Airship Association, London, UK

Email: barry_prentice@umanitoba.ca, chairman@airship-association.org

Copyright © 2014 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Received 11 March 2014; revised 8 April 2014; accepted 2 May 2014

ABSTRACT

The advance of transportation technology depends on science and economics. During the 1930s, airships and airplanes competed head-to-head for the Atlantic passenger market. When World War 2 broke out, everything changed. Over the next five years, the combined combatants built over half of a million military airplanes. By the end of the war, four-engine, high-altitude bombers and jet engines were developed. Further investment in airplane technology was stimulated by the Cold War. All this public investment was adapted to civilian passenger jet airplanes. By 1980, dedicated jet airplanes were in use as cargo carriers. Despite the growth of the cargojet market over the past three decades, rising fuel costs and environmental concerns are changing the economics of airships and airplanes again. Investment in large cargo airships is returning. Much of the technology developed for fixed-wing aircraft can be applied to cargo airships. New materials, better engines, control systems and engineering eliminate the need for large ground crews and improve airship reliability and safety. However, two fundamental design issues have yet to be resolved: structural integrity and buoyancy control. A worldwide competition is underway on three continents to develop the dominant design for a cargo airship. This paper examines the alternative design approaches and presents the status of the international competition.

Keywords:Cargo Airships, Dominant Design, World Developments

1. Introduction

The development of a new generation of large commercial airships is creating interest worldwide. Air cargo demand has been growing rapidly for the past three decades, despite the rising costs of operating jet aircraft and the increasing recognition of adverse environmental impacts of jet aircraft. Current trends in the price of petroleum suggest that jet aircraft costs will increase, while the environmental impact of air freighters will come under more scrutiny. Some further improvements in engine technology are possible, but no practical substitutes exist for Jet-A fuel. Jets are the most polluting form of transportation and carbon taxes could be imposed on jet airplanes to reduce the emissions of Greenhouse Gases (GHG). The potential for cargo airships to replace jet aircraft as a lower cost and more sustainable form of air transport is stimulating research and development globally.

As a buoyant aircraft, an airship only requires energy for propulsion to move through the air. The lift is provided by the lighter-than-air gas. This cuts in half of the fuel consumption of an airship (per tonne-kilometre). Airships can also use alternative fuels, including hydrogen that has zero carbon emissions, because large airships can accommodate bulky, low pressure fuel tanks.

Why did the giant rigid airships of the 1930s go away? The rapid technological development of fixed-wing aircraft during World War 2 was quickly adapted to civilian passenger aircraft after the war. Further technical improvements followed as the Cold War stimulated more military spending on faster and larger airplanes. Oil was inexpensive, airplanes were considered to be safer, speed was more important than costs, and no one even thought about carbon emissions. So, no market existed for older, slower passenger airships when airplanes were readily available.

The inherent nature of airship technology makes it more environmentally sustainable. About half of the fuel consumed by an airplane is used just to keep the vehicle aloft, while the other half of the fuel is used for forward motion. The costs of operating jet aircraft are inexorably increasing. The environmental problems from operating jet aircraft are becoming better known. The technological advantage developed for fixed-wing aircraft during World War 2 still exists, but is decreasing rapidly.

After seven decades of investment in jet airplane technology few opportunities exist for major improvements. In contrast, the opportunities to improve airship performance using modern technology and materials are virtually unexplored. Moreover, the market for air cargo is not focused on speed. Few products need to be transported at 500 miles per hour, and few shippers can afford to pay the costs of jet transport. Consequently, the market for cargo airships is emerging.

Even if only the achievements of the earlier period were replicated, cargo airships would be interesting technology. The giant Zeppelins of the 1930s could cruise at 80 miles per hour and carry useful loads of 70 tons on scheduled flights across the oceans. Of particular note is the Graf Zeppelin that circumnavigated the globe in 1929 and made over 150 Atlantic crossings. These records were established without sophisticated communication equipment or navigation facilities.

Cargo airships are being considered mainly for use in remote areas, like the Arctic, the Amazon and Africa that lack roads or other infrastructure. Once cargo airships reach the size of the giant airships that were built and operated from 1909 to 1940 by the German Zeppelin company, air cargo services across the oceans can compete with cargo airplanes.

The ability to adapt airship technology for cargo transport is recognized and developments are moving forward internationally. This paper reviews the status of cargo airship developments on three continents. The technological approaches are compared and examined for the emergence of a dominant design.

2. Search for the Dominant Design

The last large airship capable of commercial cargo haulage was built before the invention of the strain gauge in 1938. All rigid airships were built on the basis of trial and error; more art, than science. Since that time, many advances in materials, engines, engineering, navigation and control systems have occurred. Modern technology also offers fire sensors and suppression, modern anti-static systems, GPS and other equipment that enhances safety. New airship designs are possible in the 21st century that could not have been contemplated during the prior age of giant airships.

The laws of physics do not change and some issues that confront airship designs remain the same. Solutions to two fundamental challenges experienced in the prior era of rigid airships that have yet to be demonstrated are structural integrity and buoyancy control.

2.1. Airship Structures

The advent of electronic instrumentation and computer modelling has eliminated the guesswork of material requirements. Stronger materials that can accommodate lighter weight designs, like composite materials, new plastics and metal alloys are available. The range of different airship structures includes:

a) Cigar-shaped rigid shell;

b) Rounded rigid shell;

c) Catamaran rigid shell;

d) Catamaran with semi-rigid envelope;

e) Catamaran with flexible envelope (non-rigid);

f) Cigar-shaped with flexible envelope (semi-rigid and non-rigid).

Rigid shell airships can retain their shape, whether or not the internal gas cells are inflated to provide lift. The external shell supports all appendages and cargo bays. The gas cells operate at atmospheric pressure.

Semi-rigid airships require the internal gas pressure within the envelope to maintain their shape, in combination with a rigid spine or keel that holds the engines, fins and cargo space.

Non-rigid airships hang all the appendages from the envelope. Some parts, such as the fins, are connected to the envelope externally. The gondola, engines and cargo space are held by a catenary curtain that is suspended internally from the top of the envelope.

2.2. Buoyancy Control

Buoyancy control refers to the ability to manage the ascent and descent of the airship. The different means of altering vertical location are changing weight (loading or unloading material), altering displacement of the lifting gas, engine propulsion and aerodynamic lift.

Airships achieve lift by the displacement of air with a lighter than air gas. Air weighs approximately 1 kilogram per cubic meter. A perfect displacement would be achieved by a vacuum, but holding the walls of a vacuum-lift airship from being crushed by the weight of the atmosphere makes this design impractical. The airship gains one kilogram of lift, for every cubic meter of air displaced by a lighter lifting gas, minus the weight of the lifting gas.

Hydrogen is the lightest gas and can obtain 93 percent of the lift that would be available with a vacuum. Helium is next best at 86 percent of the lift. Even gases like methane and ammonia could be used but they would only provide 50 percent of the lift created by a vacuum.

Airships need a minimum amount of buoyancy control to offset the weight of the fuel they burn. The giant Zeppelins would seek rain clouds to gather water ballast to gain weight. They also captured water vapour condensed from the engine exhaust. Dumping the water ballast would provide lift. Of course, water or other ballast material can be added on the ground. The Zeppelins also used to vent hydrogen to descend, but helium is too expensive to waste in this manner.

Buoyancy control can be obtained by changing the space occupied by the lifting gas. Any change in pressure or temperature of the gas can effect vertical movement of the airship. Ballonets are used by inflatable airships to control buoyancy. Air is pumped in and out of an inner bladder, called a ballonet, to add weight and reduce the displacement of the lifting gas.

The airship’s propellers can be used to push the airship up or down. Airships can also use aerodynamic lift and drag to control altitude. By pointing the nose of the airship up or down, aerodynamic forces will cause it to change vertical location.

2.3. Structure and Cargo Exchange

Buoyancy control is necessary for ascent, descent, and cargo exchange. In order to maintain a constant altitude, buoyancy must be increased to compensate for any cargo loaded onto an airship. Buoyancy must be reduced to compensate for any cargo removed from an airship. Most airship developers have chosen one of two routes to address load exchange and ground handling issues. A hybrid aircraft technology has been designed that avoids the need for buoyancy control because the vehicle is heavier-than-air when empty. Engine thrust is used to create aerodynamic lift to carry the cargo and fuel. The manufacturers that have embraced this approach are Lockheed Martin (U.S.), Hybrid Air Vehicles (U.K.) and Aero Vehicles (Argentina).

Approximately 60 to 80 percent of a hybrid airship’s lift is static, while the remainder is produced by the airship’s aerodynamic shape. Although not necessarily critical to flight, some hybrid airships also combine hovercraft technology for ground handling. Rather than wheels, these airships float on modified air cushions. When moored, the fans in the air cushions can be reversed to create suction that (in theory) holds the vehicle while loading and unloading.

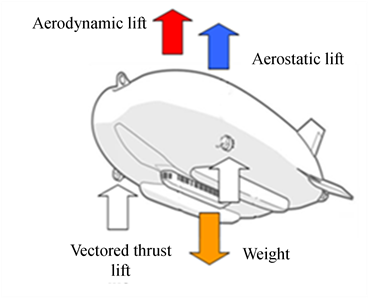

Figure 1 illustrates the concept of the hybrid airship’s methods of lift [1] . A hybrid airship’s varied sources of lift give it more flexibility to deliver cargo to an unprepared site. This could be particularly important for a military exercise or humanitarian logistics that has no prepared terminal facilities. The combination of sources of lift reduces the complication of cargo loading and unloading, but hybrid airships burn much more fuel than traditional airships to obtain this benefit.

A conventional airship has enough buoyancy to lift itself and the payload. The first methods employed to compensate for changes to the cargo load involved the addition or removal of a dense, readily available material. To contain operating costs it is also an advantage if the material is inexpensive, reusable, and portable. Provision of material to balance cargo changes is a non-trivial problem. For example, water has been suggested as an easily available, appropriate material, but the problems that can occur in obtaining water for desert operations should be obvious. It is sufficient to note that an amount of material with weight equal to the cargo must always be present. As the airship offloads cargo, it must either load an equal weight of cargo or some ballast, such as water, to its stowage.

A new approach to controlling buoyancy is to compress the lifting gas to offset the cargo weight. Built with a rigid structure, these designs can control lift at all states with Vertical Takeoff and Landing (VTOL) capabilities. They can also carry maximum payload while in hover. The leading companies taking this approach are Worldwide Areos (U.S.), RosAeroSystems (Russia) and Varialift (U.K.).

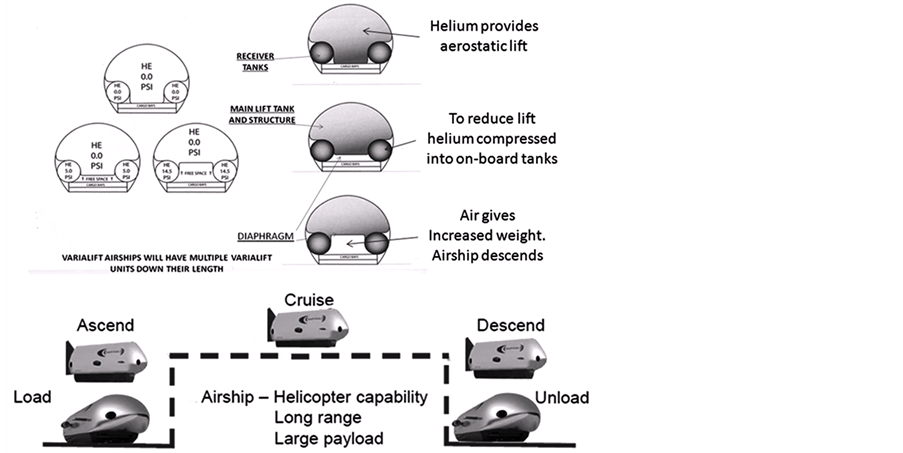

Figure 2 illustrates Varialift’s approach to variable buoyancy control. Lift is altered by moving helium

Figure 1. Hybrid airship: methods of lift.

Figure 2. Variable buoyancy concept.

between lifting-gas cells and pressurized tanks inside the airship. Compressing the helium shrinks the gas cells which makes the vehicle heavier than air for easier ground handling and cargo unloading. Decompressing the helium expands the gas cells and displaces air inside the vehicle which makes it neutrally buoyant.

Rigid airships must be larger than semi-rigid and non-rigid airships to obtain the same useful cargo lift because more lifting gas is required to overcome the deadweight of their structure. However rigid airships lose less gas through leakage. The rigid shape is maintained by the hull, and the gas cells operate at atmospheric pressure. Semi-rigid and non-rigid airships pressurize the gas within their envelope above the ambient atmosphere. At higher pressures the tiny molecules of the lifting gas are pushed out of every pinhole and leaky seam. There is an economic trade-off between the increased weight of a rigid airship, and the cost of replacing helium that leaks out of a non-rigid design.

3. Current and Developing Heavy Lift Airships

Twice as many “paper” airship projects can be found on the internet as there are actual projects in which a physical airship is tested at some level. The current state of heavy lift airship technology is outlined below for the leading airship companies.

3.1. Worldwide Aeros Corporation

Worldwide Areos was founded at San Bernardino, California in 1987. They build aerostats and small blimps, but their long term dream has been to build a cargo airship. During the past decade, Aeros has obtained contracts from DARPA and other US defense projects to develop its technology.

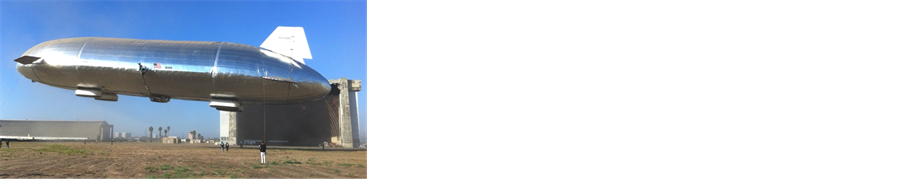

Their most recent US Department of Defense project is to build a demonstrator, called an Aeroscraft, that they have christened The Dragon Dream. The Aeroscraft is a rigid airship, with catamaran structure and a variable buoyancy system. The half-scale demonstrator began tethered flight testing in September 2013.

The Aeroscraft uses a compression system to control its buoyancy. It can compress a certain amount of its lifting gas and put it into fabric tanks. The density of the compressed gas is higher so that it is no longer lighter than air, and therefore causes the airship to change its buoyancy. The company calls this system COSH, an acronym for “Control of Static Heaviness” [2] . A photo of the Aeroscraft’s Dragon Dream is shown in Figure 3.

The Aeroscraft prototype is 266 ft (79 m) long and 97 ft (29.5 m) wide. It is powered by three swivelling engines—two on the sides and one in the back—that provide both aerodynamic lift and thrust to propel it forward.

The rear engine gives control at low airspeeds by pushing the tail around, side to side or up and down. Two sets of wing-like control surfaces are mounted fore and aft, and two large rudders push up vertically from the tail end. These aerodynamic surfaces are used at higher speeds (above 20 mph/30 kph).

The structures under airship are landing pads; a type of inflated hovercraft skirt that allows the airship to rest on ground, water or ice. The airship is a one-half scale prototype—the final design is expected to be more than 400 feet (121 m) long and be able to lift a cargo weight of 66 tons [2] .

3.2. Augur Aeronautical Centre

Moscow-based, Auguar Aeronautical Centre was founded in 1991. They build aerostats and small blimps, under the name RosAeroSystems. They have announced a new dirigible program, the Atlant. The Atlant 30 is a rigid, round-top airship with a flat bottom that is designed to carry 30 tons.

An active ballasting system is proposed for the Atlant to help control the dirigible’s free lift (in-flight and parked) by compressing air or helium [3] . A unique feature of this design is side opening cargo doors that form

Figure 3. Aeroscraft: Dragon Dream.

ramps to facilitate loading. The Atlant shape can provide aerodynamic lift, but it is designed to operate principally as a vertical take-off and landing vehicle. One advantage that this Russian company has over competing manufacturers is its history of cold weather operations. Many of the most promising markets, like Alaska and Canada, have weather conditions similar to Siberia.

Figure 4 is an artist’s impression of the Atlant. The company recently reported that it expects to receive its first round of funding in August 2013. Expectations are that the Atlant 30 will fly in 2017 and the larger Atlant 100 in 2018 [4] .

3.3. Hybrid Air Vehicles (HAV)

Hybrid Air Vehicles (HAV) at Bedford, England is the successor company of a series of corporations founded originally in 1971 by Roger Munk. With the exception of the Zeppelin Company, HAV can claim the longest pedigree in the modern field of lighter-than-air technology. HAV has specialized in inflatable structures (blimps) and this is the direction they use in their design for a cargo airship.

In June 2010, the US Army commissioned HAV and Northrup Grumman to build a full-size hybrid air vehicle for surveillance purposes. The program called the Long Endurance Multi-Intelligence Vehicle (LEMV) specified a hybrid airship optimised for surveillance purposes. The airship was designed with a relatively small 1100 kg (2425 lbs) payload and large fuel tanks to enable the aircraft to stay aloft for up to 21 days. If the same 92 metre (301 feet) long vehicle were optimised for heavy lift (cargo) operations, it would offer a 10 metric tonne payload capacity [5] .

From its LEMV experience HAV has developed the Airlander 50 design, an aircraft that can be used for manned persistent surveillance and heavy lift. In the heavy lift configuration, the Airlander 50 is designed to carry 50 metric tonnes. It can also be operated like a helicopter with vertical take-off, landing and hovering, but its cargo lift is cut by 60 percent. A photograph of the LEMV’s first flight and an artist’s impression of the proposed Airlander 50 are shown in Figure 5.

One significant advantage of airships is their immense size which allows them to feature a huge cargo bay, with loading ramps at each end. The payload area of the Airlander 50 is sized to take six 20 feet containers in two rows of 3 each, sitting abreast, whilst still having space for 50 passengers (subject to the 50 tonne maximum payload weight) [6] .

The 300-foot-long LEMV was the largest lighter-than-air vehicle to fly since the early 1960s. Despite a successful test flight in August 2012, the LEMV programme faced mounting problems: the vehicle was overweight; the programme was behind schedule; and, its original need, the war in Afghanistan was winding down. The US Army cancelled the programme in February 2013.

In October 2013 the US Army sold the LEMV to its original designer HAV [7] . HAV has brought the airship to the UK, where they plan to re-launch it as the HAV 304. The most recent reports picture the HAV 304 (also known as the Airlander 10) inflated in the Cardington Sheds [8] [9] .

Figure 4. RosAeroSystems: Atlant 30.

Figure 5. HAV: LEMV and Airlander 50.

3.4. Lockheed Martin

Lockheed Martin (LM) has two divisions that research airships. LM researches high-altitude, traditionally shaped airships at the former Goodyear Aircraft Airdock at Akron, Ohio and hybrid airships at their Skunk Works research centre at Palmdale, California. In January 2006, they flew the P-791 hybrid airship demonstrator.

The P-791 was designed as multi-mission capable of manned or unmanned intelligence gathering or for transport [10] . This is a non-rigid (inflatable), catamaran-shaped hybrid airship that depends on aerodynamic lift for buoyancy control.

Figure 6 presents a photograph of the P-791 together with an artist concept of the SkyTug cargo airship.

LM announced in 2011 that they had reached an agreement with a commercial partner to develop a scaled-up hybrid airship version of the P-791 demonstrator. The planned initial variant, the SkyTug, would have a 20-ton capacity payload. One version of SkyTug will have diesel engines and conventional takeoff and landing capability. Another will have more powerful turboshaft engines giving a vertical take-off and landing capability.

3.5. Aero Vehicles Inc.

Aerovehicles was originally founded in California in 2002, but now operates out of San Luis, Argentina. They are proposing to build the Aerocat R40 that is a semi-rigid, hybrid design that will carry 40 tonnes. The Aerocat differs from the SkyTug and Airlander by the use of a composite nose cone and internal structure. This innovation was added to deal with the effect of high winds. An artist’s depiction of the airship is presented in Figure 7.

The Aerocat R40 is designed with a smooth top to eliminate the collection of snow and ice. Like other hybrid designs, the Aerocat is envisioned with a landing system based on modified hovercraft cushions.

Despite significant investment in engineering and design, no prototype has been flown as yet. However, the

Figure 6. LM: P-791 and SkyTug.

Figure 7. Aerocat: R40.

company reports that it has obtained sufficient commercial interest to meet its required milestones for continued funding.

3.6. Airship do Brasil Industria Aeronautica (ABD)

Airship do BrasilIndustria Aeronautica (ADB) is a Brazilian private equity firm, belonging to Groups ENGEVIX and Bertolini. They are one of the biggest logistics companies in Brazil, involved in cargo shipping, storage facilities, road equipment construction and naval dockyard construction. About 80% of Brazil’s roads are unpaved. This presents major problem to cargo transporting vehicles. Mud and congestion seriously hamper road transport. ABD is developing and planning to operate cargo airships to serve their own transportation needs. Figure 8 presents an artist’s impression of ABD’s proposed airship.

Details are sketchy on this semi-rigid cargo airship. The proposed capacity is 30 tons. Their first flight is expected in July 2016. The company aims to carry out a test flight of the craft in July 2016 [11] .

3.7. Varialift Airships

Varialift Airships is a U.K. based airship company that has designed an all-metal (aluminium), rigid airship. They are establishing manufacturing facilities at a former French Air Force base near to the city of Cambrai in the north east of France. Pending funding, the company plans to complete the design of the ARH 50 and construct the airship within 24 months of the site being opened. Cranfield University in the UK is assisting in the design work. A production line is planned together with a pilot training school [12] .

The ARH 50 has a length of 150 metres (492 feet) and a payload capacity of 50 tonnes. It will use the company’s patented helium compression technology, previously shown in Figure 2, for buoyancy control. The compression system is also designed to alter the lift along the length of the airship to provide trim and stability. An artist’s impression is given in Figure 9.

Varialift Airships plans an initial production rate of one ARH per month using modular assembly. A second production line will be installed during months 36 to 48. When the ARH50 development work is complete larger airships are planned [12] . One of the advantages of the all-metal construction is that this airship has the potential to be constructed without the expense of a large hangar. The proposed manufacturing technique resembles the method of fabricating ocean going ships.

4. Current and Future Airship Capabilities

A decade ago, the only commercial markets for airships were advertising and carrying TV cameras at football games. All these airships were inflatables, or “blimps”. Now a worldwide competition has emerged to develop cargo airships. The dominant design of the cargo airship has yet to be established. Designs with rigid hulls that are made of aluminum or composite materials are being put forward, as well as non-rigid designs, and even

Figure 8. Airship do Brasil.

Figure 9. Varialift: ARH50.

some semi-rigid variants.

The proposed cargo lift for this first generation of cargo airships varies from 20 to 66 tonnes. However, the cargo bays are much larger than the dimensions of trucks or containers. Consequently, these aircraft will be able to carry much lower density cargoes without reaching their volume limits. Most designs have vertical take-off and landing ability so they can carry slung loads. Hybrid vehicles are more limited than traditional airships in this configuration.

All proposed cargo airship designs have vectoring engines, tail thrusters and modern aircraft avionics that give pilots sufficient control to land and take off independently. This eliminates the need and expense of large ground crews. The issue still in flux is the role of aerodynamic lift versus static lift. One camp favors static lift with active buoyancy adjustment (gas compression), while the other side favors a heavier-than-air design with aerodynamic lift to provide control of buoyancy. Both ideas have merits and the dominant design could incorporate elements.

The most important remaining barrier to a cargo airship industry is the lack of business confidence. Any of the projects described in this report could have a vehicle ready for certification within three years of funding, and some are even further along. However, no project has yet announced success in financing. Once any cargo airship does reach this stage of commercialization, more investors will step forward to take advantage of the latent market for air cargo transportation. As competition for sales and market share occurs the dominant cargo airship design will emerge.

References

- DOD (2012) Hybrid Airships Operational Concepts. Office of the US Assistant Secretary of Defense for Research and Engineering. Rapid Reaction. www.hsdl.org/?view&did=728732

- Govers III, F.X. (2013) Aeroscraft Begins Flight Testing Following FAA Certification. http://www.gizmag.com/aeros-gets-faa-approval-for-testing/28970/

- Russian Radio (2013) A Daring Project of Russian Airship Designers. 6 February 2013.

- Talesnikov, M. (2013) Atlant. 3rd Cargo Airships for Northern Operations Workshop, Anchorage, Alaska, 10-12 July 2013. http://event.arc.nasa.gov/airships/2013Workshop

- Giesler, H. (2013) Access to the Arctic: Time to Try Something Different. Press Release (30 February), Hybrid Air Vehicles Ltd.

- Hybrid Air Vehicles (undated) Civil Heavy Lift. http://www.hybridairvehicles.com/heavylift.aspx

- Schechter, E. (2013) US Army Sells Cancelled LEMV Airship to Original Designer, Flight Global. http://www.flightglobal.com/news/articles/us-army-sells-cancelled-lemv-airship-to-original-designer-392226/

- Pocock, C. (2013) Hybrid Air Vehicles Attempts to Revive Lighter-than-air Aircraft. Aviation International News (AIN). http://www.ainonline.com/aviation-news/dubai-air-show/2013-11-17/hybrid-air-vehicles-attempts-revive-lighter-air-aircraft

- Economist (2014) Inflated Ideas: Reviving Airships. 8 March.http://www.economist.com/news/science-and-technology/21598613-reviving-airships?frsc=dg%7Ca

- Dornheim, M.S. (2006) Lockheed Martin’s Secretly Built Airship Makes First Flight. Aviation Week. http://www.aviationweek.com/

- Transportes Bertolini (2013) Airship compra area para produzir dirigiveis.http://www.tbl.com.br/noticias-detalhes-08.jsp

- AAJ (2013) “Varialift Moves Manufacture to France”, Airship. The Journal of the Airship Association, Number 181, 18, September 2013.