Journal of Minerals and Materials Characterization and Engineering

Vol.07 No.03(2019), Article ID:91886,14 pages

10.4236/jmmce.2019.73008

Influence of Boron Fiber Powder and Graphite Reinforcements on Physical and Mechanical Properties of Aluminum 2024 Alloy Fabricated by Stir Casting

H. S. Kumaraswamy1*, Vinjamuri Bharat2, T. Krishna Rao2

1Department of Mechanical Engineering, BNM Institute of Technology, Bangalore, India

2Department of Mechanical Engineering, Global Academy of Technology, Bangalore, India

Copyright © 2019 by author(s) and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: March 24, 2019; Accepted: April 16, 2019; Published: April 19, 2019

ABSTRACT

In this study, boron fiber powder and graphite is reinforced to Al 2024 alloy to develop hybrid metal matrix composite by stir casting process. Hybrid MMCs developed with different weight fraction for 4%, 6%, 8% and 10% of boron fiber and 2% of graphite. Stirring parameters are optimized to obtain solid casting. Reinforcements are poured into molten aluminium at 15 g/min and stirrer is rotated for 5 minutes at 250 rpm with two stages stirring. 1% of magnesium was added to improve the wettability of Al 2024. Cast samples are machined as per the standards to investigate the microstructure, physical and mechanical properties. Optical and SEM analysis was carried out on machined sample to study the uniform distribution of particles. XRD and EDAX analysis is carried out to confirm the dispersion of particles into the matrix. Uniform distribution of the particles is found in optical and SEM images for these stirring parameters. The peak representation of boron and graphite particles is also observed in XRD and EDAX analysis. Theoretical and experimental density of the cast sample is determined by rule of mixture and Archimedes principle. Result shows the density of the composite decreases by increasing percentage of reinforcements. Micro Vickers hardness was tested on the cast composites and the result showed Al 2024 alloy hardness was increased by 31.25% by reinforcing boron and graphite. Similarly, tensile and compression strength increased by increasing the percentage of reinforcement. Tensile and compression strength of Al 2024 alloy increased by 45.23% and 29.18% respectively. The ductility of the composites decreased by increasing the percentage of reinforcements.

Keywords:

Al 2024, Boron, Graphite, Stir Casting, SEM, EDAX, Micro Vickers Hardness, Tensile Strength and Compression Strength

1. Introduction

Structural applications require high specific strength and therefore matrix material having light weight like magnesium, titanium or aluminum is mainly used. Also, the same matrix metal is used for very high temperature application. In the recent past, research is mainly focused on aluminum matrix composites (AMCs) due to its light weight and high specific strength which is an essential property for any structures.

The most commonly used reinforcements are silicon carbide, alumina, boron carbide, fly ash, graphite, tungsten carbide (WC) & molybdenum disulphide etc. Generally, there are three types of composites, namely metal matrix composites, polymer matrix composites and ceramic matrix composites. Metal matrix composites (MMCs) are composite materials consisting of metals as matrix and metal or non-metal as reinforcement. Reinforcements are used to improve mechanical and tribological properties. MMCs with more than one reinforcement are called as hybrid MMCs. Aluminum is reinforced with ceramic particles and fibers to improve mechanical and tribological properties like high strength, good malleability, good machinability, good corrosion resistance, improved wear resistance, improved hardness and high thermal conductivity. MMCs are fabricated by solid state and liquid state processes [1] . The selection process for fabricating MMCs plays a very important role. Stir casting is the most economical method for manufacturing MMCs compared with other manufacturing techniques. Generally, stir casting technique (liquid state) is employed as it is economical and can provide enhanced properties by attaining uniform distribution of reinforcements in the matrix. Stir casting technique has many challenges in developing the metal matrix composite. Uniform distribution of particles is the biggest challenge in this technique. Stirring process parameters play an important role to achieve the uniform distribution of particles. In this study, initially the following stirring parameters are selected initially to optimize. At 250 rpm of stirring speed, 10 minutes of stirring time at 800/°C, it gives the better distribution particles into the matrix [2] . Selection of stirring parameters like stirring speed and stirring time will have effect on the uniform distribution of particles and also affect the mechanical properties. At 600 rpm for 10 minutes, duration will give the uniform distribution of particles and good mechanical properties for different volume fraction of silicon carbide with aluminum [3] . The parameters considered for developing a MMC are 600 & 700 rpm of stirring speed and 5, 10, 15 min stirring time. The effects of these parameters on the microstructure and mechanical properties of the produced composites were analysed using reflected light microscopy (RLM), scanning electron microscopy (SEM and FESEM), image analysis, density measurement and tensile test. Image analysis of the as-cast microstructures revealed that higher stirring speeds and time resulted in higher reinforcement content in the as-cast microstructure and consequently the sample under 700 rpm stirring speed with 15 min total stirring time had incorporated most of the added B4C particles [4] . Aluminum Metal Matrix Composite using Al2O3/B4C/Gr particles, developed by stir casting technique and the details of composition are Al + 5% Al2O3 + 1% Gr + 1% B4C (b) Al + 10% Al2O3 + 3% Gr + 2% B4C (c) Al + 15% Al2O3 +5% Gr + 3% B4C (d) Al + 20% Al2O3 + 8% Gr + 4% B4C (e) Al + 25% Al2O3 + 11% Gr + 5% B4C composites. The results show that the composite specimen with 15% alumina, 5% graphite and 3% boron carbide showed highest hardness of 70 HV; however, with increasing the content of reinforcements, the variations in micro hardness also increased. This variation is due to the non-uniform dispersion of reinforcements, which allowed agglomeration of particles and causes spots of variable hardness. Though, hardness of higher reinforced composites is much higher, but higher variations in different locations were obtained. The tensile strength of composites increased with increase in the reinforcement content up to 10% aB4C composite with 186.12 MPa and was 54.82% higher strength than the base aluminum alloy (120.79 MPa). The presence of higher amount of reinforcements in the matrix increases the discontinuities, which leads to lower strength. The hard phases present in the matrix prevents the higher order deformations and percentage elongation of material gets reduced. Tribological studies revealed that hardest composite revealed least wear and the presence of appropriate amount of graphite (5%) leads to uniform tribo layer. At higher loads and higher sliding velocity, the formed layer gets smeared; resulting in increased coefficient of friction and wear rate of composites [5] .

In the present study Aluminium hybrid composite is developed stir casting by selecting Al 2024 as a matrix and reinforced with boron fiber powder and graphite developed by stir casting process by optimizing the stirring parameter.

2. Materials and Methodology

In the present study aluminium 2024 is used as a matrix, Boron fiber powder and graphite is used as a Reinforcements. The chemical composition of Al 2024 is shown in Table 1 mechanical properties of boron fiber powder is as shown in Table 2.

2.1. Experimental Detail

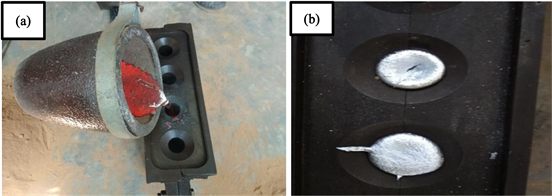

The liquid metallurgy route also called as stir casting technique was used for the development of hybrid metal matrix composite. Aluminum 2024, boron fiber powder and graphite is used as a matrix and reinforcements. The volume fraction of 4%, 6%, 8% and 10% aluminum composites are developed separately and 2% of graphite was used for each volume fraction to develop Al 2024 hybrid MMCs. Initially the Al 2024 ingots are cut to accommodate in graphite crucible. 8% of Boron fiber powder and 2% of graphite was preheated in the muffle furnace for 2 hours at 500˚C.the set up used to develop hybrid MMCs is as shown in Figure 1(a).

Then the temperature range in the stir casting setup is set upto 850˚C, the temperature will raise slowly, and once temperature reaches 700˚C, Al 2024 ingots start melting, once the aluminum become completely molten state, C2Cl6 degasification tablets are dispersed in the molten aluminum to remove the slag, wettability is one of the biggest challenge for aluminum 2024 alloy, addition of 1% of Magnesium improve the wettability of the aluminum molten [6] [7] . On the other side cast iron die is preheated to 500˚C for easy flow of molten metal and to maintain the temperature of molten metal constant. Once the temperature reaches 850˚C, pour the preheated reinforcements at 15 g/min, simultaneously

Table 1. Chemical composition of Al 2024.

Table 2. Properties of Boron fiber.

Figure 1. (a)Stir casting set up; (b) Stirring molten metal.

the stirrer is placed inside the crucible and rotate at 250 rpm for 5 minutes which is as shown in Figure 1(b). After 5 minutes of stirring, the temperature of the molten mixture is slowly lower down to 750˚C, then the mixture is again stirred at 5 minutes till it form the vortex, then the temperature of the crucible is again raised up to 850˚C. once the temperature reaches 850˚C, with the help of suitable foundry tools lift the crucible from the furnace and pour the molten metal into the preheated die and allow the molten metal to solidify for 2 hours, once the solidification is done separate the two halves of the die and separate the solidified casting sample. The stirring process, pouring the molten metal into preheated die and solidified samples are as shown in Figure 2(a) & Figure 2(b). Same procedure was used to develop different volume fraction Al 2024 hybrid MMCs.

2.2. Microstructure Analysis

Microstructure analysis of boron and graphite reinforced Al 2024 hybrid MMCs are carried out using optical micrograph and Scanning Electron Microscope. Optical micrograph and SEM images are used to analyze the distribution of reinforced particles in the composite. Sample used for optical and SEM study was prepared as per the standards. Initially the caste composites are machined for 10 mm length and 5 mm diameter using lathe machine, after machining, the sample are polished using 120, 400 and 600 grit sandpapers, later using polishing machine the specimens are polished to mirroring surface using Al2O3 paste and diamond paste, Keller’s reagent is applied on the surface of the polished specimen [8] [9] , which activates the boron and graphite particles and helps in the visibility of reinforcement particles distribution in the composite during Optical and SEM analysis.

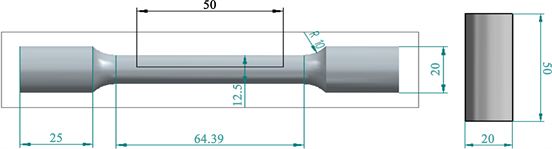

XRD Analysis

X-ray diffraction (XRD) is conducted to identify different phases present in the samples. XRD technique is conducted with a computer-controlled diffractometer fitted with Ni filter which was operated at 30 kV voltage and 20 mA current with Cu-k α radiation. The diffraction angle (2 h) range is given from 20˚ to 90˚ at a scan speed of 2˚/min. XRD testing reveals the percentage of different alloys present in the cast composite and also used to identify the chemical reaction between the material [10] .

Figure 2. (a) Pouring molten metal into metal die; (b) Solidified casting samples.

2.3. Physical and Mechanical Properties

2.3.1. Density

Rule of mixture was used to calculate the theoretical density of the composites for the different weight fraction from 4% to 10% and 2% of graphite similarly experimental density is calculated using Archimedes’ principle for the different composites

Rule of mixture is given by:

2.3.2. Porosity

Porosity is one of the most common defects in stir casting method. The porosity of the hybrid composite is determined by considering theoretical and experimental density

2.3.3. Micro Vickers Hardness

The micro hardness of composite evaluates the interface bonding strength between reinforcing particles and matrix. The Micro hardness is the most accurate method to find the hardness of the caste composites, here the hardness will be measured for micro level and the indentation will be on the particles. The composite billets fabricated in the preliminary experiments are first sectioned to enable an estimation of the uniformity of dispersion. After that, sectioned samples are polished with 120, 400 and 600 grit sandpapers, respectively. Finally, the polishing is finished on cloth using Al2O3 paste. The micro Vickers hardness was carried out with diamond indenter. 500 g load is considered with a dwell time of 10 seconds. 3 to 4 trails are taken on each composite and average values are considered as a micro Vickers hardness number [11] .

2.3.4. Tensile and Compression Strength

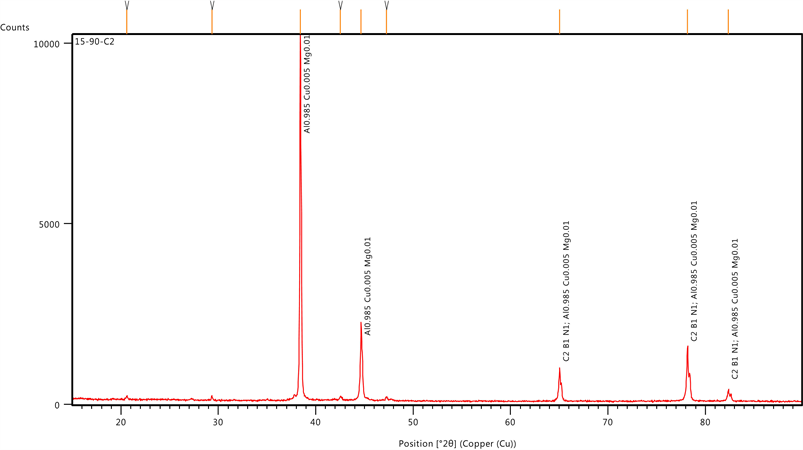

The tensile and compression strength of Al 2024 hybrid MMCS is tested using a computerized universal testing machine. The specimens are prepared as per the ASTM E-8 standards.

The specimen was machined as per ASTM E8 with 50 mm gauge length, 12.5 mm diameter, 25 mm length for holding the specimen on both side and fillet of 10 mm radius was developed to analyze the tensile strength. Similarly, 20 mm diameter and 50mm length specimens are machined to study the compression strength. Figure 3 shows the specimens used for testing the tensile strength and compression strength [12] .

Figure 3. Tensile and compression specimen as per ASTM E8 Standard.

3. Result and Discussion

The following test has carried out on the developed hybrid MMC to analyze the different characterization. The following testing is carried out on the developed MMC.

3.1. Microstructure Analysis

3.1.1. Optical Micrograph

Optical microstructure study is carried out on Al 2024 hybrid composites and Al2024 with boron reinforced composite to study the uniform distribution of particles, optical images shows that boron powder and graphite particles are distributed uniformly in the matrix. The optical image samples of 92% of Al 2024 with 8% boron fiber and 90% of Al 2024 with 8% of boron fiber and 2% graphite hybrid MMCs is as shown in Figure 4(a) and Figure 4(b).

The grain boundary and grain size are decreased by increasing the percentage of reinforcements. The dark particles with big in size represent the boron particles and dark particles with small in size represents graphite. The optical images represent the uniform distribution of particles and no clustering of particles. This is due to the optimized stirring speed and two stage stirring of molten during pouring of reinforcements. The images also show that the particles are strongly bonded with the matrix.

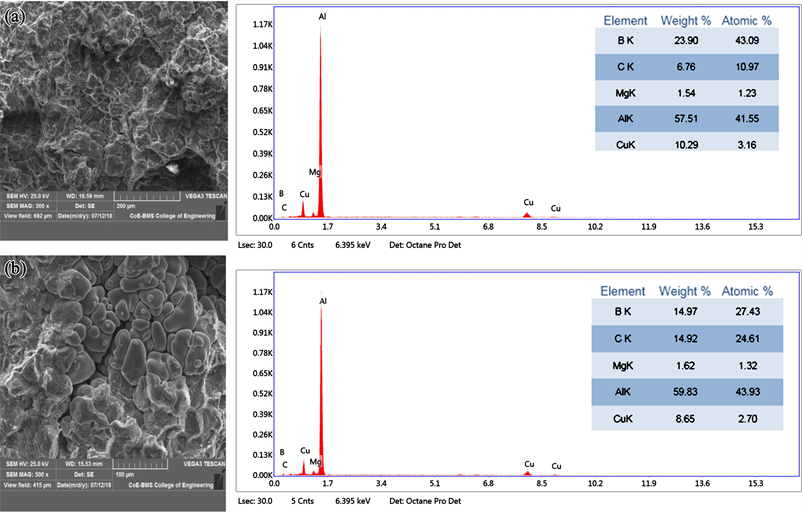

3.1.2 SEM and EDAX

The composites with different volume fraction are examined to analyze the particle distribution by scanning electron microscope (SEM). The SEM images show uniform distribution of particles into the matrix. The dark colour represents the presence of boron fiber powder and graphite particles. EDAX analysis was also carried to confirm the presence of boron and graphite in the matrix. The result shows, there is presence of boron and graphite in the matrix and peak representation of boron (b) and carbon (c) is as shown in Figure 5 this confirm the presence of boron and graphite. SEM and EDAX analysis of boron and graphite reinforced Al 2024 hybrid MMCs is as shown in Figure 6(a) and Figure 6(b).

3.2. XRD Analysis

For 8% of boron fiber powder and 2% of graphite, the reaction products Carbide

Figure 4. (a) Optical image of Al 2024 - 8%B; (b) Optical image of Al 2024 - 8%B - 2%Gr.

Figure 5. XRD analysis of 8% of boron fiber powder, and 2% of graphite.

Figure 6. (a) SEM Analysis and EDAX analysis of Al 2024 - 8%B - 2%Gr; (b) Al 2024 - 8%B.

and Nitride with boron is found at the interface which is identified in XRD. The secondary phase with any combination of materials like Al, carbide and carboborite will increases the strength of the composites. The secondary phase of reaction product peaks for 2θ is observed at 45.56˚ and 66.36˚, 78.96˚ and 83.23˚ respectively.

3.3. Density and Porosity

Theoretical density of the hybrid composite was calculated by rule of mixture and experimental density was calculated by Archimedes principle. The result shows the theoretical density of the composite decreased by increasing the percentage of reinforcements. Experimental density was found out by Archimedes principle and result shows that density of the hybrid composite decreased with increasing the percentage of reinforcements. Theoretical and experimental density was compared and the density obtained experimentally was almost equal to the theoretical density. Similarly, porosity of hybrid MMCs was calculated. The result shows the porosity of the Al 2024 MMCs increased by increasing the percentage of reinforcements. Table 3 shows theoretical density, experimental density and porosity of boron and graphite reinforced Al 2024 hybrid MMCs.

3.4. Micro Vickers Hardness

The Micro Vickers hardness test result for various combinations of matrix and reinforcement materials in weight percentage are examined. Micro Vickers hardness of Al MMC and hybrid MMC is as shown in Figure 7(a) & Figure 7(b).

Micro Vickers hardness number was determined by considering 500 g load for 10 seconds with diamond indentation on the boron and graphite reinforced Aluminium MMCs and Aluminium hybrid MMCs. Result shows that composite material become much harder by increasing the percentage of reinforcements. Figure 7(a) represents the micro Vickers hardness number of Al 2024 and boron MMCs, it shows the effect of boron on hardness on Al 2024 alloy, result shows hardness is increased by increasing the percentage of boron particles. Al 2024 alloy hardness was 110 HV and increased upto 149 HV. The Al 2024 alloy micro Vickers hardness was increased by 27.17% by the addition of boron, this

Table 3. Theoretical density, experimental density and porosity of boron and graphite reinforced Al 2024 hybrid MMCs.

shows addition of boron particles into Al 2024 increases the hardness of base matrix. Similarly, Figure 7(b) represents micro Vickers hardness number of Al 2024 hybrid MMCs with boron and graphite reinforcements. Here the effect of boron and graphite on hardness of Al 2024 was studied. Result shows addition of graphite along with the boron also increases the hardness of Al 2024 alloy. Al 2024 alloy Vickers hardness was increased to 159 HV from 110 HV. This shows addition of graphite along with the boron increased the micro Vickers hardness of Al 2024 by 27.67%.

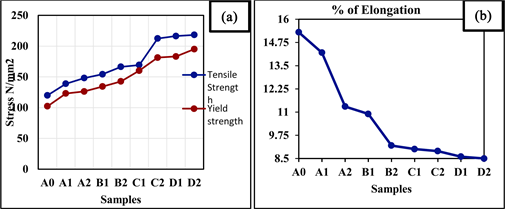

3.5. Tensile Strength

The tensile test is conducted on hybrid MMCs using computerized universal testing machine as per ASTM -E8 standard specimens, the result reveals that the tensile strength of the composites increases with increasing the percentage of reinforcements. Cast Al 2024 is having a tensile strength of 120 MPa without reinforcing boron and graphite. Figure 8 shows tensile test specimens after failure.

Figure 9(a) shows the tensile and yield strength of the boron and graphite reinforced Al 2024 hybrid MMCs along with the Al 2024 alloy. The result shows, tensile strength of the matrix Al 2024 alloy was increased to 219.23 MPa from 120 MPa. Al 2024 alloy tensile strength was increased by 45.23%. This shows the effect of boron and graphite on the tensile strength of the Al 2024 alloy. From the result, it’s concluded that addition of boron and graphite into Al 2024 matrix alloy, increase the tensile strength and yield strength. Similarly, Figure 9(b) shows

Figure 7. (a) Micro Vickers Hardness of Al 2024-Boron MMCs; (b) Al 2024-Boron-Gr Hybrid MMCs.

Figure 8. (a) Tensile test samples after failure; (b) Compression test samples after failure.

that the% elongation of Al hybrid MMCs and Al 2024 alloy. From result, it’s observed that composite material is become more ductile by increasing the percentage of reinforcements. The ductility of the Al 2024 hybrid MMCs increased by increasing the percentage of boron and graphite.

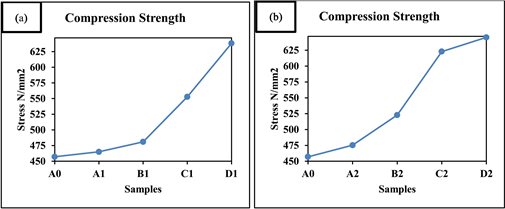

3.6. Compression Strength

The specimens are prepared as per ASTM -E8 standard to study the compression strength of hybrid MMCs using computerized universal testing machine, Figure 10(a) and Figure 10(b) shows the effect of boron and graphite on compression strength of Al 2024 alloy separately. Figure 10(a) shows compression strength of the Al 2024 alloy was increased by increasing the percentage of boron. Compression strength of the casted Al 2024 alloy was 457 MPa this was increased upto 638.23 MPa by the addition of boron, which is almost equal to 28.39%. The result reveals that when the percentage of boron fiber increases, the compression strength is also increasing, Figure 10(b) shows compression strength of the Al 2024 alloy was increased by increasing the percentage of boron and graphite. Compression strength of the casted Al 2024 alloy was 457 MPa this was increased upto 645.3 MPa by the addition of graphite. The result reveals that when the percentage of boron and graphite increased, the compression strength is also increase, which is almost equal to 29.18%. From the results it can be concluded that addition born and graphite reinforcements into Al 2024 matrix alloy increase the compression strength of the base matrix.

Figure 9. (a) Tensile strength & Yield strength; (b) Percentage of elongation.

Figure 10. (a) Compression Strength of Al 2024-boron MMCs (b) Compression Strength of Al 2024-boron-Gr Hybrid MMCs.

The graph shows the compression behaviour of Al 2024 with different percentage of boron fibre which is in the form of powder and graphite.

3.7. Fracture Analysis of Tensile Samples

Achieving uniform distribution in the stir casting is the biggest challenge. The strength of the composites is depending on the uniform distribution of the particles in the matrix, stirring parameters is one of the key points in stir casting to achieve the uniform distribution of the particles. Since the density of the ceramic material used is less than aluminium chances are more either floating of reinforcement or settling of reinforcement particles in the bottom of crucible is a reason for uneven distribution of particles. As a result of optimized stirring parameters, reinforced particles are distributed uniformly in the matrix and supporting the base metal at the time failure [13] .

Figure 11 shows the reinforcement are bonded together and supporting base matrix to improve the strength while fracturing. Proper bonding is observed between the matrix and reinforcement. There is a pull out of particles while breaking has found. This is due to the level of affinity between Al 2024 alloy and boron fiber powder and graphite. Also grain size and shape of reinforcement particle determine bonding ability. If the reinforcement does not mix and bond with metal matrix, the strength of the composites will decrease. It is observed during tensile test due to the proper bonding between the matrix and reinforcement

Figure 11. (a) Tensile Fracture of 92% Al + 8%B + 2%gr and (b) 90% Al + 8% B.

the tensile strength is increased with the percentage of reinforcement increases. The reason for increasing the strength of Al 2024 by increasing percentage of reinforcements was more particles bonding and supporting the matrix Figure 11(b) number of particles are more since the percentage of reinforcement is more and this cause supporting the matrix will increases hence the strength of the Al 2024 alloy increases by increasing the percentage of reinforcements EDAX analysis shows that there is a presence of boron and graphite particle near the fracture surface.

4. Conclusions

The following conclusions are drawn after the completion of testing:

1) The density of the Al 2024 alloy s is decreased by increasing the percentage of reinforcement.

2) The porosity of the Al 2024 alloy is increases by increasing the percentage of reinforcement.

3) The optical and SEM analysis shows there is uniform distribution of reinforce particle in the hybrid MMCs.

4) Micro Vickers hardness value of Al 2024 alloy is increased by 33.33% by reinforcing 10% boron and 2% graphite.

5) Tensile strength and yield strength of the Al 2024 alloy are increased by increasing the percentage of reinforcement particles.

6) Al 2024 casted alloy compression strength is increased by 29.18% with reinforcing 10% boron and 2% graphite.

7) Tensile fracture SEM images show proper bonding of matrix and reinforcement and no breaking of reinforced particles.

Conflicts of Interest

The authors declare no conflicts of interest regarding the publication of this paper.

Cite this paper

Kumaraswamy, H.S., Bharat, V. and Rao, T.K. (2019) Influence of Boron Fiber Powder and Graphite Reinforcements on Physical and Mechanical Properties of Aluminum 2024 Alloy Fabricated by Stir Casting. Journal of Minerals and Materials Characterization and Engineering, 7, 103-116. https://doi.org/10.4236/jmmce.2019.73008

References

- 1. Kumaraswamy, H.S., Bharat, V. and Krishna Rao, T. (2018) Influence of Mechanical & Tribological Behaviour of Al 2024 MMC Fabricated by Stir Casting Technique—A Review. Materials Today: Proceedings, 5, 11962-11970.

- 2. Kumaraswamy, H.S., Bharat, V. and Krishna Rao, T. (2018) Effect of Stirring Parameters on Micro-Structure of Aluminum Hybrid Metal Matrix Composites. IOP Conference Series: Materials Science and Engineering, 376, Article ID: 012096. https://doi.org/10.1088/1757-899X/376/1/012096

- 3. Balasivanandha, S., et al. (2006) Influence of Stirring Speed and Stirring Time on Distribution of Particles in Cast Metal Matrix Composite. Journal of Materials Processing Technology, 171, 268-273. https://doi.org/10.1016/j.jmatprotec.2005.06.071

- 4. Durowoju, M.O., Agunsoye, J.O., Mudashiru, L.O., Yekinni, A.A., Bello, S.K. and Rabiu, T.O. (2017) Optimization of Stirring Process Parameters to Improve the Hardness Properties of Al/RHA Matrix Composites. European Journal of Engineering Research and Science, 2, No. 11.

- 5. Sozhamannan, G. and Venkatagalapathy, V.S.K. (2012) Effect of Processing Paramters on Metal Matrix Composites: Stir Casting Process. Journal of Surface Engineered Materials and Advanced Technology, 2, 11-15. https://doi.org/10.4236/jsemat.2012.21002

- 6. Raei, M., et al. (2016) Effect of Stirring Speed and Time on Microstructure and Mechanical Properties of Cast Al-Ti-Zr-B4C Composite Produced by Stir Casting. Russian Journal of Non-Ferrous Metals, 57, 347-360.

- 7. Kalaa, H., Merb, K.K.S. and Kumar, S. (2014) A Review on Mechanical & Tribological Behaviour of Stir Cast Aluminium Metal Matrix Composites. Procedia Materials Science, 6, 1951-1960.

- 8. Louis, M.J. (2014) Fabrication, Testing & Analysis of Aluminum 2024 Metal Matrix Composite. IJRAME Journal, 2, 29-37.

- 9. Abhijith, R. and Harish, T.M. (2016) Fabrication & Analysis of Aluminum 2024 & Tungsten Carbide (WC) Metal Matric Composite by In-Situ Method. International Journal of Engineering and Technical Research, 5, 400-407.

- 10. Boopathi, M., et al. (2013) Evaluation of Mechanical Properties of Aluminum Alloy 2024 Reinforced with Silicon Carbide & Fly ash Hybrid Metal Matrix Composites. American Journal of Applied Science, 10, 219-229. https://doi.org/10.3844/ajassp.2013.219.229

- 11. Kok, M. (2005) Production and Mechanical Properties of Al2O3 Particle Reinforced 2024 Aluminium Alloy Composites. Journal of Materials Processing Technology, 161, 381-387. https://doi.org/10.1016/j.jmatprotec.2004.07.068

- 12. Purazrang, K., Abachi, P. and Kainer, K.U. (1994) Investigation of the Mechanical Behaviour of Magnesium Composites. Composites, 25, 296. https://doi.org/10.1016/0010-4361(94)90222-4

- 13. Rao, B., Rao, D.V., Murthy, I.N. and Bhargava, N. (2012) Mechanical Properties and Corrosion Behavior of Fly Ash Particles Reinforced AA 2024 Composites. Journal of Composite Materials, 46, 1393-1404. https://doi.org/10.1177/0021998311419876