Food and Nutrition Sciences

Vol.3 No.11(2012), Article ID:24464,4 pages DOI:10.4236/fns.2012.311192

Comparisons of the Properties of Whitemouth Croaker (Micropogonias furnieri) Surimi and Mechanically Deboned Chicken Meat Surimi-Like Material*

![]()

1Laboratory of Food Technology, School of Chemistry and Foods, Federal University of Rio Grande, Rio Grande, Brazil; 2Laboratory of Bioengineering, Faculty of Engineering, Federal University of Grande Dourados, Dourados, Brazil.

Email: #ggf@ufgd.edu.br

Received August 9th, 2012; revised September 7th, 2012; accepted September 15th, 2012

Keywords: Fish; Chicken; Surimi-Like Material; Whiteness; Texture; Sensory

ABSTRACT

The aim of this work was to evaluate and compare the color, texture and sensory characteristics of whitemouth croaker (Micropogonias furnieri) surimi and mechanically separated chicken meat (MDCM) surimi-like material (SLM). The whiteness of the MDCM-SLM was higher (P > 0.05) than that from the surimi. Higher breaking force (P < 0.05) and gel strength (P < 0.05) were also observed for the MDCM-SLM when compared to the surimi. The deformation did not vary significantly for these two products (P > 0.05). The MDCM-SLM was more accepted by the panelists (P < 0.05). The mean scores of overall desirability for MDCM-SLM was similar to that observed for walleye Pollack surimi that is the parameter of quality. The differences in the acceptability of poultry and fish food products are probably due to peoples’ eating habits.

1. Introduction

Surimi is an intermediary semi-processed fishery product. It is an odorless and tasteless crude myosin extract obtained by repeated washings of minced fish with aqueous solution, to remove fat, pigments, and other water soluble substances, then blended with cryoprotectants agents [1-3]. In recent years, there has been considerable interest in manufacturing surimi-like materials from the muscle of animal species other than fish [4-7].

Along with a tremendous growth in production and consumption worldwide, surimi and surimi-based products have been established as internationalized goods [8]. The application of the surimi technology in the production of a surimi-like material from mechanically deboned chicken meat provides a new approach towards increasing its value and utilization, e.g. for the development of meat based products and analogs, as alternative protein sources [9-12].

The use of MDCM in heat-processed meat products, as frankfurters, various loaf products, fermented and smoked sausages, and restructured chicken products has become a common ingredient due its low price [11,12]. The whitemouth croaker (Micropogonias furnieri) is a migratory fish found in the Atlantic Ocean that is one of the most abundant and important for the south Brazilian fishing industries [11].

The aim of this work was to evaluate and compare the color, texture and sensory characteristics of surimi and surimi-like material obtained from whitemouth croaker (M. furnieri) and mechanically deboned chicken meat, respectively.

2. Materials and Methods

2.1. Whitemouth Croaker Meat and Mechanically Deboned Chicken Meat (MDCM)

Fresh whitemouth croakers and MDCM were supplied from two local fish and poultry processing plants, respectively. They were transported under refrigerated conditions to our laboratory and kept at −18˚C before use. The whitemouth croakers were eviscerated before frozen. The MDCM was produced in 3 mm particle size using a meat-bone separator (Baader model 694, Lübeck, Germany), operating at inlet 6˚C and outlet 10˚C. It was obtained from broiler’s necks, frames, thighs and backs, 24 h after the slaughtering [11,12].

2.2. Whitemouth Croaker Surimi and MDCM Surimi-Like Material

Whitemouth croaker meat or MDCM were washed in 3 cycles utilizing in each cycle a washing solution: meat ratio of 4:1 (v/w), temperature of 7˚C, for 10 min. In each washing cycle, the stirring was kept constant at 220 rpm using a mechanical agitator (Marconi model MA- 259, Piracicaba, Brazil). It was utilized 0.5% NaHCO3 solution for the first and second washings and 0.3% NaCl solution for the last one. After each washing cycle, samples were centrifuged at 7˚C (Sigma model 6 - 15, Osterode, Germany). The first and second centrifugations were carried out at 3000 × g for 15 min, while the third one at 7000 × g for 25 min. The supernatant containing fat and water-soluble proteins was discarded. The final slurry was sieved through a 1 mm-mesh metal screen to remove connective tissues, blended with 4% sucrose, 4% sorbitol, and 0.2% Na-tripolyphosphate, packaged in 5-layer nylon propylene bags, and stored at −18˚C. To prepare the gel, whitemouth croaker surimi or MDCM surimi-like material was added of 2.5% salt. The mixture was chopped for 5 min at 4˚C to obtain the homogenous sol. The sol was then stuffed into stainless steel cylinders (30 mm diameter, 30 mm height) and both ends of casing were sealed tightly. Two-step heated gels were prepared by setting the sol at 40˚C for 30 min, followed by heating at 90˚C for 20 min. The gels were then cooled in iced water and stored for 24 h at 4˚C prior to analysis [11].

2.3. Color

The color [CIE L* (lightness), a* (redness), b* (yellowness)] of the samples was evaluates using a colorimeter (Minolta model Chroma Meter CR400, Osaka, Japan), with measurements standardized with respect to the white calibration plate. Five readings were made from the surface of samples. Whiteness [13] as an index for the general appearance of the test samples was calculated according to Equation (1):

(1)

(1)

2.4. Texture

Texture analysis of the gels was carried out using a texture analyzer Model TA-XT2 plus (Stable Micro Systems, Surrey, England). Gels kept at 4˚C were equilibrated at room temperature (22˚C - 25˚C) before analysis. Cylindrical samples, 2.5 × 3.0 cm, were prepared and placed in the texture analyzer equipped with a spherical plunger (5 mm diameter; 60 mm/min depression speed). Analyses were performed at least in triplicate. The results were expressed as breaking force (g) and deformation (mm) representing the hardness and cohesiveness of the sample, respectively. Gel strength was expressed as the product of breaking force and deformation [14].

2.5. Sensory Evaluation

Sensory analyses of gels were conducted by at least 70 non trained panelists. For testing, casing gels were cut into bite-sized (3 mm) samples and, after being warmed slightly for 3 min (approximately 25˚C), draining the liquid and holding on a warming tray in covered plates. All samples were served randomly and at times other than during meal hours. All panelists were asked to score four characteristics (odor, taste, texture, and whiteness), as well as overall desirability using a 5-point hedonic scale [1) dislike extremely; 2) dislike moderately; 3) neither like nor dislike; 4) like moderately; and 5) like extremely] [8]. A score of 3 was the division between acceptable and unacceptable.

2.6. Statistical Analysis

The statistical analysis of the results was performed using the statistical one-way analysis of variance (ANOVA), followed by the Tukey test using the Statistica v. 8.0 software (Statsoft™, Inc., Tulsa, USA.) to determine significant difference between experimental responses. Statistical significance was indicated at 95% confidence level.

3. Results and Discussion

Surimi and surimi-like material were compared in terms of color, texture and sensory properties aiming its potential incorporation into restructured products.

3.1. Color

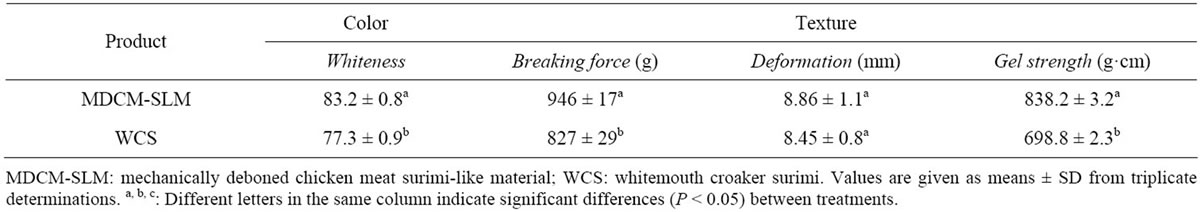

The whiteness of the MDCM surimi-like material was higher (P > 0.05) than that from the surimi (Table 1).

The whiteness of the surimi was very similar to that obtained for silver carp surimi, inferior to that reported for walleye Pollack surimi [8] and superior to those found for Spanish mackerel [15] and grass carp surimi [16]. The whiteness obtained for the surimi-like material was slightly higher than that calculated from color parameters reported for chicken breast surimi-like material [5]. The whiteness of the surimi or surimi-like material is related to the efficiency in the removal of the sarcoplasmic protein from muscle [6] and the elimination of heme pigments [17], which mostly depend of the characteristics of the raw material, number of washing and type of washing solution [11,12].

Table 1. Texture and color of the obtained mechanically deboned chicken meat surimi-like material and whitemouth croaker surimi.

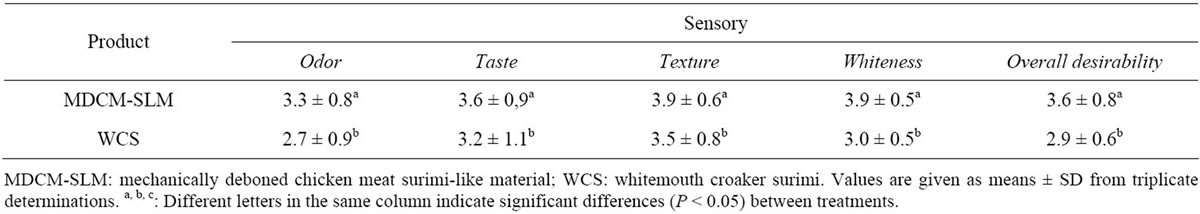

Table 2. Sensory evaluation of the obtained mechanically deboned chicken meat surimi-like material and whitemouth croaker surimi.

3.2. Texture

The textural properties (breaking force, deformation, and gel strength) of the surimi and surimi-like material are shown in Table 1. A higher breaking force (P < 0.05) was observed for the surimi-like material when compared to the surimi. Considering that the deformation did not vary significantly for these two products (P > 0.05), the behaviour of gel strength was similar to that observed for the breaking force (P < 0.05). Considering the MDCM surimi-like material, our values for breaking force were much superior to that reported for chicken breast surimilike material at similar processing conditions; however their obtained gel strength was higher [4]. Moreover, breaking force was higher than that reported for spent hen surimi-like material, but the gel strength was quite similar due the lower deformation observed here [18]. The breaking force of MDCM surimi-like material was also higher than results obtained for bigeye croaker, lizardfish, threadfin bream, bigeye snapper [19,20], silver carp, walleye Pollack [8], and whitemouth croaker surimi [21]. The texture parameters observed here for whitemouth croaker surimi were also superior to that observed for these fish species [8,18-20]. Most of the differences might be explained by the protein quality and concentration [8], washing conditions [15,22], and setting conditions [23], which may lead to different gelling characteristics.

3.3. Sensory

The sensory evaluation results indicated that there were significant differences (P > 0.05) for all sensory characteristics (odor, taste, texture, and whiteness), as well as overall desirability between MSCM surimi-like material and whitemouth croaker meat surimi (Table 2). The mean scores of overall desirability for MDCM surimilike material was similar to that observed for walleye Pollack surimi [8] that is the parameter of quality.

The successive washings and the solubilization of the muscle sarcoplasmic proteins improve the taste by removing carboxyl compounds [17]. In this way, the whiter instrumental color obtained for the surimi-like material (Table 1) can be related to the better evaluation for taste observed for it (Table 2). The higher whiteness of the surimi-like material was also observed by the panelists (Table 2). Moreover, the better sensory overall desirability observed for the surimi-like material might be explained due its better quality and texture parameters [24].

4. Conclusion

From these results we concluded that the surimi-like material made from MDCM was more accepted by the panelists. The presented results indicate that the differences in the acceptability of poultry and fish food products are probably due to peoples’ eating habits.

5. Acknowledgements

We acknowledge “Minuano Companhia de Alimentos” and “Pescal S/A” for providing the raw materials.

REFERENCES

- T. C. Lanier, “Functional Properties of Surimi,” Food Technology, Vol. 40, No. 3, 1986, pp. 107-114.

- J. W. Park and M. T. Morrissey, “Manufacturing of Surimi from Light Muscle Fish,” In: J. W. Park, Ed., Surimi and Surimi Seafood, Marcel Dekker, Inc., New York, 2000, pp. 23-58.

- K. B. Belibagli, R. A. Speers and A. T. Paulson, “Thermophysical Properties of Silver Hake and Mackerel Surimi at Cooking Temperatures,” Journal of Food Engineering, Vol. 60, No. 4, 2003, pp. 439-448. doi:10.1016/S0260-8774(03)00067-0

- S.-K. Jin, I.-S. Kim, S.-J. Kim, K.-J. Jeong, Y.-J. Choi and S.-J. Hur, “Effect of Muscle Type and Washing Times on Physico-Chemical Characteristics and Qualities of Surimi,” Journal of Food Engineering, Vol. 81, No. 3, 2007, pp. 618-623. doi:10.1016/j.jfoodeng.2007.01.001

- S. K. Jin, I. S. Kim, Y. J. Choi, G. B. Park and H. S. Yang, “Quality Characteristics of Chicken Breast Surimi as Affected by Water Washing Time and pH Adjustment,” Asian-Australasian Journal of Animal Sciences, Vol. 21, No. 3, 2008, pp. 449-455.

- G. H. Kang, S. H. Kim, J. H. Kim, H. K. Kang, D. W. Kim, J. C. Na, D. J. Yu, O. S. Suh and Y. H. Choi, “Effects of Washing Methods on Gel Properties of Chicken Surimi Prepared from Spent Hen Breast Muscle,” Poultry Science, Vol. 88, No. 7, 2008, pp. 1438-1443. doi:10.3382/ps.2008-00212

- I. Ismail, N. Huda and A. Fazilah, “Surimi-like Material from Poultry Meat and Its Potential as a Surimi Replacer,” Asian Journal of Poultry Science, Vol. 5, No. 1, 2011, pp. 1-12. doi:10.3923/ajpsaj.2011.1.12

- X. Wang, T. Hirata, Y. Fukuda, M. Kinoshita and M. Sakaguchi, “Acceptability Comparison of Kamaboko Gels Derived from Silver Carp Surimi and from Walleye Pollack Surimi between the Chinese and Japanese,” Fisheries Science, Vol. 68, No. 1, 2002, pp. 165-169. doi:10.1046/j.1444-2906.2002.00403.x

- S. K. Jin, I. S. Kim, Y. J. Choi, B. G. Kim and S. J. Hur, “Effect of Surimi Containing Spent Laying Hen Breast on the Quality of Crab Analogue,” Journal of Food Process Engineering, Vol. 33, No. 4, 2010, pp. 745-762. doi:10.1111/j.1745-4530.2008.00302.x

- F. Perlo, P. Bonato, G. Teira, R. Fabre and S. Kueider, “Physicochemical and Sensory Properties of Chicken Nuggets with Washed Mechanically Deboned Chicken Meat,” Meat Science, Vol. 72, No. 4, 2006, pp. 785-788. doi:10.1016/j.meatsci.2005.09.007

- W. R. Cortez-Vega, G. G. Fonseca, V. A. Feisther, T. F. Silva and C. Prentice, “Evaluation of Frankfurters Obtained from Croaker (Micropogonias furnieri) Surimi and Mechanically Deboned Chicken Meat Surimi-like Material,” CyTA-Journal of Food, 2012. doi:10.1080/19476337.2012.680199

- W. R. Cortez-Vega, G. G. Fonseca and C. Prentice, “Effects of Soybean Protein, Potato Starch and Pig Lard on the Properties of Frankfurters Formulated from Mechanically Separated Chicken Meat Surimi-like Material,” Food Science and Technology International, 2012. doi:10.1177/1082013212457667

- J. W. Park, “Evaluation of Functional Ingredients,” In: J. W. Park, Ed., Surimi and Surimi Seafood, Marcel Dekker, Inc., New York. 2000, pp. 381-382.

- S. Rawdkuen, S. Benjakul, W. Visessanguan and T C. Lanier, “Chicken Plasma Protein Affects Gelation of Surimi from Bigeye Snapper (Priacanthus tayenus),” Food Hydrocolloids, Vol. 18, No. 2, 2004, pp. 259-270. doi:10.1016/S0268-005X(03)00082-1

- X. Luo, R. Yang, W. Zhao, Z. Cheng and X. Jiang, “Gelling Properties of Spanish Mackerel (Scomberomorus niphonius) Surimi as Affected by Washing Process and High Pressure,” International Journal of Food Engineering, Vol. 6, No. 4, 2010. doi:10.2202/1556-3758.1913

- L. Mao and T. Wu, “Gelling Properties of Kamaboko Gels from Grass Carp (Ctenopharyngodon idellus) Influenced by Chitosan,” Journal of Food Engineering, Vol. 82, No. 2, 2007, pp. 128-134. doi:10.1016/j.jfoodeng.2007.01.015

- S. R. Maza, “Caracterización de la Pulpa de Pescado,” In: Tecnologia de Procesamiento de Productos Pesqueros Congelados Preformados, Instituto Tecnológico Pesquero del Perú, Callao, 2001, pp. 99-103.

- A. A. K. M. Nowsad, S. Kanoh and E. Niwa, “Thermal Gelation Characteristics of Breast and Thigh Muscles of Spent Hen and Broiler and their Surimi,” Meat Science, Vol. 54, No. 2, 2000, pp. 169-175. doi:10.1016/S0309-1740(99)00091-1

- S. Benjakul, W. Visessanguan, C. Thongkaew and M. Tanaka, “Effect of Frozen Storage on Chemical and Gel-Forming Properties of Fish Commonly Used for Surimi Production in Thailand,” Food Hydrocolloids, Vol. 19, No, 2, 2005, pp. 197-207. doi:10.1016/j.foodhyd.2004.05.004

- S. Benjakul, C. Thongkaew and W. Visessanguan, “Effect of Reducing Agents on Physicochemical Properties and Gel-Forming Ability of Surimi Produced from Frozen Fish,” European Food Research and Technology, Vol. 220, No. 3-4, 2005, pp. 316-321. doi:10.1007/s00217-004-1092-1

- G. V. Gautério, I. R. Freitas and C. Prentice, “Evaluation of Textural Characteristics of Fish Muscle,” Higiene Alimentar, Vol. 25, 2011, pp. 1333-1335.

- M. Chaijan, W. Panpipat and S. Benjakul, “Physicochemical Properties and Gel-Forming Ability of Surimi from Three Species of Mackerel Caught in Southern Thailand,” Food Chemistry, Vol. 121, No. 1, 2010, pp. 85-92. doi:10.1016/j.foodchem.2009.12.007

- S. Benjakul, C. Chantarasuwan and W. Visessanguan, “Effect of Medium Temperature Setting on Gelling Characteristics of Surimi from Some Tropical Fish,” Food Chemistry, Vol. 82, No. 4, 2003, pp. 567-574. doi:10.1016/S0308-8146(03)00012-8

- M. C. Gómez-Guillén, A. J. Borderias, and P. Montero, “Rheological Properties of Gels Made from Highand Low-Quality Sardine (Sardina pilchardus) Mince with Added Nonmuscle Proteins,” Journal of Agricultural and Food Chemistry, Vol. 44, No. 3, 1996, pp. 746-750. doi:10.1021/jf950338q

NOTES

*The present study was supported by the CHILL-ON project, contract number: FP6-016333-2, as part of the Sixth Framework Programme, Priority 5, Food Quality and Safety.

#Corresponding author.