American Journal of Operations Research

Vol.3 No.1(2013), Article ID:27513,13 pages DOI:10.4236/ajor.2013.31002

Bi-Criteria Optimization Technique in Stochastic System Maintenance Allocation Problem

Department of Statistics & Operations Research, Aligarh Muslim University, Aligarh, India

Email: *irfii.ali@gmail.com

Received November 11, 2012; revised December 15, 2012; accepted December 28, 2012

Keywords: Selective Maintenance; Weighted Tchebycheff Technique; Multi-Criteria Optimization; Stochastic Programming; Chance Constrained; Modified E-Model; System Reliability

ABSTRACT

In this paper, the problem of optimum allocation of repairable and replaceable components in a system is formulated as a Bi-objective stochastic non linear programming problem. The system maintenance time and cost are random variable and has gamma and normal distribution respectively. A Bi-criteria optimization technique, weighted Tchebycheff is used to obtain the optimum allocation for a system. A numerical example is also presented to illustrate the computational details.

1. Introduction

We consider a system which requires performing a sequence of identical production runs after every given (fixed) period. A production run in the system consists of several subsystems where each subsystem can work properly if at least one of its components is operational. The following assumptions are also made:

1) all the components can be repaired if deteriorated or failed;

2) all component states are independent.

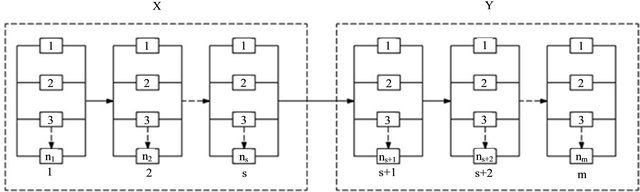

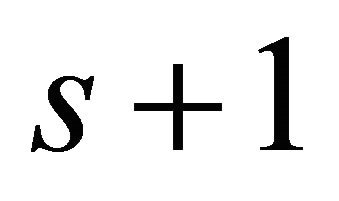

We assume that the system comprises two types of subsystem. One is the type of subsystems in which the components are very sensitive to the functioning of the whole system and, therefore, on deterioration these should be replaced by new ones. Let these subsystems range from 1 to . The other type of subsystems is those in which the components after deterioration can be repaired and then replaced. Let such subsystems range from

. The other type of subsystems is those in which the components after deterioration can be repaired and then replaced. Let such subsystems range from  to

to . In Figure 1 the Group X consists of the

. In Figure 1 the Group X consists of the  subsystems with sensitive components which on failure are replaced by new ones and Y the remaining

subsystems with sensitive components which on failure are replaced by new ones and Y the remaining  subsystems in which the components can be repaired (see Ali et al. [1]).

subsystems in which the components can be repaired (see Ali et al. [1]).

Ideally, all the failed components in all the subsystem of Group X are replaced by new ones prior to the beginning of the next mission/ run. In a similar way, ideally all the failed components in subsystem of Group Y are repaired and then replaced prior to the beginning of the next mission/run. However, due to the constraints on the cost and time it may not be possible to repair and replace all the failed components in Groups X and Y. For this a mathematical programming frame-work is established for assisting decision-makers in determining the optimal subset of maintenance activities to perform prior to beginning of the next mission. This decision-making process

Figure 1. Parallel components in repairable and replaceable subsystem.

is referred to as selective maintenance. The selective maintenance models presented allow the decision-maker to consider limitations on maintenance time and budget, as well as the reliability of the system. Selective maintenance is an open research area that is consistent with the modern industrial objective of performing more intelligent and efficient maintenance.

For this let us suppose  be the total failed components in the subsystems and

be the total failed components in the subsystems and  be the number of components in the

be the number of components in the  subsystem, which can be repaired and replaced prior to the beginning of the next mission (See Rice et al. [2]). Thus under the selective maintenance the number of components available for the next mission in the

subsystem, which can be repaired and replaced prior to the beginning of the next mission (See Rice et al. [2]). Thus under the selective maintenance the number of components available for the next mission in the  subsystem will be

subsystem will be

(1)

(1)

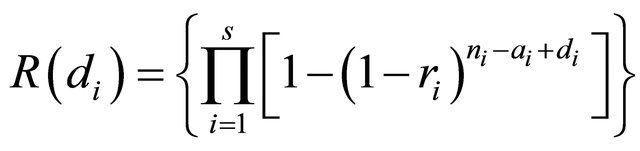

Therefore the reliability of the subsystems range from 1 to  for a production run is given by

for a production run is given by

(2)

(2)

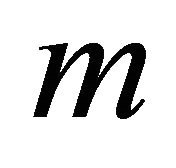

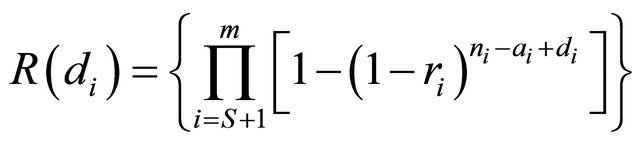

and the reliability of the subsystems range from  to

to for a production run is given by

for a production run is given by

(3)

(3)

The maintenance time constraint for the system is given as

(4)

(4)

and the maintenance cost constraint for the system is given as

(5)

(5)

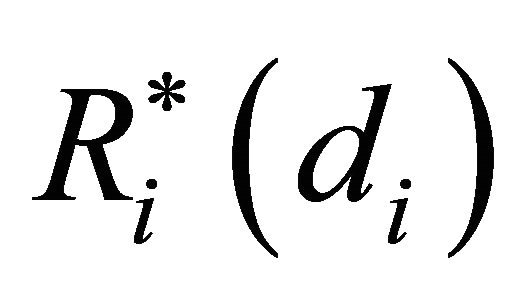

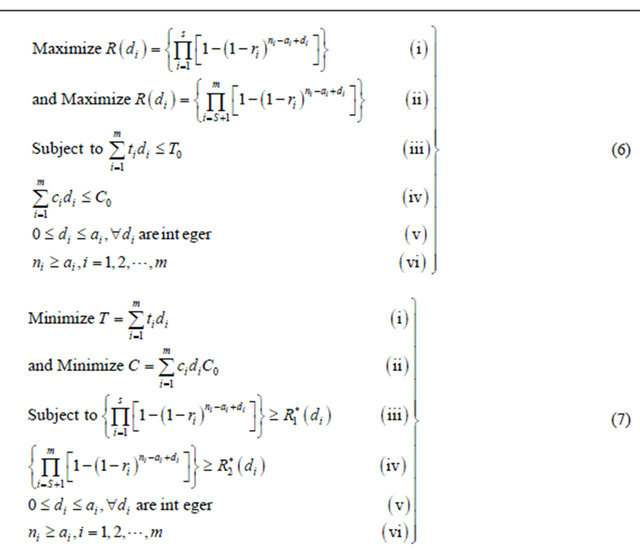

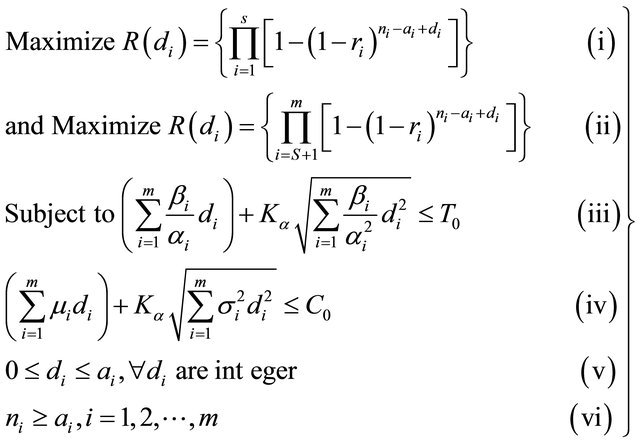

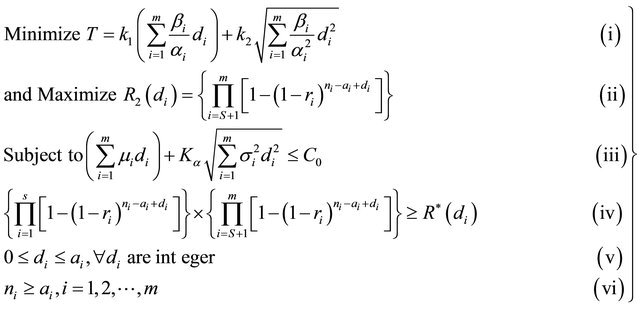

However, in the event the reliability of the subsystems of Groups X and Y time are of equally serious concern. Let us consider, for instance, the following multi-objective problem (please see the Equation (6) below).

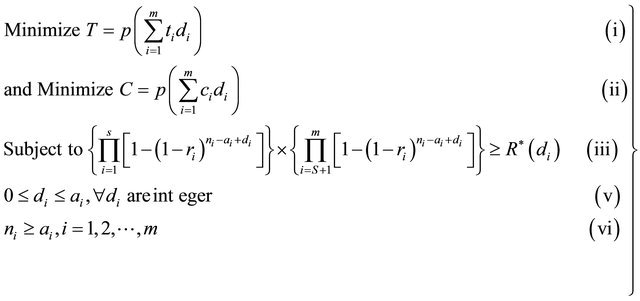

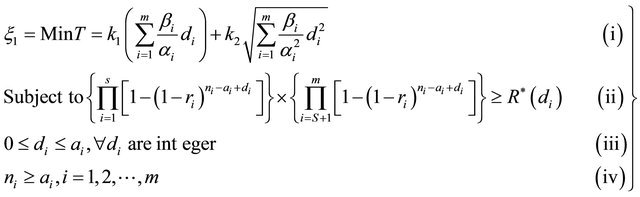

Secondly, a Bi-objective programming problem in which time and the cost spent on system maintenance is minimized simultaneously for the required reliability  (say). The mathematical model of the problem is given as Equation (7) below.

(say). The mathematical model of the problem is given as Equation (7) below.

Recently many authors have discussed the allocation problem of repairable components. Among them are Rice et al. [2], Schneider and Cassady [3], Rajaopalan and Cassady [4], Schneider et al. [5], Iyoob et al. [6], Ali et al. ([1,7-10]), Faisal and Ali [11] and many others.

In this paper, we have formulated stochastic system maintenance problem as a multi-objective programming

problem. We have discussed components repairable and replaceable time and cost as a random variable in the constraint and has Gamma and Normal distribution respectively. The Probabilistic constraints function is then converted into an equivalent deterministic non-linear programming form by using chance constrained programming.

2. The Chance Constrained Programming

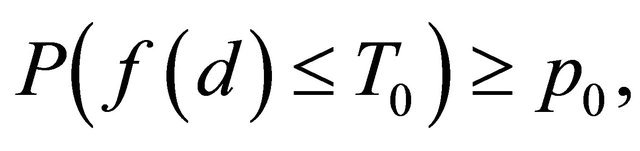

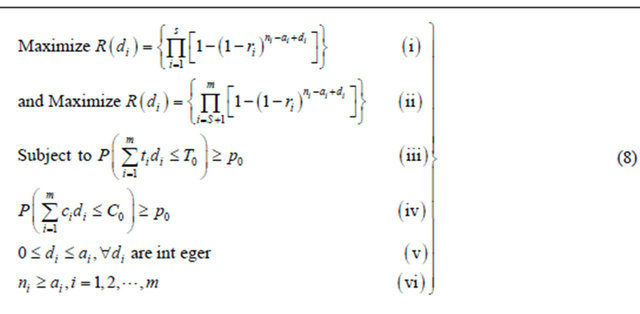

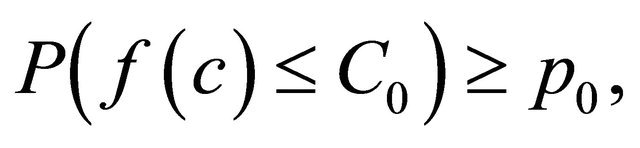

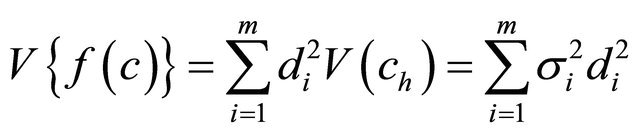

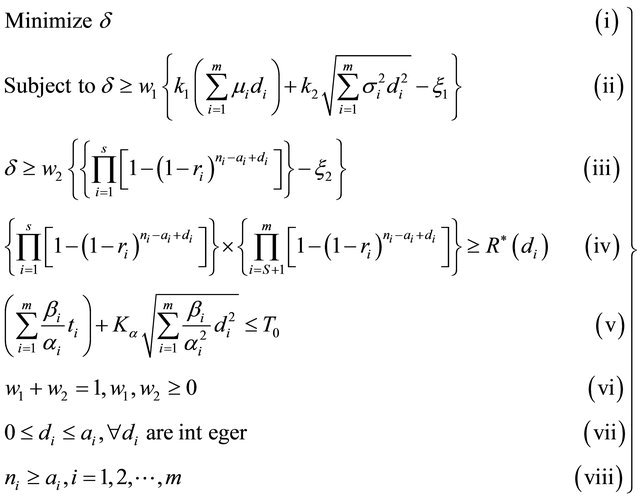

In many practical situations the constraint Equations (iii) and (iv) are not fixed and taken as probabilistic. Thus the above problem (6) can be written in the following chance constrained programming form as Equation (8) below, where is a specified probability.

is a specified probability.

In the above problem (8), let us assume that  and

and  are independently gamma and normally distributed random variables.

are independently gamma and normally distributed random variables.

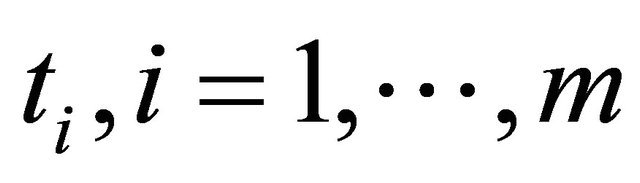

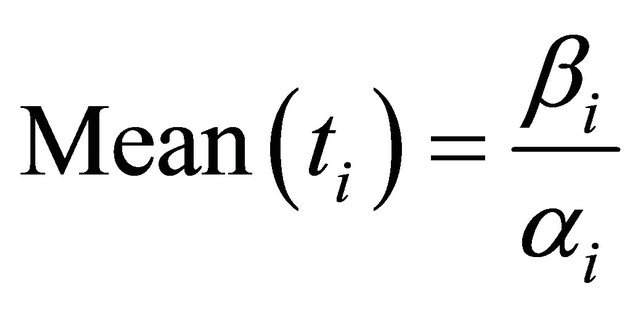

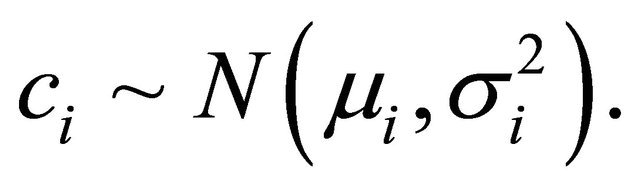

Let us assume that  are independent Gamma distributed random variables in the constraint 8 (iii), i.e.,

are independent Gamma distributed random variables in the constraint 8 (iii), i.e.,

Then the,

,

, .

.

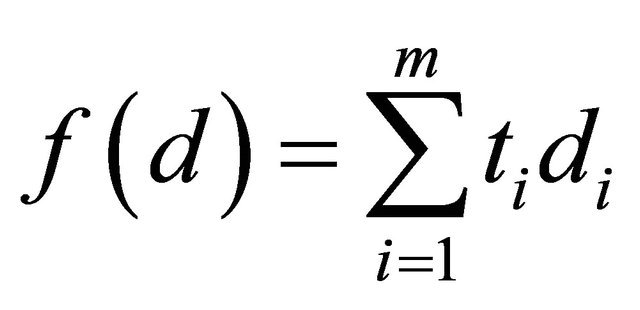

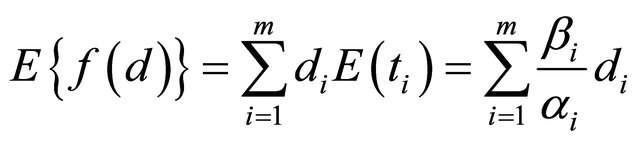

Now let

Then mean is

Further, as  are independently distributed, we have

are independently distributed, we have

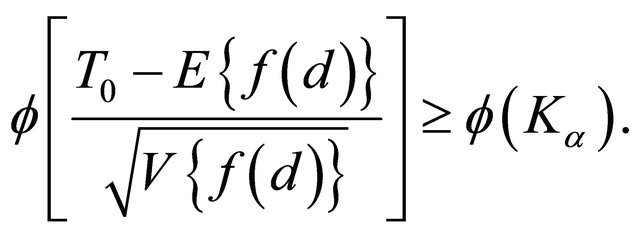

Now the constraints 8 (iii) can be written as

(9)

(9)

Since number of components within the system are assumed to be large we have from Liapounoff’s central limit theorem

.

.

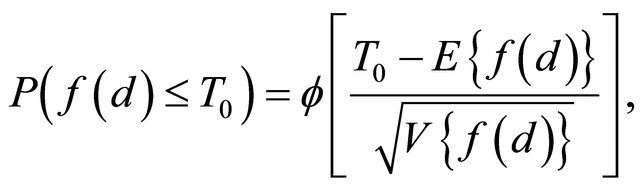

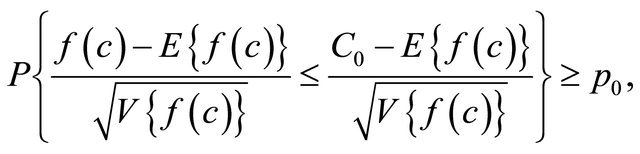

Thus (9) is equivalent to

where  is a standard normal variate with mean zero and variance one. Thus the probability of realizing

is a standard normal variate with mean zero and variance one. Thus the probability of realizing  less than or equal to

less than or equal to  can be written as

can be written as

(10)

(10)

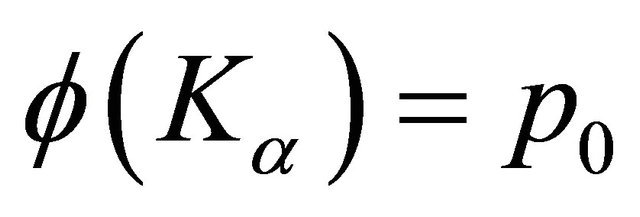

where  represents the cumulative density function of the standard normal variable evaluated at Z. If

represents the cumulative density function of the standard normal variable evaluated at Z. If  represents the value of the standard normal variable at which

represents the value of the standard normal variable at which , then the constraint (10) can be written as

, then the constraint (10) can be written as

(11)

(11)

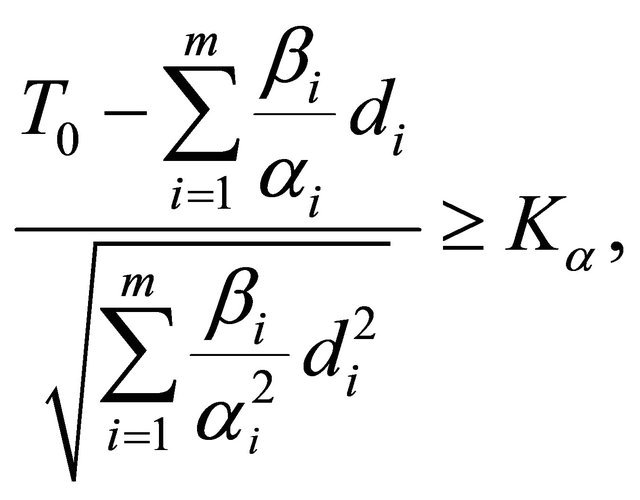

The inequality will be satisfied only if

or equivalently

Thus an equivalent deterministic constraint to the stochastic constraint is given by

(12)

(12)

Now we consider the case when are independently normally distributed random variables in the constraint 8 (iv), i.e.

are independently normally distributed random variables in the constraint 8 (iv), i.e.

The constraint  is equivalent to

is equivalent to

(13)

(13)

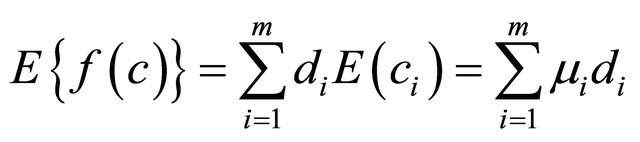

Now in this case

and

Therefore, the deterministic equivalent of 8 (iv) in this case is

(14)

(14)

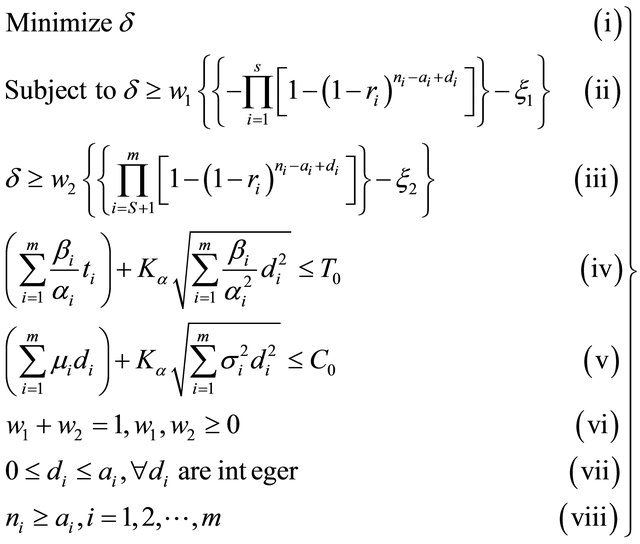

The equivalent deterministic non-linear programming problem (8) to the stochastic programming problem is given by

(15)

(15)

3. Modified E-Model

Consider the situations in which the time taken and cost spent on maintenance are not fixed and taken as probabilistic in the objective function in Equations (i) and (ii). Thus the above problem (7) can be written in the following probabilistic objective function form as:

(16)

(16)

Using Modified E-model technique, the problem (16) is formulated as

(17)

(17)

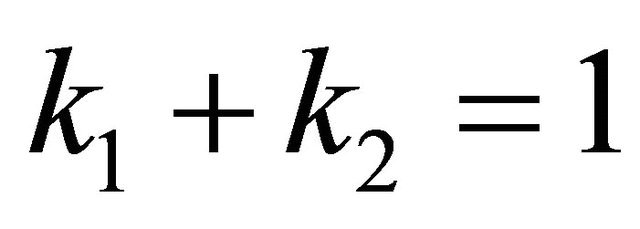

where  and

and  are non-negative constants, and their values show the relative importance of the expectation and the variance. Some authors suggest that

are non-negative constants, and their values show the relative importance of the expectation and the variance. Some authors suggest that see Rao [12].

see Rao [12].

The two others Bi-objective programming models in different prospects for the decision-makers are

Model 1:

(18)

(18)

Model 2:

(19)

(19)

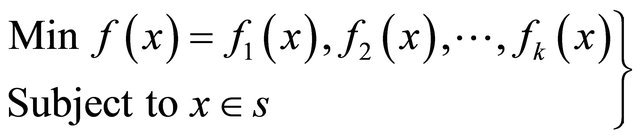

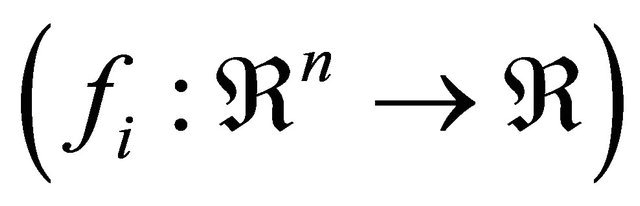

4. A Multi-Criteria Weighted Tchebycheff Optimization Technique

Let us consider a multi-objective programming problem

(20)

(20)

assumed to have  competing objective functions

competing objective functions  that are to be minimized simultaneously. The following definitions illustrate the concepts of efficient and weakly efficient decision vectors.

that are to be minimized simultaneously. The following definitions illustrate the concepts of efficient and weakly efficient decision vectors.

Definition: A decision vector  is efficient (Pareto optimal) for multi-objective programming problem if there does not exist a

is efficient (Pareto optimal) for multi-objective programming problem if there does not exist a  such that

such that  with strict inequality holding for at least one index

with strict inequality holding for at least one index  (

( is efficient,

is efficient,  is non-dominated).

is non-dominated).

Definition: A decision vector  is weakly efficient (weakly Pareto optimal) for multi-objective programming problem if there does not exist a

is weakly efficient (weakly Pareto optimal) for multi-objective programming problem if there does not exist a

such that

such that  for

for . (

. ( is weakly efficient,

is weakly efficient,  is weakly nondominated).

is weakly nondominated).

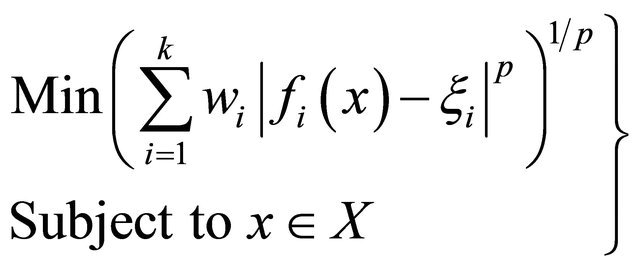

There are several metrics that are found in the literature related to multi-objective programming problem. If  is the reference point and the ideal point,

is the reference point and the ideal point,

is used as the reference point, the general weighted

is used as the reference point, the general weighted  is defined as

is defined as

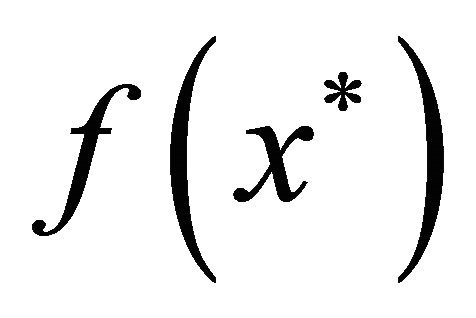

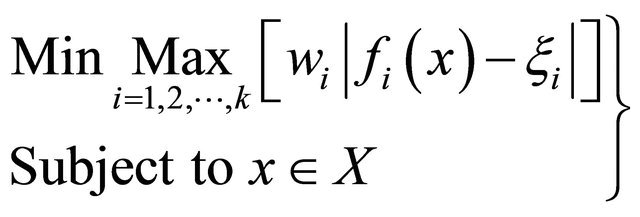

(21)

(21)

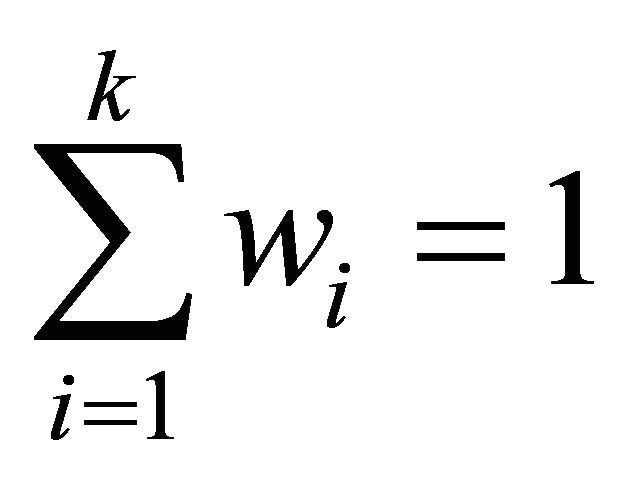

We assume that  and

and where the

where the ’s are weighting coefficients provided by the decision maker reflecting the relative importance. If

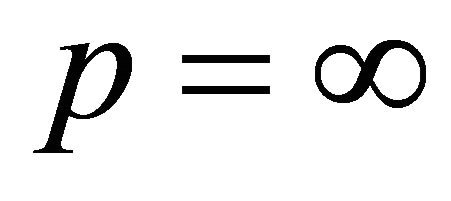

’s are weighting coefficients provided by the decision maker reflecting the relative importance. If , problem (21) reduces to a “weighted Tchebycheff Technique” (see Bowman [13]).

, problem (21) reduces to a “weighted Tchebycheff Technique” (see Bowman [13]).

(22)

(22)

If the reference point is the global optimal solution of , then the absolute value signs in problem (22) can be removed (see Miettinen [14]) yielding

, then the absolute value signs in problem (22) can be removed (see Miettinen [14]) yielding

(23)

(23)

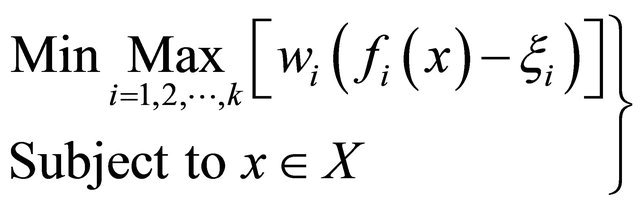

Miettinen [14] also showed that if the objectives and constraints are differentiable form of problem (23) can be defined as

(24)

(24)

The solution of problem (24) is guaranteed weekly non-dominated for positive weights and at least one non-dominated solution is also guaranteed. If the solution is unique, then it is non-dominated, however if it is not unique, then it might be weakly non-dominated (see Wierzbicki [15].

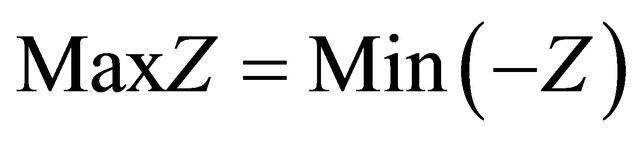

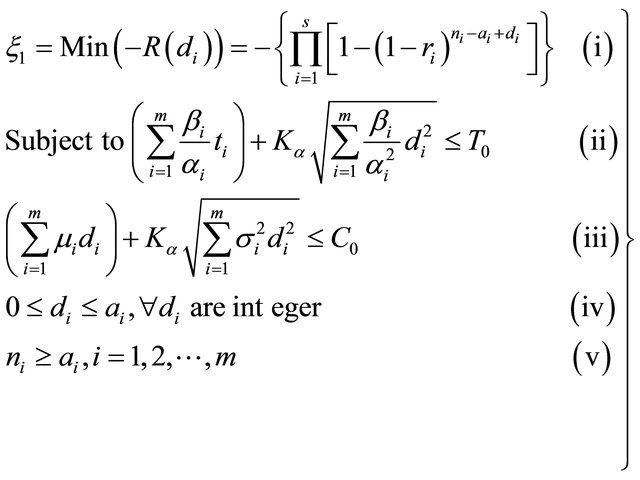

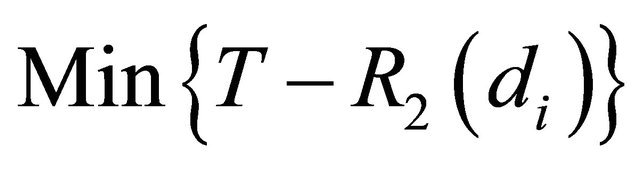

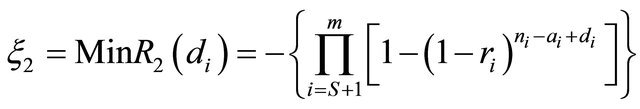

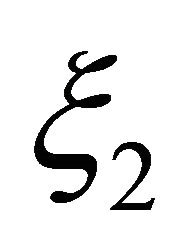

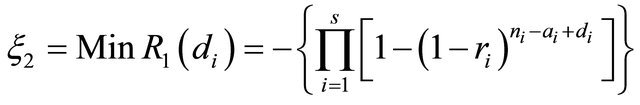

The two objective functions in the Equation (15) are to be maximizing the total reliability of replaceable components of Group X and the reliability of repairable components of Group Y. We have convert the following maximizing problem into minimization problem using the property . Therefore the problem defined in Equation (15) is converted into a two criterion minimization problem:

. Therefore the problem defined in Equation (15) is converted into a two criterion minimization problem:  subject to the constraints (see Khasawneh et al. [16]). Now the efficient solution is obtained by using the weighted Tchebycheff technique

subject to the constraints (see Khasawneh et al. [16]). Now the efficient solution is obtained by using the weighted Tchebycheff technique

(25)

(25)

In practice,  can be defined as the minimum individual values of the following problems:

can be defined as the minimum individual values of the following problems:

(26)

(26)

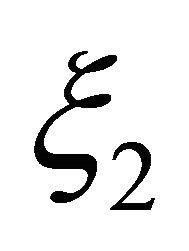

and similarly

(27)

(27)

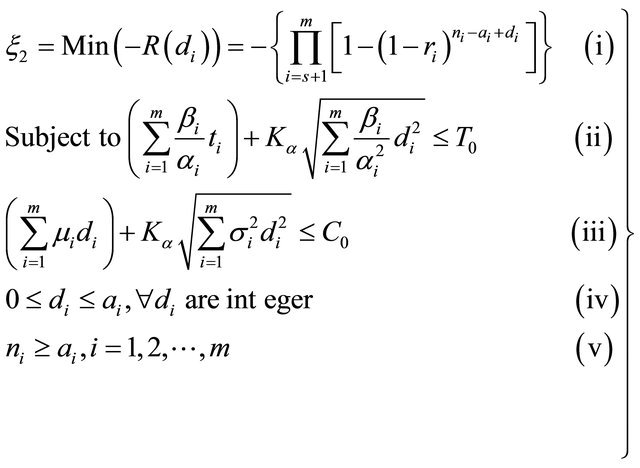

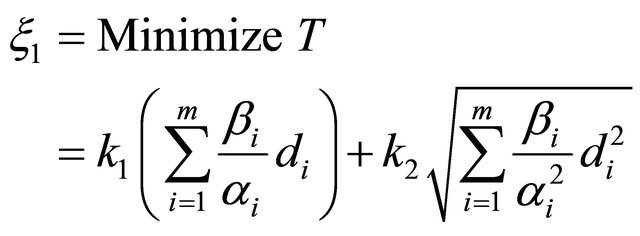

In similar way, the problem defined in Equation (17) is also a two criterion minimization problem:  subject to the constraints. Now the efficient solution is obtained by using the weighted Tchebycheff technique

subject to the constraints. Now the efficient solution is obtained by using the weighted Tchebycheff technique

(28)

(28)

The values of  can be defined as the minimum individual values of the following problems:

can be defined as the minimum individual values of the following problems:

(29)

(29)

and similarly

(30)

(30)

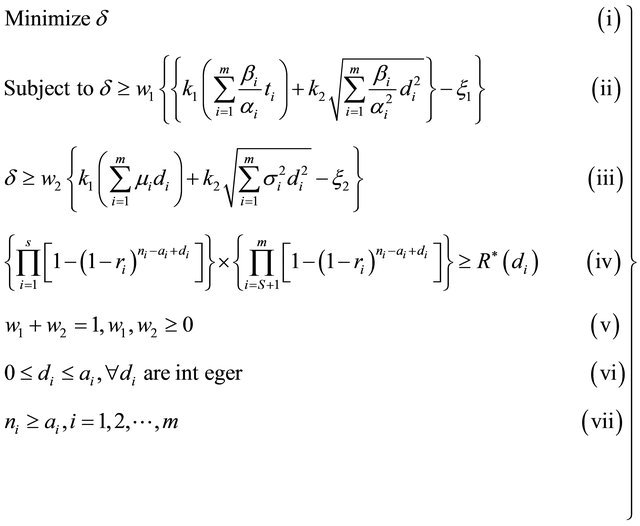

Now the problem defined in Model 1; Equation (18) is also a two criterion minimization problem:

subject to the constraints. Now the efficient solution is obtained by using the weighted Tchebycheff technique

subject to the constraints. Now the efficient solution is obtained by using the weighted Tchebycheff technique

(31)

(31)

The values of  and

and  is the minimum individual values obtained as

is the minimum individual values obtained as

subject to the (iii) to (vi) of Equation (18)

subject to the (iii) to (vi) of Equation (18).

In Model 2, Equation (19) is also a two criterion minimization problem:  subject to the constraints. Now the efficient solution is obtained by using the weighted Tchebycheff technique

subject to the constraints. Now the efficient solution is obtained by using the weighted Tchebycheff technique

(32)

(32)

where the values of  and

and  is the minimum individual values obtained as

is the minimum individual values obtained as

subject to the (iii) to (vi) of Equation (19)

subject to the (iii) to (vi) of Equation (19).

5. Numerical Illustrations

Consider a system having the Group X consisting of 3 subsystems and also the Group Y consisting of 4 subsystems. The available time between two missions for repairing and replacing is 150 time units. The available cost of maintenance for repairing and replacing for the next mission is 860 units. For simplicity we have considered in the above numerical illustration: the reliability of each component in a subsystem is same, cost spent and time taken on replacing and repairing each component within a subsystem are same. The remaining parameters for the various subsystems are given in Table 1.

5.1. Solution of Chance Constrained Programming by Using Weighted Tchebycheff Technique

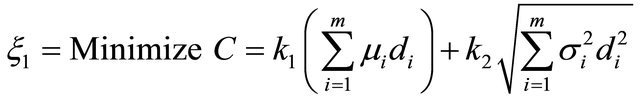

Before applying the Weighted Tchebycheff Technique firstly we find the individual optimum values .

.

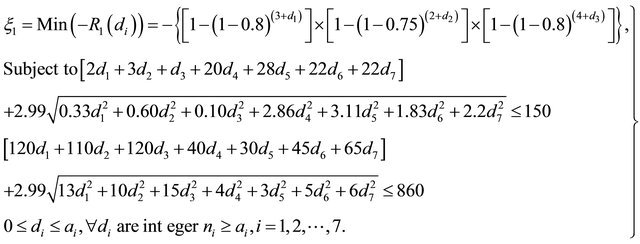

For the values given in Table 1, the SNLPP (26) for the first optimum value is

(33)

(33)

The optimal solution of (33) provided by LINGO is

with the value of objective function as

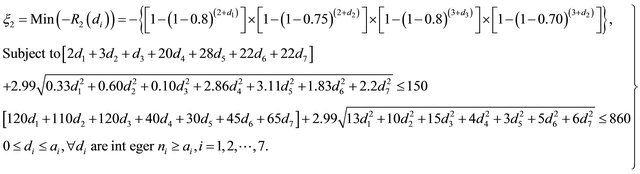

Similarly using (27) the SNLPP for the second optimum values

Table 1. The number of failed components and the respective cost and time etc. in the various subsystems.

(34)

(34)

The optimal solution of (34) provided by LINGO is

with the value of objective function as

.

.

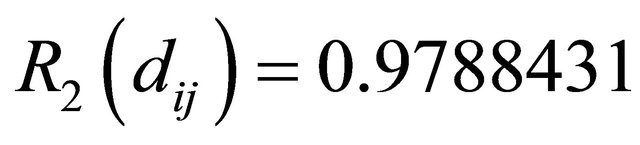

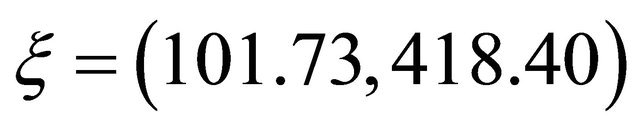

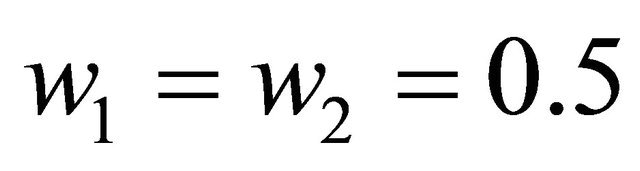

From the Equations (33) and (34) the optimum values

. For simplicity we assumed that the reliability of both the Groups X and Y subsystems are equally important, that is

. For simplicity we assumed that the reliability of both the Groups X and Y subsystems are equally important, that is .

.

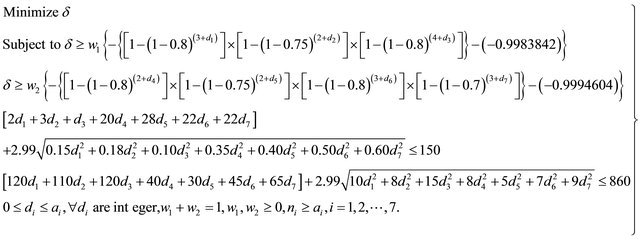

For the values given in Table 1, the SNLPP (25) efficient solution is obtained by using the weighted Tchebycheff Technique

(35)

(35)

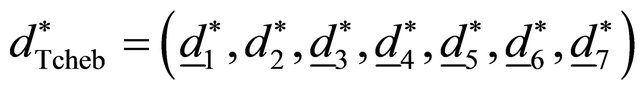

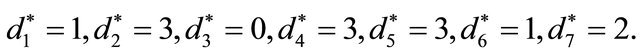

The optimum allocation under the Weighted Tchebycheff Technique

is obtained as

The corresponding value of objective function is 0.00076.

5.2. Solution of Modified E-Model by Using Weighted Tchebycheff Technique

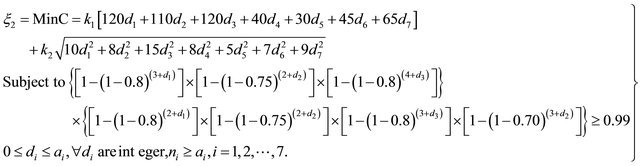

The individual optimum values . For the values given in Table 1 and for simplicity take k1 = k2 = 0.5 then the SNLPP (29) for the first optimum value is

. For the values given in Table 1 and for simplicity take k1 = k2 = 0.5 then the SNLPP (29) for the first optimum value is

(36)

(36)

And the SNLPP (30) for the second optimum value

(37)

(37)

From the Equations (36) and (37) the optimum values .

.

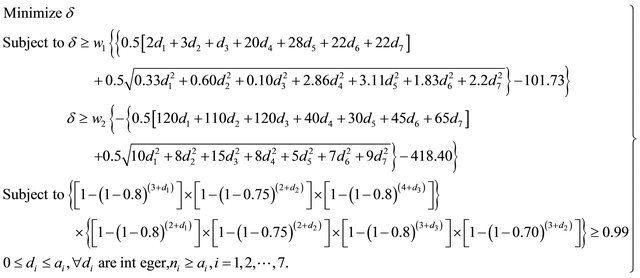

For simplicity we assumed that the maintenance time taken and cost spent for both the Groups X and Y subsystems are equally important, that is . For the values given in Table 1, the SNLPP (28) efficient solution is obtained by using the weighted Tchebycheff Technique

. For the values given in Table 1, the SNLPP (28) efficient solution is obtained by using the weighted Tchebycheff Technique

(38)

(38)

The optimum allocation under the Weighted Tchebycheff Technique

is obtained as

The corresponding value of objective function is 6.48.

The individual optimum values of Model 1 are . Therefore, the optimum allocation under the Weighted Tchebycheff Technique of SNLPP (31) is obtained as

. Therefore, the optimum allocation under the Weighted Tchebycheff Technique of SNLPP (31) is obtained as

The corresponding value of objective function is 0.01306.

In the same manner, we obtained the individual optimum values for Model 2 are . Therefore, the optimum allocation under the Weighted Tchebycheff Technique of SNLPP (32) is obtained as

. Therefore, the optimum allocation under the Weighted Tchebycheff Technique of SNLPP (32) is obtained as

The corresponding value of objective function is 0.00299.

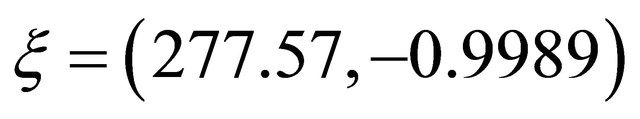

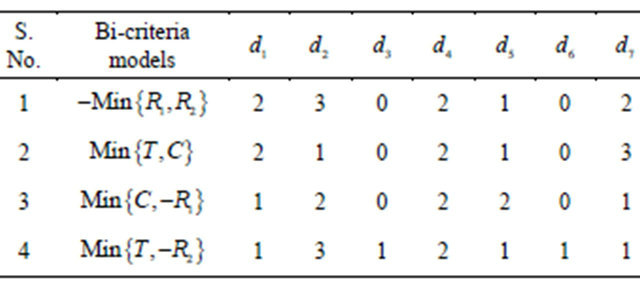

The optimum allocations obtained corresponding to the various Bi-criteria models are summarized as given below in Table 2.

6. Conclusions

The multi-objective problem of allocation of repairable and replaceable components becomes complicated because an allocation that is optimal for one objective is usually far from optimal for other objectives. In such situations, we need a compromise criterion that gives an allocation which is optimum for all objectives in some sense. This paper is an attempt to utilize weighted Tchebycheff approach to the solution of optimum compromise allocation of repairable and replaceable components in a system.

The allocation problem of repairable and replaceable components for a parallel-series system considered as a Bi-objective stochastic optimization problem and discussed the four different situations. In the first situation, the reliabilities of Groups X and Y are considered as two different objectives. While in the next three situations

Table 2. Optimum allocation of replaceable and repairable components under various Bi-criteria models.

the maintenance cost and time, maintenance cost and Group X subsystem reliabilities, maintenance time and Group Y subsystem reliabilities respectively are considered as two different objectives. Selective maintenance policy is used to select the repairable and replaceable components.

An equivalent deterministic model of these Bi-objective stochastic optimization problems is established by using Chance Constrained programming method. The following four different stochastic problems are then solved by using the Bi-criteria optimization technique, weighted Tchebycheff. The weighted Tchebycheff technique provides compromise allocations of repairable and replaceable components which are optimum for both the objectives function (see Table 2). Since a compromise criteria differ from method to method, so comparison can not be made.

REFERENCES

- I. Ali, M. F. Khan, Y. S. Raghav and A. Bari, “Allocating Repairable and Replaceable Components for a System Availability Using Selective Maintenance with Probabilistic Constraints,” American Journal of Operations Research, Vol. 1, No. 3, 2011, pp. 147-154. doi:10.4236/ajor.2011.13016

- W. F. Rice, C. R. Cassady and J. A. Nachlas, “Optimal Maintenance Plans under Limited Maintenance Time,” Proceedings of the 7th Industrial Engineering Research Conference, Banff, 9-10 May 1998.

- C. R. Cassady, E. A. Pohl and J. Song, “Managing Availability Improvement Efforts with Importance Measures and Optimization,” IMA Journal of Management Mathematics, Vol. 15, No. 2, 2004, pp. 161-174. doi:10.1093/imaman/15.2.161

- R. Rajagopalan and C. R. Cassady, “An Improved Selective Maintenance Approach,” Journal of Quality in Maintenance Engineering, Vol. 12, No. 2, 2006, pp. 172-185. doi:10.1108/13552510610667183

- K. Schneider, L. M. Maillart, C. R. Cassady and C. Rainwater, “Selective Maintenance Decision-Making over Extended Planning Horizons,” IEEE Transactions on Reliability, Vol. 58, No. 3, 2009, pp. 462-469. doi:10.1109/TR.2009.2026689

- I. M. Iyoob, C. R. Cassady and E. A. Pohl., “Establishing Maintenance Resource Levels Using Selective Maintenance,” The Engineering Economist, Vol. 51, No. 2, 2006, pp. 99-114. doi:10.1080/00137910600695627

- I. Ali, Y. S. Raghav and A. Bari, “Allocating Repairable and Replaceable Components for a System Availability Using Selective Maintenance: An Integer Solution,” Safety and Reliability Society, Vol. 31, No. 2, 2011, pp. 9-18.

- I. Ali, Y. S. Raghav and A. Bari, “Integer Goal Programming Approach for Finding a Compromise Allocation of Repairable Components,” International Journal of Engineering Science and Technology, Vol. 3, No. 6, 2011, pp. 184-195.

- I. Ali, Y. S. Raghav and A. Bari, “Compromise Allocation in Multivariate Stratified Surveys with Stochastic Quadratic Cost Function,” Journal of Statistical Computation and Simulation, 2011. doi:10.1080/00949655.2011.643890

- I. Ali, M. F. Khan, Y. S. Raghav and A. Bari, “Selective Maintenance in System Reliability with Random Costs of Repairing and Replacing the Components,” Communications in Statistics—Simulation and Computation, 2012. http://www.tandfonline.com/doi/abs/10.1080/03610918.2012

- M. F. Khan and I. Ali, “Allocation Problem of Repairable and Replaceable Components for a System Reliability using Selective Maintenance: An Integer Solution,” International Journal of Scientific and Engineering Research, Vol. 3, No. 5, 2012, pp. 1-4.

- S. S. Rao, “Optimization Theory and Applications,” Wiley Eastern Limited, New Delhi, 1979.

- V. J. Bowman Jr., “On the Relationship of the Tchebycheff Norm and the Efficient Frontier of Multiple-Criteria Objectives,” In: H. Thiriez and S. Zionts, Eds., “Multiple Criteria Decision Making,” Lecture Notes in Economics and Mathematical Systems, Springer-Verlag, Berlin, 1976, pp. 76-85.

- K. M. Miettinen, “Non Linear Multiobjective Optimization,” Kluwer Academic Publishers, Boston, 1999.

- A. P. Wierzbicki, “On the Completeness and Constructiveness of Parametric Characterizations to Vector Optimization Problem,” Operations-Research-Spektrum, Vol. 8, No. 2, 1986, pp. 73-87. doi:10.1007/BF01719738

- M. T. Khasawneh, S. R. Bowling, S. Kaewkuekool and B. R. Cho, “A Cost-Effective Strength-Stress Reliability Modeling and Optimization in Engineering Design,” Proceeding of the Industrial Engineering Research Conference, Orlando, 19-21 May 2002.

NOTES

*Corresponding author.