Smart Grid and Renewable Energy, 2012, 3, 139-147 http://dx.doi.org/10.4236/sgre.2012.32020 Published Online May 2012 (http://www.SciRP.org/journal/sgre) 1 Optimal Configuration for Design of S tand-Alone PV System Khaled Bataineh1, Doraid Dalalah2 1Mechanical Engineering Department, Jordan University of Science and Technology, Irbid, Jordan; 2Industrial Engineering Depart- ment, Jordan University of Science and Technology, Irbid, Jordan. Email: k.bataineh@just.edu.jo Received January 9th, 2012; revised March 5th, 2012; accepted March 13th, 2012 ABSTRACT This paper presents a design for a stand-alone photovoltaic (PV) system to provide the required electricity for a single residential household in rural area in Jordan. The complete design steps for the suggested household loads are carried out. Site radiation data and the electrical load data of a typical household in the considered site are taken into account during the design steps. The reliability o f the system is quantified by the loss of load probability. A computer program is developed to simulate the PV system behavior and to numerically find an optimal combination of PV array and bat- tery bank for the design of stand-alone photovoltaic systems in terms of reliability and costs. The program calculates life cycle cost and annualized unit electrical cost. Simulations results showed that a value of loss of load probability LLP can be met by several combinations of PV array and battery storage. The method developed here uniquely deter- mines the optimum configuration that meets the load demand with the mini mum c os t. Th e difference between the costs of these combinations is v ery large. The optimal unit electrical cost of 1 kWh for LLP = 0.049 is $0.293 ; while for LLP 0.0027 it is $0.402. Th e results of the study encouraged the use of the PV systems to electrify the remote sites in Jordan. Keywords: Renewable Energy Systems; Photovoltaic Stand-Alone Power System; Sizing; Optimization; Storage; Loss of Load Probability; Life Cycle Cost (LCC) 1. Introduction Renewable-energy sources are becoming more and more attractive especially with the constant fluctuation in oil prices. Solar has good po tential and the d irect conversion technology based on solar photovoltaic has several posi- tive attr ibutes especial ly in remote areas [1-4]. The Photo- voltaic (PV) system is considered one of the important alternative sources in this regard. Because PV energy pro- duction is clean, freely infinitely available and of high reliability, it is a very attractive power source for many applications, especially in rural and re mote areas in Medi- terranean countries where they have a large quantity of solar radiation around the year. Jordan is blessed with an abundance of solar energy. The possible amount of generating power and the scope of thermal applications using solar energy is huge. Most parts of Jordan get 300 days of sunshine per year. This makes the country a very promising place for solar en- ergy utilization [5]. The annual daily average solar ir- radiance (average insulation intensity on a horizontal surface) ranges between 4 - 7 kWh/m2, which is one of the highest in the world. This corresponds to a total an- nual of 1400 - 2300 kWh/m2 depending upon location. Jordan has successfully completed the plan for electrifi- cation for most of the villages through the utility grid. Due to remoteness and cost, for some parts of Jordan it is unlikely that the main grid connection will ever be estab- lished. A stand-alone PV system with storage battery will be excellent choice for such areas. A photovoltaic (PV) cell converts su nlig h t into electri c- ity. A PV or solar cell is the b asic building block of a PV system. An individual PV cell is usually quite small. PV cells are connected together to form larger units called modules which can be connect ed t o form even larger units called arrays. These arrays are connected in parallels and series to meet the required electricity demand. PV arrays produce power only when illuminated, and it is therefore standard to employ a large energy storage mechanism, most commonly a series of rechargeable batteries. To pre- 2vent harmful battery over-charge and over-discharge condition s and to drive AC loads, a charge controller and a converter m ust be implemented. Sizing of the PV array, inverter and battery bank for a stand-alone PV system is an important part of system design. This part requires solar radiation data for the in- tended geographical location of the site, load demand and Copyright © 2012 SciRes. SGRE  Optimal Configuration for Design of Stand-Alone PV System 140 manufacturing data for PV modules, inverters and bat- teries and their operational efficiencies. Numerous stud- ies have been conducted to develop a sizing method which is both easy to apply and highly reliable [6]. Most of these methods assume constant system load and con- trol the variables that have an influence on the degree of reliability. Methods that are based on the concept of power supply during a number of autonomous days are typically used. These methods are simple and assure the required reliability of the PV system during autonomous days. In these methods, the storage system meets the load demand. The storage system capacity is regarded as a measure of reliability of the PV system. So the reliability is determined by the autonomous days. These methods exhibit no direct relationship between the PV array out- put and the storage system capacity. Also, the resultant sizing of the combination of PV array and battery bank for a solar PV system is not necessarily optimal. Method based on the study and characterization of daily energy balances is developed [7,8]. More universal results are obtained when implementing these methods. Another method design of a stand-alone PV system is based on the concep t of reliability of the power supply to the load , which is usually quantified by the loss of power supply probability (LPSP) [9-17]. This concept is defined as the relationship between the energy deficit and the energy demand during the total operation time of the installation. In statistical terms, the LLP value refers to the probabil- ity that the system will be unable to meet energy demand. Due to the random nature of the energy source, great effort must be made to optimize the design of stand-alone photovoltaic systems in terms of both energy consump- tion and costs. The cost of RE generation plays a major role in determining the effectiveness of the RE systems. Hernández et al. examined the development of the four main renewable energy technologies (RET) in Spain in the latest years: biomass, small hydro (SH), solar photo- voltaic (solar PV) and wind [18]. The study concluded that Spain is suitab le in meeting the RE generation target but not efficient in costs. The task of sizing should com- promise between cost and reliability. Accurate sizing ensures that demand is met and allows costs to be cut in the future. This will allow a practical use of these sys- tems in the renewable energies market. Sizing a PV sys- tem means determining both the number and area of modules to install and the capacity or total number of ampere-hours collectable in the battery. In this work a standard model based on daily energy balance is used to determine system size. Several design criteria are investigated. Numerical methods based on de- tailed simulations of PV system behavior which are per- formed over a specific period of time are used. The energy balance of the PV system and the state of charge of the battery are calculated daily. The simulation period is taken to be one year to have statistical significance of the value of loss of load probabilities LLP. A computer program is developed to simulate the PV system behavior and to nu- merically find an optimal combination of PV array and battery bank for the design of stand-alone photovoltaic systems in terms of reliability and costs. The detailed de- sign and economical analysis of a stand-alone PV system to provide the required electrical energy for a single resi- dential household in Jordan is presented. The considered location is Jordan University of Science and Technology, which is located in t he northern part of Jordan. 2. Ease the Household PV System Configuration The basic configuration of a PV stand-alone system shown in Figure 1 is considered in this study. The system con- sists mainly of solar panels, inverter, batteries and load. The function of the PV array is to convert the sunlight directly into DC electrical power. The inverter is used to convert the DC electrical power into AC power; to match the requirements of the common household AC appliances. The excessive part of DC power is stored in the b attery to be used when there is no sunshine. The controller m onit ors the electrical input from the solar panels and controls the amount going directly into the inverter and the amount for charging and discharging of the battery bank. 3. Prepare Site Meteorological Data To predict the performance of a PV system in a location, it is necessary to collect the meteorological or environ- mental data for the site location under consideration. The monthly average daily solar radiation data incident on a horizontal surface at the considered site is shown in Fig- ure 2. It is clear from Figure 2 that solar energy incident in the considered site is very high especially during the summer months, where it exceeds 7 kWh/m2/day on hori- zontal. Table 1 lists the average number of clear days for each month and the average number of shining hours for each month. It is clear from Table 1 that even in winter, Jordan enjoys more than twenty days of sunshine per month. The total number of sunshine days in Jordan ex- ceeds 300 annually. Figure 1. Schematic of stand-alone PV system. Copyright © 2012 SciRes. SGRE  Optimal Configuration for Design of Stand-Alone PV System 141 0 1 2 3 4 5 6 7 8 9 123456789101112 M onths Solar Radiat ion (kWh/m 2 .Day) Horizontal T ilted Figure 2. Monthly average daily global radiation (total ir- radiance) on a horizontal surface and on a 30 o tilted plane at the considered site. Table 1. Clear days and sunshine hours average numbers. Month Average No. of clear daysAverage No. of hours of sunshine January 20 232 February 22 260 March 24 296 April 25 275 May 25 348 June 30 405 July 31 380 August 31 390 September 29 334 October 25 280 November 26 264 December 22 233 4. Electrical Demand The household in the remote area in Jordan is assumed to be simple—not requiring large quantities of electrical energy. The electrical loads include lighting, medium size refrigerator, one microwave oven and other ordinary household electrical appliances, e.g. TV sets, hair dryers, etc. The daily electrical demand in a typical day for each device is shown in Table 2. It is assumed that this load is constant around the year. The corresponding load profile for a typical day is indicated in Figure 3. The average daily load demand EL can be calculated from Table 2 to be 13205 Wh/day. 5. PV System Design Jordan is a relatively small coun try. The northern part of Jordan is located near 30.58˚ latitude and 36.23˚ longi- tude. Tilt angle is defined as the angle of inclination of a module measured from the horizontal. Since the consid- ered site is located at 30.58˚ North latitude and 36.23˚ east longitude, the optimal angle for solar panels is to be 30˚ degree f a cing south. Table 2. The Household Load Data. Wh/day Wattage Per Unit used Operating Hours Per Day No. of units Electrical Load 180 15 12 6 Lights 1000100 10 2 Ceiling fan 375 375 1 1 Washing machine 900 225 4 1 Computer 5400600 9 1 Refrigerator 650 1300 0.5 1 Microwave 4200300 14 1 TV 500 1000 0.5 1 Laundry Total = 13205 Wh/day 0 500 1000 1500 2000 2500 0510 1520 Ti m e ( h ) Load (Watt) Figure 3. The load profile of the household. The output of a PV array is related to the light inten- sity falling on the PV array, ambient temperature, cell temperature, load status and characteristics of PV mod- ules. Since the PV array considered in this study is tilted 30˚ facing south, the hourly global radiation on a hori- zontal surface should be converted to that on PV modules. Chenni et al. developed a simple method to calculate global, diffuse and d irect irradiance on vertical and tilted surfaces for all uniform sky conditions (clear sky and overcast sky) [19]. Since the hourly global radiation on a horizontal surface is available, the total irradiance on tilted plane with any orientation can be given using Hay’s sky diffusion anisotropic mode l [20]. 0.51 cos 0.511cos bB d Bbobo GGR G G RGGGG (1) where, G is total irradiance on horizontal surface (W/m2), Gb is direct radiation incident on horizontal surface W/m2), Gβ is total irradiance on tilted surface (W/m2), Gd is diffuse incident on horizontal surface W/m2), and RB the ratio of the direct radiation on the tilted plane to that on a horizontal surface and has the following form: cos cos i Rz (2) The remaining variables and quantities are determined by: Copyright © 2012 SciRes. SGRE  Optimal Configuration for Design of Stand-Alone PV System 142 1 1 1 coscoscossinsincos, coscos sincoscos cos, 1180, 2 sin cos sinsin 11, 1otherwise 1otherwise 1 izzs z ew ns sewnsso so z w ew ns w e 0 1 0tan , cos 1otherwise tan ew (3) where, θ theta is incidence angle of light rays (deg), θz is Zenith angle (deg), β is the Tilt angle of plane to gorund (deg), δ is d eclination of the sun (deg), ϕ is latitude, is azimuth angle of inclidned plane (deg), s is solar azi- muth angle (deg), is hours angle (deg). The hourly tilted solar irradiation is calculated using the above Equations (1)-(3). The average monthly tilted irradiation is shown in Figure 2. 5.1. Design Criteria To design a stand-alone PV system for the considered household, the size of the PV array and battery bank ca- pacity should be determined. Two design criteria are used: average daily solar radiation and average lowest month. The ability of the resulting sizes from these two criteria to meet the daily demand is investigated. The size of the PV array used in this study can be calculated by the following equ a tion [21]: PV PV areaTCF L in out E G (4) where, Gin is solar energy input per day on PV panels, TCF is the temperature correction factor, ηPV is PV effi- ciency, ηout is battery efficiency (ηB) × inverter efficiency (ηInv). As for the sizing of the battery, the storage capacity of the battery can be calculated according to the following relation [22,23]: Storage capacityDOD cL out NE η (5) where, Nc is number of autonomous days (the largest number of continuous cloudy days of the site). DOD is maximum permissible depth of discharge of the battery. The selected modules are PS-P 60 mono-crystalline sili- con (see [24]), with the following specifications at stan- dard test conditions (i.e., 1000 W/m2 and 25˚C): -Max Power = 250 W; -Max Current = 8.17 Amps; -Max Voltage = 29.4 Volts; -Nominal Output Voltage 24 Volts; -PV Efficiency ηPV = 14%. For the first design criteria based on average daily so- lar radiation, the average daily solar energy input over the year (Gav) on a south facing surface tilted at an angle equal to 30˚ is calculated from Figure 2 to be about 5.475 kWh/m2·day. If the cell temperature is assumed to reach 45˚C in the field, then the temperature correction factor (TCF) will be 0.9 as indicated in [21]. Assuming battery efficiency ηB = 0.85 and inverter efficiency ηInv = 0.94, then ηout = 0.85 * 0.94. Thus, using Equation (4), the PV area is 25.4 m2, if the largest number of continuous cloudy days Nc in the selected site is ab out 3 days. Thus, for a maximum depth of discharge for the battery DOD of 0.8, the storage capacity according to Equation (5) is 61.975 kWh. For the second design criteria based on the average lowest month of solar irradiation, Figure 2 shows that the lowest irradiation corresponds to Dec. with tilted average equal to 3.4 kWh/m2·day. The design will be based on this value Gmin . According to equation (4), the PV area is 40.9 m2. T he requir ed stor age capacity for five autonomous days is 61.975 kWh. In order to determine the ability of the resulting sizes from these two criteria to meet the daily demand, the daily amount of charge remaining in the batteries is cal- culated. The batteries supply the required electricity when there is no direct electricity PV production. The batteries recharge during the daylight if extra energy is available. Figure 4 shows the daily amount of charge remaining in the batteries for fou r months in row starting in Oct. On October first, the batteries are assumed to be fully charged. The amount of energy in fully charged batteries is 61.975 kWh. For PV area = 25.4 m2, the bat- tery completely discharged on Dec. 6 and this failure continued for the next two months. On the other hand, when PV area = 40.9 m2, the stand-alone PV system meet the required load without any failure. However, if there is a ch arge controller set to pr event discharging the batteries at 20%, then there will be power out for five nights. For PV area = 25.4 m2, the amount of extra PV -10 0 10 20 30 40 50 60 70 0306090 Days Battery Storage ( kW.h) 120 PV area = 25. 4 m 2 PV area = 40. 9 m 2 Oct.Nov. Dec.Jan. Figure 4. Daily amount of charge remaining in the batteries. Copyright © 2012 SciRes. SGRE  Optimal Configuration for Design of Stand-Alone PV System 143 production completely charge the batteries during Oct. However, during November, there is not enough PV production to completely charge the batteries during the daytime. The amount of battery charge kept decreasing during November all the way until it is completely dis- charged on the beginning of December. It took the sys- tem over two months to completely rech arge the batteries. As for PV area = 40.9 m2, the PV production during day is able to completely recharge the batteries until the be- ginning of December. The amount of energy stored in the batteries stays relatively large except for few days at the beginning of January. After that is increased rapidly. 5.2. Design of the Battery Charge Controller The primary function of a charge controller in a stand- alone PV system is to maintain the battery at highest possible state of charge while protecting it from over- charge by the array and from over discharge by the loads. Wu et al. developed a new fast charging method that is applied to micro-grid photovoltaic systems to eliminate batteries underch arge or overcharge due to random ch anges of solar radiation [25]. Some PV systems can be effec- tively designed without the use of charge control. In the present study, a charge control is required due to the fact that the load is unpredictable. Another reason for the charge control is that the battery storage is optimized resulting in undersized system, a charge control is need to prevent the severe discharge resulting in short life of the battery. The algorithm or control strategy of a battery charge controller determines the effectiveness of battery charging and PV array utilization, the ability of the sys- tem to meet the load demands and extend the lifetime of a battery. When the irradiation is high (typically during summer), energy generated by the PV array often ex- ceeds the electrical load demand. To prevent battery dam- age resulting from overcharg e, a charge controller is used to protect the battery. A charge controller should prevent overcharge of a battery regardless of the system siz- ing/design and seasonal changes in the load profile, op- erating temperatures and solar irradiation. It has to be capable of carrying the short circuit current of the PV ar- ray. Thus, in this case, it can be chosen to hand le 73.4 A and to maintain the DC bus voltage to about 36 V. 5.3. Design of the Inverter The selected inverter must be able to handle the maxi- mum expected power of AC loads. The rated power of the inverter Prat, inv taken to be 20% higher than the rated power of the total AC loads that presented in Table 2. Thus the rated power of the required inverter will be 1800 W. the specification of the required inverter will b e 1800 W, 36 VDC, and 50 Hz. 5.4. Sizing of the Battery The life of battery is a function of maximum depth of discharge DOD. The maximum depth of discharge for the battery is taken to be 0.8. The sizing method for barratry storage is based on the concept of power supply during a number of autonomous days; during these days the load demand is met solely by the sto rage system. If the largest number of continuous cloudy days (number of autono- mous days) is NC, then the minimum required ampere- hours of the batt ery AhtotB is calculated by: Storage capacity Ah DC nominal voltage totB (6) If the selected battery is lead acid with nominal volt- age = 12 Volts and rated capacity = 220 Amp-hrs, then the number of Batteries in Parallel NBp is calculated by: Ah Ah rated capacity220 totB totB P NB (7) Thre e batteries a re needed to meet the system nominal voltage. Finally, the total number of batteries s is NMP × NMS batteries. 5.5. Sizing of PV Modules The numbers of PV modules are determined by the fol- lowing expressions: peak power PV Number of modules Peak power of a module (8) where PVpeak power is calculated by Peak PowerareaPV PV PV PSI (9) where PSI is the maximum radiation intensity take n to be 1000 W/m2, and the peak power of the selected module is 250 W. The number of modules in parallel NMp and series are calculated by: Ah , , DCAh, AhDCAh totS tot pStot MFm S L tot S IV NM NM I IDV N E f V (10) where, : Module Operating Current , : Module Derate Factor, : The Total PV Array Current, : Tot al System Load, : System Nominal Voltage, : Losses and Safety Factor, : The Average Nu M F tot L S S I D I E V f Nmber of Solar hrs, Copyright © 2012 SciRes. SGRE  Optimal Configuration for Design of Stand-Alone PV System 144 DCAh: The Total DC Amp-hours/Day, : Number of Module in Series, : Number of Module in Parallel. S P NM NM NS is calculated from Table 1, to be 6 hours and the sys- tem nominal voltage is taken to be 36 volt. The losses and safety factor is assumed to be 1.2. The total number of modules NMtot is totP S NMNM NM (11) 5.6. Sizing Optimization As mentioned previously, the method presented here is quit simple and quick, but the resulting sizing of the combination of PV array and battery bank for a solar PV system is not necessarily optimal. It is the objective of this section to find a sizing combination that minimizes the cost while maintaining desired values of reliability. The reliability of power supply of system is expressed in terms of the loss of load probability (LLP), defined as the power failure time Tf divided by the estimated period of time T, i.e. LLP = Tf/T. For the given LLP value of the whole year, many configurations can meet this reliability demand of power supply. In this study, a program for calculating the LLP values and the total cost of different configurations is developed. In the program, a PV area and number of autonomous days are provided to the pro- gram. The program calculates the daily PV output for the whole year according to the following equation PV PVPV area outinB Inv G (12) and compares it with the daily demand EL. A charge controller is simulated that prevents the both overcharge and the undercharge of batteries bank. The amount charge stored in batteries is calculated daily. A power failure is indicated if the amount of charge reaches the lower limits, which is specified here to be 20% of the storage capacity given by Equation (5). The program counts these times and calculate LLP for the given combination. The pro- gram calculates the total number of PV modules (paral- lels and series) required according to Equations (10) and (11). The program has calculated the whole year’s LLP values of different configurations with PV area changing from 30 m2 to 50 m 2 and number of autonomous days changing from 1 to 7. The trade-off curves between the numbers of PV modules and number of batteries for several LLPs are shown in Figure 5. Figure 5 shows only parts of cal c ul at ion results. The objective function of the optimization problem is the life cycle cost (LCC) of stand-alone PV system. The LCC of any system consists of the total costs of owning and operating it over its lifetime, expressed in today’s money. The costs of a stand-alone PV system include acquisition costs, operating costs, maintenance costs, and replacement costs. The LCC of the PV system includes the sum of all the present worth’s (PWs) of the costs of the PV modules, storage batteries, battery charger, and inverter, the cost of the installation, and the maintenance and operation cost (M&O) of the system. The details of the used cost data for all items are shown in Table 3. These data was obtained from the manufacturer of PV system [26]. The lifetime N of all the items is considered to be 20 years, except that of the battery which is considered to be 5 years. Thus, an extra three groups have to be purchased, after 5 years, 10 years, and 15 years. Assuming an infla- tion rate i of 3% and an interest rate d of 10%. The program calculates the LLC for any com binations according to the following equations: PV array cost CPV is given by: PVPeak Power 242 $WPVC . (13) where PVpeak power is calculated by Equation (9) Initial cost of batteries is given by: 1 $AhAh tot C (14) where Ahtot is the required ampere-hour of the batteries calculated from Equation (6) $0.5W nvrat, inv C P (15) The charger cost is given by: $0.5 W C CSC I (16) 15 17 19 21 23 25 27 29 31 258 111417 No. of Batteries No. of PV modul e s LLP = 0 LLP = 0. 011 LLP = 0. 022 LLP = 0. 03 LLP = 0. 033 LLP = 0. 049 Figure 5. Trade off curves between the numbers of batteries and PV modules for the different LLP values. Table 3. The used cost of all items. M&O/ Year Installation Charge controller InverterBatteryPV Item 2% of PV cost 10% of PV cost $3.2/A 0.5 $/W1$/Ah2.42 $/WCost Copyright © 2012 SciRes. SGRE  Optimal Configuration for Design of Stand-Alone PV System Copyright © 2012 SciRes. SGRE 145 The LCC of the system is calculated by summing all the above cost, I’e The installation cost is taken to be 10% of the PV co st. As for the current value of the maintenance cost CMPW is calculated by [25] : PV1PW 2PW 3PW MPW LCC BB B BIns c inv CCC C CCCCC (19) MPW 11 1 1 Myr 1111 id i Cdi d (17) Table 4 list sample of the calculation results output from the program developed. For a given value of LLP there is an optimum configuration that has the lowest cost. For example, for LLP = 0.0027, the cost of the combination that meet this requirement ranges from $22,267 to 26,177. However, the optimum combination is number of batteries = 10 and PV modules = 20. An- other example for LLP = 0.033, the cost of the system The maintenance cost per year (M/yr) is assumed 2% of the PV cost. The present value of the nth extra group of batteries CBnPW purchased after N years is calculated by: PW 11 Bn B CCid (18) Table 4. Sample of the calculation results. PV area (m2) No of autono- mous days Number of Batteries Number of PV modules LLP LLC ($)PV area (m2) No of autono- mous days Number of Batteries Number of PV modules LLPLLC ($) 35 4.5 11 20 0.00002323948.5 1 3 28 0.01124011 33.5 5 12 19 0.00002332050 1 3 29 0.01124679 45 3.5 9 26 0.00002619734 2 5 20 0.01419048 40 6 14 23 0.00002771434.5 2 5 20 0.01419270 50 6.5 15 29 0.00003292035.5 2 5 20 0.01419716 49.5 7 17 28 0.00003344631 5 12 18 0.01422206 50 7 17 29 0.00003366930.5 6 14 18 0.01423481 34.5 4 10 20 0.00272226730 7 17 17 0.01424757 35 4 10 20 0.00272249033.5 2 5 19 0.01918825 37 3.5 9 21 0.00272263232 2.5 6 18 0.01918905 37.5 3.5 9 22 0.00272285537.5 1.5 4 22 0.01919858 36 4 10 21 0.00272293538 1.5 4 22 0.01920081 33 5 12 19 0.00272309731 4 10 18 0.01920707 49.5 2 5 28 0.00272595531.5 2.5 6 18 0.02218683 50 2 5 29 0.00272617735 1.5 4 20 0.02218744 34 3.5 9 20 0.00552129537.5 1 3 22 0.02219109 34.5 3.5 9 20 0.00552151838 1 3 22 0.02219332 35 3.5 9 20 0.00552174131 3.5 9 18 0.02219958 37.5 3 7 22 0.00552210630.5 5.5 13 18 0.02222732 36 3.5 9 21 0.00552218634 1.5 4 20 0.02518298 39.5 2.5 6 23 0.00552224830.5 5 12 18 0.02521983 38 3 7 22 0.00552232830 5.5 13 17 0.02522509 33.5 4.5 11 19 0.00552257030 6 14 17 0.02523258 43 2 5 25 0.00552305835 1 3 20 0.02717995 49.5 1.5 4 28 0.00552520533.5 1.5 4 19 0.02718076 50 1.5 4 29 0.00552542830.5 4 10 18 0.02720484 34 3 7 20 0.00822054630.5 4.5 11 18 0.02721234 36 2.5 6 21 0.00822068830 5 12 17 0.02721760 34.5 3 7 20 0.00822076934.5 1 3 20 0.03017772 36.5 2.5 6 21 0.00822091133 1.5 4 19 0.03017853 35 3 7 20 0.00822099132 2 5 18 0.03018156 37 2.5 6 21 0.00822113430 4.5 11 17 0.03021011 39.5 2 5 23 0.00822149833 1 3 19 0.03317104 38 2.5 6 22 0.00822157931.5 1.5 4 18 0.03317184 38.5 2.5 6 22 0.00822180234 1 3 20 0.03317549 32 5 12 18 0.00822265131.5 2 5 18 0.03317934 44 1.5 4 25 0.00822275530 4 10 17 0.03320262 44.5 1.5 4 25 0.00822297731 1 3 18 0.04916212 34 2.5 6 20 0.01101979730.5 1.5 4 18 0.04916739 34.5 2.5 6 20 0.01102002030 2 5 17 0.04917265 35 2.5 6 20 0.01102024230 2.5 6 17 0.04918014  Optimal Configuration for Design of Stand-Alone PV System 146 ranges from $17,104 to $20,262. The op timum combina- tion corresponds to number of b atteries = 3 and PV mod- ules = 19. For LLP = 0, the stand-alone system works without any power failure. The optimal cost for such sys- tem is $23,239, which is comb ined of 11 batteries and 20 PV modules. However, for LLP = 0.049, which means there are 18 nights without power in the whole year. The optimal cost for such system is $16,212. Knowing this difference can help the designer decided to install an- other auxiliary hybrid system or not. It is sometimes useful to calculate th e LCC of a system on an annual basis. The annualized LCC (ALCC) of the PV system in terms of the present day dollars can be calculated by: 11 ALCCLCC 11 11 N i dd i (20) Unit electrical cost of 1 kWh is ALCC 365 E. Table 5 summarizes the optimal configurations and the corresponding unit cost of electricity. The calculated current unit cost of PV systems depends on the LLP val- ues. There values range b etween 0.419 S/kWh and 0.293 $/kWh. Although this price is very high compared to the current unit cost of electricity in Jordan (0 .114 $/kWh), it is predicted that this price will drop significantly in the future due to decrease in the initial cost of the PV mod- ules. At the same time, if the future unit cost of electric- ity in Jordan increases due to the rapid increase in the conventional fuel prices, therefore PV energy generation will be promising in the future house electrification due to its expected future lo wer unit electricity cost, efficiency increase, and clean energy generation compared to the convention al utility grid. 6. Conclusion An electrification study for a single residential house in a remote isolated site of Jordan is carried out using a Table 5. Summary of the optimal configurations size and cost for given LLPs. PV area (m2) No of Autonomous Days Number of Batteries Number of PV Modules LLP LLC ($)Cost of 1 kWh 35 4.5 11 20 0.0000 232390.419 34.5 4 10 20 0.0027 222670.402 34 3.5 9 20 0.0055 212950.384 34 3 7 20 0.0082 205460.371 34 2 5 20 0.014 190480.344 34.5 1 3 20 0.030 177720.321 33 1 3 19 0.033 171040.309 31 1 3 18 0.049 162120.293 stand-alone PV system. The complete design steps and the life cycle cost analysis of the PV system is presented. A method based on calculating the yearly loss of load probability LLP has been presented for a PV sizing. A computer program that simulates the stand-alone PV system daily behavior is developed. According to local hourly measured meteorological data, load demand, the characteristic and price of the components and reliability requirement on power sup ply, the optimum configu ration which meets the load demand with the minimum cost can be uniquely determined by the program. The unit electri- cal cost for electrifying a remote isolated house using PV systems is calculated. The results of study indicates that using the optimal configuration for electrifying remote areas in Jordan is beneficial and suitable for long-term investments, especially if the in itial prices of the PV sys- tems are decreased and their efficiencies are increased. Therefore, in remote sites that are too far from the Jorda- nian power grid, it is encouraged to in stall PV systems to generate electricity. REFERENCES [1] A. Guglielmo, S. Stefano Redi, A. Tatnall and T. Markvart, “Harnessing High-Altitude Solar Power,” IEEE Transac- tions Energy Conversion, Vol. 24, No. 2, 2009, pp. 442-451. doi:10.1109/TEC.2009.2016026 [2] G. C. Bakos and M. Soursos, “Techno-Economic Assess- ment of a Stand-Alone PV/Hybrid Installation for Low- Cost Electrification of a Tourist Resort in Greece,” Ap- plied Energy, Vol. 73, No. 2, 2002, pp. 183-193. doi:10.1016/S0306-2619(02)00062-4 [3] W. M. Rohouma, I. M. Molokhia and A. H. Esuri, “Com- parative Study of Different PV Modules Configuration Reliability,” Desalination, Vol. 209, No. 1-3, 2007, pp. 122-128. doi:10.1016/j.desal.2007.04.020 [4] D. Lowe and C. R. Lloyd, “Renewable Energy Systems for Remote Areas in Australia,” Renew Energy, Vol. 22, No. 1-3, 2001, pp. 369-378. doi:10.1016/S0960-1481(00)00043-4 [5] Jordan Meteorological Department, “Jordan Annual Cli- mate JMD,” Amman, Jordan, 1998. [6] S. Silvestre, “Review of System Design and Sizing Tools. Practical Handbook of Photovoltaics: Fundamentals and Applications,” Elsevier, Oxford, 2003, 543 p. [7] M. Egido and E. Lorenzo, “The Sizing of a Stand-Alone PV Systems: A Review and A Proposed New Method,” Solar Energy Materials and Solar Cells, Vol. 26, No. 1-2, 1992, pp. 51-69. doi:10.1016/0927-0248(92)90125-9 [8] R. Posadillo and R. Luque, “Approaches for Developing a Sizing Method for Stand-Alone PV Systems with Vari- able Demand,” Renewable Energy, Vol. 33, No. 5, 2008, pp. 1037-1048. doi:10.1016/j.renene.2007.06.004 [9] E. Ofry and A. Braunstein, “The Loss of Power Supply Probability as a Technique for Stand-Alone Solar Elec- trical (Photovoltaic) Systems,” IEEE Transactions on Power Copyright © 2012 SciRes. SGRE  Optimal Configuration for Design of Stand-Alone PV System 147 Apparatus and Systems, Vol. 102, No. 5, 1983, pp. 1171- 1175. doi:10.1109/TPAS.1983.318057 [10] L. L. Bucciarelli Jr., “Estimating Loss-of-Power Probabil- ities of Stand-Alone Photovoltaic Solar Energy Systems,” Solar Energy, Vol. 32, No. 2, 1984, pp. 205-209. doi:10.1016/S0038-092X(84)80037-7 [11] L. Barra, S. Catalanotti, F. Fontana and F. Lavorante,” An Analytical Method to Determine the Optimal Size of a Photovoltaic Plant,” Solar Energy, Vol. 33, No. 6, 1984, pp. 509-514. doi:10.1016/0038-092X(84)90005-7 [12] B. Bartoli, V. Cuomo, F. Fontana, C. Serio and V. Silves- trini, “The Design of Photovoltaic Plants: An Optimiza- tion Procedure,” Applied Energy, Vol. 18, No. 1, 1984, pp. 37-47. doi:10.1016/0306-2619(84)90044-8 [13] M. Cardona and L. L. López, “A Simple Model for Sizing Stand-Alone Photovoltaic Systems,” Solar Energy Mate- rials and Solar Cells, Vol. 55, No. 3, 1998, pp. 199-214. doi:10.1016/S0927-0248(98)00093-2 [14] Chapman, “Sizing Handbook for Stand-Alone Photovol- taic/Storage Systems,” Sandia National Laboratories, 1987. [15] M. Sidrach-de-Cardona and L. L. Mora López, “A Gen- eral Multivariate Qualitative Model for Sizing Stand- Alone Photovoltaic Systems,” Solar Energy Materials and Solar Cells, Vol. 59, No. 3, 1999, pp. 185-197. doi:10.1016/S0927-0248(99)00020-3 [16] I. Abouzahr and R. Ramkumar, “Loss of Power Supply Probability of Stand-Alone Photovoltaic Systems: A Closed Form Solution Approach,” IEEE Transactions on Energy Conversion, Vol. 6, No. 1, 1991, pp. 1-11. doi:10.1109/60.73783 [17] S. A. Klein and W. A. Beckman, “Loss-of-Load Prob- abilities for Stand-Alone Photovoltaic Systems,” Solar Energy, Vol. 39, No. 6, 1987, pp. 499-512. doi:10.1016/0038-092X(87)90057-0 [18] F. Hernández and M. Hernández-Campos, “The Devel- opment of the Renewable Energy Technologies in Spain,” Smart Grid and Renewable Energy, Vol. 2, No. 2, 2011, pp. 110-115. doi:10.4236/sgre.2011.22013 [19] R. Chenni, E. Matagne and M. Khennane, “Study of Solar Radiation in View of Photovoltaic Systems Optimiza- tion,” Smart Grid and Renewable Energy, Vol. 2, No. 4, 2011, pp. 367-374. doi:10.4236/sgre.2011.24042 [20] J. E. Hay, “Calculation of Monthly Mean Solar Radiation for Horizontal and Inclined Surface,” Solar Energy, Vol. 23, No. 4, 1979, pp. 301-308. doi:10.1016/0038-092X(79)90123-3 [21] T. M. I. Alamsyah, K. Sopian and A. Sha hrir, “In Techno- economics Analysis of a Photovoltaic System to Provide Electricity for a Household in Malaysia,” Proceedings of the International Symposium on Renewable Energy: En- vironment Protection & Energy Solution for Sustainable Development, Kuala Lumpur, 2003, pp. 387-396. [22] M. Kolhe, “Techno-Economic Optimum Sizing of a Stand- Alone Solar Photovoltaic System,” IEEE Transactions on Energy Conversion, Vol. 24, No. 2, 2009, pp. 511-519. doi:10.1109/TEC.2008.2001455 [23] S. R. Wenham, M. A. Green and M. E. Watt, “Applied Photovoltaics,” Center for Photovoltaic Devices and Sys- tems, Australia, 1994. [24] Philadelphia. http://solar.com/default.aspx [25] R. Messenger and J. Ventre, “Photovoltaic Systems En- gineering, CRC,” Press LLC, Boca Raton, 2000. [26] T. Wu, Q. Xiao, L. Wu, J. Zhang and M. Wang, “Study and Implementation on Batteries Charging Method of Micro- Grid Photovoltaic Systems,” Smart Grid and Renewable Energy, Vol. 2, No. 4, 2011, pp.324-329. Copyright © 2012 SciRes. SGRE

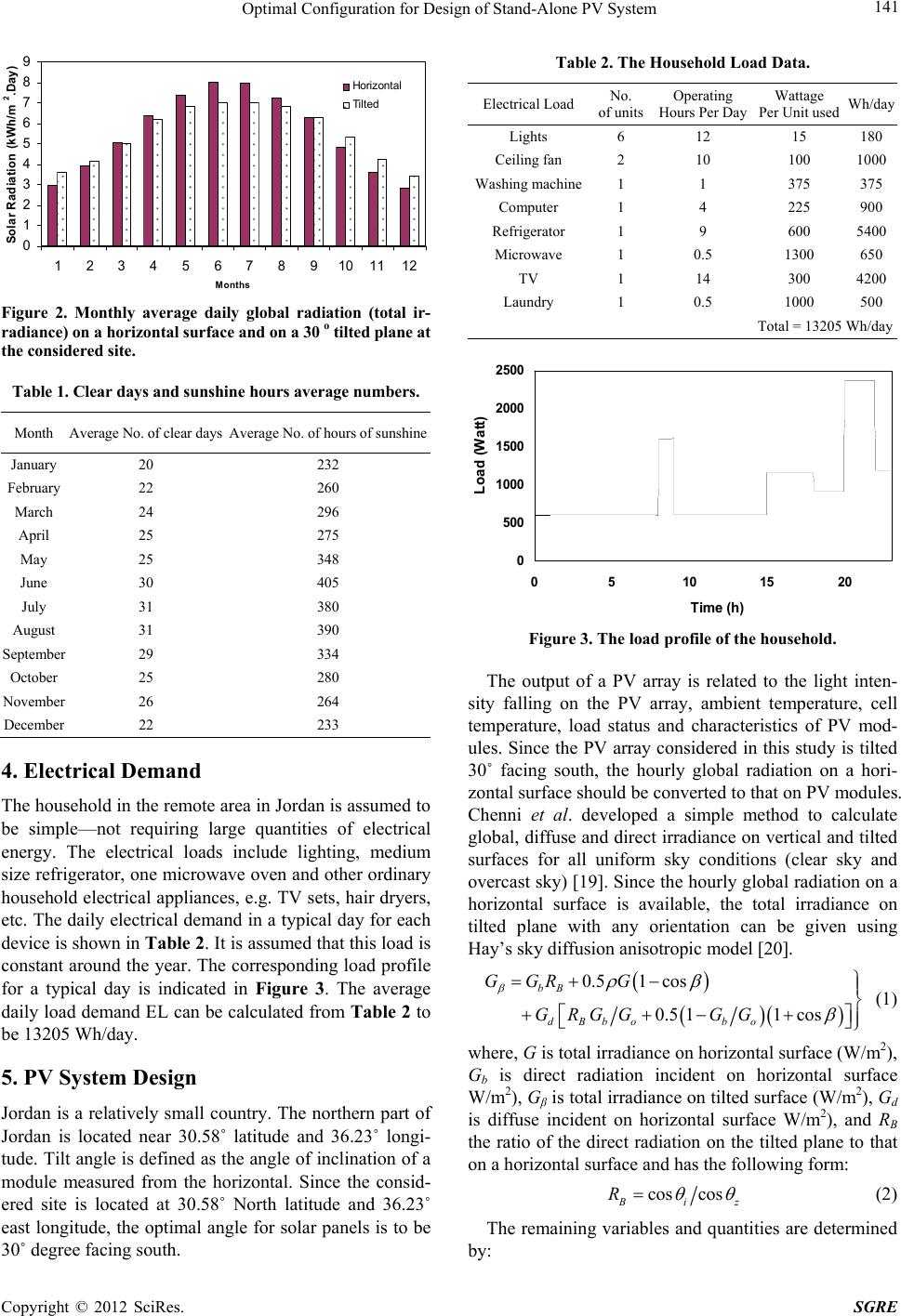

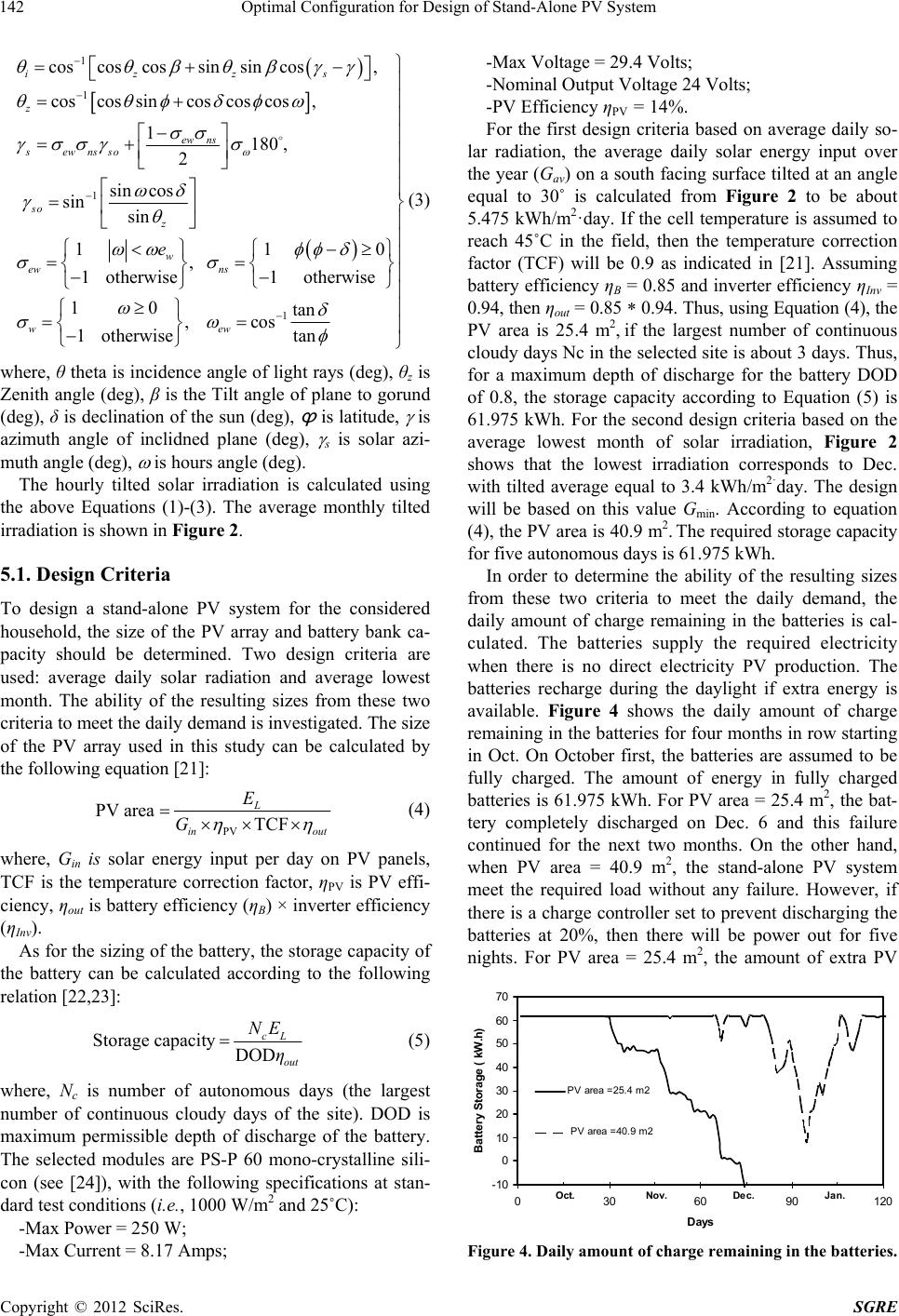

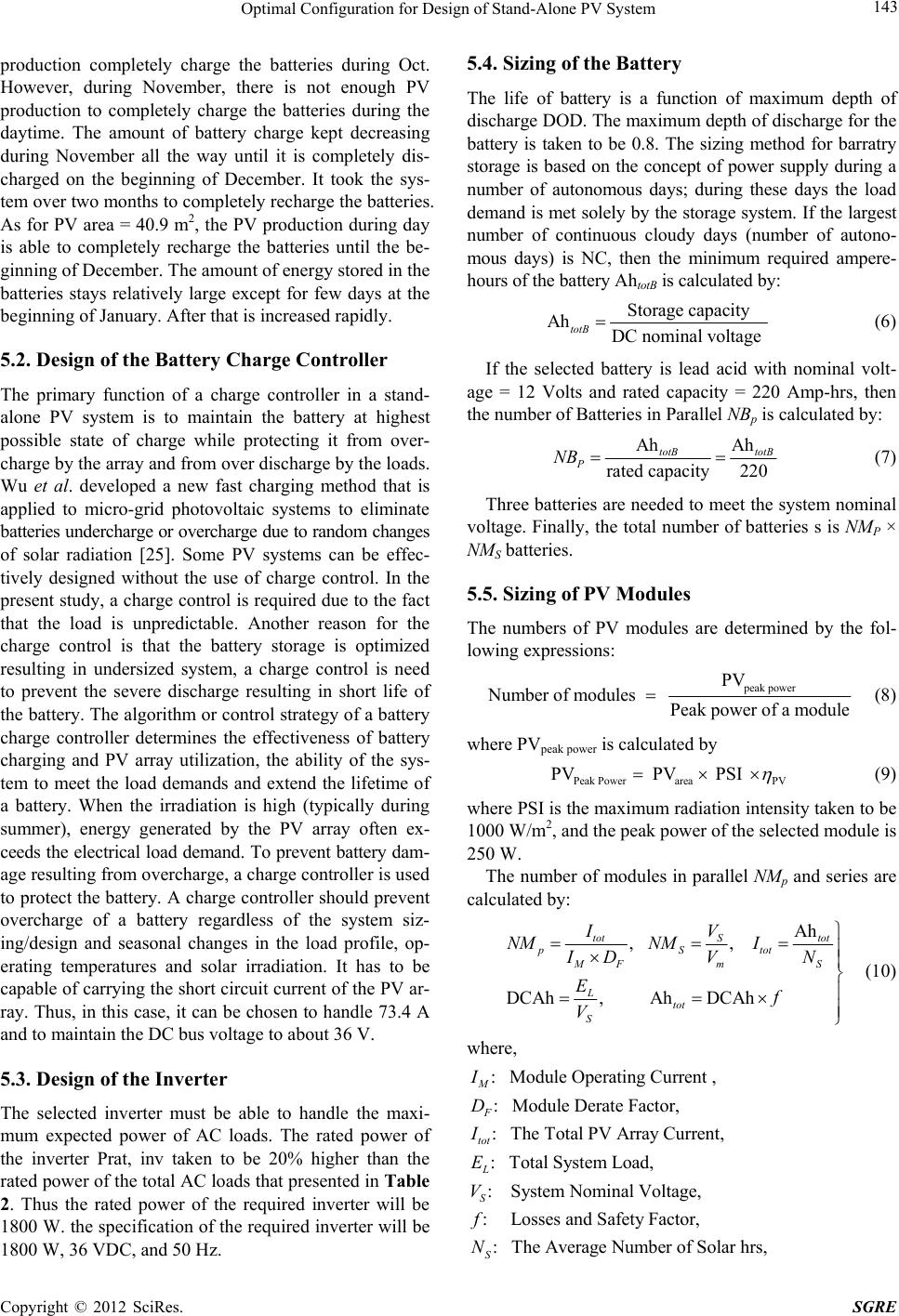

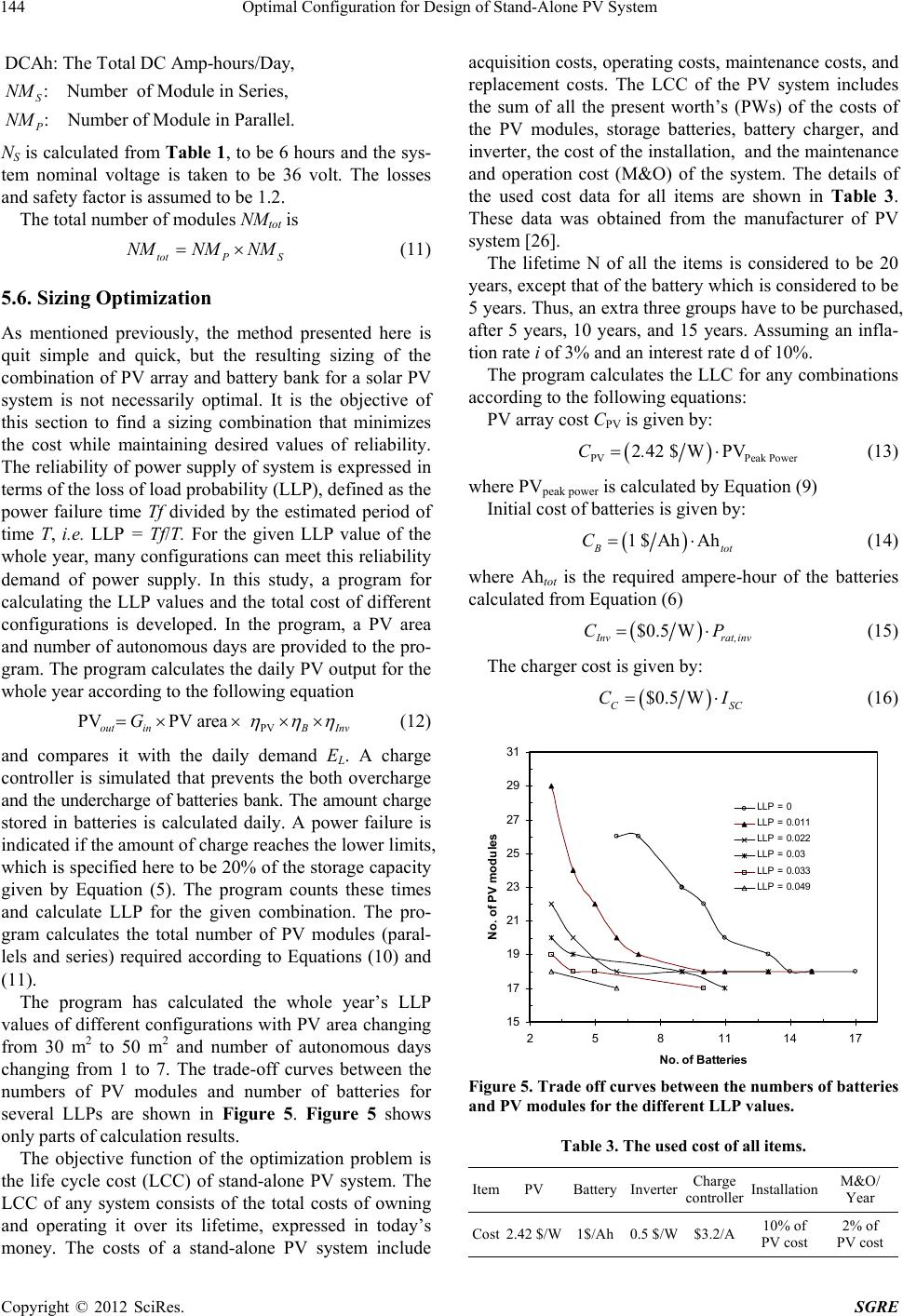

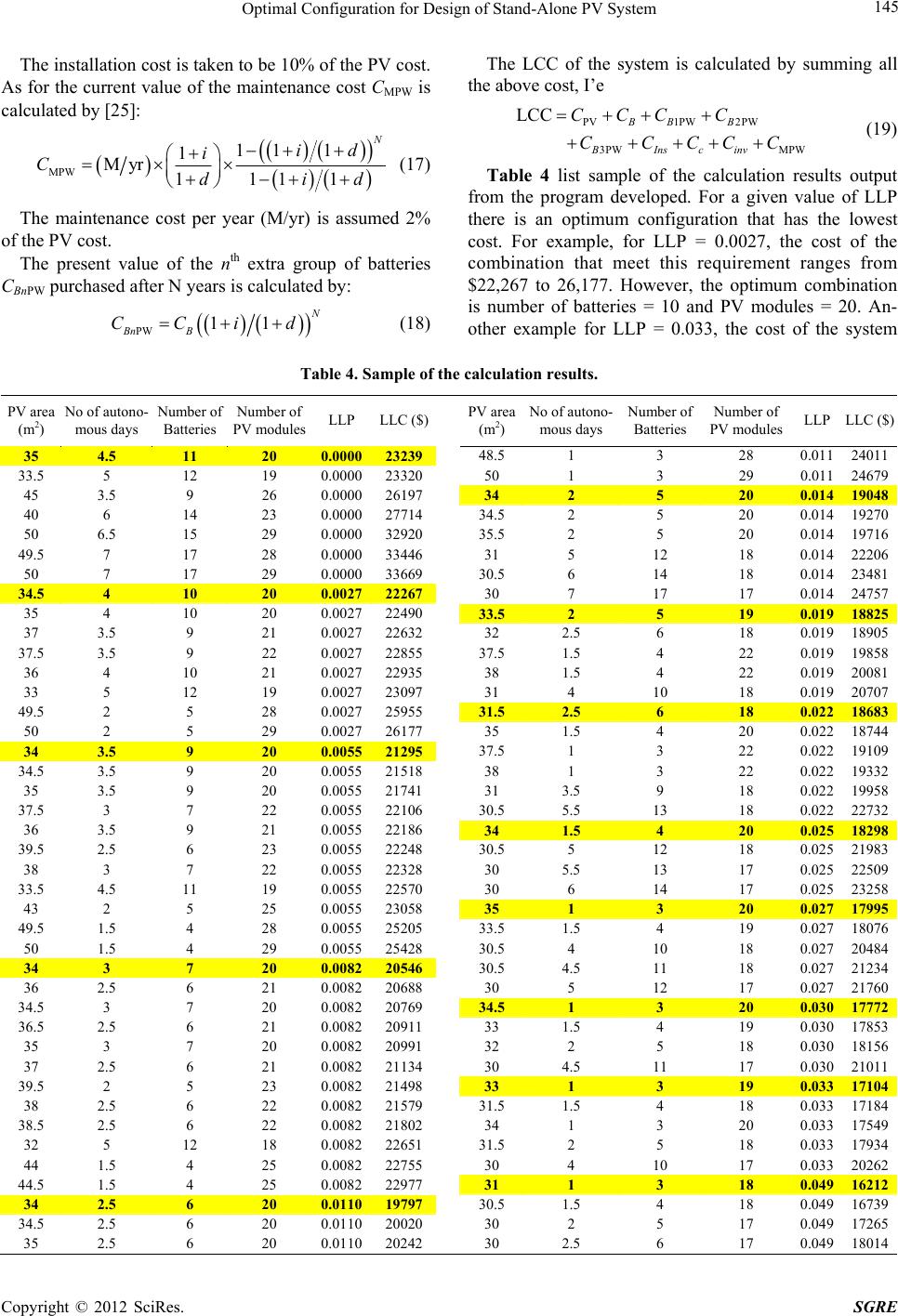

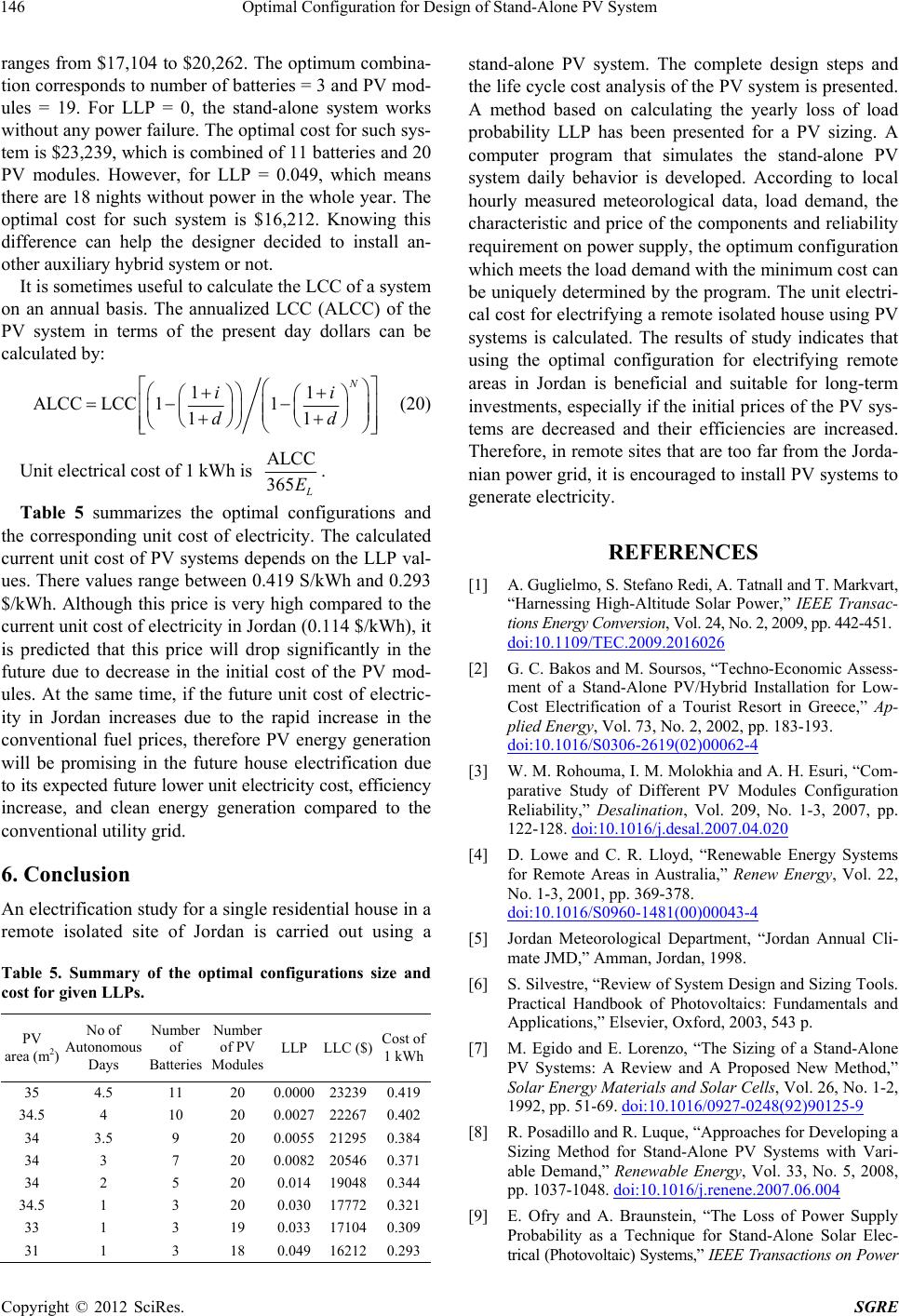

|