Open Journal of Statistics, 2012, 2, 224-235 http://dx.doi.org/10.4236/ojs.2012.22028 Published Online April 2012 (http://www.SciRP.org/journal/ojs) Productivity Growth, Technological Progress, and Efficiency Change in Vietnamese Manufacturing Industries: A Stochastic Frontier Approach* Nguyen Khac Minh1, Pham Van Khanh2, Nguyen Thi Minh3, Nguyen Thi Phuong Anh4 1Faculty of Economics, Water Resources University, Hanoi, Vietnam 2Military Technical Academy, Hanoi, Vietnam 3National Economics University, Hanoi, Vietnam 4Hanoi University of Science and Technology, Hanoi, Vietnam Email: khacminh@gmail.com, van_khanh1178@yahoo.com Received February 3, 2012; revised March 8, 2012; accepted March 19, 2012 ABSTRACT This study applies a stochastic frontier production approach to decompose the sources of total productivity (TFP) growth into technical progress and changes in technical efficiency of 8057 firms in Vietnamese manufacturing indus- tries during 2003-2007. Using both total manufacturing industry and sub-manufacturing industrial regressions, the analysis focuses on the trend of technological progress (TP) and technical efficiency change (TEC), and the role of productivity change in economic growth. According to the estimated results, the annual technical progress for the manufacturing industry and sub-manufacturing industries are calculated directly from the estimated parameters of the translog stochastic frontier production function by taking a partial derivative of output with respect to time t. The aver- age technical changes in manufacturing industry and sub-man ufacturing industries are positive, with an average techni- cal change about 5.2%, 5.8%, 5.4%, 11.8%, 4.6%, 4.1%, 7.3%, 4.8%, 4.8% and 4.8% for total sample, food products & beverages, textile & wearing apparel, footwear, paper & products, industrial chemicals, rubber & plastic products, non- metallic mineral, basic & fabricated metal and other sub-industries, respectively. Total TFP in the manufacturing sector has grown at the annual rate of 0.052, although the rate of growth decreased continuously during the sample period. For the sub-industry estimates during the sample period, TFP grew fastest in the footwear sub-industry, with annual average growth rate of 11.8%, followed by the rubber & plastic products with a rate of 7.3%, and the food products & beverages with a rate of 5.8% pe r ann um . Keywords: Total Factor Productivity; Technical Efficiency Change; Technological Progress; Stochastic Frontier Approach; Vietnamese Manufacturing Industry 1. Introduction In the “Solow residual approach”, technical progress is usually considered to be the unique source of TFP growth. TFP growth can be defined as the residual of output growth after the contribution of labor and capital inputs and subtracted from total output growth . This appro ach is based on the assumption that the economies are produc- ing along the production possibility frontier with full technical efficiency (it does not allow inefficiency). The concept of the efficiency frontier has been used to present inefficiencies. A varies of methods have been used to measure effi- ciency and decomposition total factor productivity (TFP) into technical progress, changes in technical efficiency. These methods differ to the assumptions on the outer bound of the frontier, which deterministic or stochastic frontier production function, and to the method of meas- urement parametric or non-parametric. For nonparametric method, such as data envelopment analysis (DEA). This method cannot separate deviation from the frontier technology into their systematic and random components. However, this method has the ad- vantage of imposing no restrictions on the underlying technology and have an advantage in dealing with disag- gregated inpu ts and multiple output technologies. An alternative method is called a stochastic frontier production function approach. The most important dif- ference between the stochastic frontier production func- tion approach and the Solow residual approach to pro- ductivity growth analysis lies in one assumption that firms do not fully utilize existing technology since vari- *The third author was supported by the National Foundation for Science Technology Development, Vietnam (NAFOSTED), No. II6.2-2010.07. C opyright © 2012 SciRes. OJS  N. K. MINH ET AL. 225 ous factors that lead to inevitable technical inefficiencies in production. The stochastic frontier production function approach allows decomposing TFP into efficiency change (TE) and technical progress (TP). From a policy perspective, the decomposition of TFP into efficiency changes and technical changes provides useful information in produc- tivity analysis. Since Nishimizu and Page [1] first proposed the de- composition of TFP into efficiency changes and technical changes, researchers have applied this approach to vari- ous datasets in order to investigate productivity growth. Bauer [2] estimated a translog cost frontier using da ta on the US airline industry to decompose TFP growth into efficiency, technical progress, and scale components. Sangho Kim and Gwangho Han [3] applied a stochastic frontier production model to Korean manufacturing in- dustries to decompose the sources of total productivity (TFP) growth into technical progress, changes in techni- cal efficiency, and changes in allocative efficiency, and scale effects. Empirical results based on data from 1980- 1994 showed that produ ctivity growth was driven mainly by technical progress, that changes in technical effi- ciency had a significant positive effect, and that alloca- tive efficiency had a negative effect. They suggested that specific guidelines are required to promote productivity in each industry, and provided additional insights into understanding the recent debate about TFP growth in Korean manufacturing. Hailin Liao et al. [4] applied a stochastic frontier ap- proach to sector-level data within manufacturing and examined total factor productivity (TFP) growth for eight East Asian economies during 1963-1998, using both sin- gle country and cross-country regression. The analysis focuses on the trend of technological progress (TP) and technical efficiency change (TEC), and the role of pro- ductivity change in economic growth. The empirical re- sults reveal that although input factor accumulation is still the main source for East Asian economies’ growth, TFP growth is accounting for an increasing and impor- tant proportion of output growth, among which the im- proved TEC plays a crucial role in productivity growth. Nguyen Khac Minh et al. [5] applied a non-parametric approach method to decompose the sources of total pro- ductivity (TFP) growth of three sectors of Vietnamese economy into technical progress and changes in technical efficiency. This study develops the study of Nguyen Khac Minh et al. [6] “A decomposition of total factor productivity growth in Vietnamese industries—a stochastic frontier approach” to decompose TFP growth in Vietnamese manufacturing industries from 2003-2007. We attempt to decompose TFP growth in Vietnamese manufacturing using a stochastic frontier production model, and provide additional insights into understanding on TFP growth of Vietnamese sub-manufacturing industries. This paper is organized as follows. Section 2 presents a decomposition of TFP and presents the functiona l form of the estimation model. Section 3 discusses the data and estimation results. Section 4 contains the conclusions. 2. Decomposition and Functional Form 2.1. Decomposition of TFP A stochastic frontier production function can be defined by ,exp it itit fxt u y 1, ,iN (1) where it is the output of the ith firm in the tth time perio d 1, ,tT ; is the production frontier; is an input vector, t is a time trend index that serves as a proxy for technical change; and u (non- negative) is the outpu t-oriented technical inefficiency. , it Taking total differentials xt with respect to time to get d dln,ln,ln, dd TP jj jj j fxt fxtfxt tt xt x j (2) whereas the first and second terms on the right-hand side are the output elasticit y of fron tier out put with resp ect to time, defined as TP, the second term measures the input growth weighted by output elasticities with respect to input , ln ln x j . A dot over a variable in- dicates its rate change. The derivative of the logarithm of (1) with respect to time t and using (3) is gi ven by: d TP d jj j u yx t (3) from Equation (3), TFP growth can be defined technical change (TP) and technical efficiency change. 2.2. Model Specification In our empirical study, we employ the stochastic frontier approach. The output of the manufacturing industry (or sub-industries) is assumed to be a function of two inputs, namely capital and labor. The components of productiv- ity change can be estimated within a stochastic frontier approach, and the time-varying production frontier can be specified in translog form as: 2 ln ln 11 lnln 22 ln, ,, itojjit t j jl litjittt jl tjjt itit j yxt xt txv ujlLK (4) Copyright © 2012 SciRes. OJS  N. K. MINH ET AL. 226 In Equation (4), it is the observed output, t is the time variable and x variab les are inpu ts, subscrip ts j an d l index inputs. The efficiency error, u, accounting for pro- duction loss due to un it-specific technical inefficiency, is always greater than or equal to zero and assumed to be independent of the random error, v, which is assumed to have the usual properties . Equation (4) can be rewritten as the following form: y 2 ~ 0, v iid N 1) Specification model for whole manufacturing in- dustry 0 2 2 1 ln lnln 2 1 lnlnln 21 ln2 jjj itL it KitLL jj KKitLK itit j tKittttit it LnyL K2 ln j it jj tL it L LK Ktttv u Lt where it is the firm’s output. The subscripts i repre- sent the ith firm for . N is equal to 8057 for the total sample. t represents year for and so T is equal to 5. The subscripts j represent the jth industry for, 1,2,,iN 1, 2,,tT , 1,2,jH it and it L represent ca- pital and labor, respectively. The and are un- known parameters to be estimated. 2) Specification model for each industry 0 2 2 1 lnln2 1 lnlnln 21 ln 2 itL it KitLL KKitLK itit tKittttit it LnyL K2 ln ln it tL it L LK Kt ttvu Lt u 2 ,u N (5) The distribution of technical inefficiency effects, it, is taken to be the non-negative truncation of the normal distribution , following Battese & Coelli [7], to take the form as T tiex itt ii uuupt , (6) Here, the unknown parameter represents the rate of change in technical inefficiency, and the non-negative random variable ui, is the technical inefficiency effect for the ith firm in the last year for the data set. That is, the technical inefficiency effects in earlier periods are a de- terministic exponential function of the inefficiency ef- fects for the corresponding forms in the final period (i.e.) iTi given that data for the ith firm are available in period t). uu i is the set of T time periods. A firm with a positive is likely to improve its level of efficiency over time and vice-verse. A value of 0 it u TE exp it it u implies no time-effect. Since the estimates of technical efficiency are sensitive to the choice of distribution assumptions, we consider truncated normal distribution for general specifications for one-sided error , and half-normal distribution can be tested by LR test. Given the estimates of parameters in Equations (5) and (6), the technical efficiency level of a firm at time t is defined as (7) and TEC is the change in TE, and the rate of technical progress is defined by, , ln TPln ln it t itttttLitKi fx LK t (8) If technical change is non-neutral then this technical change may vary for different input vectors. Hence, we use the geometric mean between adjacent periods as a proxy, 12 ,1, 1 ln ln TP 111 1 it jit t it fx fx tt TEit TPit (9) Both and vary over time and across the firms. The output elasticities of input K and L are ln ln ln ln ln ln ln ln KKKKLKt LL KLLLLt Y Lt K Y Lt L e The above equations indicate the percentage change in output due to a 1% change in inputs. They can be used to obtain an estimate of aggregate return to scale. The elas- ticity of scale is defined as : e L . The elasticity of scale (e) measures how output varies as a particular input bundle is augmented by a scalar. If the scale elasticity is unity, then the technology exhibits constant returns to scale. 3. Data and Empirical Results 3.1. Data Issues The panel data of Vietnamese manufacturing sectors’ annual time-series during 2003-2007 are used in esti- mating production functions. The sectors and their SIC classification numbers are listed in Table 1. The sample consists of 8057 firms in Vietnamese manufacturing industries. Data for these firms have been taken for 5 years from 2003 to 2007. All these firms that are selected at least 5 workers. The basic data for the analysis have been drawn the Database, 2007 version from General Statistics Office (GSO). It contains information for about characterized enterprises. The coverage includes public, private, and Copyright © 2012 SciRes. OJS  N. K. MINH ET AL. 227 Table 1. Manufacturing sectors. 1) Manufacturing sector (Total sample) 6) Industrial chemicals 2) Food products an d beverages 7) Rubber and plastic products 3) Textile and wearing apparel 8) Non-metallic mineral 4) Footwear 9) Basic & fabricated metal products 5) Paper & products 10) Other manuf act uring industries joint sector companies. The coverage of this database is total manufacturing firms that existed from 2003 to 2007 with number of workers greater than 5. The available Information includes data from the en- terprises’ profit, balance sheets. Key variables on which data were collected for this study include gross fixed assets, wages, revenue, gr oss out put a n d fo re ign eq uity . 3.2. Variables for the Estimation of the Model As discussed above, a two-input production function framework is used to estimate technical efficiency. This requires, for each firm, data on output, labor input and capital input. Deflated revenue has been taken as the measure of output. For this purpose, the products of each enterprise were matched with the wholesale price indices classifica- tion, and the best available price series was chosen for deflation. Total number of employees connected to the produc- tion has been taken as the measure of labor input for each firm in our sample. Gross fixed capital stock at constant prices (at year 2000) has been taken as the measure of capital input. 4. Empirical Results The estimation of parameters in the stochastic frontier mode given by Equations (8) and (9) are carried out via maximum-likelihood method, using the program FRON- TIER 4.1. Two kinds of panel are constructed. Individual sub-Industry panel is used in the single regression, con- sisting of total sample and 9 sub-manufacturing sectors and 5 years’ observations; panel data is used in the re- gression. Instead of directly estimating 2 v and 2 u , FRONTIER 4.1 seeks estimates of 22 u , 222 uv v v (10) which are also reported in the result table. These are as- sociated with the variances of the stochastic term in the production function, it and the inefficiency term it . The parameter must lie between zero and one. If the hypothesis 0 is accepted, this would indicate that 2 u is zero and thus the efficiency error term, should be remove from the model, leaving a specification with parameters that can be consistently estimated by OLS. Conversely, if the value of is one, we have the full-frontier model, where the stochastic term is not pre- sent in the model. 4.1. Hypotheses Tests and Preferred Model Chosen We performed a number of LR test to identify the ade- quate functional form and presence of inefficiency. We examine various hypotheses, such as non-presence of technical inefficiency effects, which can be tested by using the generalized likelihood ratio statistics , given by: it v 01 2ln lnLH LH where L(H0) is the value of the likelihood function for the frontier model in which the parameter restrictions specified by the null hypothesis H0 are imposed and L(H1) is the value of the likelihood function for the general frontier model. If the null hypothesis is true, then has approximately a mixed Chi-Squared distribution with degrees of freedom equal to the difference between the numbers of parameters estimated under H1 and H0, res- pectively. 4.2. Hypotheses Tests for Aggregated Samples Table 2 presents the test results of various null hypothe- ses on the total sample. 1) The first null hypothesis that the technology in Vietnamese manufacturing is a Cobb-Douglas :0H oLL KKKL tt , is rejected for the total sample and all aggregated-samples. Thus, the Cobb- Douglas production function is not an adequate specifi- cation for the Vietnamese manufacturing sector, given the assumptions of the translog stochastic frontier pro- duction function model, implying that the translog pro- duction function better describes the technology for Vietnamese manufacturing industries. 2) The second null hypothesis, that there is no techni- cal change :0H o ttKtLtt is strongly rejected by the data in all cases. It implies that the exis- tence of technical progress, given the specified produc- tion model. 3) The third null hypothesis, that technical progress is neutral :0H otK tL. Not that the translog parameterization of this stochas- tic frontier model allows for non-neutral TP. TP is neu- tral if all tj s are equal to zero. Total sample, food & beverages, footwear, paper & products, Industrial chemi- cals, non-metallic mineral, basic & fabricated metal and ther manufacturing industries cannot reject the hypothe- o Copyright © 2012 SciRes. OJS  N. K. MINH ET AL. Copyright © 2012 SciRes. OJS 228 Table 2. Generalized likelihood ratio of hypotheses for parameters of the SFPF for Vietname se manufac turing industries. Hypothesis Log-likelihood value Test statistics Critical value Decision 1% 5% Cobb-Douglas production function, H0: all s are equal to zero (df = 6) Total sample –48319.83 21475.94 16.81 12.59 reject Food products & be verages –7559.98 31.65 16.81 12.59 reject Textile & wearing apparel –4781.91 41.92 16.81 12.59 reject Footwear –1007.15 29.69 16.81 12.59 reject Paper & products –2731.46 25.00 16.81 12.59 reject Industrial chemicals –1604.32 21.13 16.81 12.59 reject Rubber & plastic products –2238.63 50.15 16.81 12.59 reject Non-metallic mineral –3394.03 107.98 16.81 12.59 reject Basic & fabricated me tal –10757.17 94.99 16.81 12.59 reject Others –9754.55 86.46 16.81 12.59 reject No technical change, 0 H :0 ttLtKtt 0:0 tL tK H (df = 4) Total samp le –38319.59 1475.40 13.28 9.49 reject Food products & beverages –7700.38 312.45 13.28 9.49 reject Textile & wearing apparel –4871.20 220.51 13.28 9.49 reject Footwear –1038.66 92.71 13.28 9.49 reject Paper & products –2786.94 135.95 13.28 9.49 reject Industrial chemicals –1622.30 57.08 13.2 8 9.49 reject Rubber & plastic products –2339.36 51.61 13.28 9.49 reject Non-metallic mineral –3408.05 136.03 13.28 9.49 reject Basic & fabrica ted metal –10900.30 381.25 13.28 9.49 reject Others –9871.85 32.06 13.28 9.49 reject Neutral technical progress : 0:0 (df = 2) Total sample –37582.35 0.99 9.21 5.99 accept Food products & beverages –7551.48 14.65 9.21 5.99 reject Textile & wearing apparel –4765.83 9.77 9.21 5.99 reject Footwear –992.42 0.23 9.21 5.99 accept Paper & products –2719.95 1.98 9.21 5.99 accept Industrial chemicals –1595.48 3.44 9.21 5.99 accept Rubber & plastic products –2216.81 6.49 9.21 5.99 reject at 5% Non-metallic mineral –3340.88 1.68 9.21 5.99 accept Basic & fabricated metal –10709.84 0.33 9.21 5.99 accept Others –9712.29 1.93 9.21 5.99 accept No technical inefficiency, H (df = 3) Total sample –48321.28 21477.8 4 10.501 7 .045 reject Food products & beverages –9464.15 3839.99 10.501 7.045 reject Textile & wearing apparel –5977.24 2432.59 10.501 7.045 reject Footwear –1277.32 569.79 10.501 7.045 reject Paper & products –3658.84 1877.77 10.501 7.045 reject Industrial chemicals –2113.51 1036.06 10.501 7.045 reject Rubber & plastic products –3076.49 1725.86 10.501 7.045 reject Non-metallic mineral –4358.00 2035.93 10.501 7.045 reject  N. K. MINH ET AL. 229 Continued Basic & fabrica ted metal –13321.73 5223.78 10.501 7.045 reject Others –12002.09 4579.61 10.501 7.045 reject Half-normal distribution of technical inefficiency, 0:0H (df = 1) Total sampl e –37582.35 837.03 6.63 3.84 reject Food products & beverages –7544.15 96.11 6.63 3.84 reject Textile & wearing apparel –4760.95 169.35 6.63 3.84 reject Footwear –992.42 32.43 6.63 3.84 reject Paper & products –2719.95 91.22 6.63 3.84 reject Industrial chemicals –1595.48 12.31 6.63 3.84 reject Rubber & plastic products –2213.56 25.55 6.63 3.84 reject Non-metallic mineral –3340.88 162.24 6.63 3.84 reject Basic & fabrica ted metal –10709.84 191.64 6.63 3.84 reject Others –9712.29 229.34 6.63 3.84 reject Time invariant technical inefficiency, 0:0H (df = 1) Total samp le –37115.2 97.27 6.63 3.84 reject Food products & beverages –7496.09 12.46 6.63 3.84 reject Textile & wearing apparel –4676.28 32 6.63 3.84 reject Footwear –976.21 33.96 6.63 3.84 reject Paper & products –2674.30 32.97 6.63 3.84 reject Industrial chemicals –1589.31 0.16 6.63 3.84 accept Rubber & plastic products –2199.78 43.45 6.63 3.84 reject Non-metallic mineral –3258.92 4.01 6.63 3.84 reject at 5% Basic & fabricated metal –10614.02 21.32 6.63 3.84 reject Others –9597.62 8.81 6.63 3.84 reject The critical value for this test involving γ = 0 is obtained fr om Table 1 of Kodde and Palm (1986). sis. Then, the existence of neutral technical progress in the data set of these industries. In the case of food prod- ucts & beverages, textile & wearing apparel and rubber & plastic products, the hypothesis is rejected it implies that the existence of non-neutral technical progress in the data set of these industries. 4) Given the specification of stochastic frontier model, there is a particular interest in testing the hypothesis of the non-existence of sector-level inefficiency, expressed by 0:0H :0H The first null hypothesis is str- ongly rejected at the 1% significance level for all sam- ples, suggesting that the average production function is an inadequate representation of the aggregated models for all cases and will underestimate the actual frontier because of the manufacturing sector for all cases and will underestimate the actual frontier because of the existence of technical inefficiency effects. 5) The fifth null hypothesis, specifying that technical inefficiency effects have half-normal distribution 0 against truncated normal distribution, is rejected at the 1% significance level for the total sample and all sub-samples. 6) The last null hypothesis, that technical inefficiency is time-invariant :0H 0 is rejected for total sam- ple, food products and beverages, textile and wearing apparel, footwear, paper & products, rubber and plastic products, non-metallic mineral, basic & Fabricated metal products and Other manufacturing industries at least the 5% significance level. The industrial chemicals are only the case that cannot reject the hypothesis. 4.3. Estimation of Stochastic Production Functions Given the specifications of translog frontier with time- varying inefficiency effects the results of statistical tests of the estimated parameters, the preferred frontier models are chosen and the estimates of their parameters are given in Tables 3 and 4. To estimate production frontier for the total sample and aggregated samples, the maximum—likelihood es- timates of the parameters in the translog stochastic fron- tier production function, defined by Equations (4) and (5), are employed in this study. Moreover, since there may exist some uncontrollable Copyright © 2012 SciRes. OJS  N. K. MINH ET AL. 230 Table 3. Panel estimation of stochastic frontier production and technical inefficiency model. Total sample Food Textiles Footwear Paper Variable Coefficient Coefficient Coefficient Coefficient Coefficient Const t 2.928*** (0.076) 2.2214*** (0.171) 3.6363*** (0.250) 3.272*** (0.477) 4.1904*** (0.256) lnK 0.497*** (0.019) 0.659*** (0.042) 0.5172*** (0.059) 0.403*** (0.124) 0.3306*** (0.070) lnL 0.555*** (0.022) 0.4891*** (0.056) 0.3559*** (0.059) 0.526*** (0.117) 0.4411*** (0.091) T t 0.13*** (0.01) 0.0968*** (0.029) –0.017*** (0.038) 0.047 (0.062) 0.0816 (0.025)*** tlnK K 0.0092** (0.004) 0.0088** (0.004) tlnL tL –0.017*** (0.005) 0.0055 (0.004) lnKlnL L –0.01*** (0.004) 0.0099 (0.011) –0.0219** (0.009) –0.086*** (0.024) 0.0011 (0.021) lnK2 K 0.005*** (0.002) –0.0214** (0.005) 0.0008 (0.005) 0.033** (0.013) 0.0055 (0.008) lnL2 L 0.005 (0.003) 0.0154 (0.009) 0.0364*** (0.007) 0.066*** (0.016) 0.0226 (0.017) t2 tt –0.017*** (0.001) –0.0198*** (0.004) –0.0133*** (0.004) –0.015* (0.008) –0.0144*** (0.004) 2 0.71*** (0.014) 0.7608*** (0.034) 0.6756*** (0.037) 0.465*** (0.045) 0.4413*** (0.028) 0.676*** (0.006) 0.6524 (0.018)*** 0.6782 (0.012)*** 0.578 (0.042)*** 0.6434 (0.021)*** 1.254 (0.032) *** 1.155*** (0.086) 1.3537*** (0.061) 1.003*** (0.14) 1.0657*** (0.067) 0.027*** (0.003) 0.0254*** (0.007) 0.0426*** (0.008) 0.103*** (0.018) 0.0493*** (0.008) log-likelihood function –37111.57 –7489.87 –4660.92 –959.229 –2657.86 Source: Authors’ estimates from the data source; Note: 1) standard errors are given in the parenthesis; 2) */**/***Denotes statically significant at the 10, 5 and 1 per cent levels, respectively. stochastic shocks, such as changes of government poli- cies or other conditions affecting firms’ production effi- ciency, a stochastic frontier production approach is ap- plied. Concerning productivity, there are two indices to indicate whether firms in Vietnamese manufacturing industry have a high or low production efficiency: 2 represents total variance of output, containing a random error term v 2 and a technical inefficiency term 2 u . However large value of 2 does not necessary mean a less efficient way of production since it includes two types of production variation. The estimates of are positive (or at least zero) in the cases, except for the non-metallic mineral sub-indus- try. Almost coefficients of variables in all equations are statistically significant. A significant along with a positive and significant implies the existence of tech- nical inefficiency that declines over the years, except for the Industry Non-metallic Mineral. Table 5 presents the average technical efficiency (TE) for Vietnamese manufacturing industries for time period during 2003-2007. Estimates of TE vary considerably, both across manufacturing industries, and cross time pe- riods. The average TE is 0.309 for the total sample. The industrial chemical and rubber and plastics industries have the highest and second highest estimates, 0.417 and 3.91, respectively. and the textile & wearing apparel and non-metal mineral industries have the lowest and second lowest estimates, 0.267 and 0.290, respectively. The other industries have estimates the range from 0.300 to 0.342. The average TE for all industries improves throughout Copyright © 2012 SciRes. OJS  N. K. MINH ET AL. 231 Table 4. Panel estimation of stochastic frontier production and technical inefficiency model. Chemical Rubber Non-metal Basic-metal Others Variable coefficient Coefficient Coefficient Coefficient Coefficient Const t 1.6381*** (0.396) 3.3089*** (0.338) 2.079*** (0.22) 3.2191*** (0.152) 3.2944*** (0.152) lnK 0.6885*** (0.107) 0.5934*** (0.089) 0.352*** (0.058) 0.3717*** (0.039) 0.4251*** (0.040) lnL 0.7403*** (0.123) 0.2795 (0.104)** 0.982*** (0.077) 0.6142*** (0.047) 0.4482*** (0.045) t t 0.1212*** (0.037) 0.0796 (0.047)* 0.138*** (0.028) 0.1571*** (0.019) 0.1733*** (0.020) tlnK K 0.0111* (0.006) tlnL tL 0.0037 (0.008) lnKlnL L –0.0783*** (0.024) 0.0174 (0.020) –0.114 (0.012) 0.0026*** (0.010) 0.0252** (0.008) lnK2 K 0.0087 (0.01) –0.0104 (0.009) 0.041*** (0.005) 0.0084* (0.004) –0.0003 (0.004) lnL2 L 0.0648*** (0.020) 0.0073 (0.015) 0.063*** (0.012) –0.0103 (0.008) –0.0125* (0.007) t2 tt –0.0114* (0.006) –0.0283 (0.005)*** –0.012** (0.004) –0.0218*** (0.003) –0.0224*** (0.003) 2 0.8327*** (0.108) 0.6324*** (0.057) 0.654*** (0.049) 0.6342*** (0.023) 0.6758*** (0.026) 0.7665*** (0.031) 0.7142 (0.026) 0.72*** (0.012) 0.617*** (0.014) 0.6288*** (0.014) 0.8437*** (0.145) 0.8421*** (0.087) 1.372*** (0.06) 1.1383*** (0.063) 1.3038*** (0.053) 0 0.0682 (0.010) –0.004 (0.008) 0.028*** (0.006) 0.016** (0.006) log-likelihood function –1589.33 –2178.06 –3256.91 –10603.4 –959 3 .2 Source: Authors’ estimates from the data source; Note: 1) standard errors are given in the parenthesis; 2) */**/***Denotes statically significant at the 10, 5 and 1 per cent levels, respectively. Table 5. The average technical efficiency (TE) for Vietnamese manufacturing industries. Eff 2003 Eff 2004 Eff 2005 Eff 2006 Eff 2007 Average Total sample 0.293 0. 3 0 1 0.309 0.318 0.326 0.309 Food products & beverages 0.319 0.327 0.334 0.342 0.35 0.334 Textile & wearing apparel 0.242 0.254 0.267 0.279 0.292 0.267 Footwear 0.27 0.3 0.332 0.365 0.398 0.333 Paper & products 0.311 0.326 0.342 0.358 0.374 0.342 Industrial chemicals 0.417 0.417 0.417 0.417 0.417 0.417 Rubber & plastic products 0.349 0.37 0.391 0.412 0.433 0.391 Non-metallic mineral 0.293 0.292 0.29 0.289 0.288 0.290 Basic & fabricated metal 0.321 0.33 0.339 0.347 0.356 0.339 Others 0.291 0.296 0.301 0.306 0.31 0.301 S ource: Authors’ estimates from the data source. Copyright © 2012 SciRes. OJS  N. K. MINH ET AL. 232 the sample period, and this trend of steady improvement is also observed in the food, textiles, footwear, paper, rubber and plastics, basic-metal and other industries. The average TE unchanging through the years in chemical and non-metal industries. Table 6 presents return to scale (RTS) for Vietnamese manufacturing industries for time period during 2003- 2007. For the total sample, food products & beverages, textile & wearing apparel, footwear, paper & products, industrial chemicals, rubber & plastic products, non- metallic mineral, basic & fabricated metal and other sub- industries, the estimates of RTS are more than unity. RTSs are remaining more than unity. For textile & wear- ing apparel and rubber & plastic products, the estimates of RTS are 0.976 and 0.984 in 2003, respectively but continuously increases more than one during the sample period. Table 7 shows the means of estimated technical effi- Table 6. The average RTS for Vietnamese manufac turing industries. TRS 2003 RTS 2004 RTS 2005 RTS 2006 RTS 2007 Total sample 1.052 1.052 1.052 1.052 1.052 Food products & b e v erages 1.148 1.14 1.131 1.122 1.114 Textile & wearing apparel 0.976 0.993 1.008 1.023 1.033 Footwear 1.026 1.027 1.028 1.028 1.026 Paper & products 1.024 1.027 1.029 1.029 1.031 Industrial chemicals 1.131 1.127 1.125 1.123 1.116 Rubber & plastic products 0.984 1.001 1.016 1.031 1.045 Non-metallic mineral 1.15 1.148 1.148 1.146 1.146 Basic & fabricate d metal 1.065 1.066 1.067 1.067 1.069 Others 1.115 1.12 1.121 1.122 1.125 Source: Authors’ estimates from the data source. Table 7. Mean technical efficiency in Vietnamese manufacturing firms, 2003-2007, by ownership category. 2003 2004 2005 2006 2007 Obs Foreign 0.332 0.341 0.349 0.357 0.366 1325 Total sample Domestic 0.285 0.293 0.302 0.310 0.318 6732 Foreign 0.406 0.414 0.421 0.428 0.436 135 Food products & beverages Domestic 0.311 0.318 0.326 0.334 0.342 1401 Foreign 0.277 0.290 0.303 0.316 0.329 288 Textile & wearing apparel Domestic 0.228 0.240 0.252 0.265 0.278 726 Foreign 0.329 0.360 0.391 0.423 0.455 71 Footwear Domestic 0.243 0.274 0.306 0.339 0.372 158 Foreign 0.350 0.365 0.380 0.395 0.410 50 Paper & products Domestic 0.308 0.323 0.339 0.355 0.371 671 Foreign 0.535 0.535 0.535 0.535 0.535 82 Industrial chemicals Domestic 0.384 0.384 0.384 0.384 0.384 297 Foreign 0.359 0.379 0.400 0.420 0.441 111 Rubber & plastic products Domestic 0.347 0.367 0.388 0.409 0.430 425 Foreign 0.462 0.460 0.459 0.458 0.457 51 Non-metallic mineral Domestic 0.281 0.280 0.279 0.278 0.276 732 Foreign 0.354 0.362 0.371 0.380 0.389 481 Basic & fabricated metal Domestic 0.313 0.321 0.330 0.339 0.348 1810 Foreign 0.331 0.336 0.341 0.346 0.351 431 Others Domestic 0.280 0.285 0.290 0.295 0.300 1591 S ource: Authors’ estimates from the data source. Copyright © 2012 SciRes. OJS  N. K. MINH ET AL. 233 ciency for the foreign owned firms, domestically owned (including private sector firms and public sector firms for different years during the period, 2003 to 2007). It is evident from the comparison presented in Table 5 that the mean technical efficiency of foreign firms was higher than that of domestically owned firms each year of the period under study. For the five-year period, 2003 to 2007, on an average, technical efficiency of foreign firms in total sample and sub-samples were higher tech- nical efficiency than domestically owned firms. The av- erage technical efficiency levels of foreign firms for in- dustrial chemicals, non-metallic mineral, footwear over period 2003-2007 are 0.535, 0.457, 0.455 about, 39, 66 and 22.3 percent higher than that for domestic firms, re- spectively. The estimates of the average annual rate of change in efficiency for the manufacturing industries and some sub-manufactu ring ind ustries are prese nted in Table 8. We calculated these efficiency changes using Equation (2) (Titst ). The rate of growth in efficiency is an indicator of an industries’ perform- ance. echnical change The estimate of the average rate of growth in effi- ciency in Vietnamese manufacturing industries suggests that the level efficiency has increased over the whole period (except Non-metallic mineral industry). For ex- ample the sub-industry, with average rate of growth in efficiency about 8.2% (highest rate) is footwear, follow- ing by rubber & plastic products (about 6.3%) and textile & wearing apparel (about 5.4%). The annual technical progress change estimates for the manufacturing industry and submanufacturing industries are presented in Table 9. The technical progress change index between any two adjacent periods s and t were calculated directly from the estimated parameters of the translog stochastic frontier production function by taking a partial derivative of output with respect to time t. Then, we calculated technical change for each sub-industry, and given period by using Equation (3). Table 10 shows that average technical changes in manufacturing industry and sub-manufacturing industries are positive, with an average technical change about 5.2%, TE TE Table 8. Technical efficiency change in Vietnamese manufacturing firms, 2003-2007. TEC 2003-2004 2004-2005 2005-2006 2006-2007 2003-2007 Total sample 0.039 0.04 0.037 0.036 0.030 Food products & b e v erages 0.034 0.03 0.032 0.031 0.025 Textile & wearing apparel 0.071 0.07 0.065 0.062 0.054 Footwear 0.111 0.11 0.099 0.09 0.082 Paper & products 0.065 0.06 0.059 0.056 0.048 Industrial chemicals 0 0 0 0 0.000 Rubber & plastic products 0.087 0.08 0.076 0.07 0.063 Non-metallic mineral –0.006 –0.01 –0.006 –0.006 –0.006 Basic & fabricate d metal 0.036 0.04 0.034 0.033 0.029 Others 0.022 0.02 0.022 0.021 0.017 Source: Authors’ estimates from the data source. Table 9. Technical progress change in Vietnamese manufacturing firms, 2003-2007. TPC 2003-2004 2004-2005 2005-2006 2006-2007 2003-2007 Total sample 0.079 0.05 0.011 –0.023 0.023 Food products & b e v erages 0.071 0.05 0.032 0.012 0.033 Textile & wearing apparel 0.041 0.02 –0.011 –0.038 0.002 Footwear 0.047 0.05 0.047 0.047 0.038 Paper & products 0.04 0.01 –0.016 –0.044 –0.002 Industrial chemicals 0.087 0. 0 6 0.041 0.019 0.041 Rubber & plastic products 0.097 0.04 –0.015 –0.071 0.010 Non-metallic mineral 0.102 0.08 0.054 0.03 0.053 Basic & fabricate d metal 0.091 0.05 0.004 –0.039 0.021 Others 0.106 0.06 0.016 –0.029 0.031 Source: Authors’ estimates from the data source. Copyright © 2012 SciRes. OJS  N. K. MINH ET AL. 234 Table 10. TFP change in Vietnamese manufacturing firms, 2003-2007. TFP 2003-2004 2004-2005 2005-2006 2006-2007 2003-2007 Total sample 0.118 0.08 0.048 0.013 0.052 Food products & b e v erages 0.104 0.08 0.064 0.043 0.058 Textile & wearing apparel 0.112 0.08 0.054 0.025 0.054 Footwear 0.158 0.15 0.146 0.137 0.118 Paper & products 0.105 0.07 0.043 0.012 0.046 Industrial chemicals 0.087 0. 0 6 0.041 0.019 0.041 Rubber & plastic products 0.184 0.12 0.061 0 0.073 Non-metallic mineral 0.096 0.07 0.048 0.024 0.048 Basic & fabricate d metal 0.128 0.08 0.039 –0.006 0.048 Others 0.128 0.08 0.038 –0.007 0.048 Source: Authors’ estimates from the data source. 5.8%, 5.4%, 11.8%, 4.6%, 4.1%, 7.3%, 4.8%, 4.8% and 4.8% for total sample, food products & beverages, textile & wearing apparel, footwear, paper & products, indus- trial chemicals, rubber & plastic products, non-metallic mineral, basic & fabricated metal and other sub-indus- tries, respectively. 4.4. Total Factor Productivity Change The total factor productivity (TFP) growth is simply the sum of efficiency and technical change. These two changes constitute the TFP change index. The decompo- sition of TFP change into technical efficient change (TEC) and technical progress change (TPC) makes it possible to understand whether the manufacturing indus- try and sub-industries have improved their productivity levels simply through a more efficient use of existing technology or through technical progress. Table 8 shows the average annual TFP growth for manufacturing indus- try and for each sub-industry. As can be seen TFP growth rates of total sample, food products & beverages, textile & wearing apparel, foot- wear, industrial chemicals, rubber & plastic products, basic & fabricated metal and other sub-industries, have positive due to increase in both TEC and TPC during 2003-2007. While TFP growth rate of paper & products has positive due to technical change and TFP growth rate of non-metallic mineral has positive due to TPC. 5. Conclusions We applied a stochastic frontier production model to Vietnamese manufacturing industries, to decompose the sources of total productivity (TFP) growth into technical progress, changes in technical efficiency during 2003- 2007. In terms of efficiency estimations, the average an- nual technical change in Vietnamese industries is posi- tive and less than 1%, except non-metallic mineral (–0.006). The most important estimate though is that total factor productivity growth. This study estimates a rate of productivity growth of 5.2%. The estimated re- sults show that TFP grew fastest in the footwear sub- industry, with annual average growth rate of 11.8%, fol- lowed by the rubber & plastic products with a rate of 7.3%. The estimated results of our study show that although productivity growth was driven mainly by technical pro- gress, changes in technical efficiency had a positive ef- fect on productivity growth. REFERENCES [1] M. Nishimizu and J. M. Page, “Total Factor Productivity Growth, Technological Progress and Technical Efficiency Change: Dimensions of Productivity Change in Yugosla- via, 1965-1978,” Economic Journal, Vol. 92, No. 368, 1982, pp. 920-936. doi:10.2307/2232675 [2] P. W. Bauer, “Decomposing TFP Growth in the Presence of Cost Inefficiency, Nonconstant Returns to Scale, and Technological Progress,” Journal of Productivity Analy- sis, Vol. 1, No. 4, 1990, pp. 287-299. doi:10.1007/BF00160047 [3] S. Kim and G. Han, “A Decomposition of Total Factor Productivity Growth in Korean Manufacturing Industries: A Stochastic Frontier Approach,” Journal of Productivity Analysis, Vol. 16, No. 3, 2001, pp. 269-281. doi:10.1023/A:1012566812232 [4] H. Liao, M. Holmes, T. W. Jones and D. Llewellyn, “Productivity Growth of East Asia Economies’ Manufac- turing: A Decomposition Analysis,” Journal of Develop- ment Studies, Vol. 43, No. 4, 2007, pp. 649-674. doi:10.1080/00220380701259723 [5] N. K. Minh and G. T. Long, “Factor Productivity and Efficiency of the Vietnamese Economy in Transition,” Asia-Pacific Development Journal, Vol. 15, No. 1, 2008, pp. 93-117. [6] N. K. Minh, N. T. Minh and G. T. Long, “A Decomposi- Copyright © 2012 SciRes. OJS  N. K. MINH ET AL. 235 tion of Total Factor Productivity Growth in Vietnamese Manufacturing Industries: A Stochastic Frontier Ap- proach,” Proceedings of the DEA Symposium, Taiwan, 19-21 January 2010, pp. 164-168. [7] G. E. Battese and T. J. Coelli, “Frontier Production Func- tions, Technical Efficiency and Panel Data: With Appli- cation to Paddy Farmers in India,” Journal of Productiv- ity Analysis, Vol. 3, No. 1-2, 1992, pp. 153-169. doi:10.1007/BF00158774 Copyright © 2012 SciRes. OJS

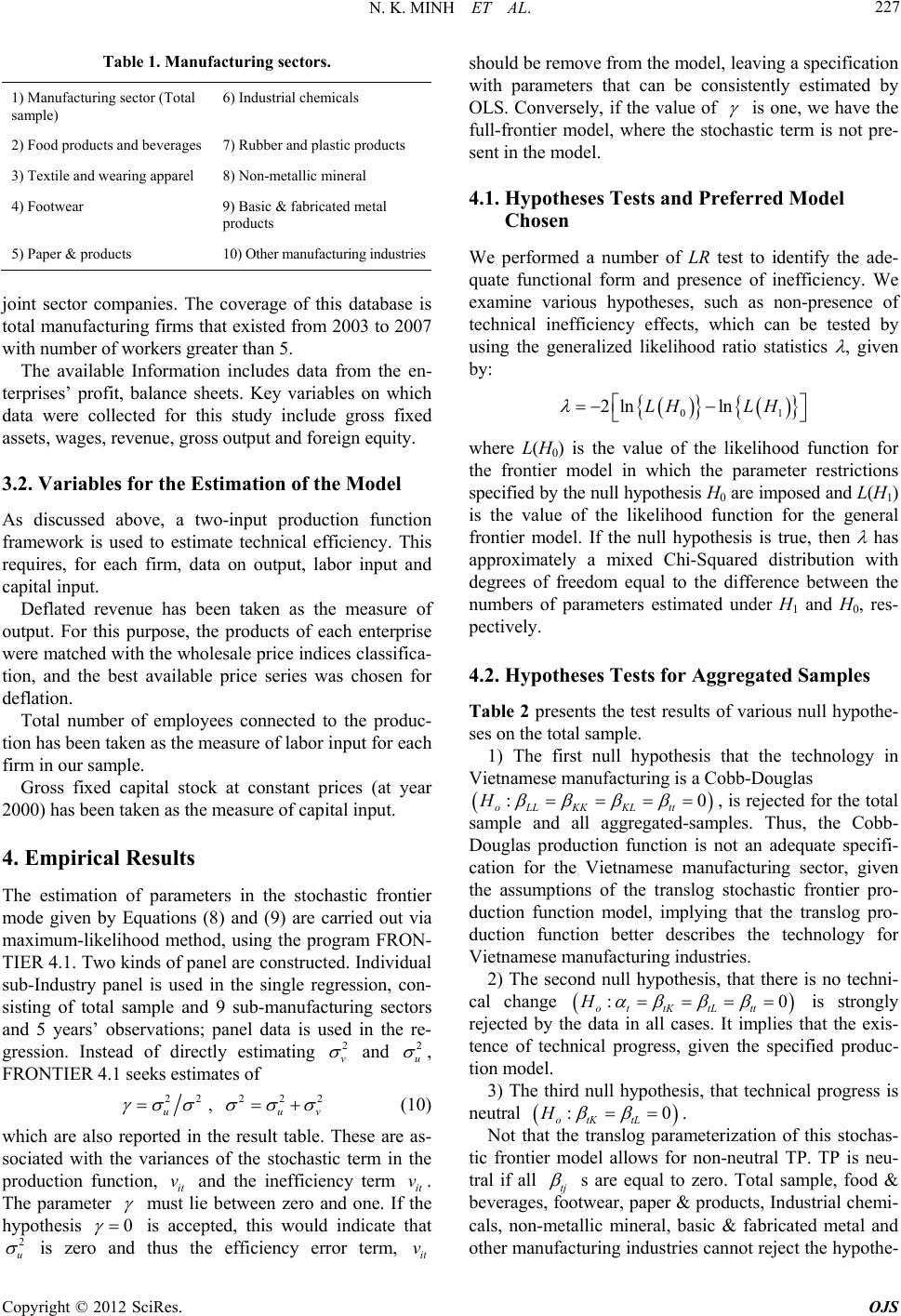

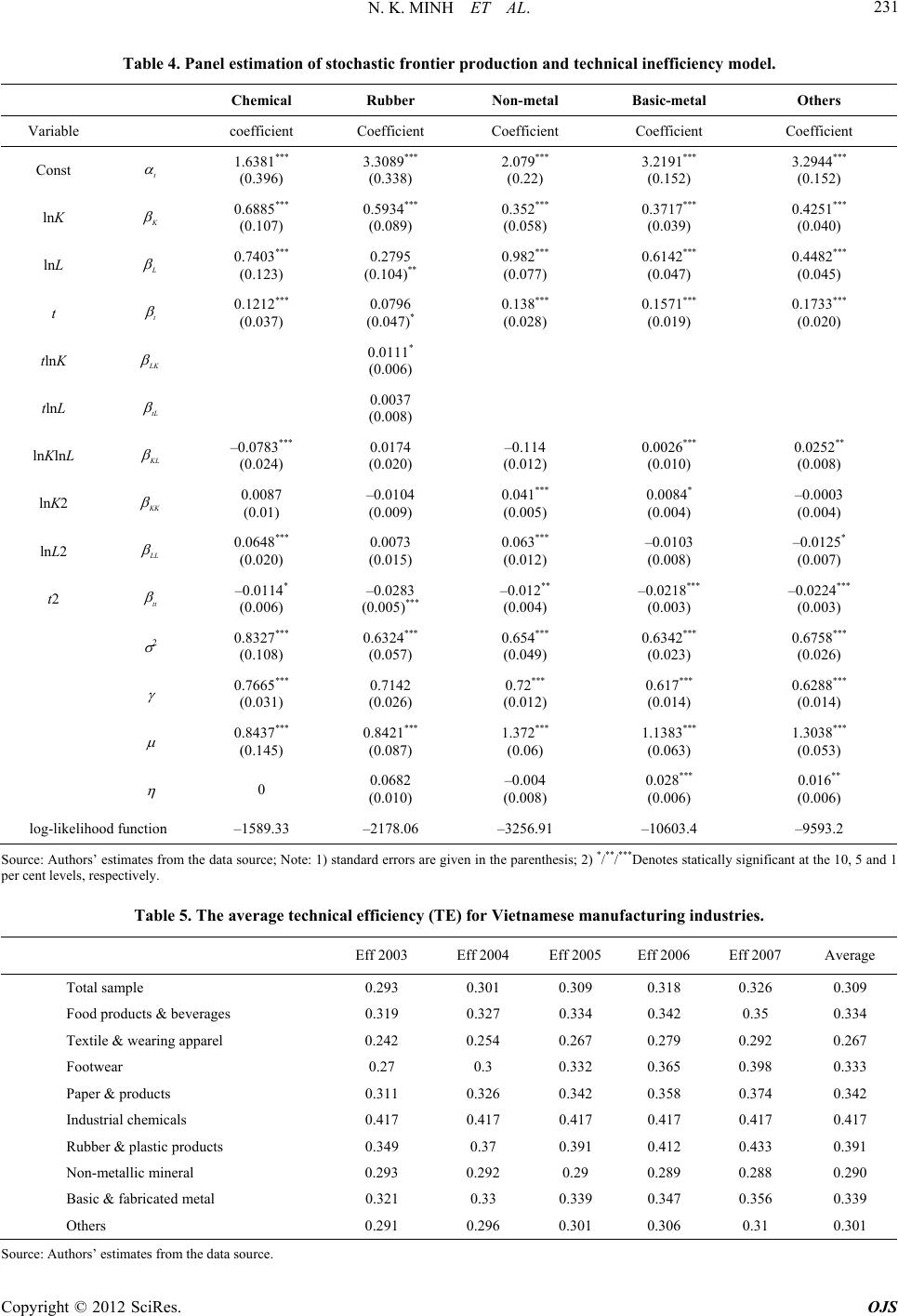

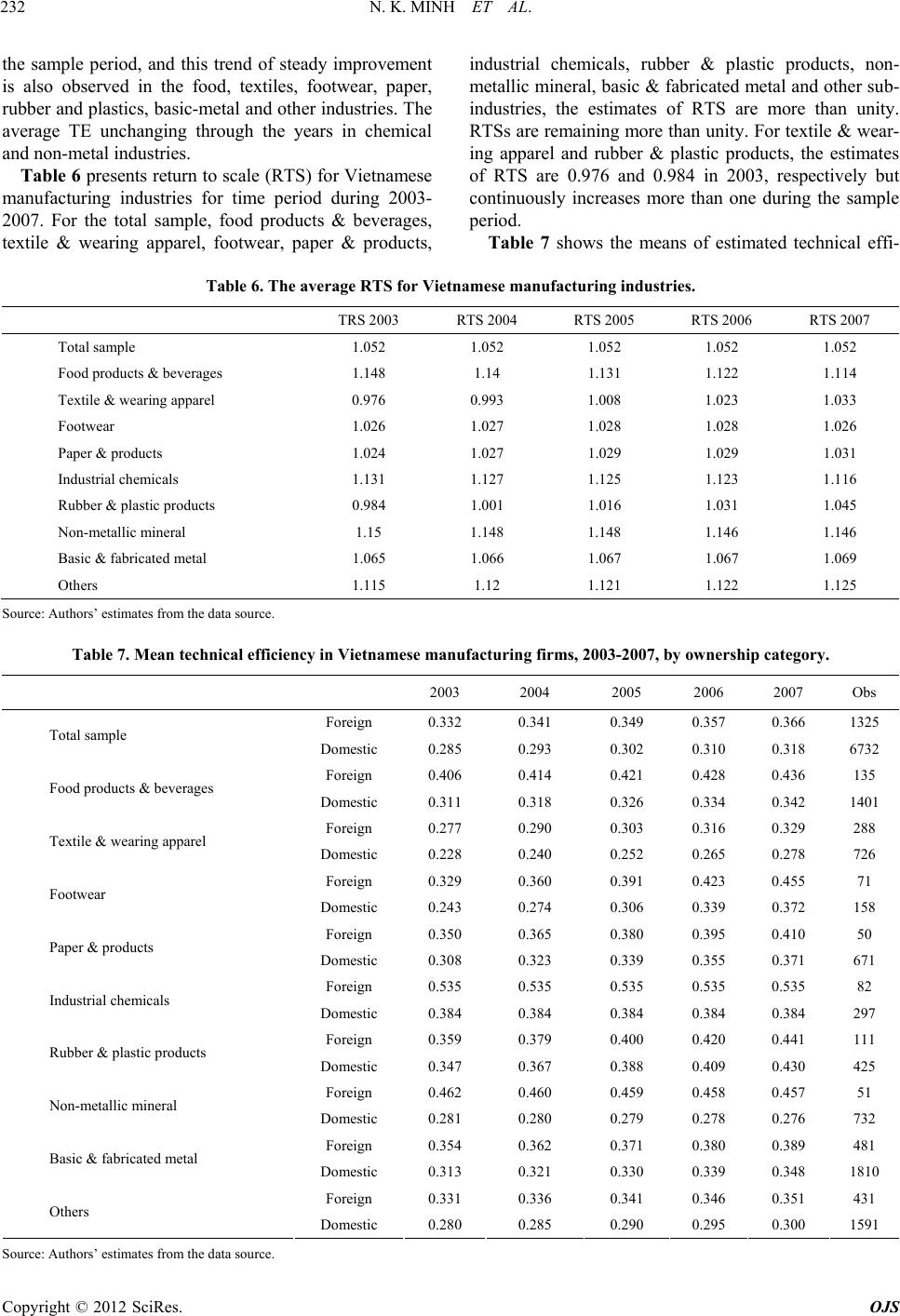

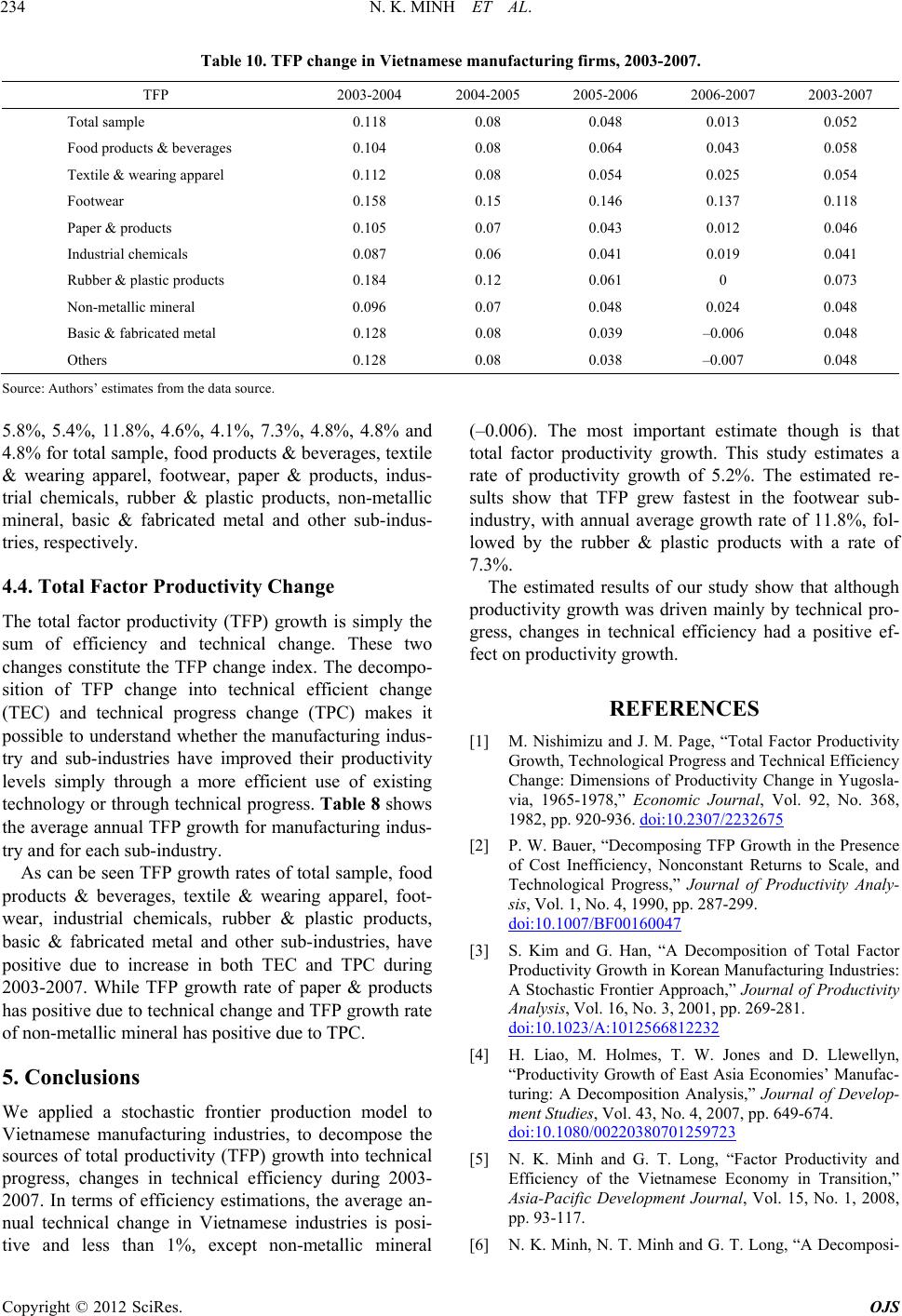

|