Paper Menu >>

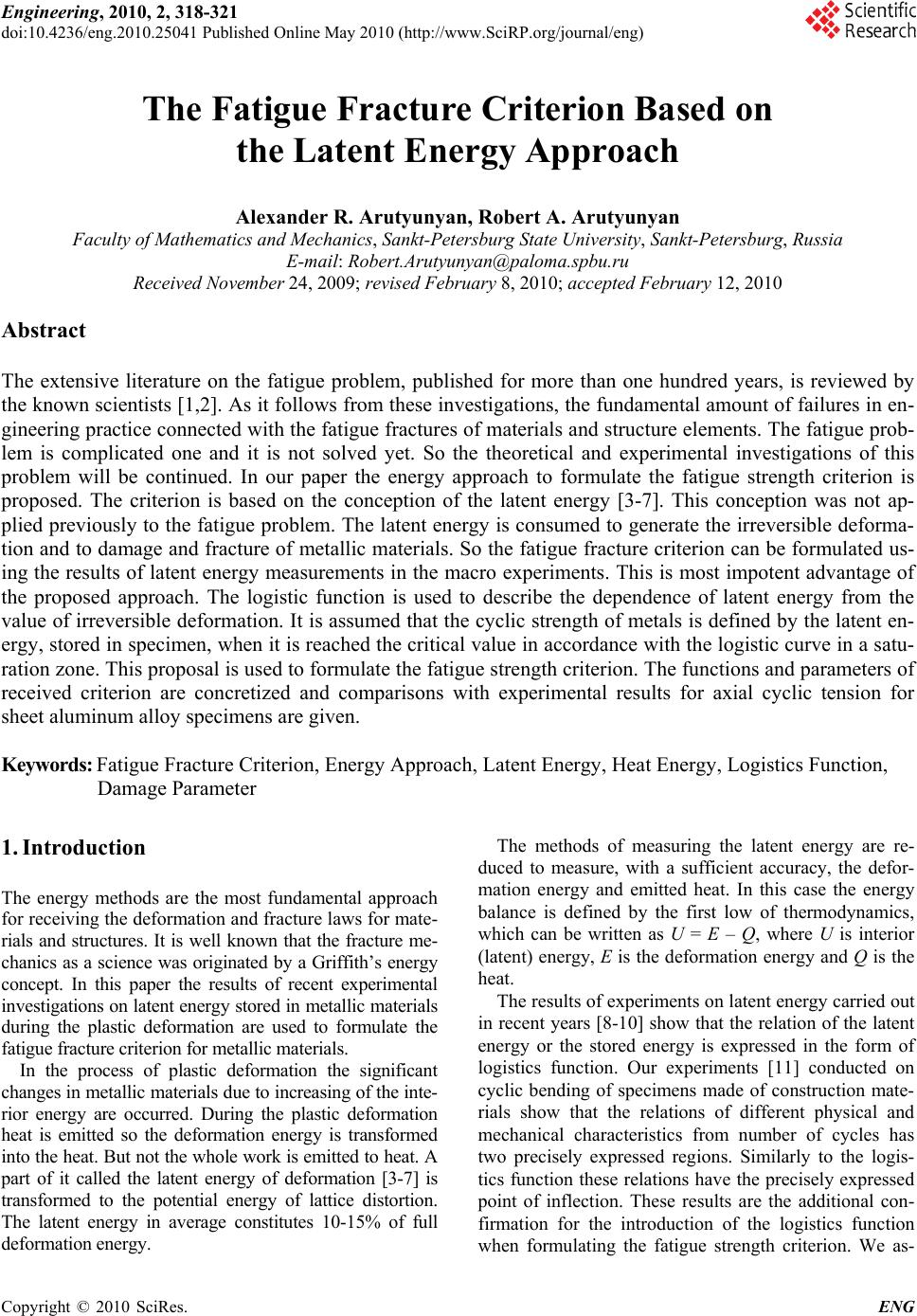

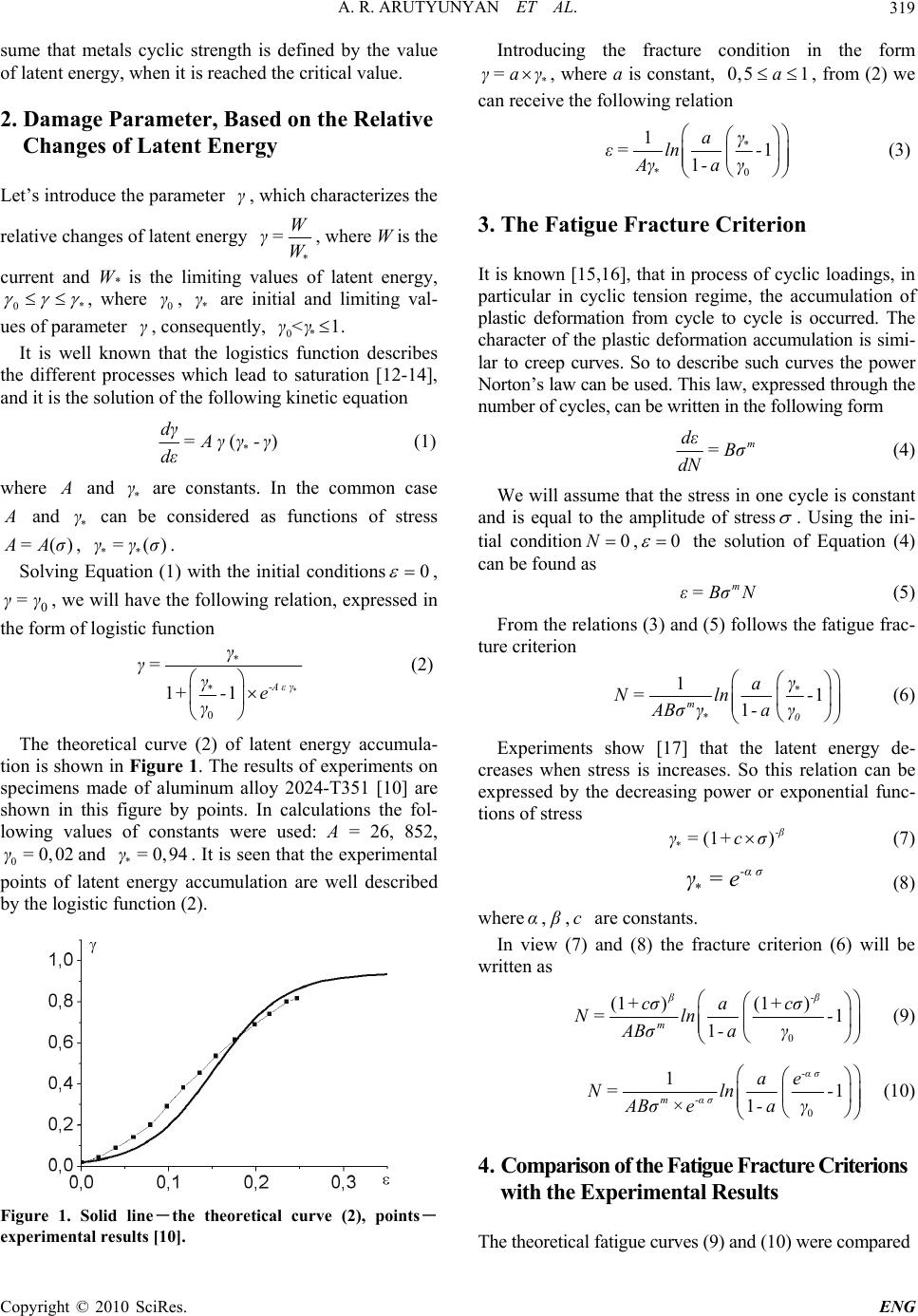

Journal Menu >>

Engineering, 2010, 2, 318-321 doi:10.4236/eng.2010.25041 Published Online May 2010 (http://www.SciRP.org/journal/eng) Copyright © 2010 SciRes. ENG The Fatigue Fracture Criterion Based on the Latent Energy Approach Alexander R. Arutyunyan, Robert A. Arutyunyan Faculty of Mathematics and Mechanics, Sankt-Petersburg State University, Sankt-Petersburg, Russia E-mail: Robert.Arutyunyan@paloma.spbu.ru Received November 24, 2009; revised February 8, 2010; accepted February 12, 2010 Abstract The extensive literature on the fatigue problem, published for more than one hundred years, is reviewed by the known scientists [1,2]. As it follows from these investigations, the fundamental amount of failures in en- gineering practice connected with the fatigue fractures of materials and structure elements. The fatigue prob- lem is complicated one and it is not solved yet. So the theoretical and experimental investigations of this problem will be continued. In our paper the energy approach to formulate the fatigue strength criterion is proposed. The criterion is based on the conception of the latent energy [3-7]. This conception was not ap- plied previously to the fatigue problem. The latent energy is consumed to generate the irreversible deforma- tion and to damage and fracture of metallic materials. So the fatigue fracture criterion can be formulated us- ing the results of latent energy measurements in the macro experiments. This is most impotent advantage of the proposed approach. The logistic function is used to describe the dependence of latent energy from the value of irreversible deformation. It is assumed that the cyclic strength of metals is defined by the latent en- ergy, stored in specimen, when it is reached the critical value in accordance with the logistic curve in a satu- ration zone. This proposal is used to formulate the fatigue strength criterion. The functions and parameters of received criterion are concretized and comparisons with experimental results for axial cyclic tension for sheet aluminum alloy specimens are given. Keywords: Fatigue Fracture Criterion, Energy Approach, Latent Energy, Heat Energy, Logistics Function, Damage Parameter 1. Introduction The energy methods are the most fundamental approach for receiving the deformation and fracture laws for mate- rials and structures. It is well known that the fracture me- chanics as a science was originated by a Griffith’s energy concept. In this paper the results of recent experimental investigations on latent energy stored in metallic materials during the plastic deformation are used to formulate the fatigue fracture criterion for metallic materials. In the process of plastic deformation the significant changes in metallic materials due to increasing of the inte- rior energy are occurred. During the plastic deformation heat is emitted so the deformation energy is transformed into the heat. But not the whole work is emitted to heat. A part of it called the latent energy of deformation [3-7] is transformed to the potential energy of lattice distortion. The latent energy in average constitutes 10-15% of full deformation energy. The methods of measuring the latent energy are re- duced to measure, with a sufficient accuracy, the defor- mation energy and emitted heat. In this case the energy balance is defined by the first low of thermodynamics, which can be written as U = E – Q, where U is interior (latent) energy, E is the deformation energy and Q is the heat. The results of experiments on latent energy carried out in recent years [8-10] show that the relation of the latent energy or the stored energy is expressed in the form of logistics function. Our experiments [11] conducted on cyclic bending of specimens made of construction mate- rials show that the relations of different physical and mechanical characteristics from number of cycles has two precisely expressed regions. Similarly to the logis- tics function these relations have the precisely expressed point of inflection. These results are the additional con- firmation for the introduction of the logistics function when formulating the fatigue strength criterion. We as-  A. R. ARUTYUNYAN ET AL.319 sume that metals cyclic strength is defined by the value of latent energy, when it is reached the critical value. 2. Damage Parameter, Based on the Relative Changes of Latent Energy Let’s introduce the parameter , which characterizes the relative changes of latent energy γ * W γ=W, where W is the current and W* is the limiting values of latent energy, 0* , where , are initial and limiting val- ues of parameter , consequently, . 0 γ* γ γ01 * γ<γ It is well known that the logistics function describes the different processes which lead to saturation [12-14], and it is the solution of the following kinetic equation ( * dγ=Aγγ-γ dε) (1) where A and are constants. In the common case * γ A and can be considered as functions of stress , . * γ ()σA= A()γγσ ** = Solving Equation (1) with the initial conditions0 , , we will have the following relation, expressed in the form of logistic function 0 γ=γ 0 11* * -A εγ * γ γ=γ +-e γ (2) The theoretical curve (2) of latent energy accumula- tion is shown in Figure 1. The results of experiments on specimens made of aluminum alloy 2024-T351 [10] are shown in this figure by points. In calculations the fol- lowing values of constants were used: A = 26, 852, and . It is seen that the experimental points of latent energy accumulation are well described by the logistic function (2). 00,02γ=0,94 * γ= Figure 1. Solid line-the theoretical curve (2), points- experimental results [10]. Introducing the fracture condition in the form * γ=a γ , where a is constant, , from (2) we can receive the following relation 0,5 1a 0 11 1 * * γ a ε=ln - Aγ-aγ (3) 3. The Fatigue Fracture Criterion It is known [15,16], that in process of cyclic loadings, in particular in cyclic tension regime, the accumulation of plastic deformation from cycle to cycle is occurred. The character of the plastic deformation accumulation is simi- lar to creep curves. So to describe such curves the power Norton’s law can be used. This law, expressed through the number of cycles, can be written in the following form m dε=Bσ dN (4) We will assume that the stress in one cycle is constant and is equal to the amplitude of stress . Using the ini- tial condition0N ,0 the solution of Equation (4) can be found as m ε=BσN (5) From the relations (3) and (5) follows the fatigue frac- ture criterion 11 1 * m 0* γ a N= ln- -a γABσγ (6) Experiments show [17] that the latent energy de- creases when stress is increases. So this relation can be expressed by the decreasing power or exponential func- tions of stress (1 )-β * γ=+cσ (7) -ασ * γ=e (8) where , α β , are constants. c In view (7) and (8) the fracture criterion (6) will be written as 0 (1)(1) 1 1 β-β m +cσa+cσ N= ln- -a γABσ (9) 0 11 1 -ασ m-ασ ae N=ln- -a γABσ×e (10) 4. Comparison of the Fatigue Fracture Criterions with the Experimental Results The theoretical fatigue curves (9) and (10) were compared Copyright © 2010 SciRes. ENG  A. R. ARUTYUNYAN ET AL. Copyright © 2010 SciRes. ENG 320 Figure 2. The theoretical fatigue curves (9)-solid line and (10)-dash line. Cross points-experimental results [15]. with the experimental results received in axial cyclic tensile tests on sheet specimens made of aluminum alloy 2024-T3 [15]. The mechanical properties of this alloy are more similar to the consequent properties of aluminum alloy used in paper [10]. The theoretical fatigue curves (9) and (10) are shown in Figure 2 by solid and dash lines consequently. The following values of constants were accepted: 26,852A 0,9a , , , , 4m -1 -15 -4 3 10MPacyclesB -3 -1 10MPa =7,5α, -1 MPac 0,61β= , . The experimental results are marked by cross points. It is seen that these curves are well describe the experi- mental points on the whole range of fatigue curves. 5. Conclusions The damage parameter defined as the relative changes of latent energy is introduced. It is shown, that this parame- ter is governed by the differential equation with the solu- tion in the form of the logistics function, capable to de- scribe different processes leading to saturation. The functions and parameters of received criterion are concretized and comparisons with the experimental re- sults for axial cyclic tension for sheet aluminum alloy specimens are given. A good agreement of theoretical and experimental results is received. 6. Acknowledgements Financial support of the Russian Foundation for Basic Research (Grant N 09-01-00513) is gratefully acknowl- edged. 7 . References [1] S. S. Manson, “Fatigue: A Complex Subject-Some Sim- ple Approximations,” Experience Mechanics, Vol. 7, 1965, pp. 193-225. [2] J. Schijve, “Fatigue of Structures and Materials in the 20th Century and the State of the Art,” International Journal of Fatigue, Vol. 25, 2003, pp. 679-702. [3] G. I. Taylor and W.S. Farren, “The Heat Developed dur- ing Plastic Extension of Metals,” Proceedings of the Royal Society A, London, Vol. 107, 1925, pp. 422-451. [4] G. I. Taylor and H. Qunnney, “The Latent Energy Re- maining in a Metal after Cold Working,” Proceedings of the Royal Society A, London, Vol. 143, 1934, pp. 307-326. [5] M. A. Bolshanina and V. E. Panin, “The Latent Energy of Deformation,” Issledovanie po fizike tverdogo tela, Academy of Science of USSR, Moscow, 1957, pp. 193-234. [6] O. W. Dillon, “The Heat Generated during Torsional Oscillations of Copper Tubes,” International Journal of Solids and Structures, Vol. 2, 1966, pp. 181-204. [7] M. B. Bever, D. L. Holt and A. L. Titchener, “The Stored Energy of Cold Work,” Progress in Materials Science, Vol. 17, 1973, pp. 5-177. [8] W. Oliferuk, M. Maj and B. Raniecki, “Experimental Analysis of Energy Storage Rate Components during Tensile Deformation of Polycrystals,” Materials Science and Engineering A, Vol. 374, 2004, pp. 77-81. [9] O. Plechov, N. Saintier and O. Naimark, “Experimental Investigation of the Processes of Energy Storage and Dis- sipation in Iron during the Elastic Plastic Deformation,”  A. R. ARUTYUNYAN ET AL.321 Journal of Technical Physics, Vol. 9, 2007, pp. 135-137. [10] P. Rosakis, A. J. Rosakis, G. Ravichandran and J. Hodowany, “A Thermodynamic Internal Variable Model for the Partition of Plastic Work into Heat and Stored Energy in Metals,” Journal of the Mechanics and Physics of Solids, Vol. 48, 2000, pp. 581-607. [11] A. R. Arutyunyan, B. A. Zimin, Y. V. Sud’enkov, “The Application of Optics-Spectroscopy Method to Investi- gate Fatigue of Construction Materials,” Proceedings of International Conference on Topical Problems of Con- tinuum Mechanics, Erevan, 2007, pp. 63-68. [12] V. I. Arnold, “Ordinary Differential Equations,” Nauka, Moscow, 1971. [13] R. A. Arutyunyan, “The Problem of Deformation Aging and Prolonged Fracture in Material Science,” S.-Petersburg University Press, Sankt-Petersburg, 2004. [14] A. N. Orlov, “The Long-Time Strength and Physics of Fracture,” Trudy TsKTI, Vol. 230, 1986, pp. 42-46. [15] P. G. Forrest, “Fatigue of Metals,” Mashinostroenie, Moscow, 1968. [16] V. T. Troschenko, “Fatigue and Nonelasticityof Metals,” Naukova Dumka, Kiev, 1971. [17] O. Plechov, O. Naimark, R. Valiev, I. Semenova, N. Saintier and T. Palin-Luc, “Experimental Investigation of Anomalous Energy Absorption in Nanocrystal Titan Un- der the Cyclic Loading,” Letters in Journal of Technical physics, Vol. 34, No. 13, 2008, pp. 33-40. Copyright © 2010 SciRes. ENG |