Y. OTSUKA ET AL. 23

s s

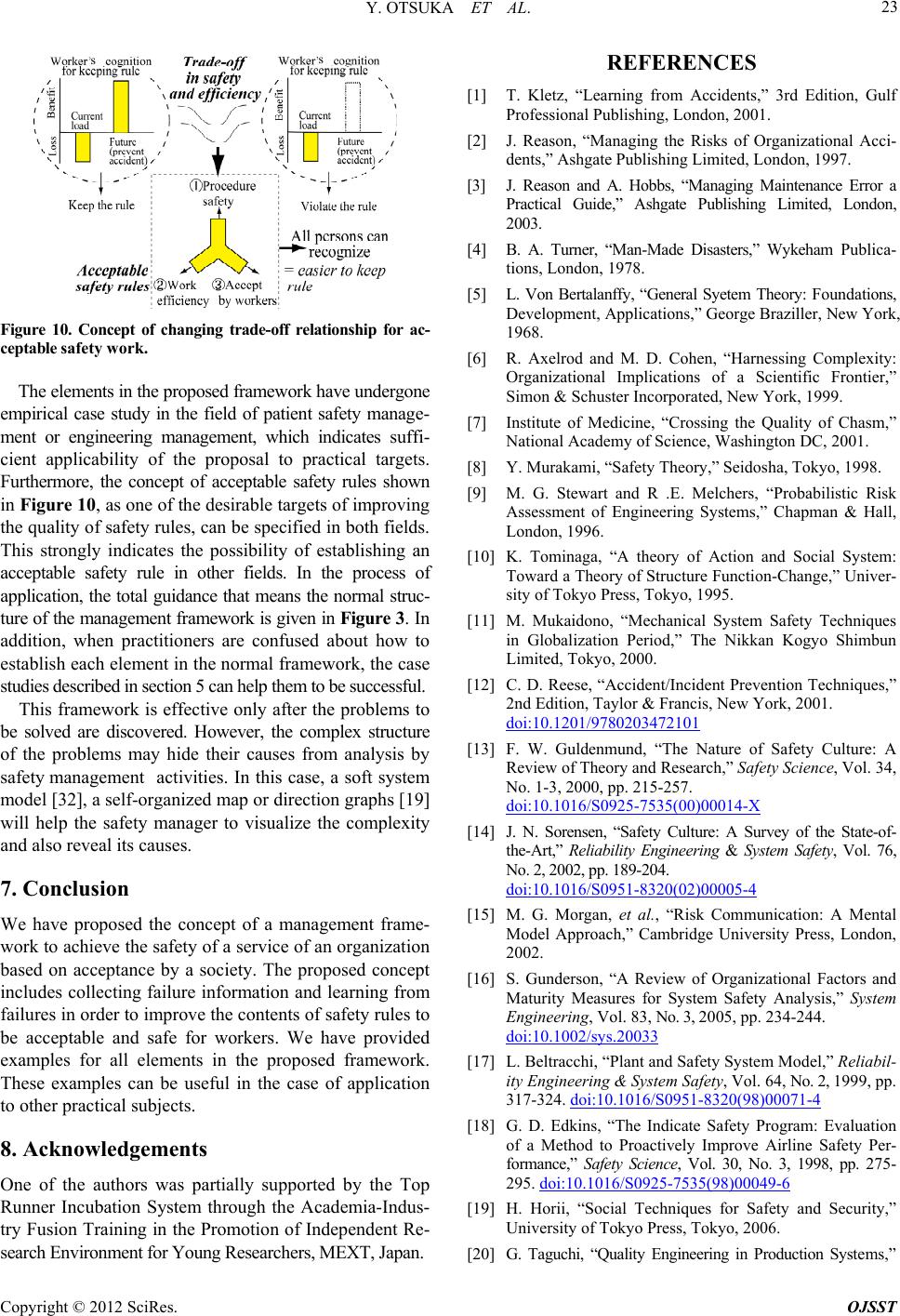

Figure 10. Concept of changing trade-off relationship for ac-

ceptable safety work.

The elements in the proposed framework have undergone

empirical case study in the field of patient safety manage-

ment or engineering management, which indicates s

cient applicability of the proposal to practical tar ets.

ules, can be specified in both fiel

Th

he contents of safety ru

fe for workers. We have provide

lements in the proposed framework.

[1] T. Kletz, “Lm Accidents,” 3rd Edition, Gulf

Professional Publishing, London, 2001.

[2] J. Reason, “MAcci-

dents,” Ashgate Publishing Limited, London, 1997.

na

Practical Guimited, London,

de Disasters,” Wykeham Publica-

l Syetem Theory: Foundations,

uffi- [7] Institute of Medicine, “Crossing the Quality of Chasm,”

National Academy of Science, Washington DC, 2001.

g

hown Furthermore, the concept of acceptable safety rules s

in Figure 10, as one of the desirable targets of improving

the quality of safety rds. Assessment of Engineering Systems,” Chapman & Hall,

London, 1996.

[10] K. Tominaga, “A theory of Action and Social System:

is strongly indicates the possibility of establishing an

acceptable safety rule in other fields. In the process of

application, the total guidance that means the normal struc-

ture of the management framework is given in Figure 3. In

addition, when practitioners are confused about how to

establish each element in the normal framework, the case

studies described in section 5 can help them to be successful.

This framework is effective only after the problems to

be solved are discovered. However, the complex structure

of the problems may hide their causes from analysis by

safety management activities. In this case, a soft system

model [32], a self-organized map or direction graphs [19]

will help the safety manager to visualize the complexity

and also reveal its causes.

7. Conclusion

We have proposed the concept of a management frame-

work to achieve the safety of a service of an organization

based on acceptance by a society. The proposed concept

includes collecting failure information and learning from

failures in order to improve tles to

d

be acceptable and sa

examples for all e

These examples can be useful in the case of application

to other practical subjects.

8. Acknowledgements

One of the authors was partially supported by the Top

Runner Incubation System through the Academia-Indus-

try Fusion Training in the Promotion of Independent Re-

search Environment for Young Researchers, MEXT, Japan.

2003.

[4] B. A. Turner, “Man-Ma

REFERENCES

earning fro

anaging the Risks of Organizational

[3] J. Reason ad A. Hobbs, “Managing Maintenance Error

de,” Ashgate Publishing Li

tions, London, 1978.

[5] L. Von Bertalanffy, “Genera

Development, Applications,” George Braziller, New York,

1968.

[6] R. Axelrod and M. D. Cohen, “Harnessing Complexity:

Organizational Implications of a Scientific Frontier,”

Simon & Schuork, 1999. ster Incorporated, New Y

[8] Y. Murakami, “Safety Theory,” Seidosha, Tokyo, 1998.

[9] M. G. Stewart and R .E. Melchers, “Probabilistic Risk

Toward a Theory of Structure Function-Change,” Univer-

sity of Tokyo Press, Tokyo, 1995.

[11] M. Mukaidono, “Mechanical System Safety Techniques

in Globalization Period,” The Nikkan Kogyo Shimbun

Limited, Tokyo, 2000.

[12] C. D. Reese, “Accident/Incident Prevention Techniques,”

2nd Edition, Taylor & Francis, New York, 2001.

doi:10.1201/9780203472101

[13] F. W. Guldenmund, “The Nature of Safety Culture: A

Review of Theory and Research,” Safety Science, Vol. 34,

No. 1-3, 2000, pp. 215-257.

doi:10.1016/S0925-7535(00)00014-X

[14] J. N. Sorensen, “Safety Culture: A Survey of the State-of-

the-Art,” Reliability Engineering & System Safety, Vol. 76,

No. 2, 2002, pp. 189-204.

doi:10.1016/S0951-8320(02)00005-4

[15] M. G. Morgan, et al., “Risk Communication: A Mental

Model Approach,” Cambridge University Press, London,

System Safety Analysis,” System

2002.

[16] S. Gunderson, “A Review of Organizational Factors and

Maturity Measures for

Engineering, Vol. 83, No. 3, 2005, pp. 234-244.

doi:10.1002/sys.20033

[17] L. Beltracchi, “Plant and Safety System Model,” Reliabil-

ity Engineering & System Safety, Vol. 64, No. 2, 1999, pp.

317-324. doi:10.1016/S0951-8320(98)00071-4

[18] G. D. Edkins, “The Indicate S

of a Method to Proactively Improve A

afety Program: Evaluation

irline Safety Per-

formance,” Safety Science, Vol. 30, No. 3, 1998, pp. 275-

295. doi:10.1016/S0925-7535(98)00049-6

[19] H. Horii, “Social Techniques

University of Tokyo Press, Tokyo, 200

for Safety and Security,”

6.

[20] G. Taguchi, “Quality Engineering in Production Systems,”

Copyright © 2012 SciRes. OJSST