Paper Menu >>

Journal Menu >>

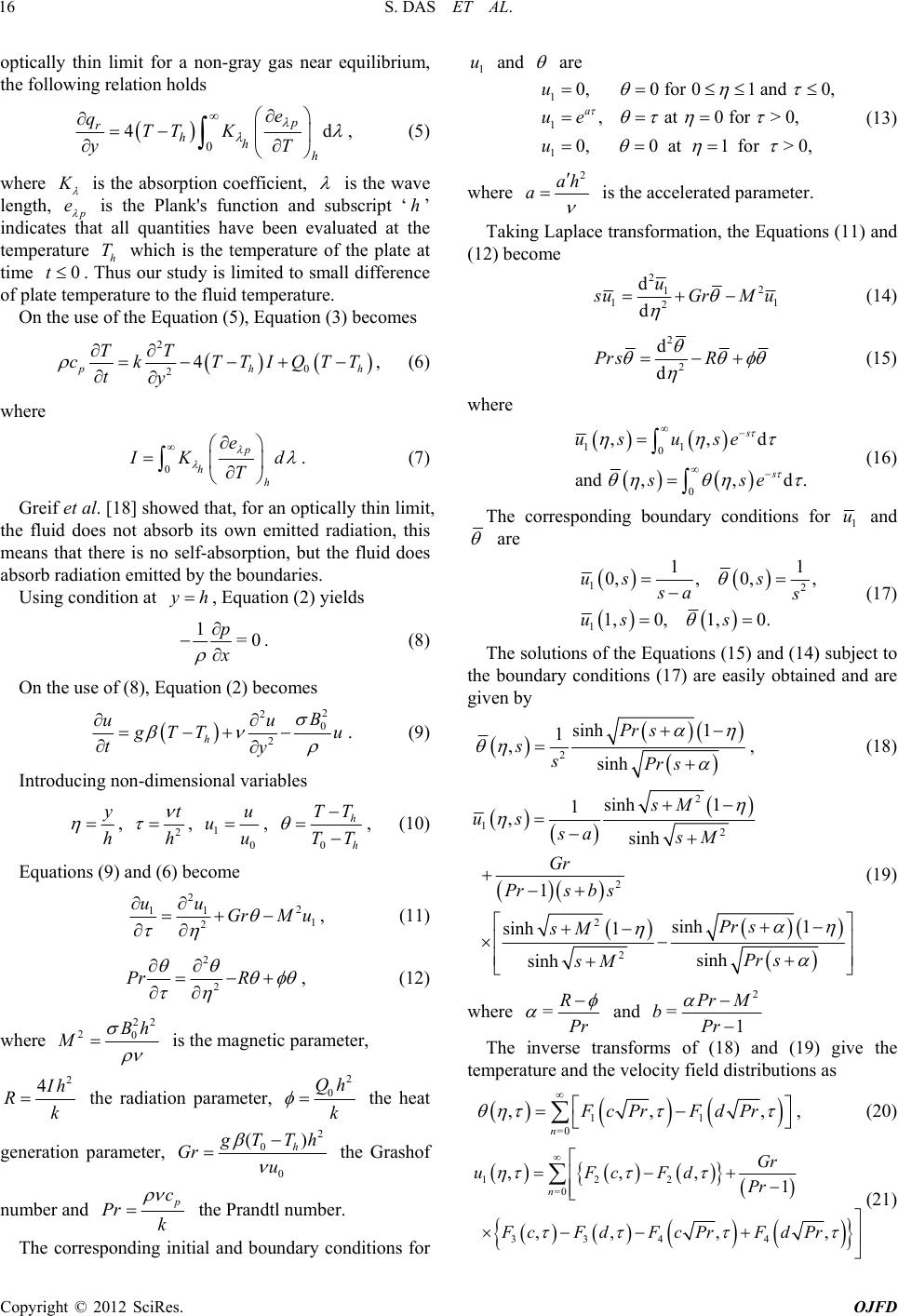

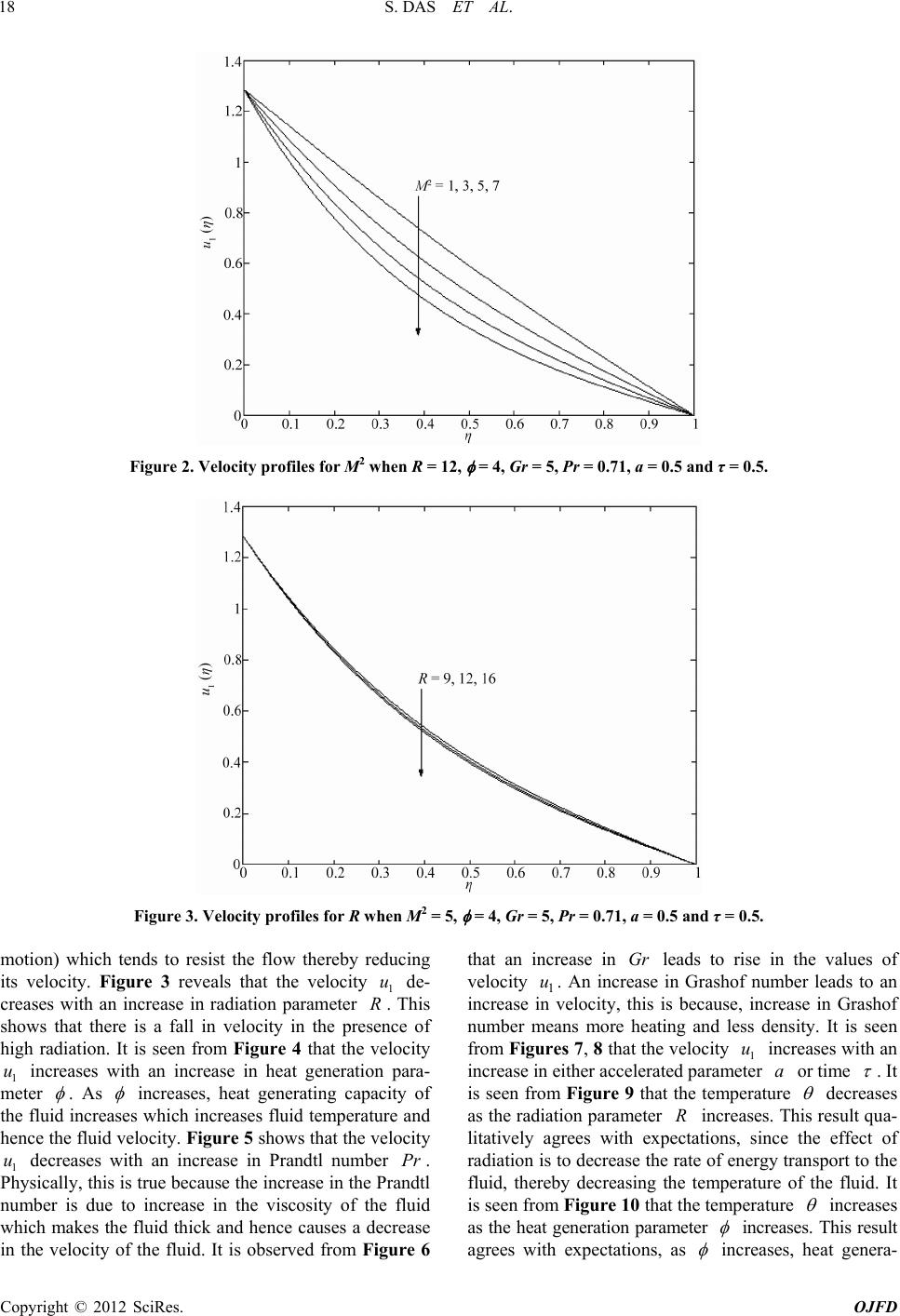

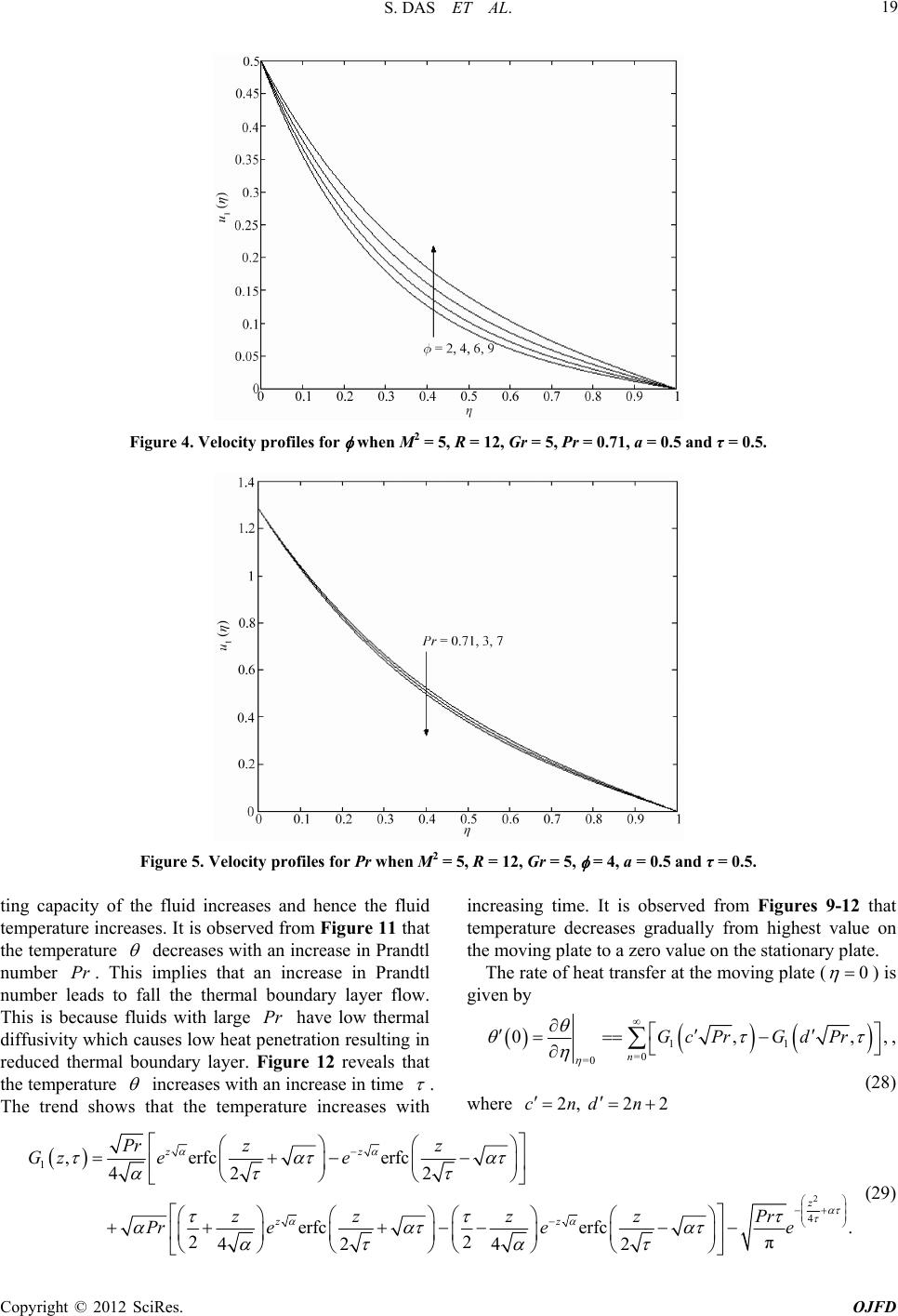

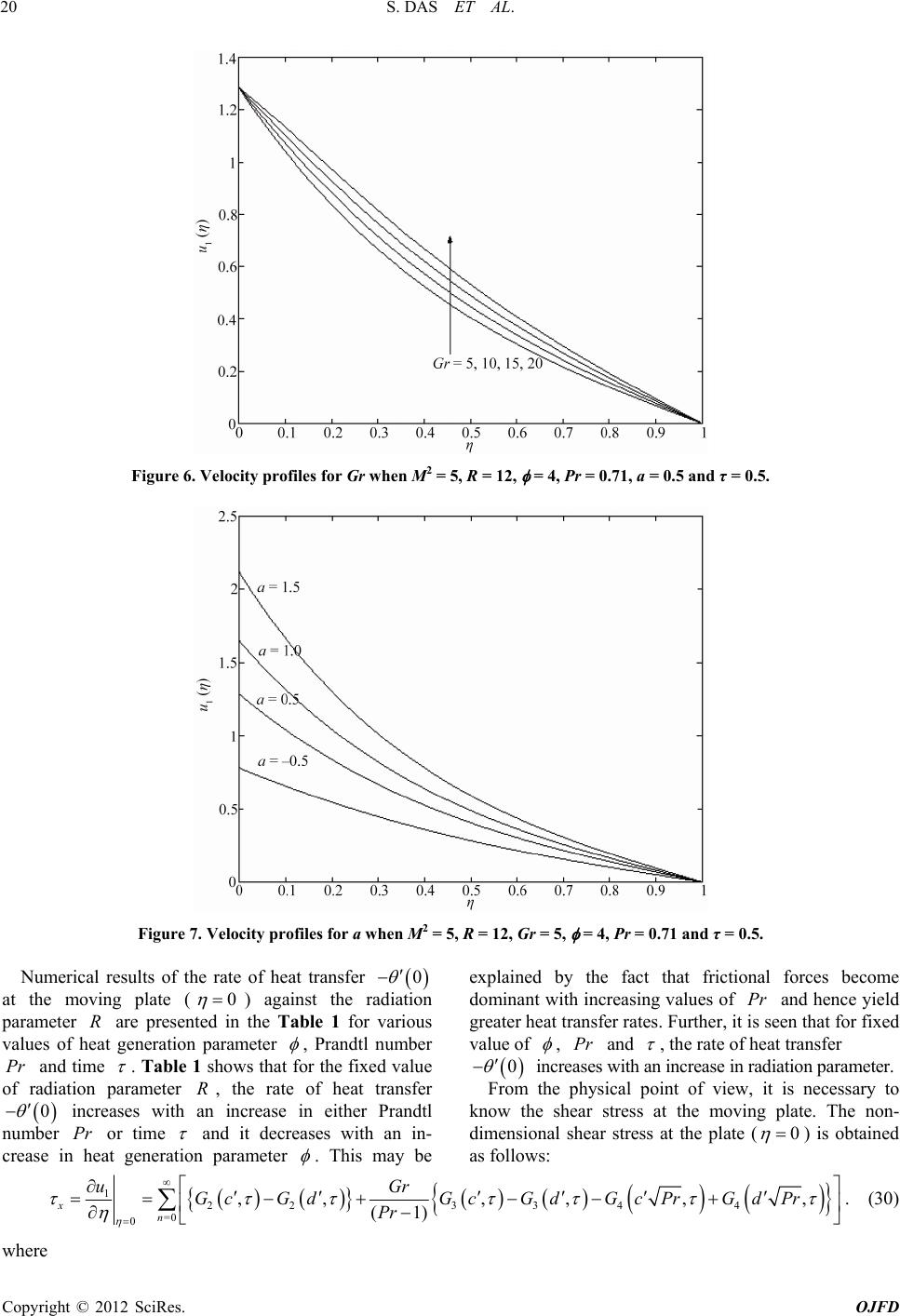

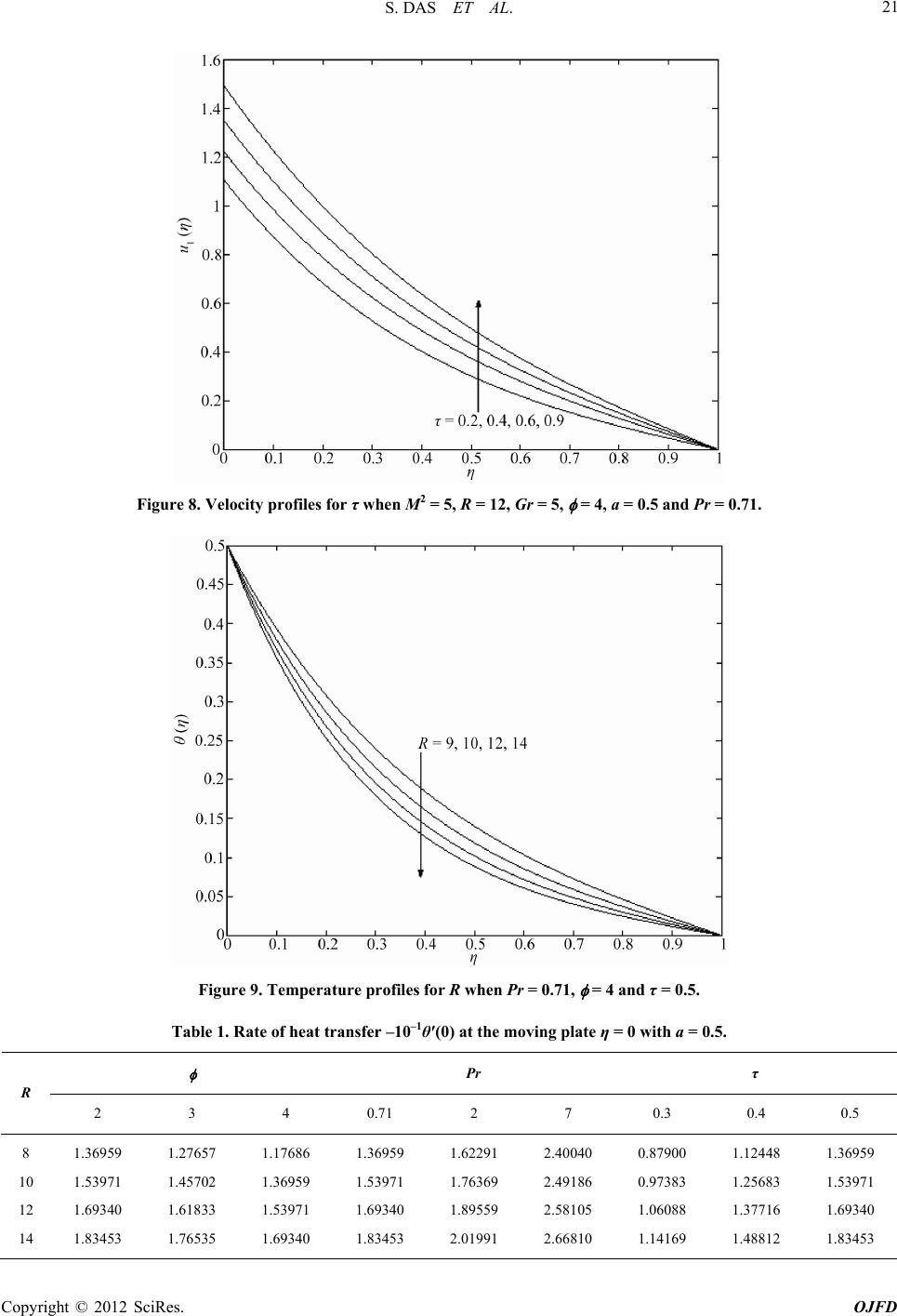

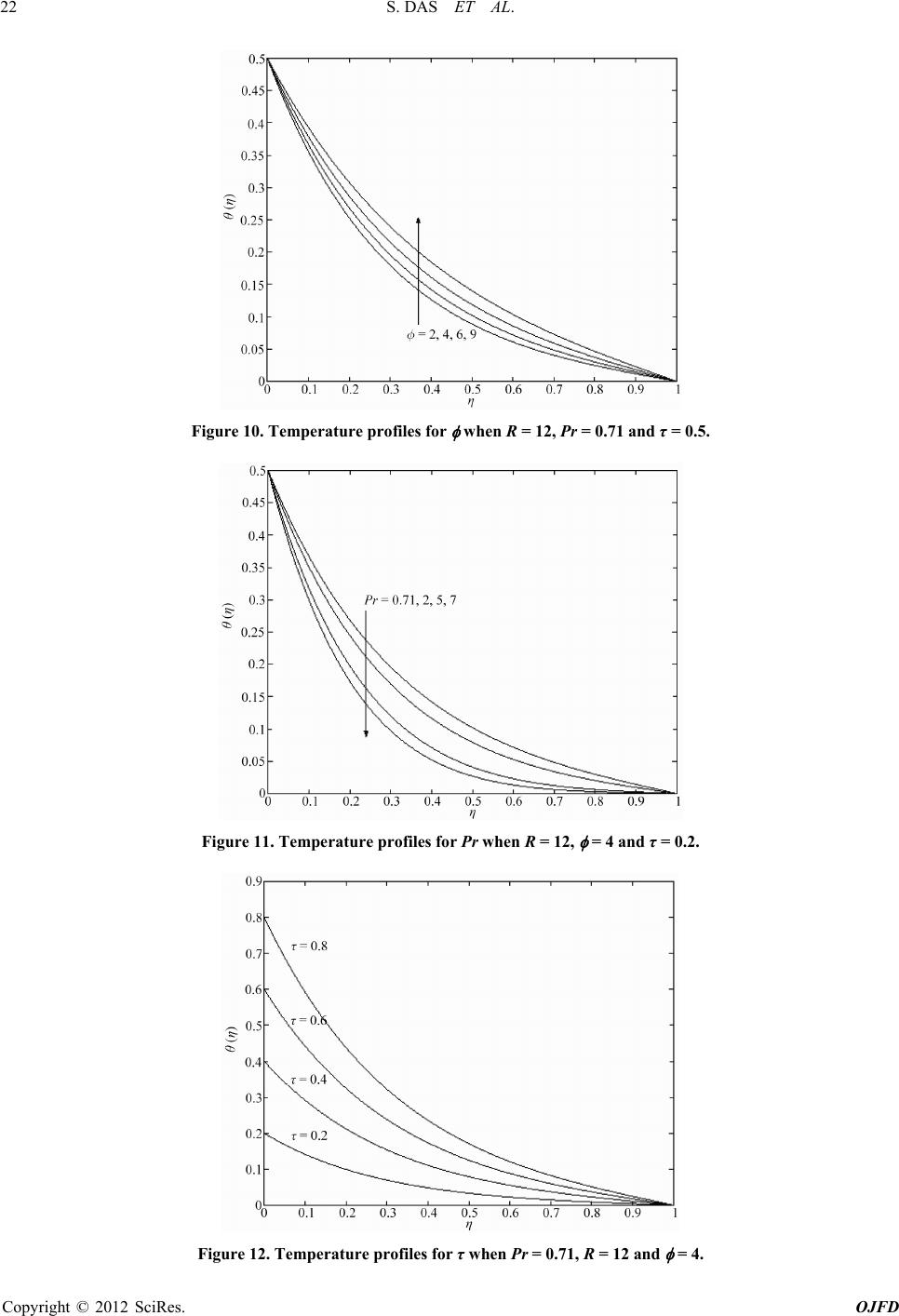

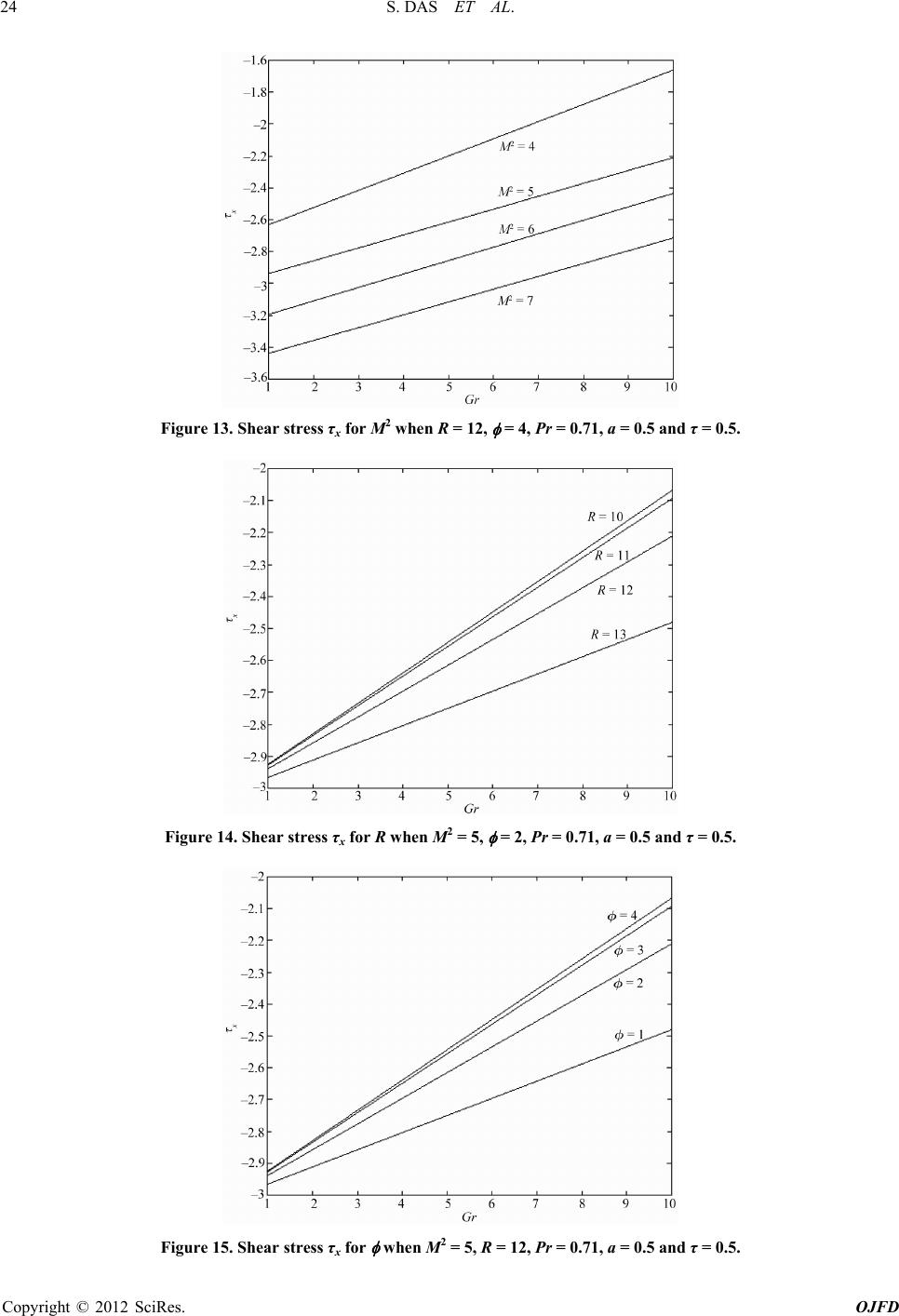

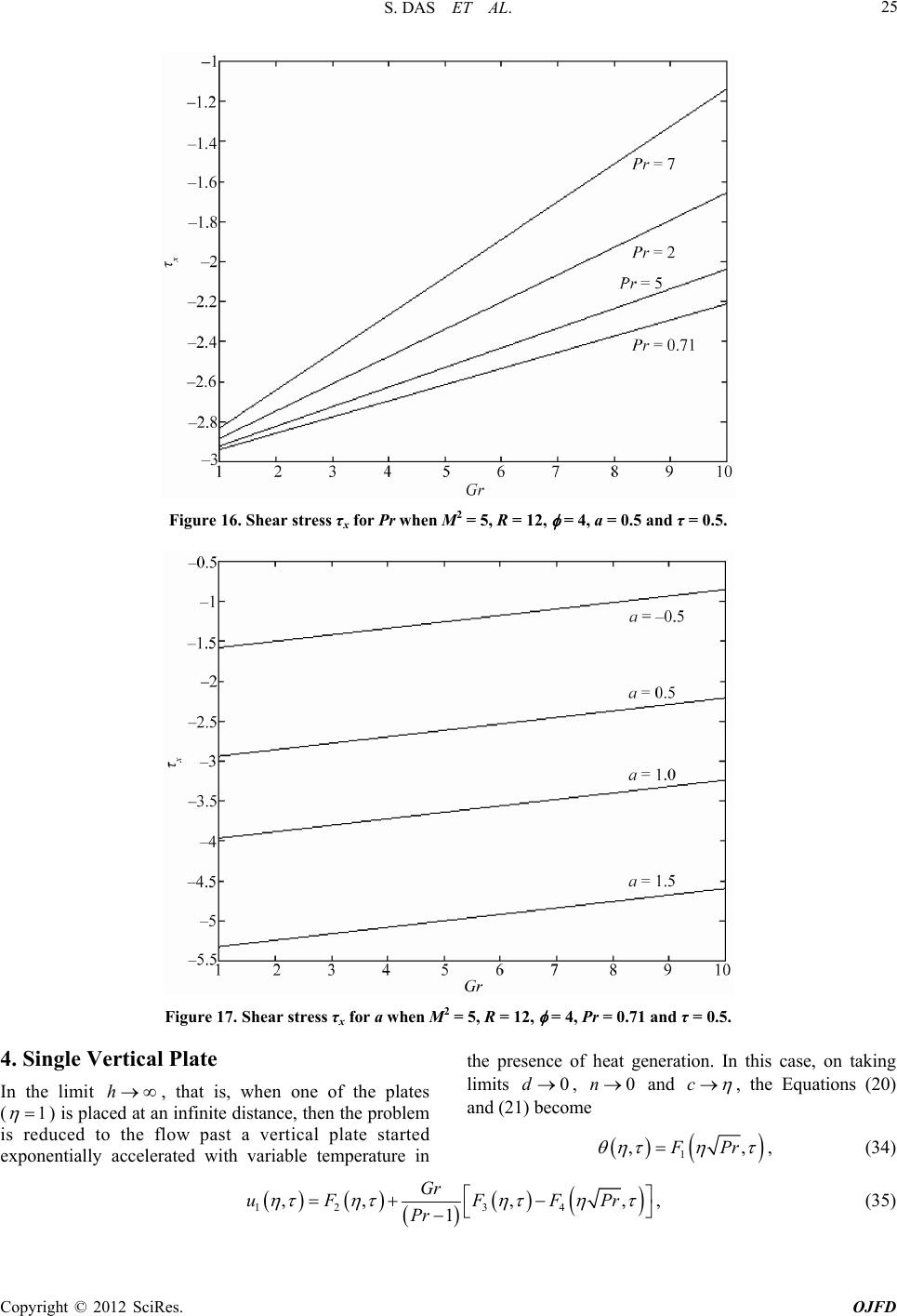

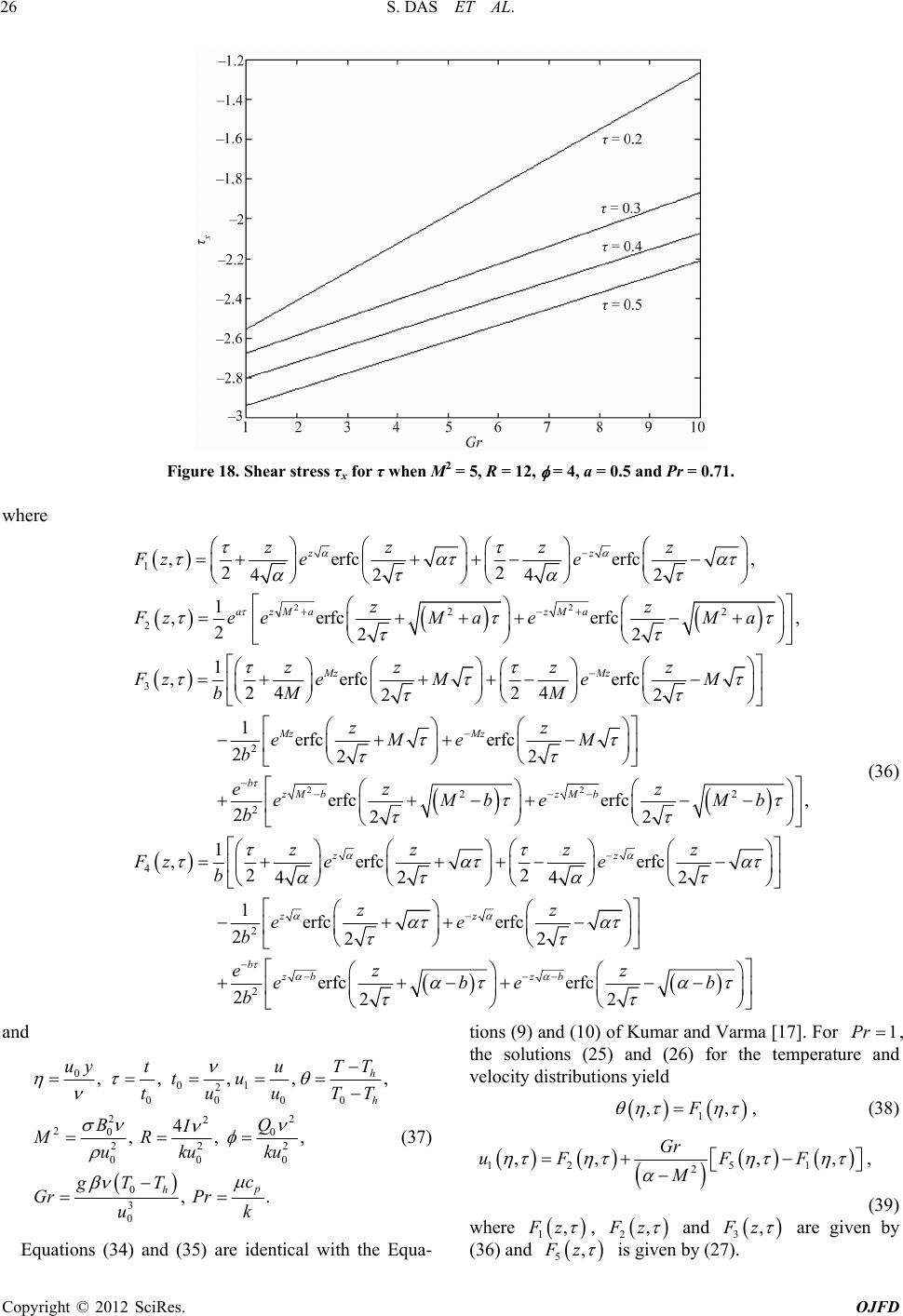

Open Journal of Fluid Dynamics, 2012, 2, 14-27 http://dx.doi.org/10.4236/ojfd.2012.21002 Published Online March 2012 (http://www.SciRP.org/journal/ojfd) Radiation Effects on Free Convection MHD Couette Flow Started Exponentially with Variable Wall Temperature in Presence of Heat Generation Sanatan Das, Bhaskar Chandra Sarkar, Rabindra Nath Jana Department of Applied Mathematics, Vidyasagar University, Midnapore, India Email: jana261171@yahoo.co.in Received December 29, 2011; revised January 29, 2012; accepted February 5, 2012 ABSTRACT Radiation effects on free convection MHD Couette flow started exponentially with variable wall temperature in the presence of heat generation have been studied. The governing equations are solved analytically using the Laplace transform technique. The variations of velocity and fluid temperature are presented graphically. It is observed that the velocity decreases with an increase in either magnetic parameter or radiation parameter or Prandtl number. It is also observed that the velocity increases with an increase in either heat generation parameter or Grashof number or acceler- ated parameter or time. An increase in either radiation parameter or Prandtl number leads to fall in the fluid temperature. It is seen that the fluid temperature increases with an increase in either heat generation parameter or time. Further, it is seen that the shear stress at the moving plate decreases with an increase in either magnetic parameter or radiation pa- rameter while it increases with an increase in either heat generation parameter or Prandtl number. The rate of heat transfer increases with an increase in either Prandtl number or time whereas it decreases with an increase in heat gen- eration parameter. Keywords: MHD Couette Flow; Free Convection; Magnetic Parameter; Radiation; Heat Generation; Prandtl Number; Grashof Number and Accelerated Parameter 1. Introduction Couette flow is one of the basic flow in fluid dynamics that refers to the laminar flow of a viscous fluid in the space between two parallel plates, one of which is mov- ing relative to the other. The flow is driven by virtue of viscous drag force acting on the fluid and the applied pressure gradient parallel to the plates. Couette flow is frequently used in physics and engineering to illustrate shear-driven fluid motion. Some important application areas of Couette motion are MHD power generators and pumps, aerodynamics heating, electrostatic precipitation, polymer technology, petroleum industry, purification of crude oil etc. In space technology applications and at higher operating temperatures, radiation effects can be quite significant. Radiative free convection MHD Cou- ette flows are frequently encountered in many scientific and environmental processes, such as astrophysical flows, heating and cooling of chambers and solar power tech- nology. Heat transfer by simultaneous radiation and con- vection has applications in numerous technological prob- lems including combustion, furnace design, the design of high temperature gas cooled nuclear reactors, nuclear reactor safety, fluidized bed heat exchanger, fire spreads, solar fans, solar collectors natural convection in cavities, turbid water bodies, photo chemical reactors and many others. Free convection in channels formed by vertical plates has received attention among the researchers in last few decades due to it’s widespread importance in engineering applications like cooling of electronic equip- ments, design of passive solar systems for energy con- version, design of heat exchangers, human comfort in buildings, thermal regulation processes and many more. Researchers in this field such as Singh [1], Singh et al. [2], Jha et al. [3], Joshi [4], Miyatake et al. [5], Tanaka et al. [6], Mohanty [7]. Jha [8] have studied the natural Convection in unsteady MHD Couette flow. The radia- tive heat transfer to magnetohydrodynamic Couette flow with variable wall temperature have been investigated by Ogulu and Motsa [9]. Chaudhary and Jain [10] have analyzed the exact solutions of incompressible Couette flow with constant temperature and constant heat flux on walls in the presence of radiation. The radiation effects on MHD Couette flow with heat transfer between two parallel plates have been examined by Mebine [11]. Jha and Ajibade [12] have discussed the free convective flow C opyright © 2012 SciRes. OJFD  S. DAS ET AL. 15 of heat generating fluid between vertical porous plates with periodic heat input. Jha and Ajibade [13] have stud- ied the unsteady free convective Couette flow of heat generating/absorbing fluid. MHD oscillatory Couette flow of a radiating viscous fluid in a porous medium with pe- riodic wall temperature have been investigated by Israel- Cookey et al. [14]. The effects of thermal radiation and free convection currents on the unsteady Couette flow between two vertical parallel plates with constant heat flux at one boundary have been studied by Narahari [15]. Unsteady free convective Couette flow of heat generat- ing/absorbing fluid in porous medium has been investi- gated by Deka and Bhattacharya [16]. Kumar and Varma [17] have studied the radiation effects on MHD flow past an impulsively started exponentially accelerated vertical plate with variable temperature in the presence of heat generation. In this present paper, we have investigated the radia- tion effects on free convection MHD Couette flow of a viscous incompressible heat generating fluid in the pres- ence of variable temperature. It is observed that the ve- locity 1 decreases with an increase in either magnetic parameter u 2 M or radiation parameter or Prandtl number . It is also observed that the velocity 1 u increases with an increase in either heat generation pa- rameter or Grashof number or accelerated parame- ter or time R Pr Gr a . An increase in either radiation pa- rameter or Prandtl number leads to fall in the fluid temperature RPr . It is seen that the fluid temperature increases with an increase in either heat generation parameter or time . Further, it is seen that the shear stress at the moving plate x decreases with an increase in either magnetic parameter or radiation pa- rameter while it increases with an increase in either heat generation parameter or Prandtl number. The rate of heat transfer increases with an increase in either Prandtl number Pr or time 0 whereas it decreases with an increase in heat generation parameter . 2. Formulation of the Problem and Its Solutions Consider the unsteady free convection MHD Couette flow of a viscous incompressible radiative heat generat- ing fluid between two infinite vertical parallel walls separated by a distance . The flow is set up by the buoyancy force arising from the temperature gradient occurring as a result of asymmetric heating of the parallel plates as well as constant motion of one of the plates. Choose a cartesian co-ordinates system with the x-axis along one of the plates in the vertically upward direction and the y-axis normal to the plates (See Figure 1). Ini- tially, at time , both the plates and the fluid are assumed to be at the same temperature and station- h 0t h T Figure 1. Geometry of the problem ary. At time , the plate at starts moving in its own plane with a velocity and is heated with >0t=0y 0 at ue temperature 0 0 hh t TTT t whereas the plate at =yh t is stationary and maintained at a constant tem- perature h, where 0 and are constants. A uni- form magnetic field of strength 0 is imposed perpen- dicular to the plates. It is also assumed that the radiative heat flux in the x-direction is negligible as compared to that in the y-direction. As the plates are infinitely long, the velocity and temperature fields are functions of and only. Tu a B y The Boussinesq approximation is assumed to hold and for the evaluation of the gravitational body force, the density is assumed to depend on the temperature accor- ding to the equation of state 00 =1 h TT , (1) where is the fluid temperature, T the fluid density, the coefficient of thermal expansion and 0 the density at the entrance of the channel. For the fully developed flow, the governing equations are 2 2 0 2 1 =h B up u g TT u tx y , (2) 2 0 2 =r p h q TT ck QTT ty y , (3) where is the velocity in the u x -direction, g the acceleration due to gravity, the kinematic coefficient of viscosity, the thermal conductivity, k p c the specific heat at constant pressure, the radiative heat flux and a constant. r q 0 The initial and the boundary conditions for velocity and temperature distribution are as follows: Q 00 0 0, for 0 and 0, , at 0 for > 0, 0, at for > 0. h at hh h uTTyht t uueTT TTyt t uTTyht (4) It has been shown by Cogley et al. [13] that in the Copyright © 2012 SciRes. OJFD  S. DAS ET AL. 16 optically thin limit for a non-gray gas near equilibrium, the following relation holds 0 4d p rhhh e qTT K yT , (5) where K is the absorption coefficient, is the wave length, p e is the Plank's function and subscript ‘’ indicates that all quantities have been evaluated at the temperature h which is the temperature of the plate at time . Thus our study is limited to small difference of plate temperature to the fluid temperature. h T 0t On the use of the Equation (5), Equation (3) becomes 2 0 24 p hh TT c kTTIQTT ty , (6) where 0 p hh e I K T d . (7) Greif et al. [18] showed that, for an optically thin limit, the fluid does not absorb its own emitted radiation, this means that there is no self-absorption, but the fluid does absorb radiation emitted by the boundaries. Using condition at , Equation (2) yields yh 1=0 p x . (8) On the use of (8), Equation (2) becomes 2 2 0 2 h B uu g TT u ty . (9) Introducing non-dimensional variables y h , 2 t h , 1 0 u uu , 0 h h TT TT , (10) Equations (9) and (6) become 2 2 11 1 2 uu GrM u , (11) 2 2 Pr R , (12) where 22 20 Bh M is the magnetic parameter, 2 4 I h Rk the radiation parameter, 2 0 Qh k the heat generation parameter, 2 0 0 () h g TTh Gr u the Grashof number and p c Pr k the Prandtl number. The corresponding initial and boundary conditions for and 1 u are 1 1 1 0,0 for 01 and 0, , at 0 for > 0, 0, 0at1for> 0, a u ue u (13) where 2 ah a is the accelerated parameter. Taking Laplace transformation, the Equations (11) and (12) become 2 2 1 11 2 d d u s uGrM u (14) 2 2 d d Prs R (15) where 11 0 0 ,,d and ,,d. s s ususe sse (16) The corresponding boundary conditions for 1 u and are 12 1 11 0,, 0,, 1,0, 1,0. us s sa s us s (17) The solutions of the Equations (15) and (14) subject to the boundary conditions (17) are easily obtained and are given by 2 sinh 1 1 , sinh Pr s ssPr s , (18) 2 12 2 2 2 sinh 1 1 , sinh 1 sinh 1 sinh 1 sinh sinh sM ussa sM Gr Prsbs Pr s sM Pr s sM (19) where =R Pr and 2 =1 Pr M bPr The inverse transforms of (18) and (19) give the temperature and the velocity field distributions as 11 =0 ,, n FcPr FdPr , , (20) 122 =0 33 44 ,,, 1 ,, ,, n Gr uFcFd Pr FcFdFcPrFdPr (21) Copyright © 2012 SciRes. OJFD  S. DAS ET AL. Copyright © 2012 SciRes. OJFD 17 where 2, 22cn dn 22 1 22 2 3 ,erfcerfc , 22 424 2 1 , erfcerfc, 222 1 , erfcerf 24 24 2 zz azMa zMa Mz Mz zzz z Fz ee zz FzeeM aeM a zz z Fze Me bM M 22 2 22 2 4 c2 1 erfcerfc 222 erfcerfc, 222 1 ,erfc 242 Mz Mz bzM bzM b z zM zz eMeM b ez z eMbe M b zz Fz e b b 2 2 erfc 242 1 erfcerfc 222 erfc()erfc() 222 z zz bzb zb zz e zz ee b ez z ebeb b (22) and erfc is the complementary error function. 122 2 =0 55 11 (,), , ,,,, n Gr uFcFd M Fc FdFcFd . (26) 2.1. Solution for Prandtl number Pr = 1 As the Prandtl number is a measure of the relative importance of the viscosity and thermal conductivity of the fluid, the case corresponds to those fluids whose momentum and thermal boundary layer thick- nesses are of the same order of magnitude. Thus, the solution for the velocity field has to be re-derived when Prandtl number . The solution of the Equations (15) and (14) subject to the boundary conditions (17) are easily obtained and are given by 1Pr 1 Pr where 5,erfc 24 2 erfc 24 2 Mz Mz zz Fze M M zz eM M (27) and 1, F z and 2, F z are given by (22). 2 sinh 1 1 ,sinh s sss , (23) 3. Results and Discussion 2 12 2 22 2 sinh 1 1 , sinh sinh1 sinh1 . () sinh sinh sM us sa sM sM s Gr sM s sM , We have presented the non-dimensional velocity and temperature for several values of magnetic parameter 2 M , radiation parameter , heat generation parameter R , Prandtl number , Grashof number , accele- rated parameter and time Pr Gr a in Figures 2-12. Fig- ures 2-8 represent the velocity 1 u against for several values of 2 M , R, , PrGr aand , , , .t is seen from Figure 2 that the velocity 1 u decreases with an increase in magnetic parameter (24) The inverse transforms of (23) and (24) give the temperature and velocity distributions as 11 =0 ,, n Fc Fd , (25) I 2 M . The application of the transverse magnetic field plays the role of a resistive type force (Lorentz force) similar to drag orce (that acts in the opposite direction of the fluid f  S. DAS ET AL. 18 Figure 2. Velocity profiles for M2 when R = 12, = 4, Gr = 5, Pr = 0.71, a = 0.5 and τ = 0.5. Figure 3. Velocity profiles for R when M2 = 5, = 4, Gr = 5, Pr = 0.71, a = 0.5 and τ = 0.5. motion) which tends to resist the flow thereby reducing its velocity. Figure 3 reveals that the velocity de- creases with an increase in radiation parameter . This shows that there is a fall in velocity in the presence of high radiation. It is seen from Figure 4 that the velocity increases with an increase in heat generation para- meter 1 u R 1 u . As increases, heat generating capacity of the fluid increases which increases fluid temperature and hence the fluid velocity. Figure 5 shows that the velocity decreases with an increase in Prandtl number . Physically, this is true because the increase in the Prandtl number is due to increase in the viscosity of the fluid which makes the fluid thick and hence causes a decrease in the velocity of the fluid. It is observed from Figure 6 that an increase in leads to rise in the values of velocity . An increase in Grashof number leads to an increase in velocity, this is because, increase in Grashof number means more heating and less density. It is seen from Figures 7, 8 that the velocity increases with an increase in either accelerated parameter aor time 1 uPr Gr 1 u 1 u .t is seen from Figure 9 that the temperature I decreas as the radiation parameter R increase. This result qua- litatively agrees with expectations, since the effect of radiation is to decrease the rate of energy transport to the fluid, thereby decreasing the temperature of the fluid. It is seen from Figure 10 that the temperature es s increases as the heat generation parameter increases. This result agrees with pectations, as ex increases, heat genera- Copyright © 2012 SciRes. OJFD  S. DAS ET AL. 19 Figure 4. Velocity profiles for when M2 = 5, R = 12, Gr = 5, Pr = 0.71, a = 0.5τ = 0.5. and Figure 5. Velocity profiles for Pr when M2 = 5, R = 12, Gr = 5, = 4, a = 0.5 and τ = 0.5. ting capacity of the fluid increases and hence the fluid temperature increases. It is observed from Figure 11 that the temperature decreases with an increase in Prandtl number Pr . Th implies that an increase in Prandtl number ls to fall the thermal boundary layer flow. This is because fluids with large Pr have low thermal diffusivity which causes low heat ptration resulting in reduced thermal boundary layer. Figure 12 reveals that the temperature is ead ene increases with an increase in time . The trend shows that the temperature increases with increasing time. It is observed from that Figures 9-12 temperature decreases gradually from highest value on the moving plate to a zero value on the stationary plate. The rate of heat transfer at the moving plate (0 ) is given by 11 =0 =0 0, n Gc PrGdPr ,, , (28) 2, 22cndn where 2 1 4 ,erfc erfc 42 2 erfcerfc. 22 π 424 2 zz z zz Pr zz Gz ee zzz zPr Pr eee (29) Copyright © 2012 SciRes. OJFD  S. DAS ET AL. 20 Figure 6. Velocity profiles for Gr when M2 = 5, R = 12, = 4, Pr = 0.71, a = 0.5 and τ = 0.5. Figure 7. Velocity profiles for a when M2 = 5, R = 12, Gr = 5, = 4, Pr = 0.71 and τ = 0.5. Numerical results of the rate of heat transfer 0 explained by the fact that frictional forces become dominant with increasing values of and hence yield greater heat transfer rates. Further,n that for fixed value of Pr it is see , Pr at the moving plate (0 ) ented in the n param against the r parameter are presTable 1 fo values of heat generatioeter adiation r various R , Prandtl and ti number Pr me . pa ases r and , the rate oeat transfer f h 0 From dime increas the nsional s es with an increas poi s at t Table thr the fixe diationrameter , the rate of he time 1 shows Rat fod value at transfer of ra num incre Pr o 0 ber e iation parameter. calnt ofi is necessary to plate. The non- ear streshe plate ( n radi ew, itphysi h with an increase in either Prandtl v know the shear stress at the moving and it decreases with an in- crease in heat generation parameter . This may be ) is obtained 0 as follows: 1 22344 =0 0 ,,,,,, (1) xn uGr GcGdGcGGcPr GdPr Pr . (30) ere 3d wh Copyright © 2012 SciRes. OJFD  S. DAS ET AL. 21 Figure 8. Velocity profiles for τ when M2 = 5, R = 12, Gr = 5, = 4, a = 0.5 and Pr = 0.71. Figure 9. Temperature profiles for R when Pr = 0.71, = 4 and τ = 0.5. Table 1. Rate of heat transfer –10–1θ′(0) at the moving plate η = 0 with a = 0.5. Pr τ R 2 3 4 0.71 2 7 0.3 0.4 0.5 8 10 12 14 1.36959 1.53971 1.69340 1.83453 1.27657 1.45 1.76535 1.17686 1.69340 1.36959 1.83453 1.62291 2.01991 2.40040 2.66810 0.87900 1.14169 12448 1.25683 37716 1.48812 1.36959 1.53971 1.69340 1.83453 702 1.36959 1.53971 1.76369 2.49186 0.97383 1.61833 1.53971 1.69340 1.89559 2.58105 1.06088 1. 1. Copyright © 2012 SciRes. OJFD  S. DAS ET AL. 22 Figure 10. Temperature profiles for when R = 12, Pr = 0.71 and τ = 0.5. Figure 11. Temperature profiles for Pr when R = 12, = 4 and τ = 0.2. Figure 12. Temperature profiles for τ when Pr = 0.71, R = 12 and = 4. Copyright © 2012 SciRes. OJFD  S. DAS ET AL. Copyright © 2012 SciRes. OJFD 23 22 22 2 4 22 2 32 , 1 2 erfc erfc 222π 11 11 ,erfc 424 424 22 zMa azMa zMa Mz Gz zz eMaeMa eMae zM zz GzMe MM bM MbM M b 22 22 22 2 4 2 4 22 2 2 4 2 12 erfc2π 2 erfcerfc, 222π zM Mz z bMb zM bzM b M b z eM e bb ez z MbeMb eMbe b Gz 2 2 2 , 11 erfc 22 22 442 44 erfc2 erfcerfc 222 z z PrzPr e Pr z bzb zb Prz Pr Pr bb bb z e ezz Prb ebeb b 2 4 2. π zPr b Pre (31) For , the non-dimensional shear stress at the moving plate ( 1Pr0 ) is given by 2255 66 2 =0 ,, ,,,, xn Gr Gc GdGcGdGc Gd M (32) where 22 5 4 1 ,424 1 erfc424 2 erfc , π 2 Mz zM Mz z Gz M MM zz eMM MM z eMe (33) and 1,Gz is given by (29) 2 6 4 , 1erfc z zz e 2 44 2 1 erfc 2 44 2 . π z z Gz zz e e and 2,Gz , 3,Gz and 4,Gz are given by (31). Numerical results of the non-dimensional shear stress x at the moving plate (0 ) are presented in Figures 18 against Grashof for various values of gnetic parameter 13- ma number 2 Gr M , radiation parameter , heat ration paramete R gene r , Prandtl number time Pr and . Gras Figures 13 and at for the fiue of hof number ss 14 , th show th e shear xed val Gr stre x decreas 2 es with rease inan inc either magnetic parameter M or crea 2 radia- on parameter wse in hof num ti Gras R a Gr nd fo it increa r the fi ses xed ith valu an in of ber es M and at the R. These resut with inccrease iile it decreases lts are in agreem cr en eithe th n r e Gr 2 fact th whvelocityreases with an in eases in with an in M or e R. It is seen from at the Figures 15 and 16 th sh ar stress x eneration increases eter with an increase in either heat g param or hof the sheas Pra Gr ndtl . number Figures Pr an fo d r fixed value of hat Gras num r stres ber 1718 reveal t x e dec ter a reases or with an increase in either accelerated paramtime for fixed value of Gras hof number Gr  S. DAS ET AL. 24 12, = 4, Pr = 0.71, a = 0.5 and τ = 0.5. Figure 13. Shear stress τx for M2 when R = Figure 14. Shear stress τx for R when M2 = 5, = 2, Pr = 0.71, a = 0.5 and τ = 0.5. Figure 15. Shear stress τx for when M2 = 5, R = 12, Pr = 0.71, a = 0.5 and τ = 0.5. Copyright © 2012 SciRes. OJFD  S. DAS ET AL. 25 Figure 16. Shear stress τx for Pr when M2 = 5, R = 12, = 4, a = 0.5 and τ = 0.5. Figure 17. Shear stress τx for a when M2 = 5, R = 12, = 4, Pr = 0.71 and τ = 0.5. 4. Single Vertical Plate In the limit, that is, when one of the plates h (1 is reduce ) is an infinite distance, then the problem dpast a vertical plate started exponentially accelerated with variable temperature in the presence of heat generation. In this case, on taking limits and placed at to the flow 0d, 0nc , the Equations (20) and (21) become 1 ,, F Pr , (34) 12 34 ,,,, 1 Gr uF FFPr Pr , (35) Copyright © 2012 SciRes. OJFD  S. DAS ET AL. 26 Figure 18. Shear stress τx for τ when M2 = 5, R = 12, = 4, a = 0.5 and Pr = 0.71. where 22 1 22 2 3 ,erfcerfc, 22 424 2 1 ,erfc erfc 222 1 , erfcerf 24 24 2 zz azMa zMa Mz Mz zzz z Fz ee zz Fze eMaeMa zzz FzeMe bM M , 22 2 22 2 4 c2 1 erfcerfc 222 erfcerfc, 222 1 ,erfc 242 Mz Mz bzM bzM b z zM zz eMeM b ez z eMbe M b zz Fze b b 2 2 erfc 242 1 erfcerfc 222 erfcerfc 222 z zz bzbzb zz e zz ee b ez z ebe b b (36) and 0 uy t 01 2 00 0 0 22 2 200 222 000 ,,,,, 4 , , , h tu u TT u BQ I MR ukuku (37) 0 3 0 , . h p h T T u t c gTT GrPr k u Equations (34) and (35) are identical with the Equa- ma [17]. For tions (9) and (10) of Kumar and Var1Pr , the solutions (25) and (26) for the temperature and velocity distributield ions y 1 ,,F , (38) ,F 12 51 2 ,, , Gr uF F M where , (39) 1, F z , 2, F z and 3, F z are given by (36) and 5, F z is given by (27). Copyright © 2012 SciRes. OJFD  S. DAS ET AL. 27 5. Conclusion The radiation effects on free convection MHD Couette flow started exponentially accelerated with variable tem- perature in the presence of heat generation have been studied. The dimensionless governing equations are solved by the usual Laplace transform technique.It is observed that the velocity decreases with an increase in either magnetic param 1 u eter 2 M . It is also with an increase or radiation parameter or Prandtl number observed that the velcity increases in either heat genen eter R o ratio Pr 1 u param orf number or acc eter or G tim rasho e Gr elerated param a . ndtl n An increase in either radiation eter umber leads to fluid temp param R erature or Pra Pr fall in the . It is seen that the fluid temperature param increase heat genen eter eases with an incrin eitherratio m or tim ng e plate . Further, it is seen that the shear stress at theovi x with an incease in either decreases r 2 M o creases r r incr adiation parameter R while it in- either heat generation para- with anease in meter 0 ber or Pr or aof he se in either Prandtl ndtl n increase tim umb s with a e er Pr n in . The rate a at trans- fer num cre Pr ration whe pa r ram eas it eter decreases with an increase int hea gene . REFERENCES [1] A. K. Singh, “Natural Convection in Unsteady Couette Motion,” Defense Science Journal, Vol. 38, No. 1, 1988, pp. 35-41. [2] A. K. Singh and T. Paul, “Transient Natural Convection between Two Vertical Walls Heated/Cooled Asymetri- cally,” International Journal of Applied Mechanics and Engineering, Vol. 11, No. 1, 2006, pp. 143-154. [3] B. K. Jha, A. K. Singh and H. S. Takhar, “Transient Free Convection Flow in a Vertical Channel due to Symmetric Heating,” International Journal of Applied Mechanics and Engineering, Vol. 8, No. 3, 2003, pp. 497-502. [4] H. M. Joshi, “Transient Effects in Natural Convection Cooling of Vertical Parallel Plates,” International Com- munications in Heat and Mass Transfer, Vol. 15, No. 2, 1988, pp. 227-238. doi:10.1016/0735-1933(88)90068-1 [5] O. Miyatake and T. Fujii, “Free Convection Heat Transfer between Vertical Plates—One Plate Isothermally Heated Thermally Insulated,” Heat Transfer—Japa- se Research, Vol. 1, 1972, pp. 30-38. [6] H. Tanaka, O. Miyatake, T. Fujii and M. Fujii, “Natural Convection Heat Transfer between Vertical Parallel Pla- tes—One Plate with a Uniform Heat Flux and the Other Thermally Insulated,” Heat Transfer—Japanese Resear- ch, Vol. 2, 1973, pp. 25-33. [7] H. K. Mohanty, “Transient Free Convection Horizontal Laminar Flow between Two Parallel Plates,” Acta Me- chanica, Vol. 15, No. 3-4, 1972, pp. 273-293. doi:10.1007/BF01304296 [8] B. K. Jha, “Natural Convection in Unsteady MHD Cou- ette Flow,” Heat and Mass Transfer, Vol. 37, No. 4-5, 2001, pp. 329-331. doi:10.1007/PL00013295 [9] A. Ogulu and S. Motsa, “Radiative Heat Transfer to Mag- netohydrodynamic Couette Flow with Variable Wall Temperature,” Physica Scripta, Vol. 71, No. 4, 2005, pp. 336-339. doi:10.1238/Physica.Regular.071a00336 [10] R. C. Chaudhary and P. Jain, “Exact Solutions of Incom- pressible Couette Flow with Constant Temperature and Constant Heat Flux on Walls in the Presence of Radia- tion,” Turkish Journal of Engineering & Environmental Sciences, Vol. 3, No. 1, 2007, pp. 297-304. [11] P. Mebine, “Radiation Effects on MHD Couette Flow With Heat Transfer between Two Parallel Plates,” Global Journal of Pure and Applied Mathematics, Vol. 3, No. 2, 2007, pp. 1-12. e Convective Flow of between Vertical Po- rous Plates with Periodic Heat Input,” International Com- munications in Heat and Mass Transfer, Vol. 36, No. 6, 2009, pp. 624-631. doi:10.1016/j.icheatmasstransfer.2009.03.003 and Other ne [12] B. K. Jha and A. O. Ajibade, “Fre Heat Generating/Absorbing Fluid [13] B. K. Jha and A. O. Ajibade, “Unsteady Free Convective Couette Flow of Heat Generating/Absorbing Fluid,” In- ternational Journal of Energy and Technology, Vol. 2, No. 12, 2010, pp. 1-9. [14] C. Israel-Cookey, E. Amos and C. Nwaigwe, “MHD Os- cillatory Couette Flow of a Radiating Viscous Fluid in a Porous Medium with Periodic Wall Temperature,” Amer- ican Journal of Scientific Industrial Research, Vol. 1, No. 2, 2010, pp. 326-331. [15] M. Narahari, “Effects Of Thermal Radiat Convection Currents on the Unsteady Couette Flow be- tween Two Vertical Parallel Plates with Constant Heat Flux at one Boundary,” WSEAS Transactions on Heat and Mass Transfer, Vol. 5, No. 1, 2010, pp. 21-30. [16] R. K. Deka and A. Bhattacharya, “Unsteady Free Con- vective Couette Flow of Heat Generating/Absorbing Fluid in Porous Medium,” International Journal of Mathe- matical Archive, Vol. 2, No. 6, 2011, pp. 853-863. [17] A. G. V. Kumar and S. V. K. Varma, “Radiation Effects on MHD Flow Past an Impulsively Started Exponentially Accelerated Vertical Plate with Variable Temperature in , No. 4 . C. Lin, “Laminar Convection of a Radiating Gas in a Vertical Fluid Mechanics, Vol. 46, 1970, pp doi:10.1017/S0022112071000673 ion and Free the Presence of Heat Generation,” International Journal of Engineering Science and Technology, Vol. 3, 2011, pp. 2897-2909. [18] R. Grief, I. S. Habib and J Channel,” Journal of . 513-520. Copyright © 2012 SciRes. OJFD |