World Journal of Nano Science and Engineering, 2012, 2, 32-39 http://dx.doi.org/10.4236/wjnse.2012.21006 Published Online March 2012 (http://www.SciRP.org/journal/wjnse) Friction and Wear of Polymer Composites Filled by Nano-Particles: A Review Ayman A. Aly*, El-Shafei B. Zeidan, AbdAllah A. Alshennawy, Aly A. El-Masry, Wahid A. Wasel Mechatronics Section, Department of Mechanical Engineering, Faculty of Engineering, Taif University, Taif, Saudi Arabia Email: *draymanelnaggar@yahoo.com Received November 14, 2011; revised December 19, 2011; accepted January 10, 2012 ABSTRACT Composites formed by adding nano-scale particles to a polymer matrix results in improving electrical, mechanical, and thermal properties of the composite. Good tribological properties can be obtained for polymers filled with nano-scale fillers compared to that filled with micro-scale particles. The friction and wear resistance of these composites is found to increase with increasing filler concentration. It is also possible to use multi-functional fillers to develop high per- formance composites which cannot be achieved by using a single filler. Keywords: Friction; Wear; Polymer Composites; Nano-Particles 1. Introduction In the past few decades, researchers and engineers inter- est has been shifting from monolithic materials to rein- forced polymeric materials. These composite materials now dominate the pharmaceutical, aerospace, leisure, auto- motive, construction, and sporting industries [1-3]. A polymer nano-composite is defined as a composite material with a polymer matrix and filler particles that have at least one dimension less than 100 nm. These en- gineering composites are desired due to their low density, high corrosion resistance, ease of fabrication and low cost [4-7]. Glass fibers are the most widely used to rein- force plastics due to their good mechanical properties and low cost. Various kinds of polymers and polymer matrix composites reinforced with metal particles have a wide range of industrial applications such as heaters, electrodes, actuators etc. [8]. When silica nano-particles are added to a polymer matrix to form a composite, they play an important role in improving electrical, mechanic- cal, and thermal properties of composites [3,9]. The in- clusion of inorganic fillers into polymers for commercial applications is primarily aimed at the cost reduction and stiffness improvement [10]. Polymer composites can be fabricated by the incorpo- ration of inorganic reinforcements into the polymer ma- trix. The properties of the resulting polymer composites depend on the characteristics, the dimensions, and the shapes of the inorganic fillers, and also on the interfacial bonding strength. It is proposed that with decreasing filler dimensions or increasing filler content a significan t improve in the contact area between the filler and matrix, and in turn it would greatly and effectively improve the transfer of the load between the fillers and the polymer matrix [11]. The inorganic nan o-fillers, ranging fro m 1 to 50 nm, were successfully incorporated into the polymeric matrix to strengthen and improve the ductile polymer to be more stiff and resistant for abrasion [12,13]. The inclusion of the ceramic nano-filler into the more flexible and lower thermal resistance polymer can sub- stantially improve its stiffness and thermal stability [14- 17]. The nano-sized silica or alumina particles without any chemical modification were incorporated into the PEEK polymer. It appears that there are occasional clus- tering occurrences for two to five nano-particles to clus- ter or align together, the majority of the nano-particles were seen to disperse semi-homogeneously in the poly- etheretherketone (P EEK) m a t rix [18]. With the booming of nano-phased materials in the re- cent years, attempts are being made to develop nano- particle filled-polymer composites with improved tribo logi- cal performance of the materials. It is expected that good tribological properties can be obtained for the polymers filled with nano-scale fillers compared to those filled with micro-scale particles [19,20]. Due to their lower strength and stiffness compared with synthetic fibers, natural fibers use in polymer composites has been limited to non-tribological applications. Very little information concerning the tribological performance of natural fiber reinforced composite materials has been reported [21]. *Corresponding a uthor. C opyright © 2012 SciRes. WJNSE  A. A. ALY ET AL. 33 Polytetrafluoroethylene (PTFE) exhibits many desir- able tribological characteristics, including high melting temperature, low friction, and chemical inertness. PTFE is an excellent solid lubricant and used commonly in bearing and seals applications [22] Unfortunately, PTFE exhibits high wear rate under normal friction conditions, which limits its application fields. Therefore, many kinds of PTFE-based composites have been produced to im- prove the wear resistance of PTFE [23,24]. It was found that some micro-scale inorganic fillers showed distinct effect on the friction and wear behaviors of PTFE com- posites [ 2 5]. The present paper presents a survey on nano-filler polymer-based composites with improved mechanical properties for low friction and low wear applications. The effect of filler particle size is summarized. Then the effect of chemical surface modification and multi func- tional fillers is reviewed. Finally some conclusions are drawn. 2. Effect of Nano-Filler Particle Size and Ratio The shape, size, volume fraction, and specific surface area of added particles have been found to affect mechanical properties of the composites greatly. Currently, many studies have focused on how single-particle size affects mechanical properties of the composites [26-29]. Ho- shino et al. [26] discussed the effects of size and shape of silica particle on the strength and fracture toughness based on particle-matrix adhesion and they found an in- crease of the flexural and tensile strength as specific sur- face area of particles increased. Yamamoto et al. [27] reported that the structure and shape of silica particle have significant effects on the mechanical properties such as fatigue resistance, tensile and fracture properties. The effects of inorganic nanometer particles, such as SiC, SiO2, Si3N4 and ZrO2 on the tribological properties of some polymers have been studied. Li et al. [24] re- ported that filling nanometer ZnO to PTFE could greatly reduce the wear of this polymer and the best anti-wear property was obtained with the composite containing 15 vol% nanometer ZnO, but the friction coefficient of nano-composite was higher than that of the unfilled PTFE. Sawyer et al. [25] investigated the tribological properties of PTFE composites filled with 40 nm Al2O3, and they found that the friction coefficient of the composite in- creased slightly compared to the unfilled sample and the wear resistance increased monotonically with increasing filler concentration. Wang et al. [30-36] have filled PEEK with various weight fractions of SiC, Si3N4, SiO2, and ZrO2. The addi- tion of the filler in fractions less than 10% by weight improved the wear resistance and reduced the friction coefficient. The improved wear and friction is attributed to two factors: the smoothing of the steel counterface, and the development of a transfer film. Schwartz and Bahadur [37] filled polyphenylene sulfide (PPS) with alumina nano-particles. Examination of these samples with scanning electron microscopy showed good disper- sion of filler particles in the PPS matrix. Wear tests were performed on a four stations pin-on-disk tribometer. The roughness of the counter face was varied. It was postu- lated that this parameter directly relates to the develop- ment of the transfer film on the counter face; the rougher surface facilitates transfer film growth. Similar to the pre- vious studies, maximum wear resistance was found at weight pe r centages below 10. As the percentage of filler increased above this opti- mum, the composite mater ial experienced more wear than the unfilled counterpart. Unlike the previous work with PEEK, the coefficient of friction increased monotonically with increasing filler concentrations. Li et al. [24] filled PTFE with nano particles of ZnO. Wear resistance was improved by nearly two orders of magnitude with a maxi- mum wear resistance at ZnO concentrations of roughly 15% by volume. In that study, the friction coefficient of the nano-composite was higher than the unfilled PTFE. Pet- rovicova et al. [38] filled Nylon 11 with silica. Wear resistance increased with increasing concentrations of nanoscale silica up to 15% by volume. They found that the friction coefficient of the nano-composite was lower than that of the unfilled Nylon. Avella et al. [39] filled polymethylmethacrylate (PMMA) with nano-scale CaCO3. The abrasion resistance increased as the filler content was increased, improving by a factor of 2% with 3% CaCO3 by weight. Yu et al. [40] filled polyoxymethylene (POM) with micrometer and submicron copper particles. The nano-composite had less wear and a lower coeffi- cient of friction than the composites filled with mi- crometer sized particles of copper and the unfilled POM. It was hypothesized that the increased surface area of the submicron copper filler particles improved the bonding strength at the filler/matrix interface. In Figure 1, the reported wear-rates of the nano-composites are each nor- malized by the reported wear-rate of the unfilled matrix and plotted versus the volume fraction of filler particles. In Table 1. the wear-rate for the most wear-resistant formulation of each nano-composite is give n [25]. This compilation of data showed that the optimum concentrations of nanometer sized filler particles is 2% - 5% by volume. A more typical optimum in polymer composites made with micrometer sized filler particles is on the order of 30%. It is also shown that consistent ob- servation that improvements in wear can be realized with polymer nano-composites. But the origin of wear resis- tance improvements in polymer nano-composites is an open question. Copyright © 2012 SciRes. WJNSE  A. A. ALY ET AL. Copyright © 2012 SciRes. WJNSE 34 Figure 1. A plot of normalized wear improvements for polymer nano-composites as a function of filler volume fraction [25]. 3. Chemical Surface Modification Table 1. A comparison of the lowest reported wear-rates for various polymer nano-composites [25]. Chemical surface modification is widely used to obtain a high wettability for a solid surface, a good dispersion of particles, and adhesion of fillers in composite materials [43]. Chemical surface modification can be categorized as follows: Matrix/nano-filler Lowest wear-rate, k (×10 - 6 mm3/Nm) PTEE/ZnO PPS/Al2O3 PEEK/SiC PEEK/Si3N4 PEEK/ZrO2 PEEK/SiO2 13 10.4 3.4 1.3 3.9 1.4 Surface modificat ion by chemical reacti on This type of surface modification promotes a chemical reaction between the polymer matrix and an inorganic filler to strengthen the adhesion. Two reagents are mainly used in chemical surface modification to obtain a hydro- phobic surface. One example of such a reagent is an alkyl silane coupling agent and another is an alcohol [44-46]. Surface modifi cat ion by non-reactive modifier As a PTFE matrix, it has been successfully filled with nano-particles of alumina, zinca, and carbon nano-tubes. Sawyer et al. [41] used 38 nm Al2O3 filler to improve the wear performance of PTFE, and the wear resistance of this nanocomposite increased monotonically with filler wt%, eventually being 600 times more wear resistant than unfilled PTFE at a loading of 20 wt%. Burris and Sawyer [42] and Li et al. [24] have found similar im- provements for metal-oxide nano-composites of PTFE at high weight percents of filler. The promise of nano-com- posites, however, was that low weight percents could provide such improvements. This study is the first in which low weight p ercentag e of filler p articles are shown to provide over 1000× improvements in wear rate. The difference between these composites and previous nano- composites of PTFE is that the nano-particles are irregu- lar in shape, as opposed to the spherical shape of previ- ous composites. In most cases the surface of the nano-particles used for nano-particle filled polymer composites prepared by dis- persive mixing for tribological applications have not been pre-treated. If no specific surface treatment is applied be- forehand, the unique nano-effect of nano-particles cannot be fully brought into play. Therefore, pre-treatment of nano-particles before every experiment is necessary. A nonreactive modifier reduces the interaction between the filler particles within agglomerates by reducing the physical attraction rather than by any chemical reaction [47,48]. Stearic acid has been widely used as a non-interacting surface modifier. Modified nano-filler can easily be in- corporated into a polymer matrix, resulting in a decrease in the melt viscosity and, in most cases, an improved dis- persion of the nano-filler in the composite [49,50]. The wettability of silica nano-particles and the adhesion be-  A. A. ALY ET AL. 35 tween the filler and the polymer matrix were improved by modifying the silica nano-particles with stearic acid [51]. The non-reactive stearic acid reduces the interaction between the filler particles within agglomerates by re- ducing the physical attraction, rather than by any chemi- cal reaction. However there has been little research re- lated to the mechanical properties of silica nano-particle reinforced PEN composites with the modification of stea- ric acid. Surface modified silica nano-particle reinforced PEN composites were melt blended to investigate the effect of stearic acid modification on the mechanical properties, crystallization behavior, and the processibility of the sil- ica nano-particle reinforced PEN composites. The inter- facial properties of the composites with stearic acid modi- fication were quantitatively analyzed from tensile test results with various theoretical models [52]. The attempts to improve the tribological properties of pure poly-electrolyte multilayers (PEMs) have been largely focused on transforming the structure of PEMs. It was found that the load carrying capacity of the polyelectro- lyte multilayer film increased and better anti-wear prop- erties can be obtained with compositing nanoparticles [53]. Zhang et al. [54-57] have systematically studied the tribological behavi or of composi t e Langmuir-Blodgett (LB) films consisted of organic molecule and inorganic nano- particles, they found that the nano-particles play a key role in increasing antiwear life of LB films, enhancing the load-carrying capacity of the films. In the present years, the organic-inorganic hybrid thin films have also attracted widespread attention because of their low fric- tion coefficient and relatively long antiwear life [58]. Nucleation and growth of ZnS nano-particles were achieved in a poly (diallyl dimethylammonium chloride) (PDDA)-poly(acrylic acid) (PAA) film prepared by the layer-by-layer deposition technique. It was found that ZnS nano-particles within PEMs possess load-carrying capac- ity and enhance antiwear life. Moreover, the PEMs with three reaction cycles show considerably lower friction coefficient and higher antiwear life than the PEMs with six reaction cycles [59]. Attapulgite (or palygorskite) is a clay mineral that to- gether with sepiolite forms the group of fibrous clay minerals. The structure of attapulgite was first proposed by Bradley [60]. It finds important uses as an animal waste adsorbent, pesticide carrier, decolorizing agent, in the oil refining and pharmaceutical industries and catalyst and catalyst support [61-63]. Due to its especial layer- chain structure and low price, nowadays attapulgite is receiving a great deal of attention. However, until now, not much information has been available on the friction and wear behaviors of the PTFE composite filled with nano-attapulgite. Silica/polymer composites were found to posses unique physical, chemical and electromechanical properties, which have extensive applicatio n potential [64]. The addition of various nano-sized fillers into polymer which may cause an improvement in the tribological feature at low filler contents due to a change of the wear mechanisms were reported by Wang and Xue [65]. Su and co-workers [66] revealed the friction and wear behaviors of the resulting carbon fabric composites sliding against AISI-1045 steel in a pin-on-disk apparatus. Nanofillers, such as TiO2, ZnO, SiO2 and Si3N4 were reported to be effective in improving the friction and wear p roperties of some po ly- mer and fabric composites [67,68]. 4. Use of Multi Functional Nano-Fillers Integrating various functional fillers is a principal route to develop high performance composite materials which cannot be achieved by using the single filler alone [69]. Considerable attempts have been made to incorporate different additional fillers in to SFRPs in order to further improve the tribological performance. In particular, lubricating particulates such as polytetrafluoroethylene (PTFE), graphite and molybdenum disulfide (MoS2) have been successfully used to reduce the friction coefficient and the wear rate of SFRPs [70-73]. These solid lubri- cants are generally helpful in developing a uniform trans- fer layer on the surface of metallic counterparts, which protects fib ers from severe abrasive wear. More recently, nano-sized inorganic particles have also come under consideration. For instance, Cho and Ba- hadur [74] reported that the addition of 2 vol% nano- CuO could generally enhance the wear resistance of short fiber-reinforced polyphenylene sulfide. The beneficial effect of nano-particles was attributed to the dev elop ment of a thin and unifor m transfer film. Zhang et al. [75] and Chang et al. [76] systematically studied the effect of nano-TiO2 on short fiber-reinforced epoxy under differ- ent loading conditions. They found that the addition of 5 vol% nano-TiO2 could significantly reduce the friction coefficient and the wear rate of epoxy composites than filling only with traditional fillers. The reduction was more pronoun ced at high pv (the product of pressure and velocity) conditions. The rolling effect of nano-particles was proposed to explain the low friction and wear loss of the nano-composites. Guo et al. [77] used surface modified nano-SiO2 filler to enhance the tribo-properties of epoxy composites filled with short carbon fibers. In order to improv e th e interface bonding between nanop articles and the po lymeric matrix, the nanoparticles were pretreated by graft polymerization. The additional nanoparticles (4 wt%) proved to be useful in enhancing the wear resistance and reducing the fric- tion coefficient of the SFRPs. This improvement mecha- Copyright © 2012 SciRes. WJNSE  A. A. ALY ET AL. 36 nisms of nano-particles could be caused by the increased strength of the matrix and better proper- ties o f the trans- fer film. These results have clearly shown that the addi- tion of nano-particles is potentially useful to improv e the tribological performance of SFRPs, even at a relatively low content. Nevertheless, the improvement mechanisms using nano-particles have not been deeply understood, although the pioneer researchers have addressed a number of significant factors affecting the wear behavior of these materials. 5. Conclusion A survey study has been conducted and showed that the interest in polymer-based composites for technical ap- plications, in w hich lo w frictio n and low wear, is increa se- ing. The survey showed that there is a significant im- provement in mechanical properties of the composite due to the addition of the n ano-p articles. Many typ es of nano- filling martials, including SiC, Si3N4, SiO2, ZrO2, ZnO, CaCO3, Al2O3, TiO2, and nano-CuO, have been used to different types of polymers such as PEEK; PMMA; PTFE and epoxy. The mechanical properties which have been improved include fatigue resistance, fracture toughness, tensile strength, wear resistance, and friction coefficient. From the results of the conducted studies there is a con- siderable increase in wear resistance and decrease in the coefficient of friction. The change of wear resistance and friction coefficient depends on the size and volume frac- tion of the nano-filling materials. It is also possible to use multi functional fillers to develop high performance com- posite materials which cannot be achieved by using a single filler. 6. Acknowledgements This study is supported by Taif University under a con- tract No. 1-432-1171. The University is highly acknowl- edged for its fi nanci al s u pp ort. REFERENCES [1] A. S. Manmode, D. M . Sakarkar and N. M. Mahajan, “Nano- particles-Tremendous Therapeutic Potential: A Revier,” International Journal of PharmTech Research, Vol. 1, No. 4, 2009, pp. 1020-1027. [2] P. Ayak, S. K. Sahoo, A. Behera, P. K. Nanda, P. L. Nayak and B. C. Guru, “Synthesis and Characterization of Soy Protin Isolate/MMT Nanocomposite Film for the Control Release of the Drug Ofloxacin,” World Journal of Nano Science and Engineering, Vol. 1, No. 2, 2011, pp. 27-36. doi:10.4236/wjnse.2011.12005 [3] L. E. Nielsen and R. F. Landel, “Mechanical Properties of Polymers and Composites,” 2nd Edition, Marcel Deckker, New York, 1994. [4] S. Nikkeshi, M. Kudo and T. Masuko, “Dynamic Viscoe- lastic Properties and Thermal Properties of Powder-Ep- oxy Resin Composites,” Journal of Applied Polymer Sci- ence, Vol. 69, No. 13, 1998, pp. 2593-2598. doi:10.1002/(SICI)1097-4628(19980926)69:13<2593::AI D-APP9>3.0.CO;2-5 [5] K. Zhu and S. Schmauder, “Prediction of the Failure Pro- perties of Short Fiber Reinforced Composites with Metal and Polymer Matrix,” Computational Materials Science, Vol. 28, No. 3-4, 2003, pp. 743-748. doi:10.1016/j.commatsci.2003.08.028 [6] I. H. Tavman, “Thermal and Mechanical Properties of Copper Powder Filled Polyethylene Composites,” Pow- der Technology, Vol. 91, No. 1, 1997, pp. 63-67. doi:10.1016/S0032-5910(96)03247-0 [7] T. Ahmad and O. Mamat, “The Development and Char- acterization of Zirconia-Silica Sand Nanoparticles Com- posites,” World Journal of Nano Science and Engineering, Vol. 1, No. 1, 2011, pp. 7-14. doi:10.4236/wjnse.2011.11002 [8] K. Jung-il, P. H. Kang and Y .C. Nho, “Positive Tem- perature Coefficient Behavior of Polymer Composites Having a High Melting Temperature,” Journal of Applied Polymer Science, Vol. 92, No. 1, 2004, pp. 394-401. doi:10.1002/app.20064 [9] S. T. Peters, “Handbook of Composites,” 2nd Edition, Chapman and Hall, London, 1998. [10] R. N. Rothon, “Mineral Fillers in Thermoplastics I: Raw Materials and Processing,” Springer, Berlin, 1999. [11] M. Sumita, T. Shizuma, K. Miyasaka and K. Ishikawa, “Effect of Reducible Properties of Temperature, Rate of Strain, and Filler Content on the Tensile Yield Stress of Nylon 6 Composites Filled with Ultrafine Particlesm,” Journal of Macromolecular Science: Physics, Vol. B22, No. 4, 1983, pp. 601-618. [12] Q.-H. Wang, J. Xue, W. Shen and W. Liu, “An Investiga- tion of the Friction and Wear Properties of Nanometer Si3N4 Filled PEEK,” Wear, Vol. 196, No. 1-2, 1996, pp. 82-86. doi:10.1016/0043-1648(95)06866-X [13] Q.-H. Wang, Q. Xue, H. Liu, W. Shen and J. Xue, “The Effect of Particle Size of Nanometer ZrO2 on the Tri- bological Behaviour of PEEK,” Wear, Vol. 198, No. 1-2, 1996, pp. 216-219. doi:10.1016/0043-1648(96)07201-8 [14] M. C. Kuo, C. M. Tsai, J. C. Huang and M. Chen, “PEEK Composites Reinforced by Nano-Sized SiO2 and Al2O3 Particulates Materials,” Chemistry and Physics, Vol. 90, No. 1, 2005, pp. 185-195. [15] T. E. Attwood, P. C. Dawson, J. L. Freeman, L. R. J. Hoy, J. B. Rose and P. A. Staniland, “Synthesis & Properties of Polyaryletherketones,” Polymer, Vol. 22, No. 8, 1981, pp. 1096-1103. doi:10.1016/0032-3861(81)90299-8 [16] P. K. Goyal, Y. S. Negi and A. N. Tiwari, “Preparation of High Performance Composites Based on Aluminum Ni- tride/Poly(Ether-Ether-Ketone) and Their Properties,” Euro- pean Polymer Journal, Vol. 41, No. 9, 2005, p. 2034- 2044. doi:10.1016/j.eurpolymj.2005.04.009 [17] P. Cassagnau, “Payne Effect and Shear Elasticity of Sil- ica-Filled Polymers in Concentrated Solutions and in Molten State,” Polymer, Vol. 44, No. 8, 2003, pp. 2455- Copyright © 2012 SciRes. WJNSE  A. A. ALY ET AL. 37 2462. doi:10.1016/S0032-3861(03)00094-6 [18] M. C. Kuo, J. C. Huang and M. Chena “Non-Isothermal Crystallization Kinetic Behavior of Alumina Nanoparticle Filled Poly(Etheretherketone),” Materials Chemistry and Physics, Vol. 99, No. 2-3, 2006, pp. 258-268. doi:10.1016/j.matchemphys.2005.10.021 [19] Q. H. Wang, Q. J. Xue, W. M. Liu and J. M. Chen, “The Friction and Wear Characteristics of Nanometer SiC and Polytetrafluoroethy lene Filled Polyetheretherketone,” Wear, Vol. 243, No. 1-2, 2000, pp. 140-146. doi:10.1016/S0043-1648(00)00432-4 [20] C. J. Schwartz and S. Bah dur, “Studies on the Tribological Behavior and Transfer Film-Counterface Bond Strength for Polyphenylene Sulfide Filled with Nanoscale Alumina Particles,” Wear, Vol. 237, No. 2, 2000, pp. 261-273. doi:10.1016/S0043-1648(99)00345-2 [21] E. Reynaud, C. Gauthier and J. Perez, “Nanophases in Polymers,” Revue De Metallurgie , Vol. 98, 1999, pp. 169- 176. [22] Q. H. Wang, Q. J. Xue and W. C. Shen, “The Fric tion a nd Wear Properties of Nanometre SiO2 Filled Polyethere- therketone,” Tribology Internatio nal, Vol. 30, No. 3, 1997, 193-197. doi:10.1016/S0301-679X(96)00042-4 [23] M. Q. Zhang, M. Z. Rong, S. L. Yu, B. Wetzel and K. Friedrich, “Improvement of Tribological Performance of Epoxy by the Addition of Irradiation Crafted Nano-Ino ganic Particles,” Macromolecular Materials and Engi- neering, Vol. 287, No. 2, 2002, 111-115. doi:10.1002/1439-2054(20020201)287:2<111::AID-MA ME111>3.0.CO;2-I [24] F. Li, K. Hu and J. Li, “The Friction and Wear Character- istics of Nanometer ZnO Filled Polytetrafluoroethylene,” Wear, Vol. 249, No. 10-11, 2002, pp. 877-882. doi:10.1016/S0043-1648(01)00816-X [25] W. G. Sawyer, K. D. Freudenberg, P. Bhimaraj and L. S. Schadler, “A Study on the Friction and Wear Behavior of PTFE Filled with Alumina Nanoparticles,” Wear, Vol. 254, No. 5, 2003, pp. 573-580. [26] A. Hoshino, K. Fujioka, T. Oku, S. Nakamura, M. Suga, Y. Yamaguchi, K. Suzuki and M. Yasuhara, “Quantum dots Targeted to the Assigned Organelle in Living Cells,” Microbiology and Immunology, Vol. 48, No. 12, 2004, pp. 985-994. [27] I. Yamamoto, T. Higashihara and T. Kobayashi, “Effect of Silica-Particle Characteristics on Impact/Usual Fatigue Properties and Evaluation of Mechanical Characteristics of Silica-Particle Epoxy Resins,” JSME Internat ional Jou r- nal, Vol. 46, No. 2, 2003, pp. 145-153. doi:10.1299/jsmea.46.145 [28] W. J. Cantwell and A. C. Moloney, “Fractography and Failure Mechanisms of Polymers and Composites,” Eles- vier, Ameserdam, 1994. [29] R. J. Young and P. W. R. Beaumont, “Failure of Brittle Polymers by Slow Crack Growth: Part 3 Effect of Com- position upon the Fracture of Silica Particle-Filled Epoxy resin Composites,” Journal of Materials Science, Vol. 12, No. 4, 1997, pp. 684-692. [30] Q. Wang, Q. Xue, H. Liu, W. Shen and J. Xu, “The Effect of Particle Size of Nanometer ZrO2 on the Tribological Behaviour of PEEK,” Wear, Vol. 198, No. 1-2, 1996, pp. 216-219. doi:10.1016/0043-1648(96)07201-8 [31] Q. Wang, J. Xue, W. Shen and W. Liu, “An Invest igation of the Friction and Wear Properties of Nanometer Si3N4- Filled PEEK,” Wear, Vol. 196, No. 1-2, 1996, pp. 82-86. doi:10.1016/0043-1648(95)06866-X [32] Q. Wang, Q. Xue, H. Liu, W. Shen and J. Xue, “The Ef- fect of Particle Size of Nanometer ZrO2 on the Tribo- lological Behavior of PEEK,” Wear, Vol. 198, 1996, pp. 216-219. doi:10.1016/0043-1648(96)07201-8 [33] Q. Wang, J. Xue, W. Shen and Q. Xue, “The Effect of Nanometer SiC Filler on the Tribological Behavior of PEEK,” Wear, Vol. 209, No. 1-2, 1997, pp. 316-321. doi:10.1016/S0043-1648(97)00015-X [34] Q. Wang, Q. Xue and W. Shen, “The Friction and Wear Properties of Nanometre SiO2-Filled Polyetheretherke- tone, Tribology International, Vol. 30, No. 3, 1997, pp. 193-197. doi:10.1016/S0301-679X(96)00042-4 [35] Q. Wang, Q. Xue, W. Liu and J. Chen, “The Friction and Wear Characteristics of Nanometer SiC and Polytetra- fluoroethylene-Filled Polyetheretherketone,” Wear, Vol. 243, No. 1-2, 2000, pp. 140-146. doi:10.1016/S0043-1648(00)00432-4 [36] Q. Wang, Q. Xue, W. Liu and J. Chen, “Effect of Nano- meter SiC Filler on the Tribological Behavior of PEEK under Distilled Water Lubrication,” Journal of Applied Polymer Science, Vol. 78, No. 3, 2000, pp. 609-614. doi:10.1002/1097-4628(20001017)78:3<609::AID-APP1 60>3.0.CO;2-D [37] C. J. Schwartz and S. Bahadur, “Studies on the Tri- bological Behavior and Transfer Film-Counterface Bond Strength for Polyphenylene Sulfide Filled with Nanoscale Alumina Particles,” Wear, Vol. 237, No. 2, 2000, pp. 261- 273. doi:10.1016/S0043-1648(99)00345-2 [38] E. Petrovicova, R. Knight, L. S. Schadler and T. E. Twardowski, “Nylon 11/Silica Nanocomposite Coatings Applied by the HVOF Process, II. Mechanical and Barrier Properties,” Journal of Applied Polymer Science, Vol. 78, No. 13, 2000, pp. 2272-2289. doi:10.1002/1097-4628(20001220)78:13<2272::AID-AP P50>3.0.CO;2-U [39] M. Avella, M. E. Errica and E. Martuscelli, “Novel PMMA/CaCO3 Nanocomposites Abrasion Resistant Pre- pared by an in Situ Polymerization Process,” Nano Letters, Vol. 1, No. 4, 2001, pp. 213-217. doi:10.1021/nl015518v [40] L. Yu, S. Yang, H. Wang and Q. Xue, “An Investigation of the Friction and Wear Behaviors of Micrometer Cop- per Particle-Filled Polyoxymethylene Composites,” Jour- nal of Applied Polymer Science, Vol. 77, No. 11, 2000, pp. 2404-2410. doi:10.1002/1097-4628(20000912)77:11<2404::AID-AP P8>3.0.CO;2-Q [41] W. Sawyer, K. Freudenberg, P. Bhimaraj and L. Schadler, “A Study on the Friction and Wear Behavior of PTFE Filled with Alumina Nanoparticles,” Wear, Vol. 254, No. 5-6, 2003, pp. 573-580. doi:10.1016/S0043-1648(03)00252-7 [42] D. Burris and W. G. Sawyer, “Tribological Sensitivity of Copyright © 2012 SciRes. WJNSE  A. A. ALY ET AL. 38 PTFE-Alumina Nanocomposites to a Range of Tradi- tional Surface Finishes,” Tribology Transactions, Vol. 48, No. 2, 2005, pp. 1-7. doi:10.1080/05698190590923842 [43] M. Fuji, T. Takei, T. Watanabe and M. Chikazawa, “Ef- fect of Wettability on Adhesion Force between Silica Par- ticles Evaluated by Atomic Force Microscopy Measure- ment as a Function of Relative Humidity, ” Langmuir, Vol. 15, No. 13, 1999, pp. 4584-4589. doi:10.1021/la981533c [44] S. C. Chung, W. G. Hahm, S. S. Im and S. G. Oh, “Poly (Ethylene Terephthalate)(PET) Nanocomposites Filled with Fumed Silicas by Melt Compounding,” Macromo- lecular Research, Vol. 10, No. 4, 2002, pp. 221-229. doi:10.1007/BF03218309 [45] J. W. Cho and D. R. Paul, “Nylon 6 Nanocomposites by Melt Compounding,” Polymer, Vol. 42, No. 3, 2001, pp. 1083-1094. doi:10.1016/S0032-3861(00)00380-3 [46] C. M. Liauw, P. Dumitru, G. C. Lees, M. L. Clemens and R. N. Rothon, “Interfacial Modification of Polystyrene- blockpolybutadiene-Block-Polystyrene/Magnesium Hydro- xide Composites, 1 Effect on Rheological Properties,” Macromolecular Materials and Engineering, Vol. 288, No. 5, 2003, pp. 412-420. doi:10.1002/mame.200390035 [47] C. M. Liauw, R. N. Rothon, G. C. Lees, P. Dumitru, Z. Iqbal, V. Khunova and P. Alexy, “Filler Surface Modifi- cation with Organic Acids and Derivatives,” Proceedings of Functional Effect Fillers, Berlin, 2000. [48] S. H. Ahn, S. H. Kim and S. G. Lee, “Synthesis and Characterization of Soluble Polypyrrole with Improved Electrical Conductivity,” Journal of Applied Polymer Sci- ence, Vol. 84, No. 14, 2002, pp. 2583-2590. doi:10.1002/app.10281 [49] S. H. Ahn, S. H. Kim and B. C. Kim, “Mechanical Prop- erties of Silica Nanoparticle Reinforced Poly (Ethylene 2, 6-Naphthalate), Macromolecular Research, Vol. 12, No. 3, 2004, pp. 293-302. doi:10.1007/BF03218403 [50] G. Decher, “Fuzzy Nanoassemblies: Toward Layered Polymeric Mul ticom-Posit es, Science, Vol. 277, No. 5330, 1997, pp. 1232-1238. doi:10.1126/science.277.5330.1232 [51] W. F. Bradley, “The Structural Scheme of Attapulgite,” American Mineralogist, Vol. 25, 1940, pp. 405-410. [52] Y. H. Lai, M. C. Kuo, J. C. Huang and M. Chen, “Ther- momechanical Properties of Nanosilica Reinforced PEEK Composites,” Key Engineering Materials, Vol. 351, 2007, pp. 15-20. doi:10.4028/www.scientific.net/KEM.351.15 [53] Y. B. Guo, D. G. Wang and S. W. Zhang, “Adhesion and friction of Nanoparticles/Polyelectrolyte Multilayer Films by AFM and Micro-Tribometer,” Tribology International, Vol. 44, No. 7-8, 2011, pp. 906-915. doi:10.1016/j.triboint.2011.03.007 [54] Q. B. Wang, M. L. Gao and S. W. Zhang, “Nanofriction Properties of Molecular Deposition Films,” Science in China (Series B), Vol. 43, No. 2, 2003, pp. 12-14. [55] P. Zhang, Q. Xue, Z. Du and Z. Zhang, “The Tribological Behavior of LB Films of Fatty Acids and Nanoparticles,” Wear, Vol. 242, No. 1-2, 2000, pp. 147-151. doi:10.1016/S0043-1648(00)00405-1 [56] P. Zhang, Q. Xue, Z. Du, et al., “The Tribological Be- havior of Ordered System Ultrathin Films,” Wear, Vol. 254, No. 10, 2003, pp. 959-964. doi:10.1016/S0043-1648(03)00300-4 [57] G. T. Gu, Z. J. Zhang and H. X. Dang, “Preparation and Characterization of Hydrophobic Organic-Inorganic Com- posite Thin Films of PMMA/SiO2/TiO2 with Low Fric- tion Coefficient,” Applied Surface Science, Vol. 221, No. 1-4, 2004, pp. 129-135. doi:10.1016/S0169-4332(03)00865-1 [58] G. B. Yang, H. X. Ma, Z. S. Wu and P. Y. Zhang, “Tri- bological Behavior of ZnS-Filled Polyelectrolyte Multi- layers,” Wear, Vol. 262, No. 3-4, 2007, pp. 471-476. doi:10.1016/j.wear.2006.06.018 [59] M. S. Barrios, L. V. F. Gonzalez, M. A. V. Rodriguez and J. M. M. Pozas, “Acid Activation of a Palygorskite with HCl: Development of Physico-Chemical, Textural and Surface Properties,” Applied Clay Science, Vol. 10, No. 3, 1995, pp. 247-258. doi:10.1016/0169-1317(95)00007-Q [60] A. Corma, A. Misfud and E. Sanz, “Influence of the Chemical Composition and Textural Characteristics of Palygorskite on the Acid Leaching of Octahedral Ca- tions,” Clay Minerals, Vol. 22, No. 2, 1987, pp. 225-232. doi:10.1180/claymin.1987.022.2.10 [61] C. N. Rhodes, M. Franks, G. M. B. Parkes and D. R. Brown, “The Effect of Acid Treatment on the Activity of Clay Supports for ZnCl2 Alkylation Catalysts,” Journal of the Chemical Society, Chemical Communications, Vol. 12, 1991, pp. 804-807. doi:10.1039/c39910000804 [62] S. Bahadur, “The Development of Transfer Layers and Their Role in Polymer Tribology,” Wear, Vol. 245, No. 1-2, 2000, pp. 92-99. doi:10.1016/S0043-1648(00)00469-5 [63] T. Suwa, M. Takehisa and S. Machi, “Melting and Crys- tallization Behavior of Poly (Tetrafluoroethylene). New Method for Molecular Weight Measurement of Poly (Tetrafluoroethylene) Using a Differential Scanning Calo- rimeter,” Journal of Applied Polymer Science, Vol. 17, No. 11, 1973, pp. 3253-3257. doi:10.1002/app.1973.070171102 [64] I. A. Ovid’Ko, “Deformation of Nanostructures,” Science, Vol. 295, No. 5564, 2002, pp. 2382-2386. [65] Q. H. Wang and Q. J. Xue, “Wear Mechanisms of Poly- etheretherketone Composites Filled with Various Kinds of SiC,” Wear, Vol. 213, No. 1-2, 2007, pp. 54-58. [66] F. H. Su, Z. Z. Zhang, K. Wang, W. Jiang and W. M. Liu, “Friction and Wear Properties of Carbon Fabric Compos- ites Filled with Nano-Al2O3 and Nano-Si2N4,” Journal of Composites Part A: Applied Science and Manufacturing, Vol. 37, No. 9, 2006, pp. 1351-1357. doi:10.1016/j.compositesa.2005.08.017 [67] E. Chabert, M. Bornert, E. Bourgeat-Lami, J. Y. Cavaille and C. Dendievel, “Filler-Filler Interactions and Viscoe- lastic Behavior of Polymer Nanocomposites,” Materials Science and Engineering: A, Vol. 381, No. 1-2, 2004, pp. 320-330. doi:10.1016/j.msea.2004.04.064 [68] F. H. Su, Z. Z. Zhang and W. M. Liu, “Study on the Fric- tion and Wear Properties of Glass Fabric Composites Filled with Nano- and Micro-Particles under Different Conditions.” Materials Science and Engineering: A, Vol. Copyright © 2012 SciRes. WJNSE  A. A. ALY ET AL. Copyright © 2012 SciRes. WJNSE 39 392, No. 1-2, 2005, pp. 359-365. doi:10.1016/j.msea.2004.09.036 [69] K. Friedrich, Z. Zhang and P. Klein, “Wear of Polymer- composites,” In: P. Sydenham and R. Thorn, Eds., Hand- book of Measuring System Design, John Wiley & Sons, Hoboken, 2005. [70] J. Bijwe J. J. Rajesh A. Jeyakumar, A. Ghosh and U. S. Tewari, “Influence of Solid Lubricants and Fiber Rein- forcement on Wear Behavior of Polyethersulphone,” Tri- bology International, Vol. 33, No. 10, 2000, pp. 697-706. doi:10.1016/S0301-679X(00)00104-3 [71] J. Wang, M. Gua, S. Bai and S. Ge, “Investigation of the Influence of MoS2 Filler on the Tribological Properties Ofcarbon Fiber Reinforced Nylon 1010 Composites,” Wear, Vol. 255, No. 1-6, 2003, pp. 774-779. doi:10.1016/S0043-1648(03)00268-0 [72] J. Bijwe V. Naidu, N. Bhatnagar and M. Fahim, “Opti- mum Concentration of Reinforcement and Solid Lubri- cant Tinpolyamide 12 Composites for Best Tribo-Per- formance in Two Wear Modes,” Tribology Letters, Vol. 21, 2006, pp. 59-66. [73] X. R. Zhang, X. Q. Pei and Q. H. Wang, “Effect of Solid lubricant on Thetribological Properties of Polyimide Com- posites Reinforced with Carbon Fibers,” Journal of Rein- forced Plastics and Composites, Vol. 27, No. 18, 2009, pp. 2005-2012. doi:10.1177/0731684408090718 [74] M. H. Cho and S. Bahadur, “Study of the Tribological Synergistic Effects in CuO-Filled and Fiber-Reinforced Polyphenylenesulfide Composites,” Wear , Vol. 258, No. 5-6, pp. 835-845. doi:10.1016/j.wear.2004.09.055 [75] Z. Zhang, C. Breidt, L. Chang, F. Haupert and K. Frie- drich, “Enhancement of the Wear Resistance of Epoxy: Short Carbon Fibe r, Gra phite , PTFE and Nano-TiO2” Com- posites Part A, Vol. 35, No. 12, 2004, pp. 1385-1392. doi:10.1016/j.compositesa.2004.05.005 [76] L. Chang, Z. Zhang, C. Breidt and K. Friedrich, “Tri- bological Properties of Epoxy Nanocomposites: I. En- hancement of the Wear Resistance by Nano-TiO2 Parti- cles,” Wear, Vol. 258, No. 1-4, pp. 141-148. doi:10.1016/j.wear.2004.09.005 [77] Q. Guo, M. Z. Rong, G. L. Jia, K. T. Lau and M. Q. Zhang, “Sliding Wear Performance of Nano-SiO2/Short Carbon Fiber/Epoxy Hybrid Composites,” Wear, Vol. 266, No. 7-8, 2009, pp. 658-665. doi:10.1016/j.wear.2008.08.005

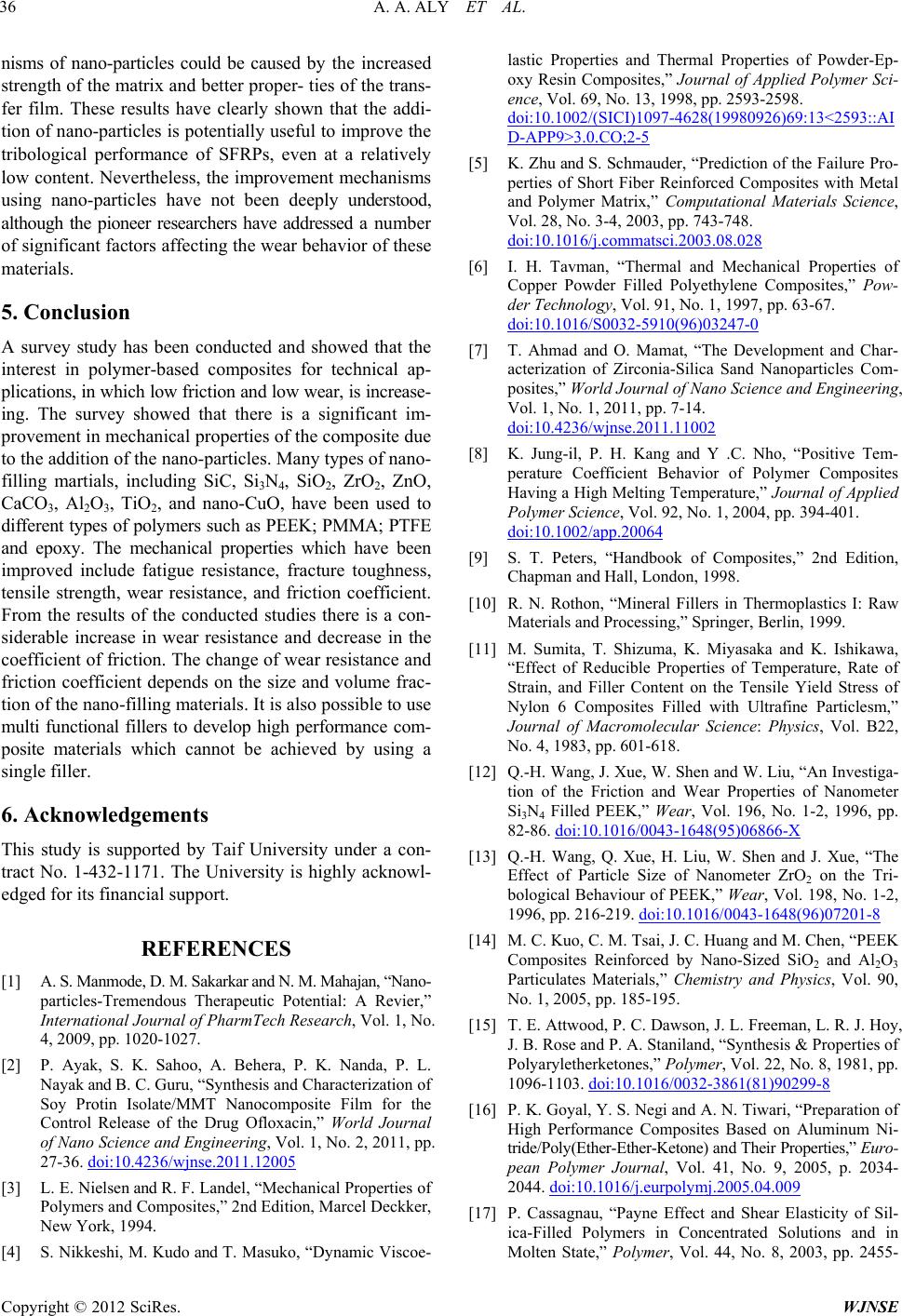

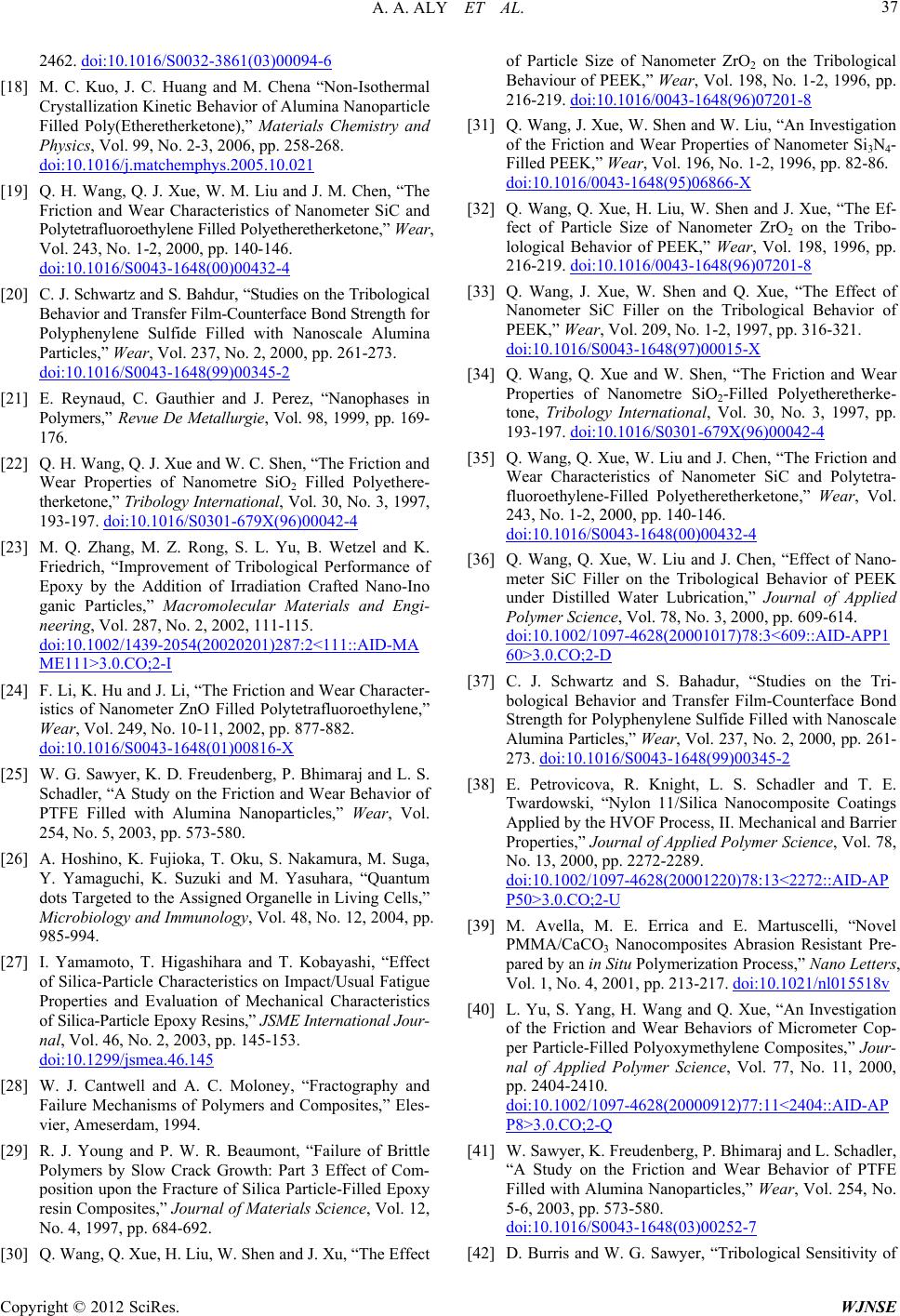

|