Journal of Modern Physics

Vol.3 No.8(2012), Article ID:21696,10 pages DOI:10.4236/jmp.2012.38104

Thermal Expansion of Solids

Faculty of Mechanical Engineering, Politechnika Koszalińska, Koszalin, Poland

Email: *Tadeusz.Hryniewicz@tu.koszalin.pl

Received June 13, 2012; revised July 7, 2012; accepted July 29, 2012

Keywords: Thermal Expansion; Coefficient of Linear Thermal Expansion; Relative Length Increment; Temperature Constant; Temperature Potential Field; Deformation Potential Field; Nominal Potential Field; Deformation-Temperature Space

ABSTRACT

The work covers a novel approach to the description of the phenomenon of thermal expansion of solids. The reason for undertaking the scientific quest is presented to follow with the analysis of existing knowledge on the characteristics of phenomenon of thermal expansion of bodies being in the state of aggregation. A critical approach to the existing law of the linear thermal expansion is given. The paper presents an adequate approach to this considered phenomenon. The description provides parametric and functional characteristics of this phenomenon. The relationships of the coefficients of linear expansion on temperature for particular interstate zones, as well as the initial coefficients related to these zones, are presented. In the summary a synthesis of all actions and considerations with the directions to the adequate knowledge with advantage on the subjected phenomenon has been performed. It regards also to the latest thermal characteristics of solids, referred to the phase transformations. All they are realized by dilatometric studies together with determination of curves of thermal expansions of solids.

1. Reason for Undertaking the Subject

This work is devoted to the linear extension of solids. The subject was undertaken due to the lack of a proper description or a very superficial approximate knowledge on the phenomenon and the characteristics existent in the literature. It touches mainly quantitative evaluation of the phenomenon, description of its characteristics, i.e. a relationship of the length relative increment of a heated body on temperature.

Until now there is no analytical description of this magnitude which results from a complex picture of the thermal expansion curve. Therefore, instead of this, there are linear approximate characteristics formed being the dependence of the length increment of the heated body on temperature. It has been the result of linearization of the real course which de facto is non-linear and has the character of curve rising by turns progressively and degressively. That curve of the thermal expansion is to be presented in this work.

That exoteric knowledge on the phenomenon has not been reconstructed, being still the so called zero or first approximation of the described reality. The author of [1] also has noticed the stoppage in the creative actions on the first approximation referring them generally to the phenomenon of oscillation motion.

Such a simplified approach cannot be tolerated. It cannot be justified by the immediate needs of practice. Especially it is important with the scientific approach. The adequate description of the course of expansion of solids requires a return to the source, which is the primary general differential equation. It may allow to obtain further detailed characteristics as the relationships of: the relative length increment on temperature, the growth length increment on temperature, which is the coefficient of the linear expansion on that independent variable.

2. Existent, Exoteric Knowledge on Characteristics of the Phenomenon of Thermal Expansion of Solids

The accessible exoteric knowledge, covering thermal expansion of solids, is not adequate. With unsuitable foundations, it does not reflect the reality. At the beginning, one may assume that in a broad range of temperature  the relative increment of the body length

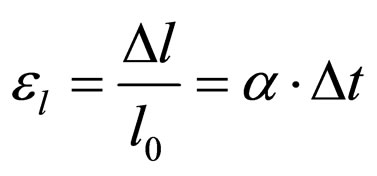

the relative increment of the body length  is a linear function of changes of the first magnitude. That means,

is a linear function of changes of the first magnitude. That means,

(1)

(1)

where α is the coefficient of a linear thermal expansion.

The derived formula on the direct increment of length, as presented here:

(2)

(2)

forms the existent law of the linear thermal expansion of solids. It is known that the direct growth of length ∆l of a body at heating is directly proportional to its initial length lo, to the temperature growth ∆t and depends on the kind of material. This dependence is expressed in a number as the coefficient characteristic for each material. This is the coefficient of a linear thermal expansion α— expressing to what extent a rod of the initial length of one meter (1 m) will be longer if the temperature rises of 1˚C.

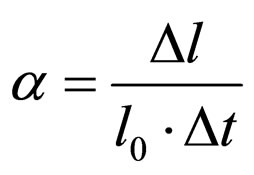

The measure/unit of that coefficient results from the describing formula, being the result of a proper transformation of the dependence (2), that is

(3)

(3)

The action on measures of the component magnitudes leads to the final result, that is

(4)

(4)

Now, taking into account the definitions of the direct variables: ,

,  , one may bring the Equation (2) to another, more developed form, which is:

, one may bring the Equation (2) to another, more developed form, which is:

(5)

(5)

Furthermore, after carrying some operations, that dependence may be written as:

(6)

(6)

where the symbol l means the length of the body after heating it up to the temperature t, and t0 refers to the initial temperature. It is worthy adding that the appearing in the formula, and earlier defined, the coefficient α is determined quantitatively for the temperatures of interval 0˚C up to 100˚C.

In the next part of the work the literature examples of thermal characteristics referred to different materials as well as to the differing initial structural states of the determined materials will be given. Those real non-linear curves with peculiar points cannot be linearized nor substituted by a continuous non-linear function. The description should refer to the consecutive fragments of the curve, with the fragments being between the neighbouring peculiar points.

3. Literature on the Dilatometric Curves

Let us begin with the above mentioned the dilatometric curves related to copper [2]. That is the dependence of the relative length increment of material on the direct temperature increase (Figure 1), i.e. . A small range of the temperature changes, covering 100˚C, has been marked. The characteristic zones, where the courses of the relative length increment differ significantly both quantitatively and qualitatively, are visible in Figure 1. In the zero zone (O) the effect of temperature has not been marked, in the first zone (I) a progressive increase of the relative length increment takes place, whereas the second zone is characteristic with a degressive increase of the latter magnitude. Further increase of temperature will cause the development of changes of the dependent variable and with this the increase of the second zone of variability of the relative length increment, explained in [3]. In a determined interval of the temperature changes the degressive course will be substituted again by a progressive one.

. A small range of the temperature changes, covering 100˚C, has been marked. The characteristic zones, where the courses of the relative length increment differ significantly both quantitatively and qualitatively, are visible in Figure 1. In the zero zone (O) the effect of temperature has not been marked, in the first zone (I) a progressive increase of the relative length increment takes place, whereas the second zone is characteristic with a degressive increase of the latter magnitude. Further increase of temperature will cause the development of changes of the dependent variable and with this the increase of the second zone of variability of the relative length increment, explained in [3]. In a determined interval of the temperature changes the degressive course will be substituted again by a progressive one.

These characteristic different courses in the zones: first (I), second (II), and then third (III) may be explained by different types of the deformations of this material (Figure 1); resilient/springy, elastic, and plastic, respectively. Lack of the reaction of copper on temperature in the zero zone (O) comes out from the thermal inertia of the material, resulting from the initial proper structural stresses.

The dilatometric curve for an abrasive material containing 1% TiS2 (Figure 2) is taken from [4,5]. Here also the characteristic zones are visible. At 900˚C a transition of TiS2 into rutile TiO2 occurs, being one of the reasons of the abnormal intensive growth of thermal expansion in the temperature interval 780˚C - 900˚C. One may admit that to avoid the abnormal expansion, the abrasive grains undergo to calcinations/roasting in the process of monocorundum/alumina manufacture.

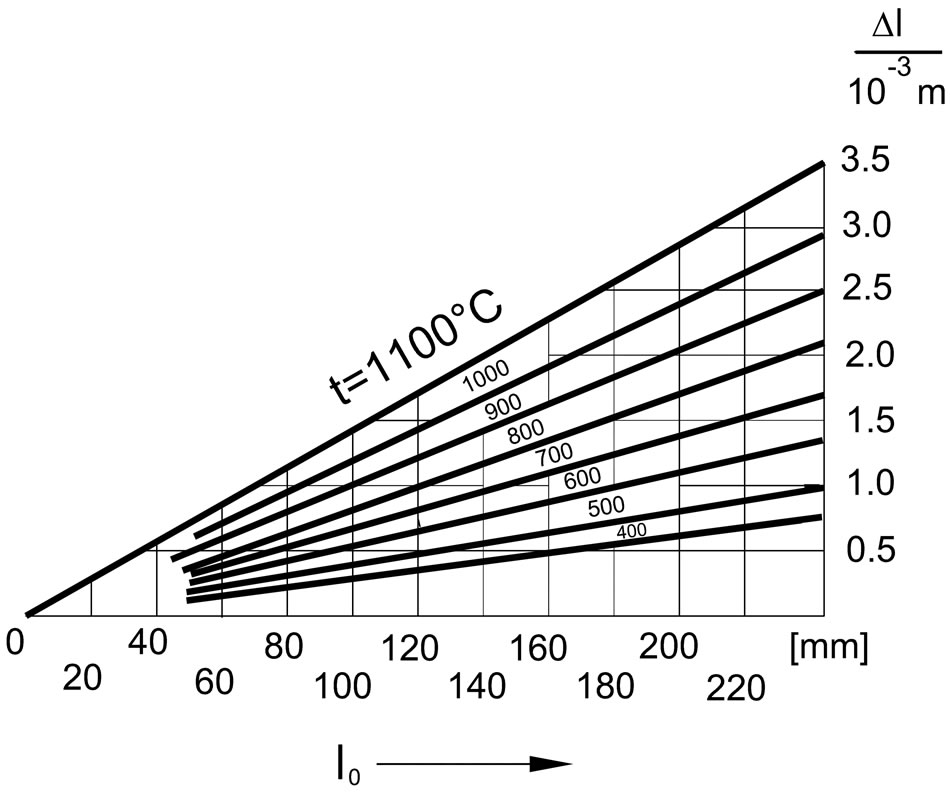

In [6] there is the diagram of the increase of linear dimensions  presented for a bearing steel LH15 dependent on its temperature t and the initial dimensions

presented for a bearing steel LH15 dependent on its temperature t and the initial dimensions  (Figure 3). It has been excerpted from the work [7].

(Figure 3). It has been excerpted from the work [7].

Figure 1. A dilatometric curve of copper [2].

Figure 2. Dilatometric curve for an abrasive material containing 1% TiS2 [4].

Figure 3. Increase of the linear dimensions Δl of a bearing steel LH15 dependent on its temperature t and the initial dimensions l0 [6].

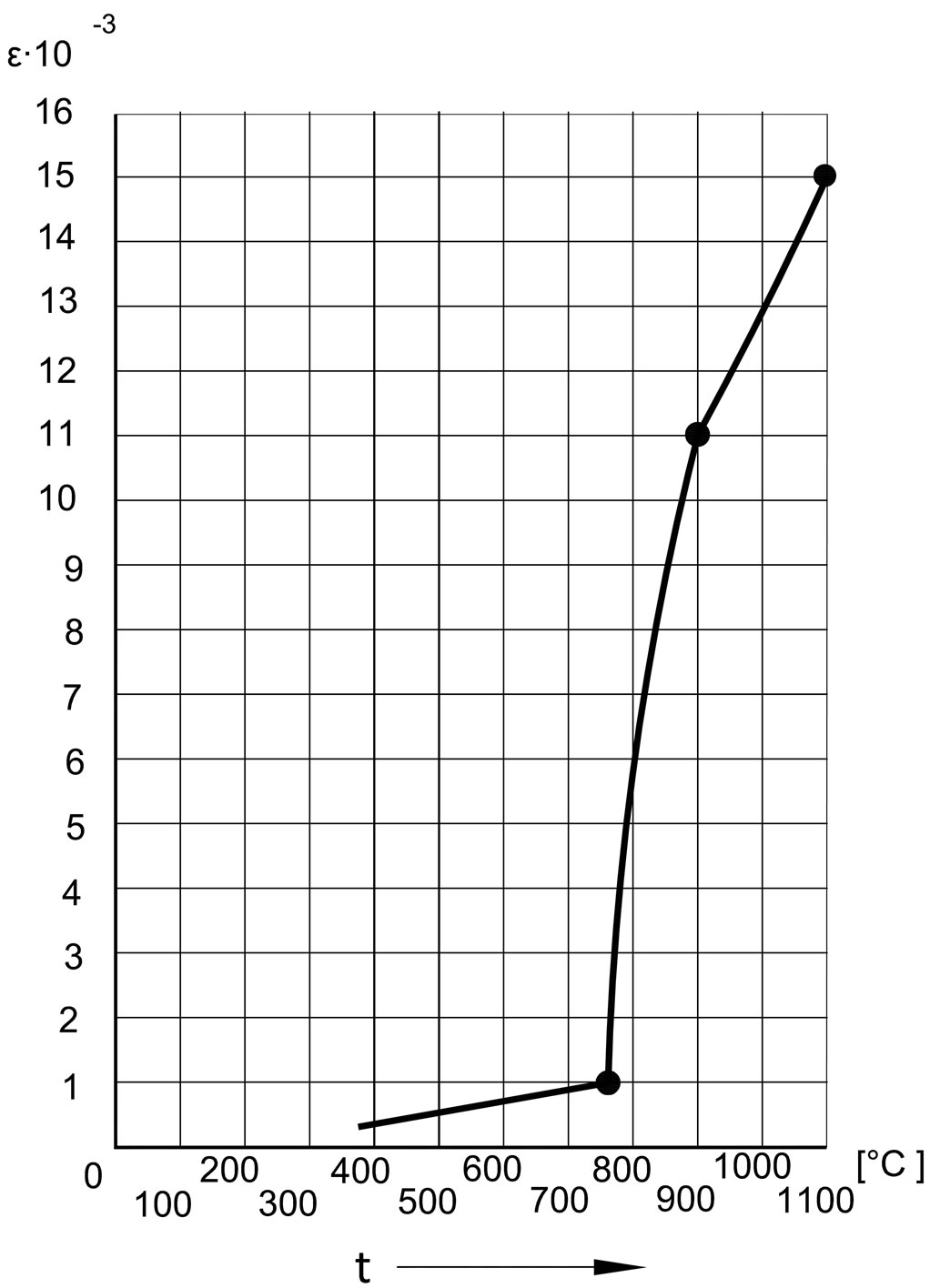

Based on these data, the diagram presenting the dependence of the relative length increment on temperature was performed (Figure 4). Here also the particular zones of changes of this dependent variable are clearly visible. They result from the determined phase transformations, described in [6].

Another example of the dilatometric curve prepared for a tool carbon steel N11E is presented in Figure 5. It has been excerpted from [8]. Here also the determined phase transformations decided of a specific course of the curve. At the beginning there is no change in the sample length caused by the temperature increase. First changes of this magnitude occur at 95˚C. That indicates the beginning of the tetragonal martensite transition into a regular martensite. At 150˚C the martensite is tempered in a great extent. Further heating results in the transition of the retained austenite also into the regular martensite. In the range of 300˚C - 360˚C a troostite structure is formed when, due to the eased diffusion, some coagulation of the cementite phase in the ferritic matrix appears. In case of further heating of the steel, a progressive coagulation of the cementite particles in the ferritic matrix occurs and a fine pearlite structure is formed. The transition of the pearlite into austenite results in the shrinkage of the steel.

Figure 4. Dilatometric curve for a bearing steel LH15 [6].

Figure 5. Dilatometric curve for a hardened carbon tool steel N11E [8].

The presented examples clearly illustrate the specifics of the phenomenon of the length increase of heated material. There are some peculiar points observed which divide the temporary thermal states (thresholds) of the material. Between these points the determined types of deformation occur. The different interphase structural transformations accompany to these phenomena.

The relative linear deformations do not progress in a continuous manner in the entire broad interval of the temperature changes. This is a quantified magnitude; that means the thermal states of the material are discrete, non-continuous in its character. A continuous variability of the magnitude takes place only in the zones of interstate spaces.

The following actions are directed onto the description of the structure of changes of relative expansion of solids. The fundamentals are in the source general differential equation related to all this type of changes of the physical magnitudes.

4. On the Adequate Description of the Considered Thermal Phenomenon

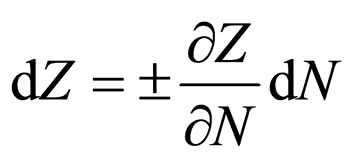

At the cognitive source of all phenomena, occurring with a variable rate, intensity or velocity, between the neighbouring energetic states, there is a general differential description, that is the equation

(7)

(7)

where: dZ—total differential of the magnitudes forming dependent variables, dN—total differential of the magnitudes forming independent variables, —partial differential of the dependent magnitudes against the independent ones. The signs

—partial differential of the dependent magnitudes against the independent ones. The signs  are the algebraic operators with a determined function. The sign

are the algebraic operators with a determined function. The sign  confirms only the physical meaning of the determined mathematical description, whereas the sign

confirms only the physical meaning of the determined mathematical description, whereas the sign  ascribes a physical meaning to the record.

ascribes a physical meaning to the record.

This general source differential equation has been presented in [9,10], and it has been referred to the detailed technological matters under different initial conditions. These initial conditions of a phenomenon or a process are connected with the beginning of measurement of the determined physical magnitudes. The measurement of these magnitudes is necessary but not a sufficient condition. The sufficient condition is limited to measure them at the very beginning of the phenomenon.

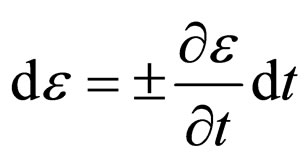

The record of the Equation (7), applied to the considered phenomenon, possesses the following configuration:

(8)

(8)

where the sign  concerns progressively rising changes of a relative material length, whereas the sign

concerns progressively rising changes of a relative material length, whereas the sign  must be referred to when describing degressively rising changes of this magnitude. In the first case the rate of the length change increases with the temperature growth; the second record informs that the rate will be decreasing respectively. Further considerations are to closer explain the role of the sign

must be referred to when describing degressively rising changes of this magnitude. In the first case the rate of the length change increases with the temperature growth; the second record informs that the rate will be decreasing respectively. Further considerations are to closer explain the role of the sign . One should add that the rate of changes of the considered magnitude is the coefficient of thermal expansion, so

. One should add that the rate of changes of the considered magnitude is the coefficient of thermal expansion, so

(9)

(9)

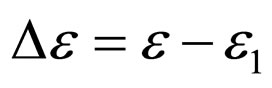

and that means

(10)

(10)

Having the analytical form of the function , one may easily obtain the dependence

, one may easily obtain the dependence , because this coefficient is, as it results from the definition formula (9), the first derivative of the relative increment of body length against temperature.

, because this coefficient is, as it results from the definition formula (9), the first derivative of the relative increment of body length against temperature.

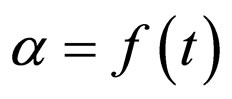

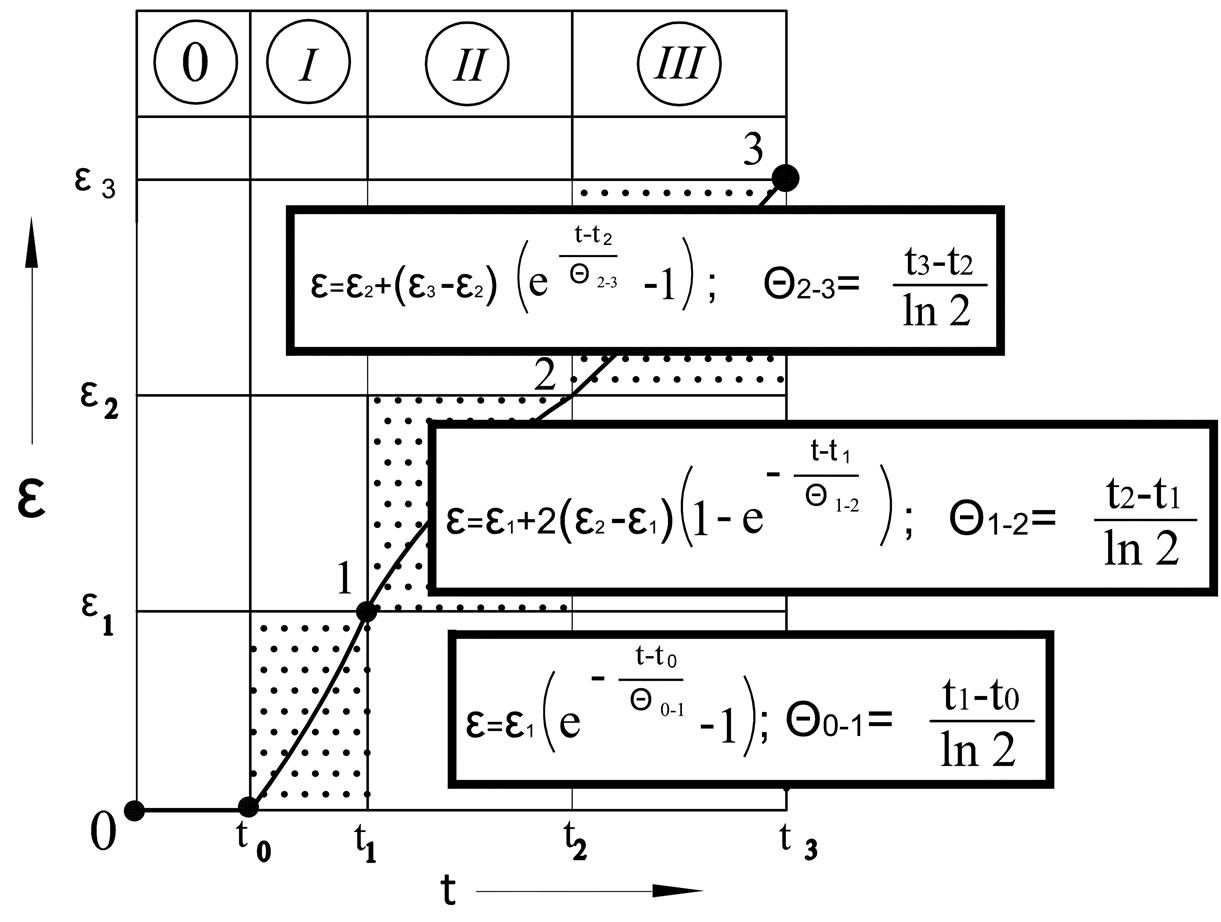

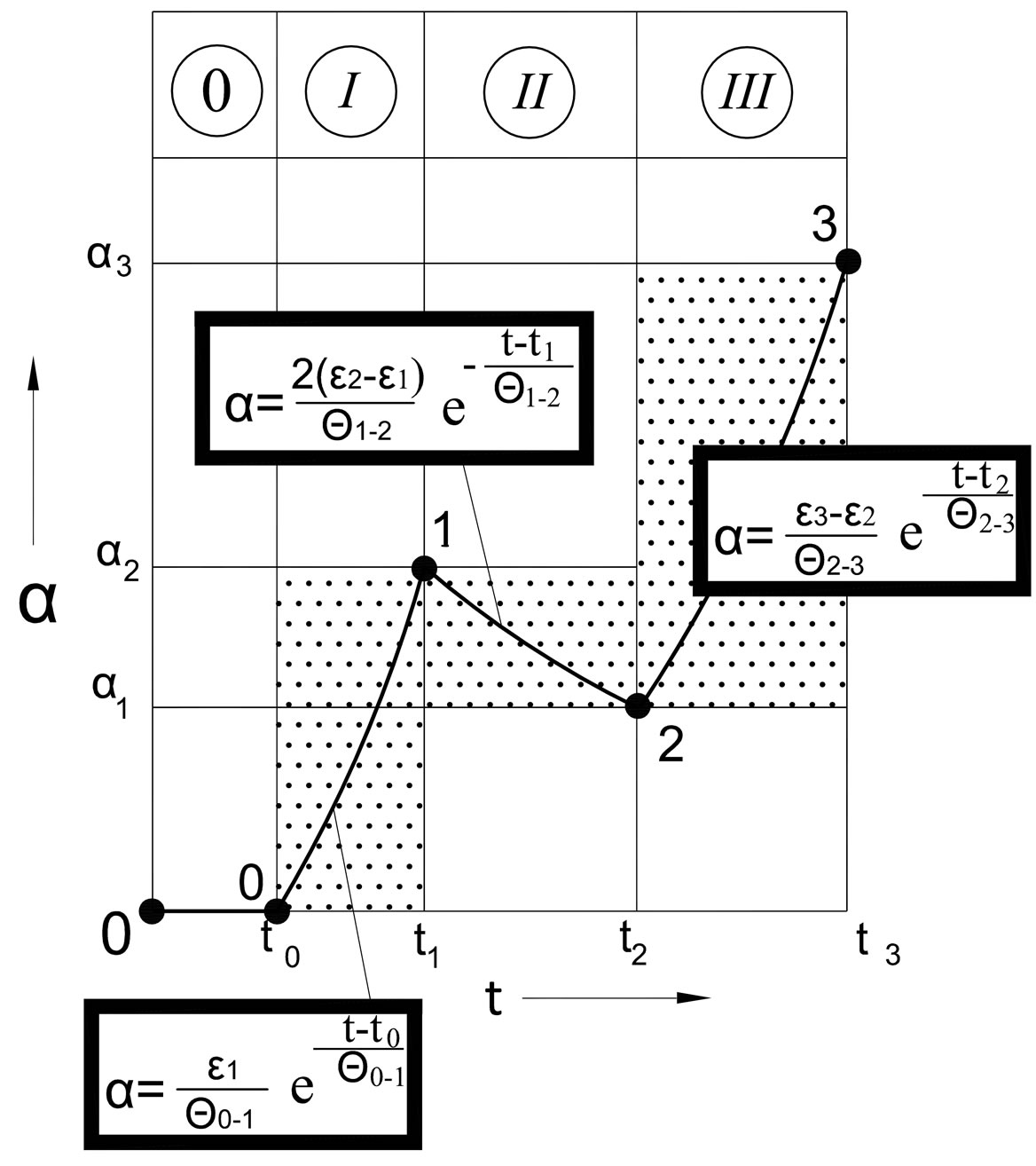

Now both total differentials should be determined to allow for further explanation of the source initial dependence. Thus one should analyze the course of the adequate dependence of increment of the material length on temperature (Figure 6).

There are characteristic points 0, 1, 2, 3 on the curve which denote four zones (0, I, II, III), being in the limits of variability of two magnitudes as the deformationtemperature spaces. In the zero space there is no increase of the material length; in the first space a progressive increase of the relative length takes place; in the second space a degressive increase of this magnitude occurs; in the third space, again a progressive increase of this magnitude appears.

Figure 6. General course of the adequate dependence of the relative extension of material on temperature.

5. Creating the Real Characteristics of Thermal Expansion of Solid

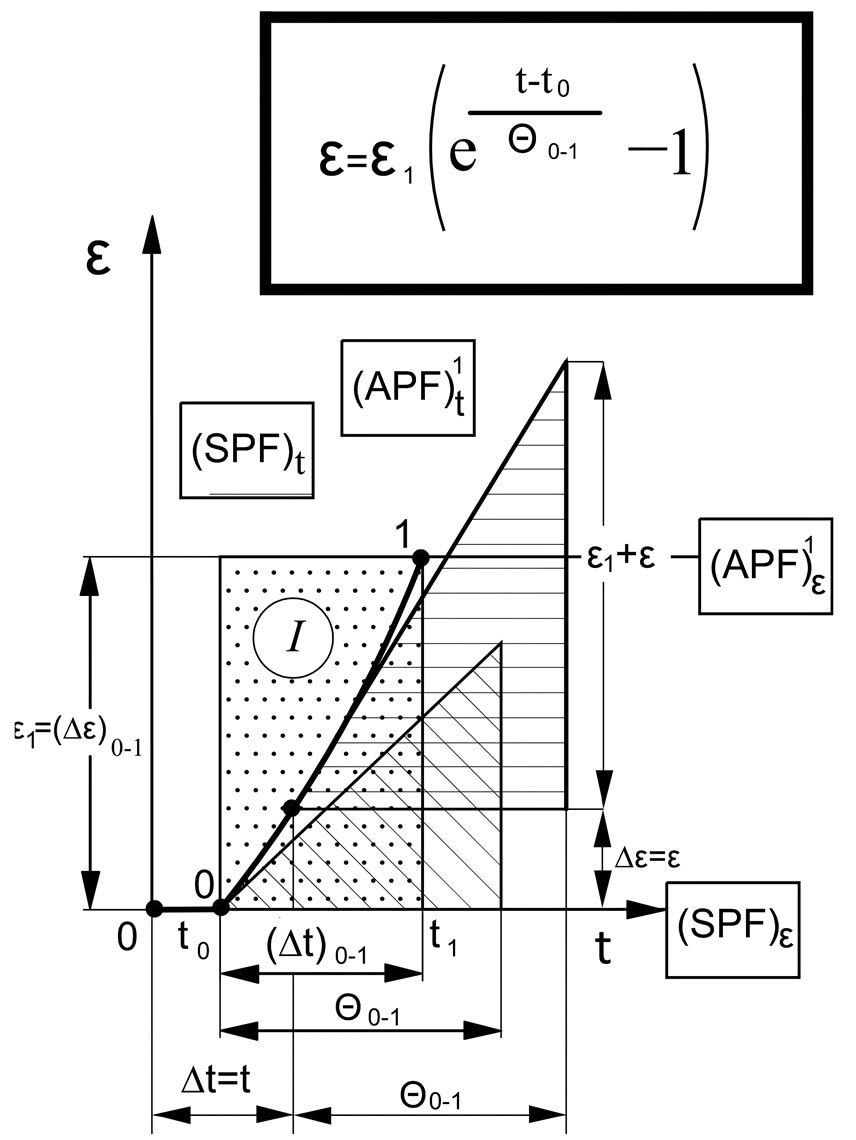

Now the essence of creation of the real characteristics of the expansion phenomenon in particular spaces is to be performed. It will be presented for the consecutive spaces; the first one where the exponential progressively rising the course of relative increment of material length (Figure 7) occurs.

The curve is the envelope of rectangular triangles of which the temperature leg is constant and equaled to the temperature constant , whereas the deformation leg changes respectively. The initial point of the curve is on the intersection of the stable potential fields: deformation stable potential field

, whereas the deformation leg changes respectively. The initial point of the curve is on the intersection of the stable potential fields: deformation stable potential field  and temperature stable potential field

and temperature stable potential field . The final point of this curve is situated on the intersection of the first unstable potential fields: the first deformation unstable potential field

. The final point of this curve is situated on the intersection of the first unstable potential fields: the first deformation unstable potential field  and the first temperature unstable potential field

and the first temperature unstable potential field  . The mentioned potential fields are the limits of the deformation-temperature space of which the dimension in the temperature direction is

. The mentioned potential fields are the limits of the deformation-temperature space of which the dimension in the temperature direction is , and in the deformation direction

, and in the deformation direction .

.

The deformation leg of this moving right-angled triangle is respectively variable, resulting from the changing position of tangent to the relative material extension. For  the length of this leg equals

the length of this leg equals .

.

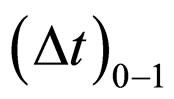

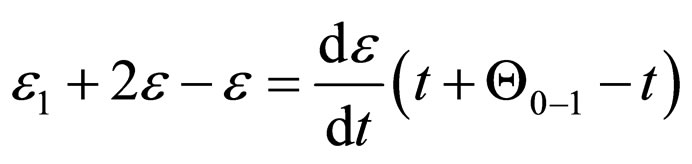

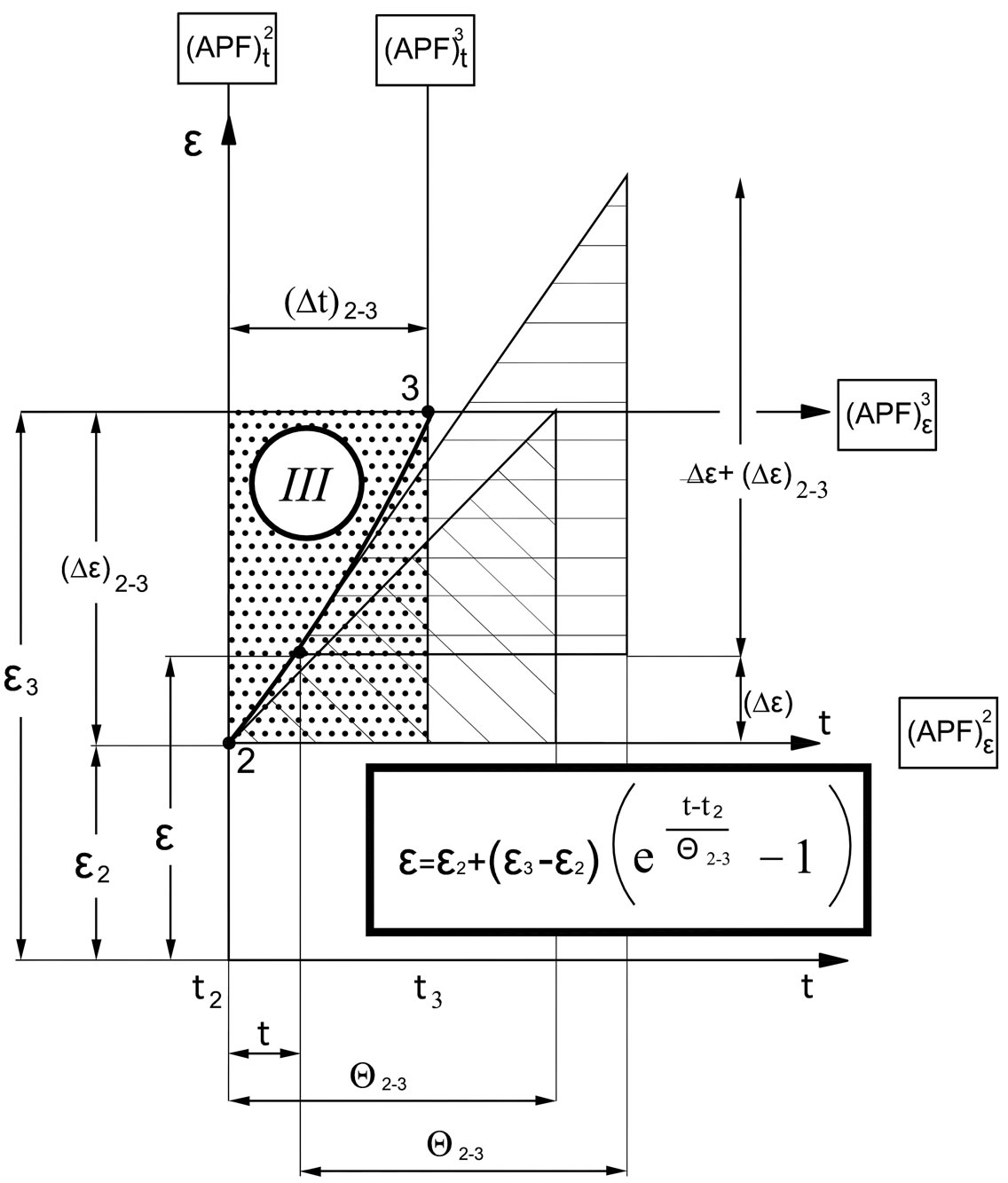

Now let us integrate the Equation (8), denoting the limits of integrals of the total differentials. That means

(11)

(11)

and next

(12)

(12)

and

(13)

(13)

or

(14)

(14)

One may note that the partial derivative was substituted by a quotient of the ordinary differentials. It may be done because the total differentials had been clearly determined by introducing limits for the integrals. It is worthy adding that the positive algebraic operator, the sign , is taken into account because the changes of the relative length increase are rising progressively.

, is taken into account because the changes of the relative length increase are rising progressively.

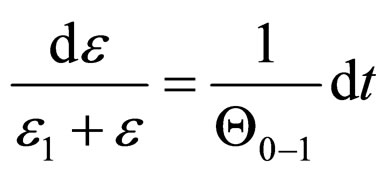

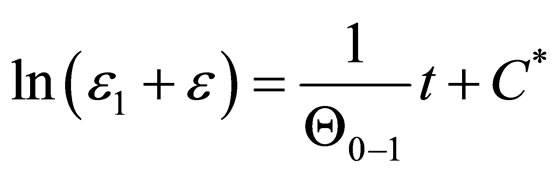

Furthermore, by integrating both sides of the Equation (14), one obtains

(15)

(15)

or

(16)

(16)

with regarding  the magnitude

the magnitude , one obtains

, one obtains

(17)

(17)

and after substituting (17) to (16)

(18)

(18)

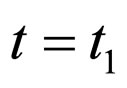

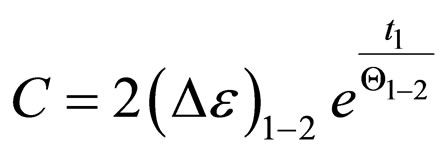

One may determine the second coordinate of the point 1, that is the temperature corresponding with the ending of phenomenon of the progressive relative increment of the material deformation. That result is obtained by introducing  and the temperature increase

and the temperature increase

to the Equation (18). Thus

(19)

(19)

or (see Figure 7)

(20)

(20)

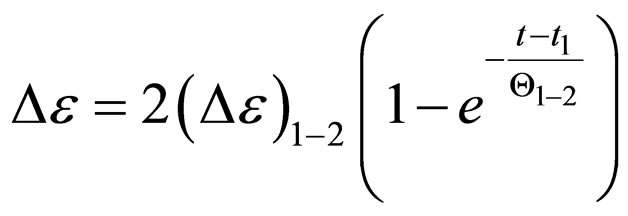

The second part of characteristics of the thermal expansion phenomenon is also rising, but degressively (Figure 8). This curve is the envelope of the right-angled triangles with the temperature leg being constant and equaling the so called temperature constant , and the deformation leg changing respectively. The initial point of the curve is a terminal point of the former course, the second point is situated on the intersection of the unstable potential fields: the second deformation unstable potential field

, and the deformation leg changing respectively. The initial point of the curve is a terminal point of the former course, the second point is situated on the intersection of the unstable potential fields: the second deformation unstable potential field  and the second temperature unstable potential field

and the second temperature unstable potential field .

.

Figure 7. Illustration of description creating the first part of the characteristics of thermal extension phenomenon.

Figure 8. Illustration of description creating the second part of the characteristics of thermal extension phenomenon.

The temperature constant  is on the nominal potential field

is on the nominal potential field , being the asymptote, to which the second apparent part of the curve approaches (dotted line). Along this field the mentioned triangle with its base is moving. The mentioned potential fields are the deformation limits of the deformation-temperature spaces: real (dotted), and neighbouring of this type apparent space.

, being the asymptote, to which the second apparent part of the curve approaches (dotted line). Along this field the mentioned triangle with its base is moving. The mentioned potential fields are the deformation limits of the deformation-temperature spaces: real (dotted), and neighbouring of this type apparent space.

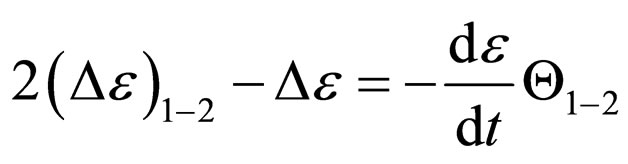

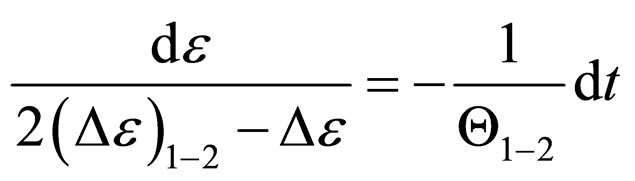

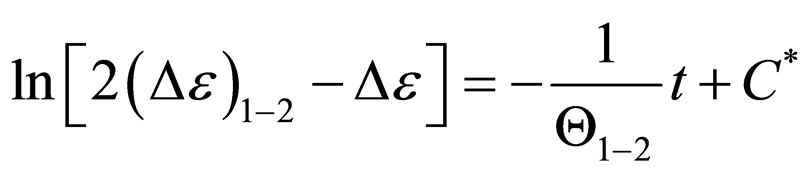

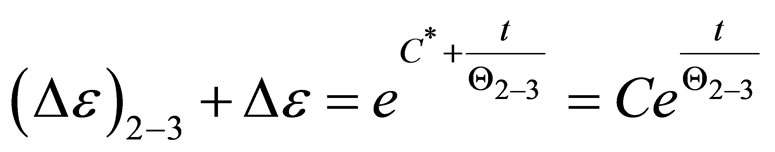

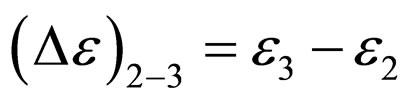

Now integrating the Equation (8) is performed, denoting the limits of the integrals of total differentials and regarding the negative sign of the algebraic operator. Thus

(21)

(21)

and next

(22)

(22)

that is

(23)

(23)

or

(24)

(24)

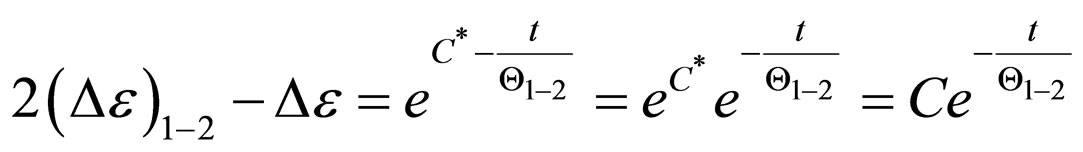

By integrating both sides of the Equation (24) one obtains the following solution

(25)

(25)

or

(26)

(26)

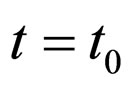

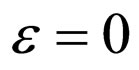

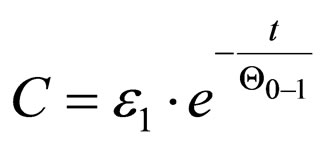

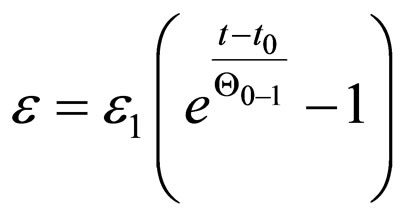

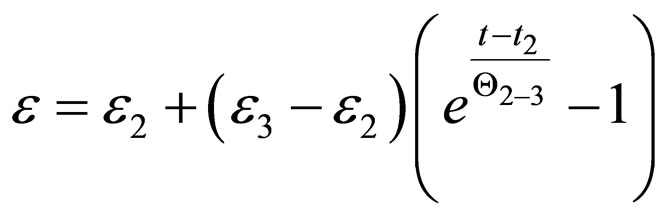

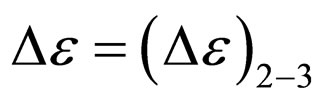

By regarding the initial conditions, meaning that for  the increment

the increment , one obtains

, one obtains

(27)

(27)

and after substituting (27) to (26)

(28)

(28)

Taking into account that  and

and  the Equation (28) may be recorded as follows

the Equation (28) may be recorded as follows

(29)

(29)

The second coordinate of the point 2, that is the temperature relating to the end of phenomenon of the degressive relative increase of the material extension, is obtained after introducing the magnitudes  and

and  to the Equation (28). Therefore

to the Equation (28). Therefore

(30)

(30)

or

(31)

(31)

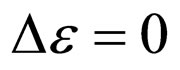

Scheme of the creating description of the third part of characteristics of the thermal expansion phenomenon (Figure 9) enables herewith to determine the limits of the integrals of total differentials corresponding with these characteristics.

Figure 9. Illustration of description creating the third part of the characteristics of thermal expansion phenomenon.

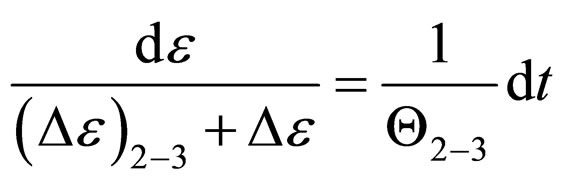

One obtains the following record

(32)

(32)

and next

(33)

(33)

or

(34)

(34)

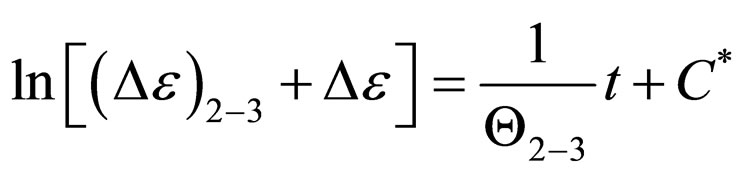

By integrating both sides of the Equation (34) one obtains

(35)

(35)

or

(36)

(36)

After considering the initial conditions, relying on the dependence that for  the magnitude

the magnitude , one obtains

, one obtains

(37)

(37)

and after substituting (37) to (36)

(38)

(38)

Furthermore, regarding , and

, and  resulting from Figure 9, the Equation (38) may be recorded as follows:

resulting from Figure 9, the Equation (38) may be recorded as follows:

(39)

(39)

The second coordinate of the point 3, that is the temperature relating to the end of third phase of the phenomenon of thermal expansion, is obtained after introducing the magnitude  and the temperature increment

and the temperature increment  to the Equation (39). Therefore

to the Equation (39). Therefore

(40)

(40)

or

(41)

(41)

Thus the characteristics of all possible three phases of the phenomenon of thermal expansion in the range of the increase of the relative material deformation have been provided. They are reflected by the following formulae (18), (29), and (39). All three formulae have been placed on the background of the indicative course of the curve (Figure 10). Moreover, also the formulae on the temperature constants, resulting from the formulae (20), (31), and (41), have been presented.

6. Courses of the Coefficient of Linear Thermal Expansion

The coefficient of the linear thermal expansion is defined by the formula (9), and it is simply the first derivative (derivative of the first order) of the relative extension against temperature. This coefficient relates with the intensity/rate of changes of the relative extension, being here the intensity of increment of this magnitude, as this direction of changes has been taken into account.

Having the primary characteristics, being the relationships of the relative extension on temperature, that is , one may easily determine these derivative characteristics of the phenomenon of the thermal expansion of solids. These functional derivative characteristics have the following analytical configurations:

, one may easily determine these derivative characteristics of the phenomenon of the thermal expansion of solids. These functional derivative characteristics have the following analytical configurations:

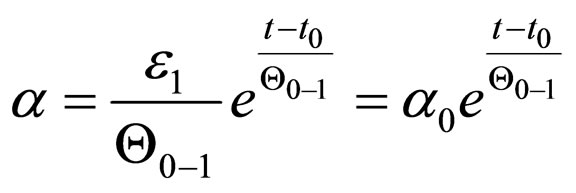

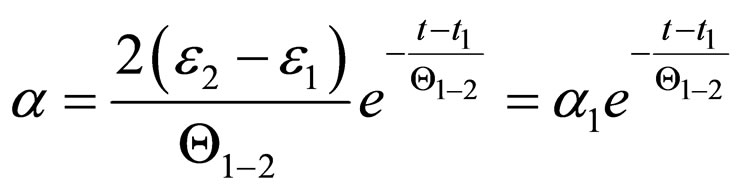

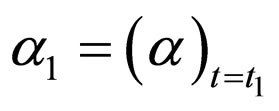

(42)

(42)

(43)

(43)

(44)

(44)

with

(45)

(45)

(46)

(46)

(47)

(47)

Figure 10. Comparison of analytical descriptions of the characteristics of thermal expansion phenomenon.

These analytical functional characteristics have been presented on the background of their graphic courses (Figure 11). There are clear differences visible in the character of the courses of this magnitude in particular ranges of the peculiar (terminal) temperatures.

7. Conclusions

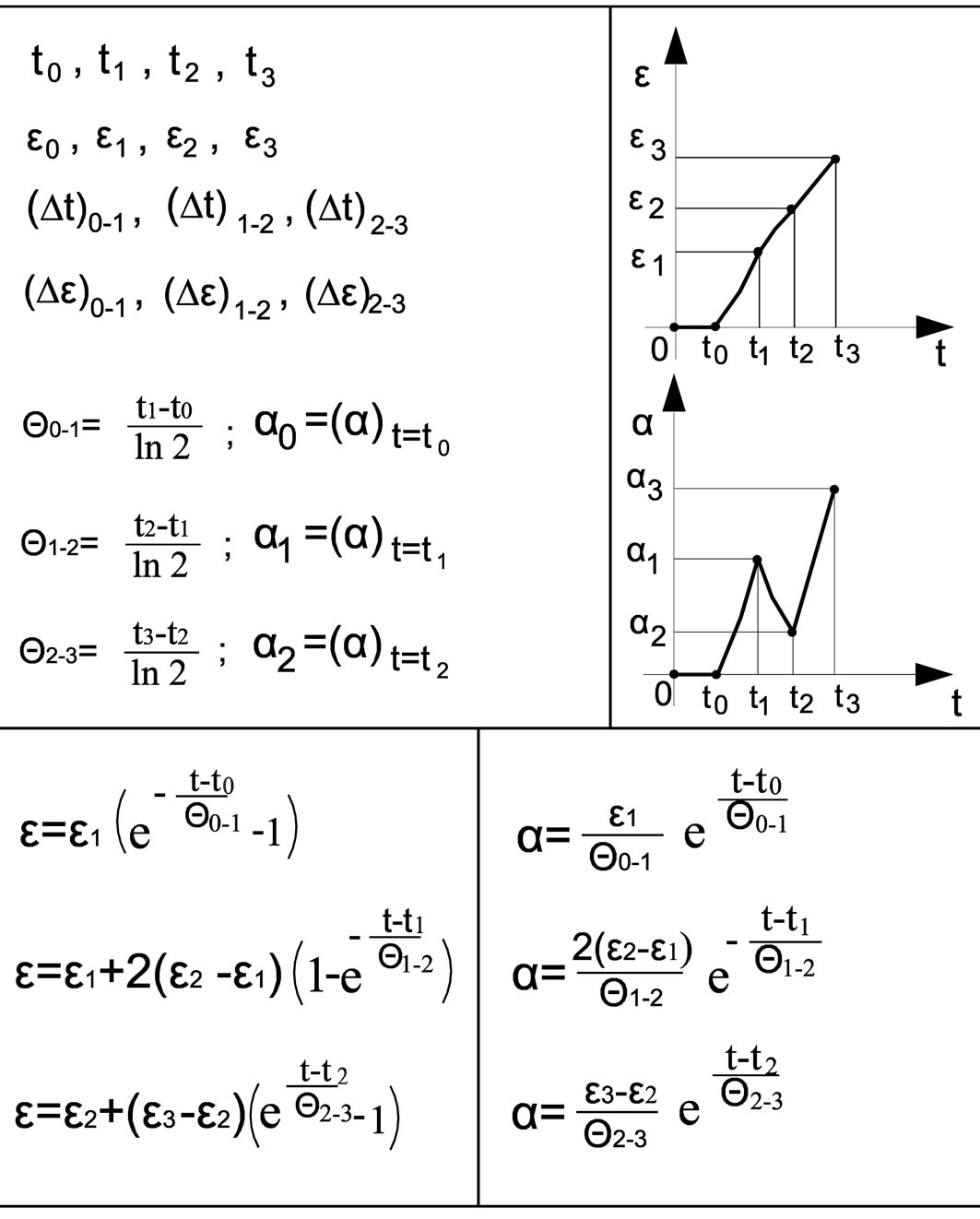

In the summary, at first all characteristics of the phenomenon of the thermal expansion of solids are combined, separating parametric and functional characteristics (Table 1). It may be noticed that all the parametric characteristics are constant magnitudes, whereas the functional ones depend on temperature and are in the form of the exponential functions. The graphic illustrations provided in Table 1 serve to explain more exactly the character of the functions.

On the background of all these courses it is distinctly visible that one cannot linearize them by treating them as the approximate, averaged, substitutional characteristics. In this light this tabled coefficient of the linear expansion, determined in the limits from zero to one hundred degree Celsius, should be recognized as requiring an essential corrigendum.

It seems to be reasonable introducing this new adequate knowledge on the phenomenon of the thermal expansion of solids to the technology/engineering and different its branches. It will allow for better forecasting the thermal behaviour of the material elements, and in a broader meaning, the forecasting of the thermal phenomena. This knowledge could be better used on the ground of the manufacturing new materials resistant to

Figure 11. Graphic and analytical presentation of the dependence of the coefficient of the linear thermal expansion on temperature.

Table 1. Parametric and functional characteristics of the phenomenon of thermal expansion of solids.

high temperatures of the properties enabling the application them in the cosmonautics. The references [11-14], concerned with the forecasting in technique, confirm the necessity for providing the firm foundations in all future actions.

In the creation of these foundations one should return to the source, that was stressed in [15] where the nonlinear vibrations were discussed as the open problem. It is worthy admitting that not only the vibrations and the considered thermal questions are of importance. For instance, it touches also thermal phenomena during the operation of transformers [16], thermo-bimetals [17,18], the phenomenon of variability of the proper resistance of metals due to the temperature changes, the phenomenon of the isothermal compressibility of liquids, the phenomenon of the isothermal expansion of liquids.

To this number of applications of the presented method of the description of non-continuous quantum physical phenomena, the uses to the description of curves of the tool edge wear [19-22], the tool life under cut [23,24], the curves of material strengthening [25,26], and the characteristics of stiffness of the design systems, may be added [27,28] .

This presented mathematical method can be also used in the area of the classical mechanics [29-31]. The dynamics of the material bodies between the static and kinematic states and between these two states in one and second direction may be also described (adequate description). They are just some phenomena mentioned herewith which required to be described adequately. All they prove the existent knowledge on the characteristics of other natural phenomena also needs to be verified.

At the end it is worthy noticing that characterizing materials referred to the phase transformations through the dilatometric studies, by determination of thermal curves of extension of solids is still open and developed. However, the dilatometric curves, regarding varied phase transformations, have no reference to the analytical descriptions.

Many recent references [32-35] are treating in-depth quite complex configurations of dilatometric curves, without their analytical descriptions. It is worthy disclosing the references of these results, with the materials and processes characterized there.

In [32], the authors describe kinetics of phase transformations under continuous heating (annealing) of newly designed hardened tool steels of varying carbon contents, assigned to manufacture of metallurgic/steelworks rolls. In [33], a high anisotropic structure of thermal extension of compounds (vanadium and niobium) under controlled external stresses, was revealed. Recently Meingast [34] investigated a high-resolution thermal expansion of superconducting rare-earth single crystals. Another work [35] is concentrated on thermal expansions in CrMn alloys at low temperatures (T < 20 K).

One can note, the thermal expansion of solids is currently investigated and referred to a variety of structurally differentiated materials. Therefore, an attempt to the analytical development of the problem, as proposed in the present work, seems to be fully justified.

REFERENCES

- Z. Osiński, “Searching for the truth in mechanics (Poszukiwanie Prawdy w Mechanice),” Przegląd Mechaniczny, Vol. 55, No. 16, 1996, pp. 11-14.

- Z. Kamiński, “Physics for the candidates to engineering college (Fizyka dla Kandydatów na Wyższe Uczelnie Techniczne),” WNT, Warszawa, 1966.

- S. Okoniewski, “Technology of metals (Technologia Metali),” PWSZ, Warszawa, 1961.

- K. Woźniak, “Abrasive materials. Manufacture and properties (Materiały Ścierne. Wytwarzanie i Własności),” WNT, Warszawa 1982.

- N. E. Filonenko and I. V. Lavrov, “Petrografia Iskusstvennych Abrazivov,” Mašgiz, Leningrad, 1958.

- W. Luty, “Metal science and the Heat Treatment of bearing steels (Metaloznawstwo i obróBka Cieplna Stali Łożyskowych),” WNT, Warszawa, 1980.

- “Podšipniki Kačenija. Spravočnoe Posobie,” Gosudarstvennoe Naučno-Techničeskoe Izd. Maš. Moskva, 1961.

- W. Precht, J. Ignaciuk, C. Bieńkowski, Z. Kanigowski, J. Kwiatkowski and P. Myśliński, “Analysis of selected methods of transformations in the Tool Steels (Analiza Wybranych Metod Przemian Fazowych w Stalach NarzędZiowych),” Prace Instytutu Inżynierii Materiałowej, Wy- ższa Szkoła Inżynierska w Koszalinie, Koszalin, Vol. 2, No. 1, 1977, pp. 122-157.

- Z. Pluta, “Fundamentals of surface smoothing by elastic Abrasive Wheels (Podstawy Wygładzania Powierzchni Ściernicami Elastycznymi),” Wydawnictwo Politechniki Koszalińskiej, Koszalin, 2007.

- Z. Pluta and T. Hryniewicz, “Advanced Model of the Tool Edge Blunting under Machining,” Int. J. Adv. Manuf. Technol, Vol. 51, No. 1-4, 2010, pp. 217-223. doi:10.1007/s00170-010-2595-5

- J. R. Bright and M. E. F. Schoeman, “Forecasting in Technology (Prognozowanie w Technice),” WNT, Warszawa, 1978 (Transl. from English).

- M. E. Merchant, “10 Years Ahead—What’s in it for Metalworking,” American Machinist, Vol. 18, 1959, pp. 142- 146.

- M. E. Merchant, “The Future of Manufacturing Technology. Frontiers in Manufacturing Technology,” University of Michigan, Ann Arbor, 1966, pp. 1-9.

- M. E. Merchant, “Progress and Problems in the Application of New Optimization Technology in Manufacturing,” CIRP Annals, Vol. 16, No. 2, 1968, pp. 151-161.

- Z. Dąbrowski, “Non-Linear Vibrations—An Open Problem (Drgania Nieliniowe—problem Nadal Otwarty),” Przegląd Mechaniczny, Vol. 66, No. 11, 2007, pp. 15-18.

- E. Jezierski, “Transformers—theoretical foundations (Transformatory—Podstawy Teoretyczne),” WNT, Warszawa, 1956.

- G. Keinath,“Bimetalle,” Archiv für Technisches Messen, Vol. 4, T-55, T-57, 1936, (Z-972-1).

- W. Tryliński, “Fine mechanisms and precision devices. Design foundations (Drobne Mechanizmy i Przyrządy Precyzyjne. Podstawy Konstrukcji),” WNT, Warszawa, 1964.

- “Analyse de l’Usure de l’Outil Pour le Tournage de Finition,” Machines Production, Vol. 19, No. 673, 1977, pp. 39-42.

- W. Y. H. Liew, B. K. A. Ngoi and Y. G. Lu, “Wear characteristics of PCBN tools in the Ultra-Precision Machining of stainless steel at Low Speeds,” Wear, Vol. 254, No. 3-4, 2003, pp. 265-277. doi:10.1016/S0043-1648(03)00002-4

- V. P. Astakhov, “The assessment of cutting tool wear,” International Journal of Machine Tools and Manufacture, Vol. 44, No. 6, 2004, pp. 637-647. doi:10.1016/j.ijmachtools.2003.11.006

- Y. Huang and S. Y. Liang, “Modeling of CBN Tool Flank Wear Progression in Finish Hard Turning,” Journal of Manufacturing Science and Engineering, Vol. 126, No. 1, 2004, pp. 98-106. doi:10.1115/1.1644543

- G. Galante, A. Lombardo and A. Passannanti, “Tool-life modeling as a stochastic process,” International Journal of Machine Tools and Manufacture, Vol. 38, No. 11-12, 1998, pp. 1361-1369. doi:10.1016/S0890-6955(98)00019-4

- L. Özler, A. Inan and C. Özel, “Theoretical and experimental determination of Tool Life in Hot Machining of Austenitic Manganese Steel,” International Journal of Machine Tools and Manufacture, Vol. 41, No. 2, 2001, pp. 163-172. doi:10.1016/S0890-6955(00)00077-8

- T. Pełczyński, “On the strengthening curves (O Krzywych Umocnienia),” Obróbka Plastyczna, Vol. 14, No. 1, 1975, pp. 22-26.

- Z. Marciniak, “Evaluation of applicability of materials in the Plastic Cold Working. Forming of rods (Ocena Przydatności Materiałów Wyjściowych w Obróbce Plastycznej na Zimno. Kształtowanie Prętów),” Mechanik, Vol. 56, No. 4, 1983, pp. 189-207.

- J. C. Ramos, J. Vinolas and F. J. Nieto, “A simplified methodology to determine the cutting stiffness and the Contact Stiffness in the Plunge Grinding Process,” International Journal of Machine Tools and Manufacture, Vol. 41, No. 1, 2001, pp. 33-49. doi:10.1016/S0890-6955(00)00062-6

- “Steifigkeit im Blickepunkt,” Maschine, Vol. 58, No. 6, 2004, pp. 58-59.

- H. Goldstein, C. Poole and J. Safko, “Classical Mechanics,” 3rd edition, Addison-Wesley, Boston, 2002.

- J. R. Taylor, “Classical mechanics (Mechanika Klasyczna),” Vol. 1, Wydawnictwo Naukowe PWN SA, Warszawa, 2006 (transl. from English).

- L. D. Landau and J. M. Lifszyc, “Theoretical physics. Mechanics (Fizyka Teoretyczna. Mechanika),” Wyd. Naukowe PWN S.A., Warszawa, 2006

- P. Bała, “The kinetics of Phase Transformations during tempering of Tool Steels with Different Carbon Content,” Archives of Metallurgy and Materials, Vol. 54, No. 2, 2009, pp. 491-498.

- T. R. Finlayson and T. F. Smith, “Stress effects on the Anisotropic Thermal Expansions of ‘martensitic’ A15 compounds,” Phase Transitions: A Multinational Journal, Vol. 69, No. 3, 1999, 409-424. doi:10.1080/01411599908209302

- C. Meingast, “High-Resolution Thermal Expansion of Solids: Recent Results on Superconducting YBa2Cu3Ox Single Crystals,” Netsu Sokutei, Vol. 33, No. 4, 2006, pp. 167-173.

- G. K. White, Y. Nakamura, M. Shiga and A. B. Kaiser, “Thermal Expansions in CrMn Alloys at Low Temperatures,” Journal of the Physical Society of Japan, Vol. 58, No. 2, 1989, pp. 3485-3488. doi:10.1143/JPSJ.58.3485

List of more important symbols

—temperature stable potential field

—temperature stable potential field

—deformation stable potential field

—deformation stable potential field

—temperature unstable potential field, first, second, and third, respectively

—temperature unstable potential field, first, second, and third, respectively

—deformation unstable potential field, first, second, and third, respectively

—deformation unstable potential field, first, second, and third, respectively

NPF—nominal potential field

—temperature in peculiar terminal points: zero, first, second, and third, respectively

—temperature in peculiar terminal points: zero, first, second, and third, respectively

—relative increment of length in peculiar terminal points: zero, first, second, and third, respectively

—relative increment of length in peculiar terminal points: zero, first, second, and third, respectively

—distances between potential fields in the direction of temperature change

—distances between potential fields in the direction of temperature change

—distances between potential fields in the direction of relative length increment

—distances between potential fields in the direction of relative length increment

—coefficients of linear thermal expansion in zero, first, and second point, respectively

—coefficients of linear thermal expansion in zero, first, and second point, respectively

—temperature constants for the courses of relative length increment in particular interstate spaces

—temperature constants for the courses of relative length increment in particular interstate spaces

NOTES

*Corresponding author.