528 N. A. Mielke et al. / J. Biomedical Science and Engineering 3 (2010) 525-528

Copyright © 2010 SciRes. JBiSE

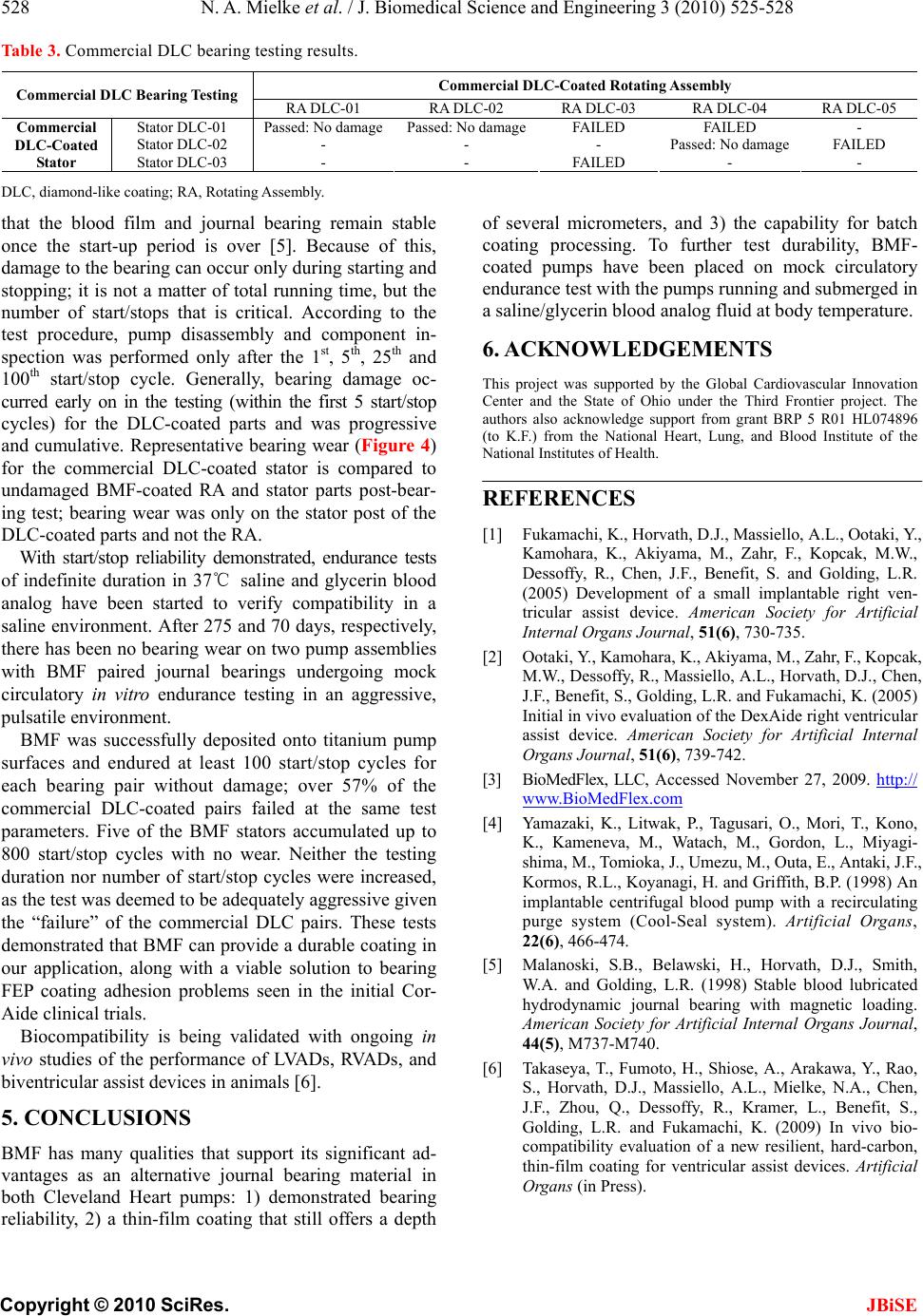

Table 3. Commercial DLC bearing testing results.

Commercial DLC-Coated Rotating Assembly

Commercial DLC Bearing TestingRA DLC-01 RA DLC-02 RA DLC-03 RA DLC-04 RA DLC-05

Stator DLC-01 Passed: No damagePassed: No damageFAILED FAILED -

Stator DLC-02 - - - Passed: No damage FAILED

Commercial

DLC-Coated

Stator Stator DLC-03 - - FAILED - -

DLC, diamond-like coating; RA, Rota ting Assembly.

that the blood film and journal bearing remain stable

once the start-up period is over [5]. Because of this,

damage to the bearing can occur only dur ing startin g and

stopping; it is not a matter of total running time, but the

number of start/stops that is critical. According to the

test procedure, pump disassembly and component in-

spection was performed only after the 1st, 5th, 25th and

100th start/stop cycle. Generally, bearing damage oc-

curred early on in the testing (within the first 5 start/stop

cycles) for the DLC-coated parts and was progressive

and cumulative. Representative bearing wear (Figure 4)

for the commercial DLC-coated stator is compared to

undamaged BMF-coated RA and stator parts post-bear-

ing test; bearing wear was only on the stator post of the

DLC-coated parts and not the RA.

With start/stop reliability demonstrated, endurance tests

of indefinite duration in 37℃ saline and glycerin blood

analog have been started to verify compatibility in a

saline environment. After 275 and 70 days, respectively,

there has been no bearing wear on two pump assemblies

with BMF paired journal bearings undergoing mock

circulatory in vitro endurance testing in an aggressive,

pulsatile environment.

BMF was successfully deposited onto titanium pump

surfaces and endured at least 100 start/stop cycles for

each bearing pair without damage; over 57% of the

commercial DLC-coated pairs failed at the same test

parameters. Five of the BMF stators accumulated up to

800 start/stop cycles with no wear. Neither the testing

duration nor number of start/stop cycles were increased,

as the test was deemed to be adequately aggressive given

the “failure” of the commercial DLC pairs. These tests

demonstrated that BMF can provide a durable coating in

our application, along with a viable solution to bearing

FEP coating adhesion problems seen in the initial Cor-

Aide clinical trials.

Biocompatibility is being validated with ongoing in

vivo studies of the performance of LVADs, RVADs, and

biventricular assist devices in animals [6].

5. CONCLUSIONS

BMF has many qualities that support its significant ad-

vantages as an alternative journal bearing material in

both Cleveland Heart pumps: 1) demonstrated bearing

reliability, 2) a thin-film coating that still offers a depth

of several micrometers, and 3) the capability for batch

coating processing. To further test durability, BMF-

coated pumps have been placed on mock circulatory

endurance test with the pumps running and su b merged in

a saline/glycerin blood analog fluid at body temperature.

6. ACKNOWLEDGEMENTS

This project was supported by the Global Cardiovascular Innovation

Center and the State of Ohio under the Third Frontier project. The

authors also acknowledge support from grant BRP 5 R01 HL074896

(to K.F.) from the National Heart, Lung, and Blood Institute of the

National Institutes of Health.

REFERENCES

[1] Fukamachi, K., Horvath, D.J., Massiello, A.L., Ootaki, Y.,

Kamohara, K., Akiyama, M., Zahr, F., Kopcak, M.W.,

Dessoffy, R., Chen, J.F., Benefit, S. and Golding, L.R.

(2005) Development of a small implantable right ven-

tricular assist device. American Society for Artificial

Internal Organs Journal, 51(6), 730-735.

[2] Ootaki, Y., Kamohara, K., Akiyama, M., Zahr, F., Kopcak,

M.W., De ssoffy, R., Massiello, A.L., Horvath, D.J., Chen,

J.F., Benefit, S., Golding, L.R. and Fukamachi, K. (2005)

Initial in vivo evaluation of the DexAide right ventricular

assist device. American Society for Artificial Internal

Organs Journal, 51(6), 739-742.

[3] BioMedFlex, LLC, Accessed November 27, 2009. http://

www.BioMedFlex.com

[4] Yamazaki, K., Litwak, P., Tagusari, O., Mori, T., Kono,

K., Kameneva, M., Watach, M., Gordon, L., Miyagi-

shima, M., Tomioka, J., Umezu, M., Outa, E., Antaki, J.F.,

Kormos, R.L., Koyanagi, H. and Griffith, B.P. (1998) An

implantable centrifugal blood pump with a recirculating

purge system (Cool-Seal system). Artificial Organs,

22(6), 466-474.

[5] Malanoski, S.B., Belawski, H., Horvath, D.J., Smith,

W.A. and Golding, L.R. (1998) Stable blood lubricated

hydrodynamic journal bearing with magnetic loading.

American Society for Artificial Internal Organs Journal,

44(5), M737-M740.

[6] Takaseya, T., Fumoto, H., Shiose, A., Arakawa, Y., Rao,

S., Horvath, D.J., Massiello, A.L., Mielke, N.A., Chen,

J.F., Zhou, Q., Dessoffy, R., Kramer, L., Benefit, S.,

Golding, L.R. and Fukamachi, K. (2009) In vivo bio-

compatibility evaluation of a new resilient, hard-carbon,

thin-film coating for ventricular assist devices. Artificial

Organs (in Press).