Paper Menu >>

Journal Menu >>

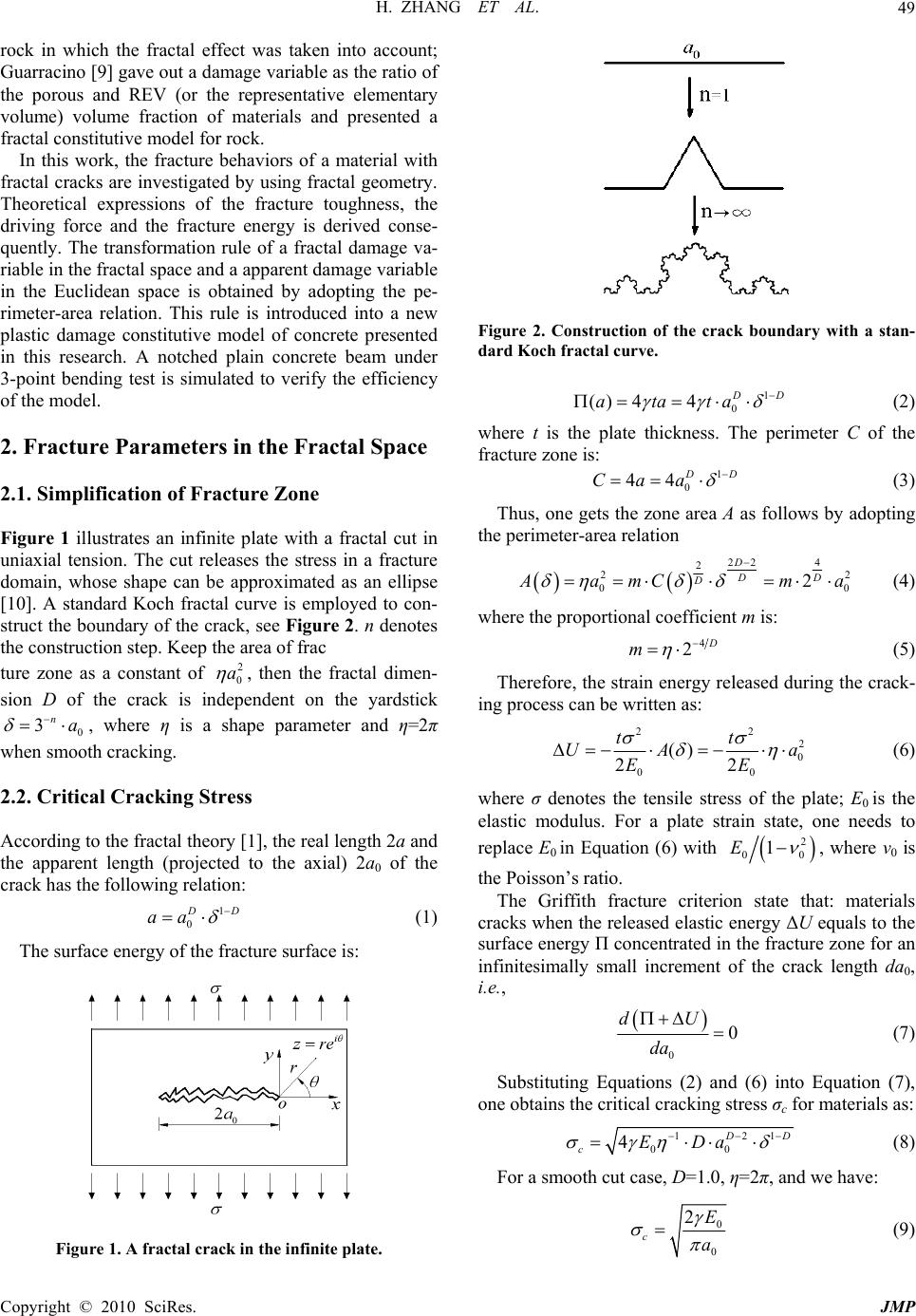

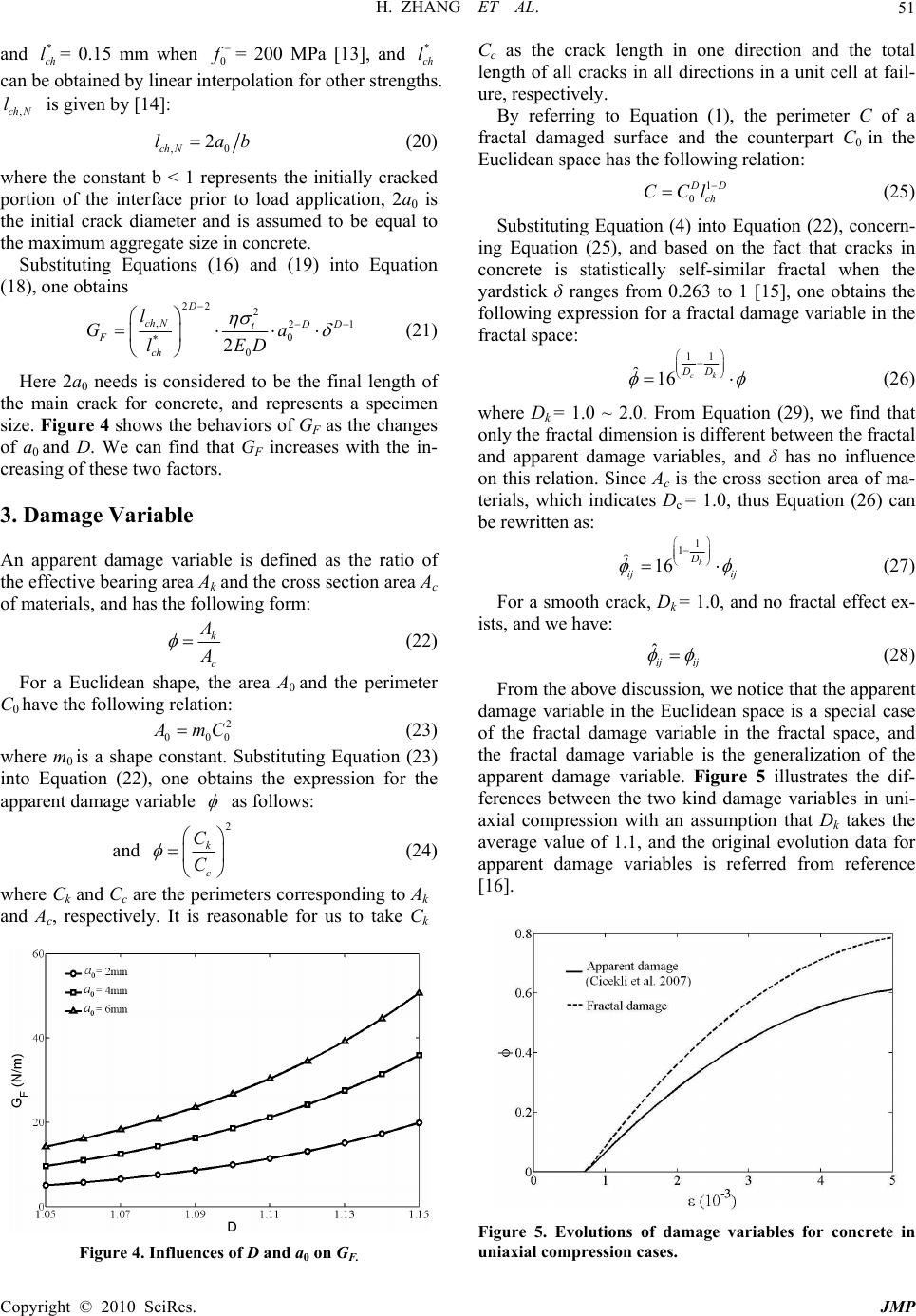

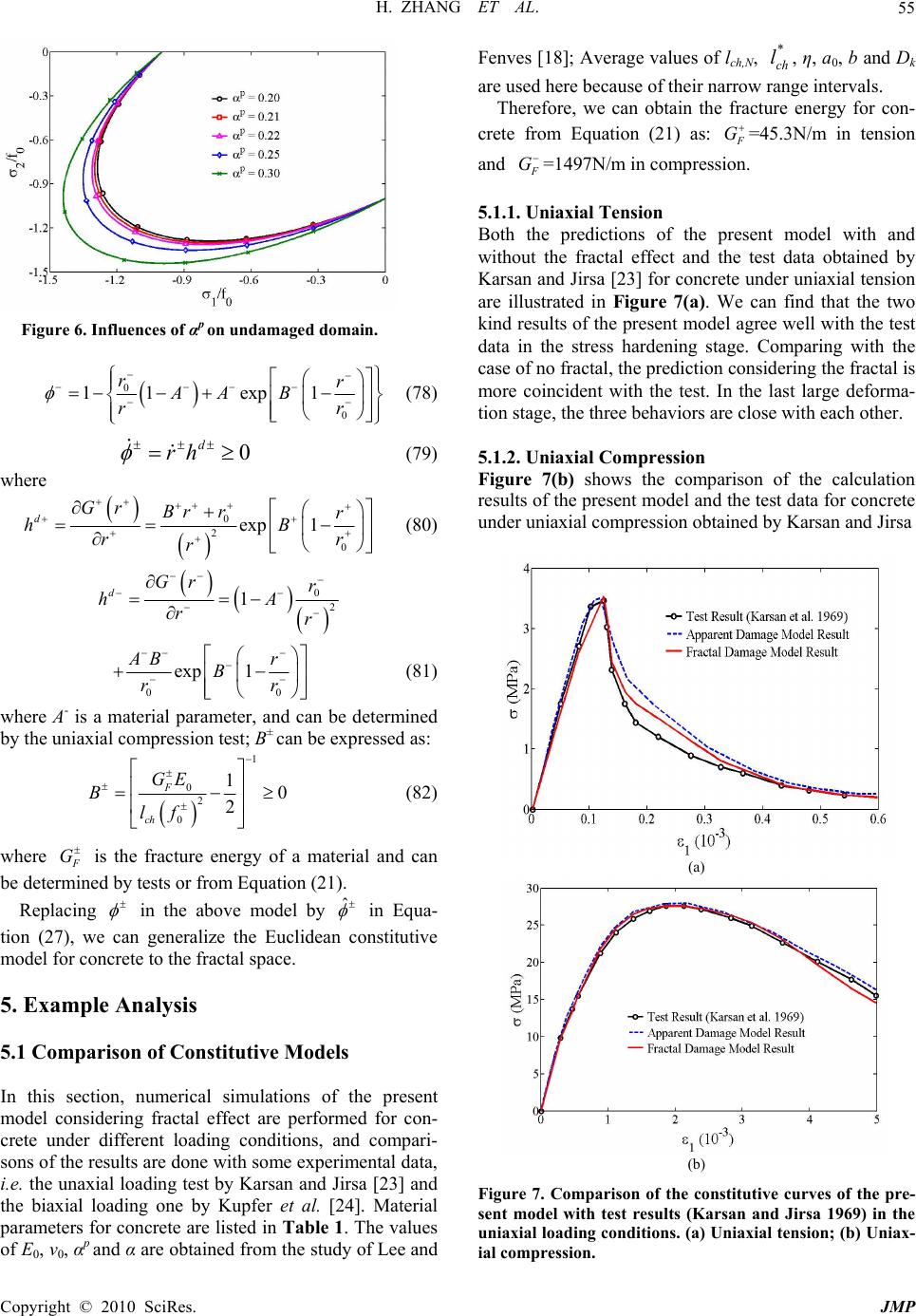

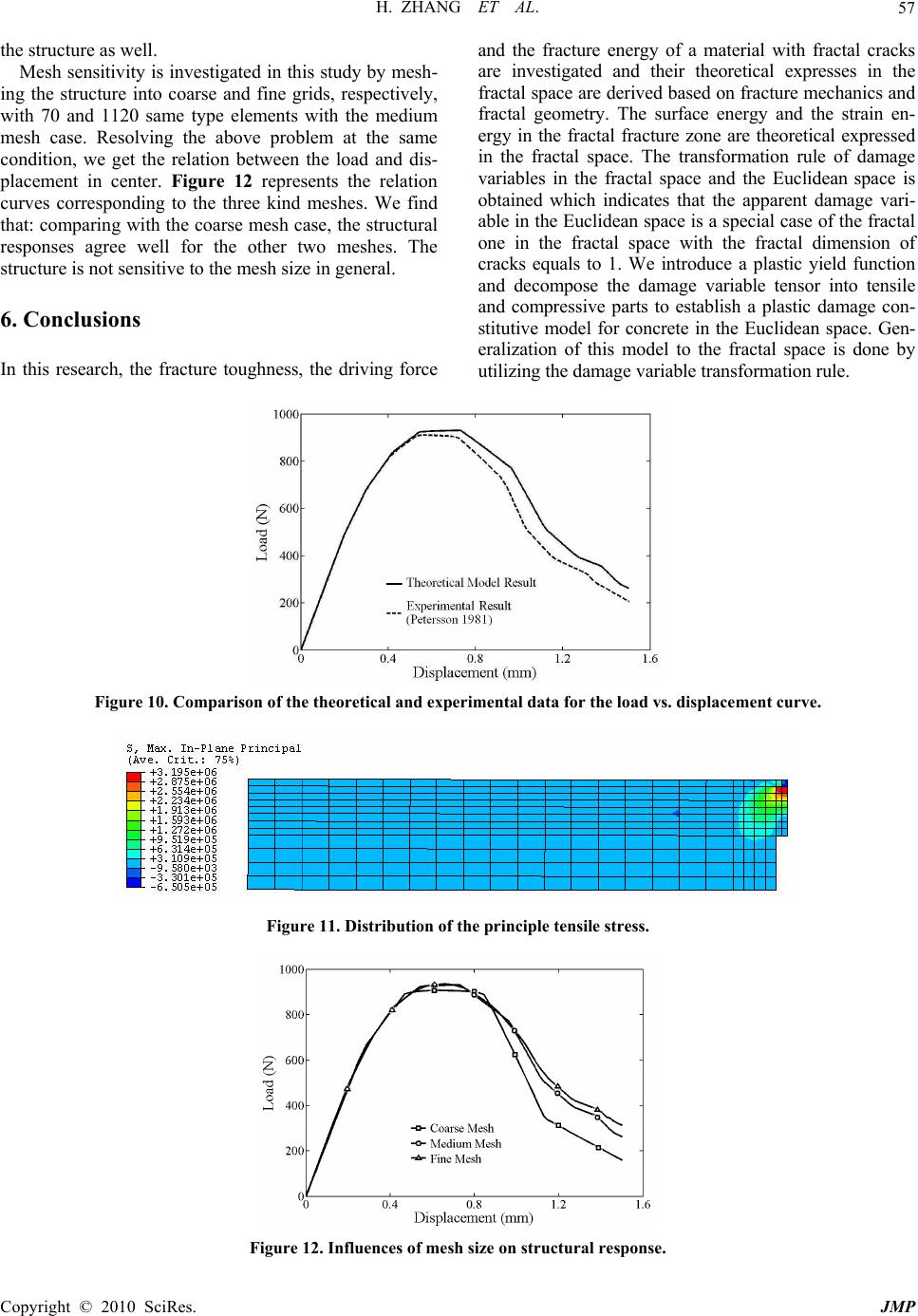

J. Mod. Phys., 2010, 1, 48-58 doi:10.4236/jmp.2010.11006 Published Online April 2010 (http://www.scirp.org/journal/jmp) Copyright © 2010 SciRes. JMP Fracture and Damage Behaviors of Concrete in the Fractal Space Heng Zhang1, Demin Wei1,2 1Department of Civil Engineering, South China University of Technology, Guangzhou, China 2State Key Laboratory of Subtropical Building Science, South China University of Technology, Guangzhou, China E-mail: heng.zh@mail.scut.edu.cn Received January 22, 2010; revised March 17, 2010; accepted March 20, 2010 Abstract The fracture toughness, the driving force and the fracture energy for an infinite plate with a fractal crack are investigated in the fractal space in this work. The perimeter-area relation is adopted to derive the transforma- tion rule between damage variables in the fractal space and Euclidean space. A plasticity yield criterion is introduced and a damage variable tensor is decomposed into tensile and compressive components to describe the distinct behaviors in tension and compression. A plastic damage constitutive model for concrete in the Euclidean space is developed and generalized to fractal case according to the transformation rule of damage variables. Numerical calculations of the present model with and without fractal are conducted and compared with experimental data to verify the efficiency of this model and show the necessity of considering the fractal effect in the constitutive model of concrete. The structural response and mesh sensitivity of a notched unre- inforced concrete beam under 3-point bending test are theoretical studied and show good agreement with the experimental data. Keywords: Fracture Mechanics, Damage Variable, Fractal Space, Constitutive Model 1. Introduction Concrete has been widely used in civil engineering for its good in-situ casting and molding abilities. As a quasi- brittle material, the fracture behavior of concrete receives much of researchers’ concerns. Though classic fracture mechanics which is based on the assumption of smooth cracking in materials can analyze concrete properties and meet the need of structure design in a certain extent, no advance is made to explain the failure mechanism from the change of the concrete internal structure. The difficulty mentioned above has a hindering effect for researchers to improve the mechanical property of concrete. Fractal geometry is established by Mandelbrot in 1970s [1], which plays an important role in the develop- ment of fracture mechanics theory. Researches show that the fracture zone of metal, rock and concrete has fractal characteristics [2-4]. This leads a widely use of fractal geometry in many fields of material science, for in- stances, the Sierpinski carpet was adopted by Carpinteri et al. [5] to simulate the composition of concrete cross section, and the fractal effect was also introduced into the cohesive crack model. Another remarkable applica- tion of fractal geometry is to describe the roughness of cracks quantitatively. Saouma et al. [6] and Issa et al. [7] investigated the crack profiles of concrete through tests and pointed out that cracks in concrete have an average fractal dimension of 1.1. Meanwhile, Issa et al. [7] ana- lyzed the fracture surface of concrete and found its frac- tal dimension is about 2.1 to 2.3. Studies on the damage of concrete point out that the propagation micro defects, i.e. microvoids and micro- cracks, etc, is the mainly cause of the macro fracture of materials. Based on this fact, a new kind of constitutive model for concrete, called the damage constitutive model, is developed within the framework of continuum damage mechanics. In this model, the choice of damage variable is a key to control the effectiveness and performance. Because of the heterogeneity of concrete, definition of the damage variable still remains at the state that the change of material macro property, such as elastic modulus and stress, are used to reflect the development of damage indirectly, and no direct relation is set with the intrinsic deflects. As the progress in studying fractal phenomena, some researchers try to explore the damage growth by means of fractal geometry. Zhao [8] defined a damage variable as a function of the area of fracture sur- face, and proposed a new damage constitutive model for  H. ZHANG ET AL. Copyright © 2010 SciRes. JMP 49 rock in which the fractal effect was taken into account; Guarracino [9] gave out a damage variable as the ratio of the porous and REV (or the representative elementary volume) volume fraction of materials and presented a fractal constitutive model for rock. In this work, the fracture behaviors of a material with fractal cracks are investigated by using fractal geometry. Theoretical expressions of the fracture toughness, the driving force and the fracture energy is derived conse- quently. The transformation rule of a fractal damage va- riable in the fractal space and a apparent damage variable in the Euclidean space is obtained by adopting the pe- rimeter-area relation. This rule is introduced into a new plastic damage constitutive model of concrete presented in this research. A notched plain concrete beam under 3-point bending test is simulated to verify the efficiency of the model. 2. Fracture Parameters in the Fractal Space 2.1. Simplification of Fracture Zone Figure 1 illustrates an infinite plate with a fractal cut in uniaxial tension. The cut releases the stress in a fracture domain, whose shape can be approximated as an ellipse [10]. A standard Koch fractal curve is employed to con- struct the boundary of the crack, see Figure 2. n denotes the construction step. Keep the area of frac ture zone as a constant of 2 0 a , then the fractal dimen- sion D of the crack is independent on the yardstick 0 3na , where η is a shape parameter and η=2π when smooth cracking. 2.2. Critical Cracking Stress According to the fractal theory [1], the real length 2a and the apparent length (projected to the axial) 2a0 of the crack has the following relation: 1 0 D D aa (1) The surface energy of the fracture surface is: Figure 1. A fractal crack in the infinite plate. Figure 2. Construction of the crack boundary with a stan- dard Koch fractal curve. 1 0 () 44 D D atata (2) where t is the plate thickness. The perimeter C of the fracture zone is: 1 0 44 D D Caa (3) Thus, one gets the zone area A as follows by adopting the perimeter-area relation 22 4 2 22 00 2 D DD D A amCm a (4) where the proportional coefficient m is: 4 2 D m (5) Therefore, the strain energy released during the crack- ing process can be written as: 22 2 0 00 () 22 tt UA a EE (6) where σ denotes the tensile stress of the plate; E0 is the elastic modulus. For a plate strain state, one needs to replace E0 in Equation (6) with 2 00 1E , where ν0 is the Poisson’s ratio. The Griffith fracture criterion state that: materials cracks when the released elastic energy ΔU equals to the surface energy Π concentrated in the fracture zone for an infinitesimally small increment of the crack length da0, i.e., 0 0 dU da (7) Substituting Equations (2) and (6) into Equation (7), one obtains the critical cracking stress σc for materials as: 121 00 4 D D cEDa (8) For a smooth cut case, D=1.0, η=2π, and we have: 0 0 2 c E a (9)  H. ZHANG ET AL. Copyright © 2010 SciRes. JMP 50 2.3. Fracture Toughness Wunk and Yavari [11] studied the stress field at the frac- tal crack tip, and presented the component σy in y direc- tion as shown in Figure 1. cos()sinsin1 2 f I y K r (10) where f I K is the fractal stress intensity factor; α repre- sents the singularity order of the stress field, and can be expressed as: 2 2 D , 12D (11) in terms of D for a self-similar fractal crack. For D=1.0, we have α=1/2 and f I I KK, and Equa- tion (10) degenerates to the smooth cracking case as: 13 cossin sin 22 2 2 I y K r (12) When σy=σc, ff I IC K K, the crack begins to grow. Re- ferring to Equations (8) and (10), one obtains the fractal fracture toughness for materials: 121 00 24 cos()sinsin1 D D f IC rEDa K (13) Figure 3 illustrates the relation among f I C K , D and a0. It can be noted from Figure 3 that f I C K decreases with the increasing of the crack length; If a0=0, f I C K tends to be infinite, and no crack exists in materials, which verifies the concept that the growth of initial de- flects leads to the final failure of materials. The greater the D value, the more bifurcated the cracks are, and the larger f I C K is, which indicates that roughness has a hin- Figure 3. Influences of D and a0 on f I C K . dering effect on the cracking of materials. 2.4. Driving Force Classic driving force is defined as the strain energy dis- sipated to form a unit fracture area [11], and can be ex- pressed as: 2 0 1 2 I UK Gta E (14) Submitting Equations (1) and (6) into Equation (14), one gets: 2 21 0 0 2 fDD Ga ED (15) For the mode I cracking case, G f reaches its maximum value max f G when σ increases to the tensile strength σt of materials: 2 21 max 0 0 2 fDD t Ga ED (16) We also have the cracking resistance GIC of materials as: 12 2 IC Gta (17) If max f I C GG, cracking occurs, and cracks does not grow when max f I C GG. This is the G-fracture criterion for fractal cracks. 2.5. Fracture Energy The fracture energy GF of materials is defined as the area under the stress vs. the crack open displacement curve in the cohesive law, and represents the energy dissipated on the unitary crack surface [12]. GF is usually determined by tests. For a large size specimen, the fracture energy * F G equals to the max driving force max f G expressed in Equation (16), approximately. Therefore, fracture energy GF for a normal size specimen has relation with max f G as: ** * max f FN F GAGA GA (18) where AN and A* are the real areas of the fracture surfaces corresponding to the normal size and large size speci- mens, respectively, with a transformation as: 22 * * , D ch N ch N l A A l (19) where * ch l and ,ch N l are the characteristic lengthes cor- responding to A* and AN, respectively. Usually, * ch l is taken to be the minimum threshold of characteristic lengths. For concrete, * ch l= 0.15 mm when0 f = 100 MPa  H. ZHANG ET AL. Copyright © 2010 SciRes. JMP 51 and * ch l= 0.15 mm when 0 f = 200 MPa [13], and * ch l can be obtained by linear interpolation for other strengths. ,ch N l is given by [14]: ,0 2 ch N lab (20) where the constant b < 1 represents the initially cracked portion of the interface prior to load application, 2a0 is the initial crack diameter and is assumed to be equal to the maximum aggregate size in concrete. Substituting Equations (16) and (19) into Equation (18), one obtains 22 2 ,21 0 * 0 2 D ch NDD t F ch l Ga ED l (21) Here 2a0 needs is considered to be the final length of the main crack for concrete, and represents a specimen size. Figure 4 shows the behaviors of GF as the changes of a0 and D. We can find that GF increases with the in- creasing of these two factors. 3. Damage Variable An apparent damage variable is defined as the ratio of the effective bearing area Ak and the cross section area Ac of materials, and has the following form: k c A A (22) For a Euclidean shape, the area A0 and the perimeter C0 have the following relation: 2 000 A mC (23) where m0 is a shape constant. Substituting Equation (23) into Equation (22), one obtains the expression for the apparent damage variable as follows: and 2 k c C C (24) where Ck and Cc are the perimeters corresponding to Ak and Ac, respectively. It is reasonable for us to take Ck Figure 4. Influences of D and a0 on GF. Cc as the crack length in one direction and the total length of all cracks in all directions in a unit cell at fail- ure, respectively. By referring to Equation (1), the perimeter C of a fractal damaged surface and the counterpart C0 in the Euclidean space has the following relation: 1 0 D D ch CCl (25) Substituting Equation (4) into Equation (22), concern- ing Equation (25), and based on the fact that cracks in concrete is statistically self-similar fractal when the yardstick δ ranges from 0.263 to 1 [15], one obtains the following expression for a fractal damage variable in the fractal space: 11 ˆ16 ck DD (26) where Dk = 1.0 ~ 2.0. From Equation (29), we find that only the fractal dimension is different between the fractal and apparent damage variables, and δ has no influence on this relation. Since Ac is the cross section area of ma- terials, which indicates Dc = 1.0, thus Equation (26) can be rewritten as: 1 1 ˆ16 k D ij ij (27) For a smooth crack, Dk = 1.0, and no fractal effect ex- ists, and we have: ˆij ij (28) From the above discussion, we notice that the apparent damage variable in the Euclidean space is a special case of the fractal damage variable in the fractal space, and the fractal damage variable is the generalization of the apparent damage variable. Figure 5 illustrates the dif- ferences between the two kind damage variables in uni- axial compression with an assumption that Dk takes the average value of 1.1, and the original evolution data for apparent damage variables is referred from reference [16]. Figure 5. Evolutions of damage variables for concrete in uniaxial compression cases.  H. ZHANG ET AL. Copyright © 2010 SciRes. JMP 52 4. Plastic Damage Constitutive Model for Concrete Among the various existed constitutive models for con- crete, the plastic damage model has a better effect to characterize the stiffness degeneration, the strain soften- ing and the unilateral effect of concrete under various loading conditions. 4.1. Decomposition of Effective Stress Tensor In view of the fact that the typical failure modes of con- crete are cracking in tension and crushing in compression, we decompose the effective stress tensor into tensile and compressive parts (denoted by σ and σ, respec- tively) by utilizing spectral decomposition technique [17,18]: : σPσ (29) : + σσσPσ (30) where P+ and P- are the fourth-order projection tensors expressed as [19]: iii ii i H Ppp (31) PIP (32) where I is the fourth-order identity tensor; i H represents the Heaviside function calculated for the ith eigenvalue i of σ; Pij is the second-order tensor and is defined as: 1 2 ijjiij ji pp nnnn (33) where ni is the ith normalized eigenvector corresponding to i . 4.2. Plasticity We adopt a plasticity yield function f and a plastic poten- tial function Fp as: 12 max ˆ ,3 fIJ σκκ 10c κ (34) 21 3 pp F JI (35) where 2xxx denotes the Macaulay bracket function, max ˆ is the algebraically maximum effective principal stress. α, β and c are parameters with the fol- lowing forms [20]: 00 00 2 b b f f f f ; 11 c c κ κ cf κκ; cf κκ (36) where 0b f and 0 f are the initial equibiaxial and uni- axial compressive yield stresses, respectively. 00b f f lies between 1.10 and 1.20 from experiments, therefore, α varies from 0.08 to 0.12. cκ represent the inner cohesion, and fκ are the evolution stresses (posi- tive values are used here in compression) in the effective stress space due to plastic hardening or softening under uniaxial tension and compression, respectively. 1 I is the first invariant of the effective stress tensor, 2 J is the second invariant of the effective deviatoric stress tensor. αp ≥ 0 is a dilation parameter with 0.2 ≤ αp ≤ 0.3 for concrete. According to the flow rule, the rate of the effective plastic strain p can be written as: 2 3 23 p ij pp pp ij ij ij s F J (37) where p is a plastic consistency factor, and can be determined by the consistency condition for the yield surface f, which can be expressed in the Kuhn-Tucker form as: 0f , 0 p , 0 pf , 0 pf (38) In this study, the linear isotropic hardening rules are introduced to describe the change of the yield surfaces in the effective stress space, and can be expressed in simple forms as [21]: p y ffE κ (39) where y f are the effective yield strengths in uniaxial tension and compression, and have approximate values as 0y f f and0y f f , respectively. 0 f are the uniaxial yield strengths of concrete corresponding to tension and compression, respectively. p E are the effective plastic hardening modulus in uniaxial case, and have relation with the elastoplastic tangent modulus ep E as [22]: 0 0 ep p ep EE EEE (40) According to the plasticity consistency condition, we have: 0 ff f σκ σκ (41) and obtain the rate form of the constitutive equation as follows: 0, p p ijijkl kl kl F C (42) where C0,ijkl is the fourth-order undamaged elastic stiff-  H. ZHANG ET AL. Copyright © 2010 SciRes. JMP 53 ness tensor. Accounting for the coupling of tension and compres- sion, κ can be written as [22]: max min ,(1)T pp ww κ (43) where max p and min p are the maximum and minimum values of the equivalent plastic strains p ij ; w is the weight factor and has the following form: 33 11 ˆˆ ii ii w (44) where ˆi are the principle stresses. Substituting Equations (42) and (43) into Equation (41), we obtain: 0, 1 p ijkl kl p ij fC h (45) where p h can be expressed in the following forms: 0, max ˆ p p p ijkl ij kl f FfF hC w (46) 0, min 1ˆ p p p ijkl ij kl f FfF hC w (47) where max ˆ and min ˆ are the maximum and minimum effective principle stresses, respectively. Therefore, we can rewrite the rate form of the relation Equation (42) for the effective stress and the strain as: ijijkl kl C (48) where Cijkl is the elasto-plastic tangent stiffness tensor and has the following form: 0, 0,0, 1p ijkl ijklijrsmnkl p rs mn Ff CC CC h (49) 4.3. Helmholtz Free Energy A damage constitutive model of a material is based on the second law of thermodynamics which states that all the selected internal variables must satisfy the Clau- sius-Duhem inequality for any irreversible process under an isothermal condition, and has a simple form as: :0 σε (50) where σ and ε are the stress and strain tensors, is the total Helmholtz free energy (HFE) which can be consid- ered as the sum of the elastic part e and the plastic part p , that is: ,,, , eeep εκΦεΦ κΦ (51) where Φ is the damage variable tensor. We decompose e into tensile and compressive parts as: ,,, eee ee e εΦεε (52) where 0 1 ,11: 2 eee eee εεσε (53) 0 1 ,11 : 2 ee eee εεσε (54) where 0:2 ee e εσε represent the initial elastic strain energy of materials; are the tensile and com- pressive components of Φ. Therefore, we derive: 00 11 ee ee ee εε σ εε 11 σσ (55) The incremental form of Equation (55) can be ex- pressed as: 11 dd + σσ σσσ (56) Equations (56) and (48) form the final plastic damage constitutive equations for the plain concrete. Similarly, we can rewrite p as: ,, , pp p κκ κ (57) Referring to the fact that the contribution to the plastic HFE from plastic strains of concrete in tension is much smaller comparing to the one in compression, we assume that 0 p . Thus, we have: 0 ,1 ppp κκ κ (58) Substituting Equations (51), (52) and (58) into Equa- tion (50), we get: :0 ep ep e σεσεκΦ κΦε (59) Since the above inequality must be satisfied for any elastic strain εe, we have: e e σ ε (60) 0YΦ (61) :0 p p σε κ κ (62) where Y is the damage energy release rate and can be expressed as: YΦ (63) According to the above discussions about the total HFE, we can rewrite Y as: 0 Y (64)  H. ZHANG ET AL. Copyright © 2010 SciRes. JMP 54 We define the damage criteria in tension and compres- sion for concrete, respectively, as: ,0gYrY r (65) where r are the current damage thresholds whose ini- tial values is denoted by 0 r. Equation (65) indicates that damage is initiated when Y exceed the corresponding damage thresholds r. Initial strain energy of materials can be written as: 00 0 1::0 2 eee ee εεεCε (66) 00 0 ee p εκ (67) where 0 e is the initial strain energy of materials in compression, and can be expressed as: 2 0 0021011 0 12 121 0 23 eJIII E (68) 021211 1 62 23 p pp J IJ II κ s 212 11 0 1 62 26 p J IJ II E (69) where 2 :2 J sss is the norm of s; 2 1: 2 J ss is the second invariant of the compres- sive effective deviatoric stress tensor s; 1 I and 1 I are the first invariant of σ and σ, respectively. 0 2p E s is a material parameter. Therefore, 0 has the following form in compres- sion case: 2 00211 221311 32 J IJ III (70) where parameters Ω0, Ω1, Ω2, Ω3 are 0 0 0 621 6E ; 1 0 3 621 p 0 2 0 12 621 ; 0 3 0 0.5 3 621 (71) Assume that concrete is in biaxial compression, which indicates σ3≡0, and we have: 22 0 012 12 00 22 121212 0 66 63 66 6 6 p YEE E (72) For an uniaxial compression case, we denote the uni- axial compressive ultimate strength as 0 f, and have σ1=0 f ,σ2=0. We can derive the initial damage threshold 0 r as: 0 0 0 361 6 p f rE (73) And for an equibiaxial compression case, we use 0b f to denote the biaxial compressive ultimate strength. One gets σ1=σ2=0b f , and derives 0 r as: 0 00 0 6161 2 6 bp f rE (74) Noticing that the initial damage threshold is unique for a material, we obtain the expression for Ω from Equa- tions (73) and (74): 2 000 2 00 61 3 6161 2 b p p b ff ff (75) For concrete, one has 00b f f = 1.10~1.16 and p = 0.2~0.3. Assuming ν0=0.2, and substituting the above three parameters into Equation (74), we find that Ω ≥ 0 is always hold. Thus we have 0 p ≥0 (see Equation (69)), and 000 ep Y ≥0, and finally have Y ≥0. Accounting for the fact that damage is irreversible, we get , ≥ 0. Therefore, the total HFE defined in Equation (51) satisfies the thermodynamic consistency, or satisfies the inequality of Equation (61). Equation (75) reaches the limit state Ω→+∞ when 2 00 2 00 1 21 b p b ff ff , and the undamaged area of a ma- terial in compression can be characterized by the follow- ing inequality: 22 22 121212 1212 p 0 1pf (76) Figure 6 illustrates the changes of the undamaged ar- eas with αp. We find that the increase of αp will lead an expansion of the undamaged area. 4.4. Evolution Laws The evolution laws proposed by Faria et al. [18] are adopted in this research. Damage variables (in the Euc- lidean space) and their rate forms are expressed as: 0 0 1exp 1 rr B rr (77)  H. ZHANG ET AL. Copyright © 2010 SciRes. JMP 55 Figure 6. Influences of αp on undamaged domain. 0 0 11 exp1 rr AA B rr (78) 0 d rh (79) where 0 2 0 exp 1 dGr Brrr hB rr r (80) 0 2 1 dGr r hA rr 00 exp 1 AB r B rr (81) where A- is a material parameter, and can be determined by the uniaxial compression test; B± can be expressed as: 1 0 2 0 10 2 F ch GE B lf (82) where F G is the fracture energy of a material and can be determined by tests or from Equation (21). Replacing in the above model by ˆ in Equa- tion (27), we can generalize the Euclidean constitutive model for concrete to the fractal space. 5. Example Analysis 5.1 Comparison of Constitutive Models In this section, numerical simulations of the present model considering fractal effect are performed for con- crete under different loading conditions, and compari- sons of the results are done with some experimental data, i.e. the unaxial loading test by Karsan and Jirsa [23] and the biaxial loading one by Kupfer et al. [24]. Material parameters for concrete are listed in Table 1. The values of E0, ν0, αp and α are obtained from the study of Lee and Fenves [18]; Average values of lch,N, * ch l, η, a0, b and Dk are used here because of their narrow range intervals. Therefore, we can obtain the fracture energy for con- crete from Equation (21) as: F G=45.3N/m in tension and F G =1497N/m in compression. 5.1.1. Uniaxial Tension Both the predictions of the present model with and without the fractal effect and the test data obtained by Karsan and Jirsa [23] for concrete under uniaxial tension are illustrated in Figure 7(a). We can find that the two kind results of the present model agree well with the test data in the stress hardening stage. Comparing with the case of no fractal, the prediction considering the fractal is more coincident with the test. In the last large deforma- tion stage, the three behaviors are close with each other. 5.1.2. Uniaxial Compression Figure 7(b) shows the comparison of the calculation results of the present model and the test data for concrete under uniaxial compression obtained by Karsan and Jirsa (a) (b) Figure 7. Comparison of the constitutive curves of the pre- sent model with test results (Karsan and Jirsa 1969) in the uniaxial loading conditions. (a) Uniaxial tension; (b) Uniax- ial compression.  H. ZHANG ET AL. Copyright © 2010 SciRes. JMP 56 [23]. Comparing with the uniaxial tension case, both of the two kind results of the model are more efficient to simulate the concrete compressive behaviors. The pre- dictions considering fractal is slightly lower than the two other data. 5.1.3. Biaxial Tension In this simulation, equibiaxial tensile condition is adopted, and material parameters are taken as the same as those listed in Table 1. Figure 8(a) gives the behav- iors obtained from the present model and the test in bi- axial tension [24]. We find that the two kind theoretical results are coincident with the test data; in the initial strain softening stage, the result concerning no fractal agrees with the test better, but there is obviously a dif- ference between them comparing with the data consider- ing the fractal effect. All these show the superiority of the proposed model. Table 1. Material parameters for concrete. E0=31.7GPa ν0=0.2 0 f =3.48MPa 0 f =20MPa α=0.12 αp=0.2 δ =0.286 * ch l=0.156mm η=2π a0=6.0mm b=0.79 Dk=1.16 (a) (b) Figure 8. Comparisons of the constitutive curves of the present model with test results (Kupfer et al. 1969) in the biaxial loading conditions. (a) Biaxial tension (σ1: σ2=1:1); (b). Biaxial compression (σ1: σ2=-1:-1). 5.1.4. Biaxial Compression In equibiaxial compression, concrete shows a good plas- tic deformation ability which can be found both in the proposed model and the test [24]; see Figure 8(b). The three curves are well close with each other. Comparing with the three other loading cases discussed above, the peak stress increases obviously, accompanied by the slowest decreasing softening stage in biaxial compres- sion, which indicates a good compressive capacity of concrete under the confining pressure condition. Spe- cially, model with fractal damage variables is more ac- curately than the one with apparent damage variables. 5.2. Structural Analysis An unreinforced notched concrete beam under 3-point bending is simulated to verify the efficiency of the pre- sent concrete damaged plasticity model. This problem has been studied extensively both experimentally by Pe- tersson [25] and analytically by Meyer et al. [26], among others. This beam is simply supported at both ends with concentrated force acting at the center. Its sketch is illus- trated in Figure 9 (unit: m). The measured parameters of concrete are: elastic mo- dulus E0=30GPa, Poisson’s ratio ν0=0.2, density ρ0 = 2400 kg/m3 and uniaxial tensile strength ft = 3.33 MPa. The present constitutive model considering the fractal effect of concrete is adopted for the theoretical analysis. The model parameters are taken as: F G = 138 N/m, 0 f = ft = 3.33 MPa, 0 f = 30 MPa, and other properties are same as that listed in Table 1. The beam is under the plane stress condition. Accounting for the symmetry of both the structure and the load, only one half of the beam is modeled. The model is meshed with 280 4-node bilin- ear, reduced integration plane elements. The beam is loaded by prescribing the vertical displacement at the center of the beam until it reaches a value of 0.0015 m. The Riks method is used to solve this problem. Figure 10 illustrates the variation curves of the con- centrated force and the center displacement of the beam calculated from the theoretical analysis and the Peters- son’s test [25]. We can note that the theoretical result is coincidence with the test at the loading stage and slightly higher then the test at the unloading branch. Figure 11 shows the distribution of the principal tensile stress of Figure 9. Notched beam: geometry and dimensions (unit: m).  H. ZHANG ET AL. Copyright © 2010 SciRes. JMP 57 the structure as well. Mesh sensitivity is investigated in this study by mesh- ing the structure into coarse and fine grids, respectively, with 70 and 1120 same type elements with the medium mesh case. Resolving the above problem at the same condition, we get the relation between the load and dis- placement in center. Figure 12 represents the relation curves corresponding to the three kind meshes. We find that: comparing with the coarse mesh case, the structural responses agree well for the other two meshes. The structure is not sensitive to the mesh size in general. 6. Conclusions In this research, the fracture toughness, the driving force and the fracture energy of a material with fractal cracks are investigated and their theoretical expresses in the fractal space are derived based on fracture mechanics and fractal geometry. The surface energy and the strain en- ergy in the fractal fracture zone are theoretical expressed in the fractal space. The transformation rule of damage variables in the fractal space and the Euclidean space is obtained which indicates that the apparent damage vari- able in the Euclidean space is a special case of the fractal one in the fractal space with the fractal dimension of cracks equals to 1. We introduce a plastic yield function and decompose the damage variable tensor into tensile and compressive parts to establish a plastic damage con- stitutive model for concrete in the Euclidean space. Gen- eralization of this model to the fractal space is done by utilizing the damage variable transformation rule. Figure 10. Comparison of the theoretical and experimental data for the load vs. displacement curve. Figure 11. Distribution of the principle tensile stress. Figure 12. Influences of mesh size on structural response.  H. ZHANG ET AL. Copyright © 2010 SciRes. JMP 58 Comparisons of the results obtained from the present model and tests for concrete under different loading con- ditions are done to verify the efficiency of this model and show the necessity of considering the fractal effect in the constitutive model of concrete. The present model con- sidering the fractal effect is used to analyze a notched plain concrete beam under 3-point bending. Mesh sensi- tivity is also concerned. The numerical results show the efficiency and validation of the present model for struc- tural analysis. 7. Acknowledgements The present research is partly supported by the National Natural Science Foundation of China (No. 90815012), which is gratefully acknowledged. 8. References [1] B. B. “Mandelbrot, Fractals: Form, Chance, and Dimen- sion,” W. H. Freeman and Company, San Francisco, 1977. [2] B. B. Mandelbrot, “The Fractal Geometry of Nature,” W. H. Freeman and Company, San Francisco, 1983. [3] H. P. Xie and F. Gao, “The Mechanics of Cracks and a Statistical Strength Theory for Rocks,” International Journal of Rock Mechanics and Mining Sciences, Vol. 37, 2000, pp. 477-488. [4] A. Yavari, “Generalization of Barenblatt’s Cohesive Fracture Theory for Fractal Cracks,” Fractals, Vol. 10, No. 2, 2002, pp. 189-198. [5] A. Carpinteri, B. Chiaia and P. Cornetti, “On the Me- chanics of Quasi-Brittle Materials with a Fractal Micro- structure,” Engineering Fracture Mechanics, Vol. 70, 2003, pp. 2321-2349. [6] V. E. Saouma, J. J. Broz, E. Bruhwiler, et al., “Effect of Aggragate and Speciman Size on Fracture Properties of Dam Concrete,” Journal of Materials in Civil Engineer- ing, Vol. 3, No. 3, 1991, pp. 204-218. [7] M. A. Issa, A. M. Hammad and A. Chudnovsky, “Corre- lation between Crack Tortuosity and Fracture Toughness in Cementitious Materials,” International Journal of Fra- cture, Vol. 60, 1993, pp. 97-105. [8] Y. H. Zhao, “Crack Pattern Evolution and a Fractal Damage Constitutive Model for Rock,” International Journal of Rock Mechanics and Mining Sciences, Vol. 35, No. 3, 1996, pp. 349-366. [9] L. Guarracino, “A Fractal Constitutive Model for Un- saturated Flow in Fractured Hard Rocks,” Journal of Hy- drology, Vol. 324, 2006, pp. 154-162. [10] T. Yokobori, “Scientific Foundations for Strength and Fracture of Materials,” Naukova Dumka, Kiev, 1978. [11] M. P. Wnuk and A. Yavari, “On Estimating Stress Inten- sity Factors and Modulus of Cohesion for Fractal Cracks,” Engineering Fracture Mechanics, Vol. 70, 2003, pp. 1659-1674. [12] A. Carpinteri, B. Chiaia and K. M. Nemati, “Complex Fracture Energy Dissipation in Concrete under Different Loading Conditions,” Mechanics of Materials, Vol. 26, 1997, pp. 93-108. [13] Z. M. Ye, Fracture Mechanics of Anisotropic and Con- crete Materials, China Railway Publishing House, Bei- jing, in Chinese, 2000. [14] T. H. Antoun, Constitutive/Failure Model for the Static and Dynamic Behaviors of Concrete Incorporating Ef- fects of Damage and Anisotropy, Ph. D. Thesis, The University of Dayton, Dayton, Ohio, 1991. [15] H. P. Xie and Y. Ju, “A Study of Damage Mechanics Theory in Fractional Dimensional Space,” Acta Mecha- nica Sinica, in Chinese, Vol. 31, No. 3, 1999, pp. 300-310. [16] U. Cicekli, G. Z. Voyiadjis and R. K. A. Al-Rub, “A Plasticity and Anisotropic Damage Model for Plain Con- crete,” International Journal of Plasticity, Vol. 23, 2007, pp. 1874-1900. [17] M. Ortiz, “A Constitutive Theory for Inelastic Behavior of Concrete,” Mechanics of Materials, Vol. 4, 1985, pp. 67-93. [18] R. Faria, J. Oliver and M. Cervera, “A Strain-Based Plas- tic Viscous-Damage Model for Massive Concrete Struc- tures,” International Journal of Solids and Structures, Vol. 35, No. 14, 1998, pp. 1533-1558. [19] R. Faria, J. Oliver and M. Cervera, “On Isotropic Scalar Damage Models for the Numerical Analysis of Concrete Structures,” In: CIMNE Monograph, Barcelona, Spain, Vol. 198, 2000, pp. 422-426. [20] J. Lee and G. L. Fenves, “Plastic-Damage Model for Cyclic Loading of Concrete Structures,” Journal of En- gineering Mechanics, ASCE, Vol. 124, 1998, pp. 892- 900. [21] J. Y. Wu, J. Li and R. Faria, “An Energy Release Rate-Based Plastic-Damage Model for Concrete,” Inter- national Journal of Solids and Structures, Vol. 43, 2006, pp. 583-612. [22] J. C. Simo and T. J. R. Hughes, “Computational Inelas- ticity,” Springer-Verlag, New York, 1998. [23] A. I. Karsan and J. O. Jirsa, “Behavior of Concrete under Compressive Loadings,” Journal of the Structural Divi- sion, ASCE, Vol. 95, 1969, pp. 2535-2563. [24] H. Kupfer, H. K. Hilsdorf and H. Rusch, “Behavior of Concrete under Biaxial Stresses,” ACI Materials Journal, Vol. 66, 1969, pp. 656-666. [25] P. E. Petersson, “Crack Growth and Development of Fracture Zones in Plain Concrete and Similar Materials,” In: Report TVBM 1006, Division of Building Materials, University of Lund, Sweden, 1981. [26] R. Meyer, H. Ahrens and H. Duddeck, “Material Model for Concrete in Cracked and Uncracked States,” Journal of the Engineering Mechanics Division, ASCE, Vol. 120, No. 9, 1994, pp. 1877-1895. |