American Journal of Plant Sciences

Vol.4 No.12(2013), Article ID:41045,5 pages DOI:10.4236/ajps.2013.412298

Mechanized Transplanting of Rice (Oryza sativa L.) in Nonpuddled and No-Till Conditions in the Rice-Wheat Cropping System in Haryana, India

![]()

1Krishi Vigyan Kendra, CCS Haryana Agricultural University, Yamuna Nagar, India; 2Regional Research Station, CCS Haryana Agricultural University, Karnal, India; 3Department of Agronomy, CCS Haryana Agricultural University, Hisar, India; 4School of Agriculture, Food & Wine, University of Adelaide, Adelaide, Australia; 5CIMMYT-IRRI CSISA Bihar Hub, Patna, India; 6Crop and Environmental Sciences Division, International Rice Research Institute, Los Baños, Philippines.

Email: b.chauhan@irri.org

Copyright © 2013 Baldev Raj Kamboj et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received October 4th, 2013; revised November 6th, 2013; accepted November 20th, 2013

Keywords: Farmer Participatory Research; Self Propelled Paddy Transplanter; Double No-Till Rice-Wheat System; Nonpuddled Transplanted Rice

ABSTRACT

The common practice of establishing rice in the rice-wheat system in India is manual transplanting of seedlings in the puddled soil. Besides being costly, cumbersome, and time consuming, puddling results in degradation of soil and the formation of a hard pan, which impedes root growth of subsequent upland crops. In addition, decreased availability and increasing cost of labor have increased the cost of rice cultivation through conventional methods. Because of these concerns, there is a need for mechanized transplanting of rice which is less labor-intensive and can ensure optimum plant population under nonpuddled and/or no-till conditions. A large number of on-farm trials were conducted at farmers’ fields in Haryana, India, from 2006 to 2010 to evaluate the performance of the mechanical transplanted rice (MTR) under nonpuddled and no-till situations as compared to conventional puddled transplant rice (CPTR). Compared with CPTR, nonpuddled MTR produced 3% - 11% higher grain yield in different years. Rice cultivars, viz. HKR47, HKR127, PR113, PR114, PB1, PB1121, CSR30, and Arize6129, performed consistently better under nonpuddled MTR as compared to CPTR. Performance of different cultivars (PR113, PR114, HKR47, and Pusa 44) was also better under no-till MTR as compared to CPTR. The “basmati” cultivar CSR30 performed equally in no-till MTR and CPTR systems. The results of our study suggest that rice can be easily grown under nonpuddled and no-till conditions with yield advantages over the CPTR system. Even in the case of similar yield between CPTR and MTR systems, the MTR system will help in reducing labor requirement and ultimately, will increase overall profits to farmers.

1. Introduction

The northwestern region of India has played a leading role in the agricultural transformation of the country [1]. Food security of India is highly dependent on this region as evident from the contribution of this region to the national buffer stock of food grains [2-4]. Therefore, sustainable production of rice (Oryza sativa L.) in this region is crucial for the food security of India. In most of the north-west India, the common practice of establishing rice in the rice-wheat (Triticum aestivum L.) systems is manual transplanting of seedlings in puddled soils [5].

Puddling is achieved by repeated intensive tillage under ponded-water conditions, which helps in reducing water losses through percolation and controlling weeds by water stagnation in rice fields. Puddling is a rather extreme form of tillage because it results in aggregate breakdown and destruction of macropores [6]. Besides being costly, cumbersome, and time consuming, puddling results in degradation of soil and other natural resources and subsequently poses difficulties in seedbed preparation for succeeding nonrice crops in rotation [5,7]. The use of continuous puddling results in the formation of a hard pan with a consequent increase in bulk density and lowering of hydraulic conductivity below the plow layer [8]. The hard pan impedes root growth of subsequent upland crops, including wheat and maize (Zea mays L.).

Decreased availability and increasing cost of labor have increased the cost of rice cultivation through conventional methods [9]. Implementation of the government’s policies [10] has been creating a labor scarcity in northwest India as rice transplanting in this region is dependent on migrant laborers from the eastern states of India [3]. In addition, the plant population of rice remains quite low in manual transplanting compared to the recommended plant density. In order to compensate for lower plant population, farmers often use excessive nitrogenous fertilizer to encourage tillering, which generally results in complex problems of insect-pests and diseases and ultimately lower yields. Because of these problematic issues, there is a need for mechanized transplanting of rice which is less labor-intensive and can ensure optimum plant population under nonpuddled and/or no-till situations.

Earlier efforts on mechanized transplanting were made in puddled conditions which failed due to the problem of soil settling (loose soil), resulting in missing plants. Therefore, in this farmers’ participatory research, efforts were concentrated on mechanized transplanting of rice under nonpuddled and no-till conditions. In our knowledge, this is the first study which was conducted in large number of farmers’ fields on mechanical transplanting in nonpuddled and no-till conditions.

2. Materials and Methods

A large number (Table 1) of on-farm trials were conducted at farmers’ fields from 2006 to 2010 to evaluate the performance of mechanical transplanted rice (MTR) systems under nonpuddled and no-till situations as compared to the conventional puddled transplant rice (CPTR) system. “Mat type” nursery was prepared for transplanting with self propelled paddy transplanter (powered by a 4.5 HP diesel engine with fuel consumption of 0.5 l hr−1 during field operations). It could plant 8 rows in one pass at a spacing of 23.5 cm × 12 or 14 cm with 35 and 30 hills m−2, respectively. Similarly, the number of plants per hill could be adjusted (2 - 4 plants per hill). Mechanical transplanting was done in nonpuddled (after cultivation in dry soils rather than in wet soils) as well as no-till situations. For transplanting in nonpuddled conditions, fields were prepared with 1 - 2 hoeing in dry or vattar conditions (depending on soil types) followed by land leveling. After this, a light irrigation was given and let the soil settled for 12 - 24 hours. Fields were again replenished with 2 - 3 cm standing water before transplanting. Under no-till situations, germinated weeds, if

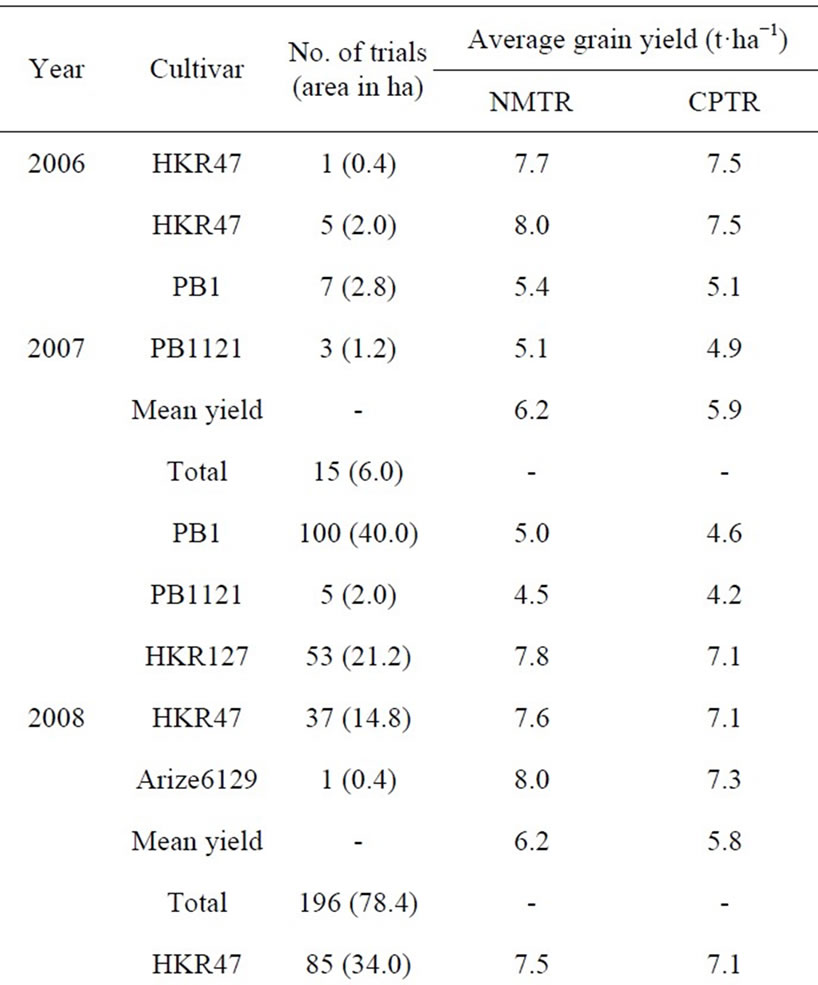

Table 1. Performance of rice cultivars in nonpuddled mechanical transplanted rice (NMTR) and conventional puddled transplanted rice (CPTR) systems at farmers’ fields in Haryana, India during the kharif seasons of 2006 to 2010. Each trial represents an area of 0.4 ha.

any, were knocked down by the use of a nonselective herbicide (glyphosate) at 7 - 10 days before transplanting. Irrigation was applied 12 hours before transplanting. Three weeks old mat type nursery was used for transplanting.

Efforts on MTR were initiated in farmer participatory research approach at village Antawa in the district Yamuna Nagar, Haryana, India, in 2006 with merely a 0.4 ha area. In 2007, the area covered under this crop establishment technique was 6 ha which increased to about 80 ha in 2008. In addition of the district Yamuna Nagar, the technique of mechanical transplanting was also demonstrated in other districts of the state Haryana (Kaithal, Jind, and Kurukshetra), covering an area of 120 ha (39 villages at 67 locations) in 2009. In 2010, 56 on-farm trials (each of 0.4 ha) on mechanical transplanting in nonpuddled conditions were conducted in two districts (Kaithal and Yamuna Nagar) of Haryana comprising 10 villages at 18 locations. MTR under no-till conditions was also compared with CPTR on 4.8 ha at four locations during the kharif season of 2009 and on 1.2 ha at two locations during the kharif season of 2010 in districts Kaithal and Yamuna Nagar.

To study the long-term impacts of double no-till systems in the rice-wheat cropping system, one trial was conducted at village Antawa, Yamuna Nagar, Haryana, India, from 2005-06 to 2010-11. Under no-till, transplanting of rice was done with a self propelled rice transplanter and sowing of wheat was done with a seed-cumfertilizer drill. Under conventional tillage, rice was transplanted manually in puddled conditions (CPTR) while wheat was sown in the prepared field with a seed-cumfertilizer drill.

3. Results and Discussion

3.1. Mechanical Transplanting under Nonpuddled Soil Conditions

In 2006, the cultivar HKR47 produced 0.2 t ha−1 higher yield in the MTR system as compared to the CPTR system (Table 1). In 2007, the average grain yields of HKR47 (five trials), PB1 (seven trials), and PB1121 (three trials) were 8.0, 5.4, and 5.1 t·ha−1 in nonpuddled MTR compared to 7.5, 5.1, and 4.9·t ha−1 under CPTR, respectively. In this year, the overall average grain yield in nonpuddled MTR was 6.2 t·ha−1 compared to 5.9 t·ha−1 in CPTR. In 2008, the average grain yields of PB1 (100 trials), PB1121 (five trials), HKR127 (53 trials), HKR47 (37 trials), and Arize6129 (one trial) in the district Yamuna Nagar were 5.0, 4.5, 7.8, 7.6, and 8.0 t·ha−1 in nonpuddled MTR compared to 4.6, 4.2, 7.1, 7.1, and 7.3 t·ha−1 in CPTR, respectively. In this year, the overall average grain yield in nonpuddled MTR was 6.2 t·ha−1 compared to 5.8 t·ha−1 in CPTR. In 2009, the average grain yields of HKR47 (85 trials), PR113 (33 trials), PR114 (110 trials), PB1 (19 trials), PB1121 (43 trials), Arize6129 (five trials), and CSR30 (nine trials) in different districts (Kaithal, Yamuna Nagar, and Jind) of Haryana were 7.5, 8.1, 8.0, 5.0, 4.5, 8.4, and 3.9 t·ha−1 in nonpuddled MTR as compared to 7.1, 7.6, 7.5, 4.8, 4.3, 7.8, and 3.7 t·ha−1 in CPTR, respectively. In this year, the average grain yield over the trials under nonpuddled MTR was 7.1·t·ha−1 compared to 6.7 t·ha−1 under CPTR. In 2010, average grain yield of rice over the trials in nonpuddled MTR was 6.0 t·ha−1 compared to 5.4 t·ha−1 in CPTR.

Compared with CPTR, nonpuddled MTR produced 3%, 5%, 8%, 6%, and 11% higher grain yield in 2006, 2007, 2008, 2009, and 2010, respectively. The results of our study suggest that rice can be grown in nonpuddled conditions with a yield advantage over CPTR. In a previous study, the yield in a nonpuddled transplanted (manual) rice system was greater (8.9 vs. 7.2 t·ha−1) than that in CPTR [11]. Even in the case of similar yield between CPTR and MTR systems, the MTR system will help in reducing labor requirement and ultimately, will increase overall profits to farmers [12].

3.2. Mechanical Transplanting under No-Till Situations

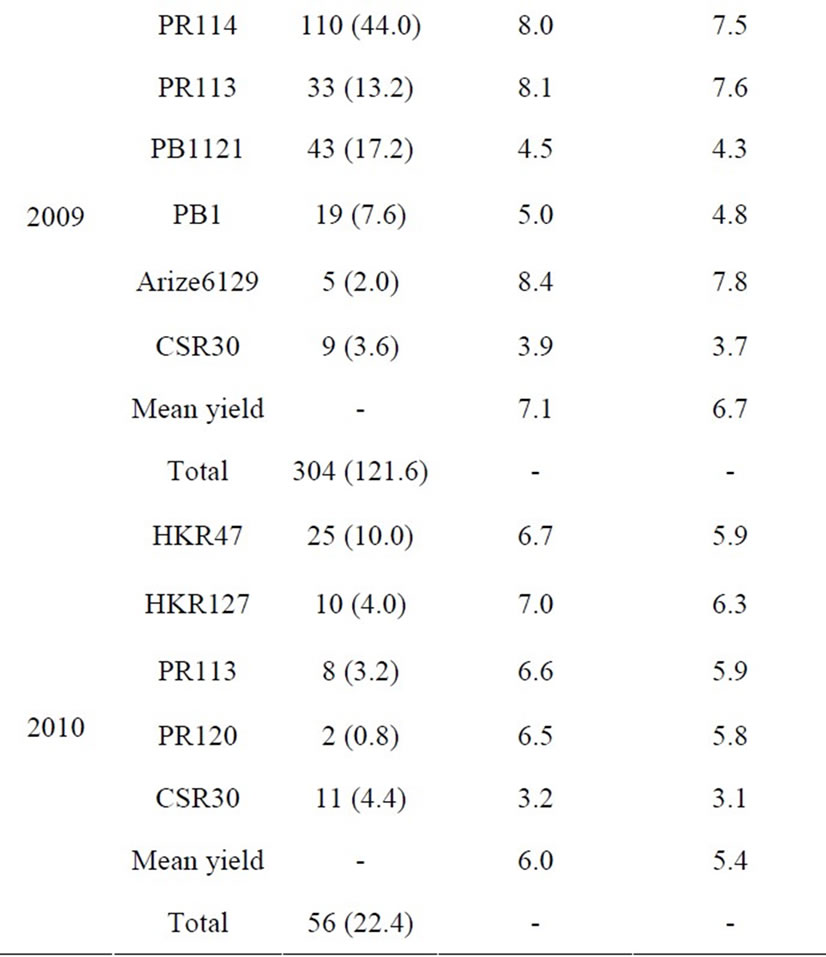

In 2009, all rice cultivars performed better when grown in no-till MTR compared with CPTR (Table 2). Based on the results of 12 trials, the average grain yield of rice was 0.4 t·ha−1 (5%) higher for no-till MTR (8.0 t·ha−1) compared to CPTR. In 2010, the performance of Pusa44 was better in no-till MTR (7.3 t·ha−1) than in CPTR (6.8 t·ha−1). The basmati cultivar CSR30 produced similar yield (3.2 t·ha−1) in no-till MTR and CPTR systems.

The performance of rice transplanters under nonpuddled (after cultivation in dry soil conditions) and no-till situations has been reported better than CPTR earlier as well [13]. Our results suggest that rice can also be grown after transplanting in no-till conditions. No-till systems reduce production costs, mainly for land preparation

Table 2. Performance of rice cultivars in no-till mechanical transplanted rice (NTMTR) and conventional puddle transplanted rice (CPTR) systems at farmers’ fields in Haryana, India.

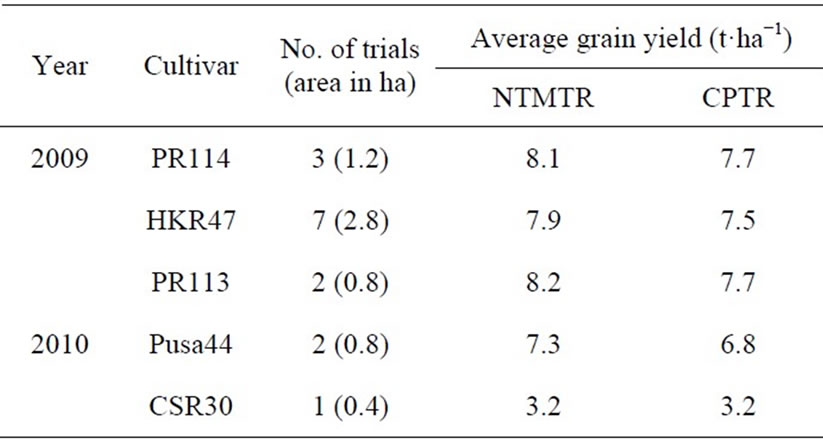

Table 3. Long-term performance of mechanical transplanted rice and wheat under double no-till (NT) and conventional tillage (CT) systems at Antawa, Yamuna Nagar, Haryana, India.

compared with transplanting in puddled and nonpuddled soil conditions [14-16].

3.3. Mechanical Transplanting of Rice under Double No-Till Rice-Wheat System

The results of the long-term study (2005-06 to 2010-11) at Antawa, Yamuna Nagar, Haryana, India, clearly revealed that the productivity of mechanical transplanted rice in no-till conditions as well as that of no-till wheat was sustainable (Table 3). The grain yield of rice over the years under no-till MTR was higher than CPTR. On an average of five seasons, no-till MTR (7.3 t·ha−1) produced 0.7 t·ha−1 higher yield than CPTR; an 11% higher. Similar trend was observed in the case of subsequent wheat crops in the rice-wheat cropping system and the average yield in no-till wheat was 5.0 t·ha−1 compared to 4.9 t·ha−1 in conventional tillage.

In summary, rice cultivars, viz. HKR47, HKR127, PR113, PR114, PB1, PB1121, CSR30, and Arize6129, performed consistently better in nonpuddled MTR systems as compared to CPTR systems in Haryana, India. Performance of different cultivars (PR113, PR114, HKR47, and Pusa 44) was also better in no-till MTR systems as compared to CPTR systems. Mechanized transplanting of all type of rice cultivars has been successful in nonpuddled and no-till situations with long-term sustainability in the double no-till rice-wheat system in Haryana, India.

REFERENCES

- B. S. Dhillon, P. Kataria and P. K. Dhillon, “National Food Security Vis-À-Vis Sustainability of Agriculture in High Crop Productivity Regions,” Current Science, Vol. 98, 2010, pp. 33-36.

- G. Mahajan, B. S. Chauhan and M. S. Gill, “Dry-Seeded Rice Culture in Punjab State of India: Lessons Learned from Farmers,” Field Crops Research, Vol. 144, 2013, pp. 89-99. http://dx.doi.org/10.1016/j.fcr.2013.01.008

- G. Mahajan, B. S. Chauhan, J. Timsina, P. P. Singh and K. Singh, “Crop Performance and WaterAnd Nitrogen-Use Efficiencies in Dry-Seeded Rice in Response to Irrigation and Fertilizer Amounts in Northwest India,” Field Crops Research, Vol. 134, 2012, pp. 59-70. http://dx.doi.org/10.1016/j.fcr.2012.04.011

- J. Rockström, M. Lannerstad and M. Falkenmark, “Assessing the Prospects for a New Green Revolution in Developing Countries,” Proceedings of the National Academy of Science USA, Vol. 104, No. 15, 2007, pp. 6253- 6260. http://dx.doi.org/10.1073/pnas.0605739104

- B. S. Chauhan, G. Mahajan, V. Sardana, J. Timsina and M. L. Jat, “Productivity and Sustainability of the RiceWheat Cropping System in the Indo-Gangetic Plains of the Indian Subcontinent: Problems, Opportunities, and Strategies,” Advances in Agronomy, Vol. 117, 2012, pp. 315-369. http://dx.doi.org/10.1016/B978-0-12-394278-4.00006-4

- A. J. Voase-Ringrose, J. M. Kirby, G. Djoywasoito, W. B. Sanidad, C. Serrano and T. M. Lando, “Changes to the Physical Properties of Soils Puddled for Rice during Drying,” Soil Tillage Research, Vol. 56, No. 1-2, 2000, pp. 83-104. http://dx.doi.org/10.1016/S0167-1987(00)00124-0

- B. S. Chauhan, “Weed Ecology and Weed Management Strategies for Dry-Seeded Rice in Asia,” Weed Technology, Vol. 26, No. 1, 2012, pp. 1-13. http://dx.doi.org/10.1614/WT-D-11-00105.1

- U. P. Singh, Y. Singh, V. Kumar and J. K. Ladha, “Evaluation and Promotion of Resource Conserving Tillage and Crop Establishment Techniques in Rice-Wheat System in Eastern India,” In: J. K. Ladha, Yadvinder-Singh, O. Erenstein and B. Hardy, Eds., Integrated Crop and Resource Management in the Rice-Wheat System of South Asia, International Rice Research Institute, New Delhi, 2009, pp. 151-176.

- S. Pandey and L. Velasco, “Trends in Crop Establishment Methods in Asia and Research Issues,” In: K. L. Heong, B Hardy and K. Toriyama, Eds., Rice Is Life: Scientific Perspectives for the 21st Century, International Rice Research Institute, Los Baños, Philippines and Japan International Research Center for Agricultural Sciences, Tsukuba, 2005, pp. 178-181.

- GOI (Government of India), “The Mahatma Gandhi National Rural Employment Guarantee Act 2005,” Government of India, Ministry of Rural Development, 2011. http://nrega.nic.in/netnrega/home.aspx

- S. Singh, A. Yadav, R. K. Malik and H. Singh, “Rice Transplanting on Raised Beds—A New Technique in Rice-Wheat Sequence,” International Workshop on Herbicide Resistance Management and Zero Tillage in RiceWheat Cropping System, Department of Agronomy, CCS Haryana Agricultural University, Hisar, 4-6 March 2002, pp. 213-214.

- B. S. Chauhan, “Strategies to Manage Weedy Rice in Asia,” Crop Protection, Vol. 48, 2013, pp. 51-56. http://dx.doi.org/10.1016/j.cropro.2013.02.015

- D. B. Yadav, A. Yadav, G. Gill and J. S. Dhankar, “Sowing and Transplanting of Rice with Machine,” Proceedings of the Workshop on Direct Seeding and Mechanized Transplanting of Rice, CCS HAU Regional Research Station, Karnal, 24 September 2010, pp. 26-31.

- R. M. Bhager, S. I. Bhuiyan, K. Moody and L. E. Estorninos, “Effect of Water, Tillage and Herbicide on Ecology of Weed Communities in Intensive Wet-Seeded Rice System,” Crop Protection, Vol. 18, No. 5, 1999, pp. 293-303. http://dx.doi.org/10.1016/S0261-2194(99)00024-1

- B. S. Chauhan, G. Gill and C. Preston, “Tillage System Effects on Weed Ecology, Herbicide Activity and Persistence: A Review,” Australian Journal of Experimental Agriculture, Vol. 46, No. 12, 2006, pp. 1557-1570. http://dx.doi.org/10.1071/EA05291

- B. S. Chauhan and J. Opeña, “Effect of Tillage Systems and Herbicides on Weed Emergence, Weed Growth, and Grain Yield in Dry-Seeded Rice Systems,” Field Crops Research, Vol. 137, 2012, pp. 56-69. http://dx.doi.org/10.1016/j.fcr.2012.08.016