American Journal of Anal yt ical Chemistry, 2011, 2, 16-25 doi:10.4236/ajac.2011.228119 Published Online December 2011 (http://www.SciRP.org/journal/ajac) Copyright © 2011 SciRes. AJAC Application of Molecularly Imprinted Polymers for the Analysis of Pesticide Residues in Food—A Highly Selective and Innovative Approach Raquel Garcia, Maria João Cabrita, Ana Maria Costa Freitas Instituto de Ciências Agrárias e Ambientais Mediterrânicas, Departamento de Fitotecnia, Escola de Ciências e Tecnologia, Universidade de Évora, Évora, Portug al E-mail: afreitas@uevora.pt Received November 15, 2011; revised December 21, 2011; accepted Decembe r 29, 2011 Abstract The increasing application of pesticides for agricultural purposes involves serious risk to the environment and human health due to either exposure or through residues in food and drinking water. Since food safety is of mandatory importance there is a growing interest on the development of selective, simple, rapid, cost-ef- fective and reliable analytical methodologies in order to ensure that pesticides residues should not be found at levels above the established maximum pesticide residue limits (MRLs). In recent years, a new methodol- ogy based on the development of molecularly imprinting polymers (MIPs) allows not only pre-concentration and cleaning of the sample but also selective extraction of the target analyte, which is crucial, particularly when the sample is complex and impurities can interfere with quantification. The scope of this review is to provide a general overview on MIPs field, with emphasis on MIP preparation and its use as sorbents for solid-phase extraction. This paper will be focused on the review of the current state of the art in the use of MIPs as selective materials in molecularly imprinted solid-phase extraction (MISPE) for the analysis of pes- ticide residues from food matrices. A review of preparation and application of MIPs in food matrices, will also be discussed. Keywords: Molecularly Imprinted Polymer, Pesticide Residues, Food 1. Introduction Nowadays, modern agriculture largely employs the ex- tensive application of agrochemicals, which includes in- organic fertilizers and pesticides, to increase world food production. Agricultural pesticides widely used belong to different classes, namely organophosphorus (OPPs), or- ganochlorine (OCPs) and pyrethroids. The use of pesti- cides can result in occurrence of residues of these che- micals, and their metabolites, in every components of environment, namely water and soil; their presence can also be extended to crops, vegetables and fruits [1]. In recent years, many studies have proved that those pesti- cides are mutagenic, carcinogenic, cytotoxic, genotoxic, teratogenic and immunotoxic; some interference in re- production function [1] has also been reported. Thus, the analysis of pesticide residues in food and environmental samples is still considered an emerging issue. The toxic- ity of pesticide residues prompted the establishment of regulatory guidelines that set maximum residue levels (MRLs) in food, providing assurance that any pesticide, remaining in food, is within safe limits in order to protect people from potential negative health effects or con- tamination. Another purpose of pesticide residue moni- toring, in food, is to assess the food safety risk due to the dietary exposure of the population to pesticides. The European Union, the Codex Alimentarius Commission of the Food and Agriculture Organization of the United Na- tions (FAO) and the World Health Organization (WHO) have established maximum residue limits (MRLs) for pesticides residues in food [2]. The low MRLs have prompted the development of more powerful and more sensitive analytical methods. Due to the wide variety of complex sample matrices, the development of analytical approaches allowing the detection of analytes with high selectivity and sensitivity constitute a challenging task. Recently, the development of molecularly imprinting polymers (MIPs) technology based on a mechanism of  R. GARCIA ET AL.17 molecular recognition, and their further application as selective sorbents in Solid Phase Extraction (MISPE) [3,4] or as stationary phases in High Performance Liquid Chromatography (HPLC) have provided a new versatile tool for the highly selective quantification of those toxics in food matrices. In fact, this technique seems to be par- ticularly suitable for extractive applications in very com- plex matrices allowing the achievement of higher analyte selectivity. The aim of this review is to describe the main developments and applications of MIPs, in the field of food matrices, with special emphasis on their analytical applications. We will also detail the advantageous of MIPs application for the quantification of pesticides in those food matrices. 2. Molecularly Imprinted Polymers (MIPs) Technology 2.1. Synthesis of Molecularly Imprinted Polymers Molecularly imprinting is a template-directed technique that allows the design and synthesis of polymers with well defined artificial generated recognition sites that are intentionally engineered and specific for a target analyte or class of analytes. Briefly, the imprinting technology leads to the formation of three-dimensional macromo- lecular structures by means of a polymerization process which uses a template molecule and a functional mono- mer for co-polymerization in the presence of a cross- linking agent and an initiator in a porogenic solvent [5]. Since the formation of a stable template-monomer com- plex is crucial for the molecular recognition phenomena the functional monomers selected for the synthesis should interact with the template molecule. In this process, mo- nomers are positioned spatially around the template and such position is fixed by copolymerization with cross- linking monomers. After removal of the template mole- cules, by extensive washing steps in order to disrupt the interactions between the template and the monomers, the MIPs binding sites enable available. The resulting im- printing molecules could be considered as a macro po- rous matrix which contain specific recognition sites, or imprints, that are sterically and chemically complemen- tary to the template molecule, and consequently to the analyte or group of related analytes, enabling the poly- mer to, selectively, “rebind” the imprint molecule and its analogues from a mixture (Figure 1). Consequently, these polymeric materials recognize and bind, selectively, only the template molecules [5]. Hence, the choice of the che- mical entities used to synthesize MIP play a crucial role since these compounds have a significant influence on the morphology, physico-chemical properties and per- formance of those polymeric materials [3]. The comprehensive understanding of the role of those chemical entities used on the preparation of MIPs is a very demanding task [7]. Attending to the literature some remarks could be considered: the relevance of the selec- tion of functional monomers, due to their role on the formation of highly specific cavities, designed for the template molecule; the importance of cross-linker mole- cules choice, due to their action on the control of the polymeric matrix morphology. These compounds are also involved on the stabilization of the imprinted binding sites, allowing the mechanical stability of the polymeric material, which play a crucial role on the capability to retain its molecular recognition [8]. Concerning the po- rogenic solvent used on the imprinting process, some factors, such as nature and volume, seems to have a key role in the molecular imprinting process. The most com- mon solvents used for MIP synthesis are toluene, chlo- roform, dichloromethane and acetonitrile. The solvent role, in the imprinting process, is related with the solu- bility of all the entities (monomer, template, initiator and cross-linker) in the same phase, during the polymeriza- tion process, leading to the formation of large pores in macroporous polymers, in order to assure reasonable “flow through” properties of the resultant MIP [5]. Thus, the solvent is also known as the “porogen”. In most common MIP synthesis, apolar and non-protic solvents (e.g. toluene and chloroform) are selected. However, if hydrophobic forces are involved in the template-mono- mer preparation, water or other protic solvents are pre- ferred [5]. The initiator also plays a relevant role on the Crosslinker Template Functional monomers Initiator Polymerisation Template removal (wash) Formation of imprinting Cavities by polymerization Figure 1. Schematic representation of a molecular imprinting process. Complexes, formed in solution by interactions between the template molecule (here black figure) and one or more functional monomer(s), become fixed during polymerization with a cross-linker. Polymeric recognition sites are formed, complementary to the template in size, shape and position of the func- tional group (Adapted from [6]). Copyright © 2011 SciRes. AJAC  R. GARCIA ET AL. 18 preparation of MIPs. Generally, a higher percentage of initiator leads to the formation of more rigid polymers with defined shape and higher specificity of imprinting cavities. In opposite, when lower amounts of initiator are used, the peak temperature inside the polymerization mixture decreases, generating polymers with good qual- ity imprinting cavities [7]. As depicted in Figure 1, these recognition sites mimic the binding sites of biomolecular systems, namely antibodies and enzymes [9]. However, in contrast to those biological entities, MIPs are stable in a broad range of pH, pressure and temperature (<180˚C). Additionally, those polymeric materials are easier to synthesize for a wide range of substances and are less expensive than antibodies [10]. Furthermore, the storage of MIPs for several years, at room temperature, seems to have no apparent reduction on their performance show- ing other inherent advantages, such as robustness and lower costs [11,12]. Moreover, these polymeric materials can be reused for several times without loss of the “memory effect” [13]. Molecular imprinting is classified according to the nature of the interactions between monomer and template during the polymerization proc- ess. Nowadays, the main methodologies applied for the preparation of MIPs are based on covalent, non-covalent, semi-covalent and metal-mediated interactions [8,13]. The non-covalent imprinting, also called as self-assem- bling approach, is characterized by weak interactions between the template molecule and the functional monomers, such as hydrogen bonds, Van der Waals forces, ion or hydrophobic interaction (Figure 3(a)). In order to increase the strength of the template-functional monomers assemblies, the template molecule should possess multiple functional sites. In this methodology, the functional monomers are used in excess compared to the template to displace the equilibrium to form the tem- plate-monomer complex since this interactions is gov- erned by an equilibrium process. Consequently, the ex- cess of free monomer is randomly incorporated to the polymeric matrix leading to the formation of heteroge- neous or non-selective binding sites. Frequently, a struc- tural analog of the target analyte, also called dummy molecule, is used due to economic reasons and to avoid the risk of residual template leaking from the polymer that represents a significant source of interferences and systematic errors in trace analysis. This phenomenon, also called as template bleeding, is considered a critical point, in particular, of MISPE technology [14,15]. In non-covalent imprinting methodology it is usually se- lected, as porogen, less polar solvents, such as chloro- form or toluene, which ease the formation of polar non- covalent interactions promoting template functional mo- nomer complex formation. The use of more polar sol- vents implies the dissociation of the non-covalent inter- actions, in the prepolymer complex, restricting their ap- plication on non-covalent imprinting process. Figure 2 represent some compounds which have been used as functional monomers and cross-linkers in the synthesis of MIPs using the non covalent imprinting [5,8]. In covalent imprinting, also known as preorganized approach, covalent reversible and easily cleavable bonds, between the template molecule and the functional mo- nomers, will be established leading to the formation of moderately homogeneous population of binding sites (Figure 3(b)). In this approach, the template-monomer complex is obtained, without use of excess of functional monomer, minimizing non-specific interactions. These techniques require the synthesis of template-monomer complex, be- fore polymerization, as well as the cleavage of covalent bounds, in order to remove the template from the poly- meric matrix, which represent some drawbacks of this methodology. Furthermore, the limited choice of func- tional monomers, which could be applied to this meth- odology, restricts the applicability of this technique. Semi-covalent methodology involves the covalent bond- ing between the template and the polymerizable group, leading to the formation of the polymer (Figure 4). Tem- plate rebinding is established by non-covalent interac- tions. As occurs in covalent imprinting, semi-covalent approach is restricted to a few numbers of functional groups requiring some synthetic procedures, on the tem- plate molecule before polymerization, followed by a chemical process to release the template. The metal-coordination interactions are quite direc- tional and offer promising opportunities to design MIPs in protic solvent environment becoming a viable way to develop MIPs with novel and enhanced recognition characteristics. In this methodology, the metal ion (gen- erally a transition metal) is complexed by a polymeriz- able ligand(s) and by the template. The strength of this interaction is influenced by the oxidation state of the metal as well as by the ligand characteristics, although it can be as strong as a covalent bond [16]. Some advan- tages could be addressed to this imprinting technique, namely the formation of these polymeric materials, which take place in aqueous medium without requiring severe conditions, the great versatility, due to the ability of metal ions to interact with different functional groups and the availability of a wide array of ligands, allowing to define the coordinating properties of the metal centers towards different analytes [17]. Therefore, the non-co- valent approach is the most straightforward and flexible procedure which can be adapted to a wide range of tem- plate molecules, despite the covalent interaction that give rises to a higher stability of prepolymerization complex. The imprinting effect, which means the evaluation of the Copyright © 2011 SciRes. AJAC  R. GARCIA ET AL.19 OH O OH OO OH OH F3CO OH OO OH N H O SO3H NH2 O O O OH O O N NH2 N N NN HN H OO N N H N H O O N HN H O OO O O ON H O O O O OO O OOH O O OO O O O O O O OO O O NH2 O N H SOH OO O Functional monomers Crosslinkers A c r ylic aci dM ethacrylic acid4- vinylbenzoic acidTrifluoromethacrylic a c idItaconic acid 2-acrylamido-2-methyl- 1-propanesulfonic acidMethacrylamide 2-hydroxyethyl m ethacrylate N,N-(diethylam ino)ethyl m ethacrylate 4 - v in y la nilin e 4- vinylpyridine 4- vinylim idazoleN,N-methylenbisacrylamide 2,6-bis-acrylamidopyridine1-(4-vinylphenyl)-3-phenyl urea Ethylene glycol dim ethacrylateN;O- bism ethacryloyl ethanolaminedivinylbenzene Trimethylolpropan e trim ethacrylatePentaerythritol triacrylate te tra a cry late Acrylam ide 2-Acrylamido-2-methylpropane sulphonic acid Figure 2. Several chemical entities involved in MIPs preparation. Template Functional monomers Polymerisation Insertion Cros slinker Preorganisation Extraction (a) Template Functional monomers Polymerisation Insertion Crosslinker Preorganisation Extraction (b) Figure 3. Schematic representation of (a) non-covalent and (b) covalent interaction approaches for the synthesis of MIP. Copyright © 2011 SciRes. AJAC  R. GARCIA ET AL. 20 Template Preorganisation Functional monomers Polymerisation Crosslinke Bond cleavage (a) Template Insertion Extraction (b) Figure 4. Schematic representation of semi-covalent approach used for the preparation of MIP. This imprinting technology involves two steps: (a) synthesis of MIP by the covalent approach and (b) molecular recognition of the template by non-covalent interactions. selectivity of the MIPs to recognize, specifically, the target analyte, comprises the study of the interactions between the template or the target analyte and the MIPs. These studies are carried out in parallel with a non-im- printed polymer (NIP), which is synthesized using the same polymerization technique but in the absence of the template. Consequently, NIP does not possess specific cavities and the strength of the interactions between template/target analyte and NIP will be much lower than in the MIPs [15]. Despite the high selectivity achieved by MIPs certain drawbacks can be attributed, which in- clude the time consuming and complicated preparation process, low binding capacity, poor site accessibility and slow binding kinetics. The attempts to overcome these problems rely on the optimization of the structure of imprinted materials with suitable forms. Recently, some research groups have introduced methods to achieve, more quickly, the optimized MIP based on combinatorial chemistry [18-20]. Another disadvantage relies on the design of water-compatible MIP, particularly when the imprinting process used for the preparation of these macro porous materials is based on non-covalent interact- tions. In this case, water molecules will compete with the template leading to the weakness, or destruction, of the non-covalent interactions between the template and func- tional monomers [5]. Nevertheless, the use of metal- mediated interactions seems to be a very promising ap- proach to enhance the association of the template and the functional monomer in water, circumventing the pro- blems associated with the development of water-com- patible MIPs based on self- assembling approach [5]. 2.2. Polymerization Techniques Among the several reported methods for the preparation of MIPs, namely bulk, suspension, precipitation, swell- ing and in situ polymerization, the former is the most widely used method owing to its simplicity and versatil- ity [12,15,21]. The bulk polymerization relies on the synthesis of block monolith polymers which are crushed, ground and sieved to yield irregular particles in the 25 - 50 μm size range. A subsequent step, involving a sedi- mentation process, is introduced to remove fine particles. Remaining particles, with appropriate size, are dried and packed, between two frits, into either disposable car- tridges, which can be used in an off-line system, or into precolumns to be coupled on line with LC. Bulk polym- erization is time consuming, labor intensive and wasteful. The non-regular shape of the particles has a great impact on the poorly packing of columns causing broad asym- metric peaks if they are used as stationary phase in LC, capillary electrochromatography (CEC) or in on-line coupling with LC [12,15,21]. In suspension polymeriza- tion the organic-based polymerization mixture is sus- pended, as droplets, in a continuous phase (water, min- eral oil or perfluorocarbon). The process occurs in the droplets phase by a free radical mechanism since each droplet acts as a mini bulk reactor. This methodology is reliable and generates polymers, with relatively high yields, possessing improved chromatographic character- istics [12,15,21].Another polymerization technique is precipitation, which differs from the other techniques due to the use of a larger amount of porogen, than the typically amounts used in the bulk method. During this process, the polymer chains grow and precipitate because of the insolubility towards the liquid phase. The accurate control of the different parameters, which influence the polymerization process (e.g. temperature, cross-linker), yields micro- and nanospheres. Besides the simplicity and high reaction yield some drawbacks can be attributed to this methodology, such as the use of higher amounts of porogen solvents and reagents. The slightly irregular shape and colloidal nature of the particles obtained are also seen as a limitation of this technique [12,15,21]. In Copyright © 2011 SciRes. AJAC  R. GARCIA ET AL.21 order to circumvent some problems related with the size distribution and the shape of the MIP particles, a polym- erization method has been developed based on the swe- lling of uniformly sized particles. This methodology has been improved, leading to the development of more so- phisticated procedure, the multi step swelling approach. Although the higher yields achieved in this technique, it is also one of the more laborious and complex procedure [12,15,21]. MIPs can be also synthesized by in situ polymeriza- tion approach. Using this technique MIPs monoliths are covalently anchored to the inner wall of fused-silica cap- illaries avoiding the use of retaining frits. To achieve polymerization, the capillaries are placed under a UV source or in a heating bath. The final step involves flush- ing of the capillaries, with appropriate solvents to re- move the excess solvent; an equilibration procedure must also be performed. This methodology is simpler and quicker when compared with previously described pro- cedures [12,15,21]. 2.3. Molecularly Imprinted Polymers in Selective Solid-Phase Extraction The application of molecularly imprinted polymers on solid phase extraction (MISPE) can be considered as the most advanced application on the MIPs field. The ex- traction procedure can be performed off-line or on-line coupled with liquid chromatography (LC), which have been reported in recent reviews [14,22,23]. In this solid phase extraction method, MIPs particles are used as se- lective sorbent materials. These polymers can be packed into an HPLC precolumn or placed between two frits in on-line and off-line mode, respectively. The on-line MI- SPE procedure minimizes sample manipulations and re- duces the possibility of analytes loss as well as eventual contaminations. The off-line method is simpler and widely used due to its simplicity. As classical SPE, the principle of MISPE comprises four steps: conditioning of the sor- bent, percolated of the sample through the MIPs, wash- ing to remove eventual interfering compounds and elu- tion of the target analytes (Figure 5). The choice of the solvent, for the loading step, must be done judiciously in order to select a solvent with a similar polarity to the one used in the polymerization process. In further steps, the solvent must be able to disrupt the interactions between the residual monomers, present at the MIPs surface, without affecting the overall retention, in the specific binding sites (washing), followed by the desorption of the analytes, using a solvent able to disrupt the interac- tions between the analytes and the MIPs (elution of the target analytes) [5,14,15]. Conditioning of sorbent Target analyte Interfering compounds Sample loading Washing Elution of the Target analytes Matrix components Figure 5. Schematic representation of the four steps of the MISPE process. 3. Application of MIPs as Sorbents for Solid Phase Extraction (SPE) of Pesticides Residues in Food Samples Pesticide residues in food can possess severe risks to human health and, therefore, they are of huge importance in food industry. Analytical techniques to detect pesti- cide residues, in food, have to be highly sensitive since the target analytes are, usually, present only in trace amounts; the differences and the complexity of samples and matrices are also a cause of concern that needs to be well addressed to achieve successful results. Any careful revision will come out with several different methodolo- gies used to identify and quantify pesticide residues in food matrices. Most have in common a first step of sam- ple preparation to allow transferring the target analytes from the complex matrix to a new media compatible with the analytical method chosen. Often this step, provides a clean up and preconcentration of the analytes in question but, it is a time consuming and if uncarefully taken care might also be a source of inaccuracy and imprecision for the subsequent analytical results. To achieve separation and quantification GC and HPLC analytical methods are usually the choice; a previous sample preparation tech- nique is demanding. Solid phase extraction is often the choice but its lack of selectivity presents a problem. Emerging as a powerful tool for sample preparation is the molecularly imprinting technology. A known limita- tion of MIPs, especially those using non-covalent inter- actions between template and monomers, is the fact that bonds formed, with the target analyte mostly hydrogen bonds, are relatively weak and prone to interferences. This means that in the extraction, when performed in water solutions, water molecules will compete with the target analytes leading to the loss of binding selectivity and capacity. The easiest way to overcome this problem is to perform extraction with an organic solvent; this does not mime reality. The common practice, now, is using MIP’s sorbent for selective elution instead of ex- Copyright © 2011 SciRes. AJAC  R. GARCIA ET AL. 22 traction. MIPs are being extensively studied and applied as sorbents for SPE (MISPE). They allow a simultaneous and efficient preconcentration of target analytes and clean- up of the samples, removing undesirable sample matrix components [24]. According to a review of SPE of food contaminants using MIP [14], there are two types of pes- ticide whose use in MISPE, on food samples, has been widely described: triazine-based and urea-based herbi- cides, being MISPE of triazine the oldest one reported in literature. SPEs of triazine herbicides have been reported to be successfully performed using MIPs, prepared in the presence of complexes of atrazine and metacrylic acid (MAA), [25] but Matsui et al. [26] pointed out that em- ploying the analyte itself, as the template, can be prob- lematic since it might not avoid the presence of residual atrazine, in the final polymer, resulting on an analysis interference. To overcome this problem the use of al- kylmelamines [27] or the use of dibutylmelamine [26], instead of atrazine, as template for the polymer synthesis, the so-called dummy-imprint polymer, has been pro- posed. In 2003 Cacho et al. [28] proposed a two-step MISPE procedure to overcome problems related to the application of MISPE to complex samples. Two-step MISPE procedure consists of a combination of two po- lymeric cartridges, one non-imprinted and one imprinted. The first cartridge retains the analytes and matrix com- pounds, but analytes are easily eluted; subsequently clean sample extracts are obtained using the MISPE pro- cedure. The application of this technique to pea, potato and corn samples allowed the identification and quanti- fication of five different triazines, at concentrations be- low the established maximum residue limits, proving the procedure suitable for monitoring these analytes in vegetable samples. Chapuis et al. [29] proposed two methacrylate-based polymers synthesized in diclorome- thane with terbutylazine and ametryn as templates to extract triazines from complex matrices. They concluded that ametryn MIP retains strongly all triazines and their metabolites; low extraction recoveries were obtained for the thiotriazines, on the terbutylazine MIP, which is more specific to the chlorotriazines and their metabolites. MIP technology is continuously being updated and im- provements are being quickly published. To obtain even more clean extracts a selective extraction technique, based on the combination of liquid membranes (micro- porous membrane liquid-liquid extraction, MMLLE) and MIPs, was applied to triazines in apples and lettuce sam- ples [30] showing that this combination has great poten- tial in the extraction of complex samples due to its high selectivity. Another selective extraction technique, based on the combination of membrane assisted solvent extrac- tion and molecularly imprinted solid phase extraction, for triazine herbicides in food samples was developed and applied to maize baby corn and cow pees. This com- bination has shown very high sensitivity revealing its great potential for the extraction of complex samples; most matrix components are prevented from binding onto the MIP particles because they have to cross the membrane barrier; it might be considered as an alterna- tive for the extraction of very complex samples [31]. Tang et al. [32] developed a MIP, by precipitation po- lymerization method, using TRIM (trimethylolpropane trimethylacrylate) as cross-linking agent, MAA as func- tional polymer, dichloromethane as porogen agent and BSM (bensulfuron-methyl) as template. They applied this polymer as SPE sorbent for soybean samples and found that the BSM imprinted polymer does not only have strong affinity for the template, but can also trap TBM (tribenuron-methyl), MSM (metsulfuron-methyl), and NS (nicosulfuron). Results show that these methodolo- gies can be used to assay a series of sulfonylureas, in just one run, in a particular food sample. Previously, another MIP was developed for fenuron (a phenylurea herbicide) also by precipitation polymerization, with MAA as func- tional agent, but using toluene as porogen agent. It was used as MISPE in samples of potato, carrot, wheat and barley, with satisfactory results; authors pointed out the necessity of the improving polymerization process to achieve spherical particles, of a given size, not only with the same kind of binding sites but also with the same porosity [33]. Considered a second generation of syn- thetic pesticides, organophosphorous pesticides are being used as an alternative to organochlorine compounds for pest control, since, although more toxic, they have lower persistence, are biodegradable and do not tend to accu- mulate in the food chain. Dimethoate is a systemic or- ganophosphorous insecticide, and acaricide, widely used as broad spectrum pesticides against a wide range of in- sects and acari on vegetables. A non-covalent MIP was developed for the extraction of dimethoate from tea leaves, using dimethoate as the template molecule, methyl methacrylate as the functional monomer and tetrahydro- furane as porogen [34]. Fenitrothion (FEN) is another organophosphorus pesticide widely used in agriculture for controlling chewing and sucking insects on fruit, vegetables, rice, cereals and stored grains [35]. This pes- ticide, and the products of its degradation, is analyzed by GC [36] or LC [37] after a SPE, SPME or LLE step [38]. Recently a MISPE was developed and applied to the determination of residues of FEN in tomatoes, using HPLC-DAD. This MIP for FEN, synthesized by bulk polymerization via non-covalent molecular imprinting approach [38], was synthesized using metacrylic acid (MAA) as functional monomer, ethylene glycol di- methacrylate (EGDMA) as cross-linker and toluene as porogenic solvent. Authors concluded that this MISPE Copyright © 2011 SciRes. AJAC  R. GARCIA ET AL.23 proved adequate for monitoring FEN residues in toma- toes and pointed out selectivity and easy regeneration as well as its low cost. Other organophosphorus pesticide extensively used for crop protection and tree treatments, as an alternative to highly persistent ones, is dichlorvos. These compounds are highly toxic since they can cause protein adduction, are suspected to be mutagenic and carcinogenic and are endocrine disruptors [39]. A sensi- tive and reliable method for their separation and quanti- fication in foods is mandatory. Dichlorvos is present in complex samples at trace levels requiring, for its analysis, an effective extraction and preconcentration step. A MISPE coupled to HPLC, for determination of trace di- chlorvos residues in cucumber and lettuce samples has been proposed; a novel imprinted functional material, by a molecular imprinting technique using a room tempera- ture ionic liquid-mediated template, was developed, the final showed improved stability, good selectivity and high adsorption capacity for dichlorvos, and proved to be more suitable for SPE than C18 [40]. Regarding syn- thetic pyrethroid pesticides, MISPE can offer a reduction in the extensive clean up steps currently employed in the analysis of composite diet samples, while decreasing so- lvent consumption and increasing selectivity. Particularly when high fat matrices are considered, the complete ex- traction of pyretroid pesticides is usually accompanied by the simultaneous extraction of fatty material; hence MISPE appears as a good way around. Three parallel approaches have been studied [41] for the development of MIP for pyretroids in composite diet samples: urea based MIPs, acrylate based MIPs and divinylbenzene based MIPs, the hydrophobic imprinting approach, pre- sented the best results for these samples. Benzimidazoles, and specially thiobendazole (TBZ), are among the most commonly used postharvest systemic fungicides for the control of diseases during fruit and vegetable storage and distribution. Maximum residue limits (MRLs) establi- shed for benzimidazoles are very low, analytical methods able to detect TBZ at trace levels are needed. The com- bination of molecular imprinting and capillary electro- chromatography (MIP-CEC) has been, for the first time, studied and successfully demonstrated, for citrus samples [42]. The use of MIPs, not as a sorbent for solid phase extraction, but as selective stationary phases, in electro- chromatographic separations was proposed. A MIM (molecularly imprinted monolith) was developed to act as stationary phase for capillary electrochromatography, using the template molecule (TBZ), the functional monomer (MAA), the cross-linker (EDMA—ethylene glycol dimethacrylate) and the initiator (AIBN—2-2’- azobisisobutyronitrile) dissolved in a toluene: iso-octane (96:4) solution, that acts as porogen agent. The use of MIPs, either as a sorbent for solid phase extraction or as a stationary phase for chromatography, may enhance pesticide residues analysis. This technology, yet in its first steps, has already proved a huge applicability, and it is expectable that researchers continue to develop new strategies for the use of MIPs. 4. Conclusions Molecular imprinting can be properly designed as a “ra- tional design” applications and become a powerful tool for the preparation of polymeric materials with specific recognition sites complementary in shape, size and func- tional groups to the template molecule, involving an in- teraction mechanism based on molecular recognition. The peculiar characteristics of MIP, namely their stabil- ity, ease of preparation and low cost for most of the tar- get analytes have made them a suitable tool contributing to the widespread application of this technology in nu- merous applications. Among them, molecular imprinting chromatography is one of the most extensively studied application field of MIP. Recently, the application of MIP as selective sorbents for solid phase extraction (SPE) procedures has also emerged has an innovative and pro- mising application since these polymeric materials allow extraction, of target analytes from complex matrices, with high selectivity and sensitivity. In contrast to other methods applied until now, it offers a large degree of freedom allowing the creation of specific separation ma- terials with predictable selectivity for the target mo- lecules. The efforts developed by several research groups proved that MIPs have potential as selective tools for the developments of various analytical techniques such as liquid chromatography and solid phase extraction for the selective extraction of target analytes from complex ma- trices. In recent years a great number of papers, devoted to molecular imprinting issue, have been published. It is expected that this subject will continue receiving enor- mous attention and research will be growing exponen- tially on this application in the food safety field. 5. Acknowledgements This work was funding by Fundos FEDER through Pro- grama Operacional Factores de Competitividade—COM- PETE and Fundos Nacionais through FCT—Fundação para a Ciência e a Tecnologia (Project PTDC/AGR-ALI/ 117544/2010). 6. References [1] J. L. Tadeo, C. Sanchez-Brunete and L. González, “Pesti- cides: Classification and Properties,” In: J. L. Tadeo, Ed., Copyright © 2011 SciRes. AJAC  R. GARCIA ET AL. 24 Analysis of Pesticides in Food and Environmental Sam- ples, CRC Press, Taylor & Francis Group LLC, Boca Raton, 2008, pp. 1-35. doi:10.1201/9781420007756 [2] K. Granby, A. Petersen, S. S. Herrmann and M. E. Pou- lsen, “Levels of Pesticides in Food and Food Safety As- pects,” In: J. L. Tadeo, Ed., Analysis of Pesticides in Food and Environmental Samples, CRC Press, Taylor & Fran- cis Group LLC, Boca Raton, 2008, pp. 287-318. doi:10.1201/9781420007756.ch11 [3] A. Kloskowski, M. Pilarczyk, A. Przyjazny and J. Nami- esnik, “Progress in Development of Molecularly Im- printed Polymers as Sorbents for Sample Preparation,” Critical Reviews in Analytical Chemistry, Vol. 39, No. 1, 2009, pp. 43-58. doi:10.1080/10408340802570223 [4] L. I. Andersson, “Solid Phase Extraction on Molecularly Imprinted Polymers: Requirements, Achievements and Future Work (chapter 10),” In: S. Piletsky, A. Turner, Eds., Molecular Imprinting of Polymers: Requirements, Landes Bioscience, Texas, 2006, pp. 140-148. [5] G. Vasapollo, R. Del Sole, L. Mergola, M. R. Lazzoi, A. Scardino, S. Scorrano and G. Mele, “Molecularly Im- printed Polymers: Present and Future Prospective,” In- ternational Journal of Molecular Sciences, Vol. 12, No. 9, 2011, pp. 5908-5945. [6] C. R. T. Tarley, M. P. T. Sotomayor and L. T. Kubota, “Polímeros Biomimétricos em Química Analítica. Parte 1: Preparo e Aplicações de MIP (“Molecularly Imprinted Polymers”) em Técnicas de Extração e Separação,” Química Nova, 2005, Vol. 28, No. 6, pp. 1076-1086. doi:10.1590/S0100-40422005000600024 [7] E. V. Piletska, A. R. Guerreiro, M. J. Whitcombe and S. A. Piletsky, “Influence of the Polymerization Conditions on the Performance of Molecularly Imprinted Polymers,” Macromolecules, Vol. 42, No. 14, 2009, pp. 4921-4928. doi:10.1021/ma900432z [8] M. C. Moreno-Bondi, F. Navarro-Villoslada, E. Benito- Pena and J. L. Urraca, “Molecularly Imprinted Polymers as Selective Recognition Elements in Optical Sensing,” Current Analytical Chemistry, Vol. 4, No. 4, 2008, pp. 316-340. doi:10.2174/157341108785914925 [9] L. Ye and K. Mosbach, “Molecular Imprinting: Synthetic Materials as Substitutes for Biological Antibodies and Receptors,” Chemistry of Materials, Vol. 20, No. 3, pp. 859-868. doi:10.1021/cm703190w [10] A. Poma, A. P. F. Turner and S. A. Piletsky, “Advances in the Manufacture of MIP Nanoparticles,” Trends in Bio- technology, Vol. 28, No. 12, 2010, pp. 629-637. doi:10.1016/j.tibtech.2010.08.006 [11] Y. Mao, Y. Bao, S. Gan, F. Li and L. Niu, “Electro- chemical Sensor for Dopamine Based on a Novel Graph- eme-Molecular Imprinted Polymers Composite Recogni- tion Element,” Biosensors and Bioelectronics, Vol. 28, No. 1, 2011, pp. 291-297. doi:10.1016/j.bios.2011.07.034 [12] C. M. Lok and R. Son, “Application of Molecularly Im- printed Polymers in Food Sample Analysis—A Perspec- tive,” International Food Research Journal, Vol. 16, No. 2, 2009, pp. 127-140. [13] O. Ramström, K. Skudar, J. Haines, P. Patel and O. Brüg- gemann, “Food Analyses Using Molecularly Imprinted Polymers,” Journal of Agricultural and Food Chemistry, Vol. 49, No. 5, 2001, pp. 2105-2114. doi:10.1021/jf001444h [14] C. Baggiani, L. Anfossi and C. Giovannoli, “Solid Phase Extraction of Food Contaminants Using Molecular Im- printed Polymers,” Analytica Chimica Acta, Vol. 591, No. 1, 2007, pp. 29-39. doi:10.1016/j.aca.2007.01.056 [15] V. Pichon and F. Chapuis-Hugon, “Role of Molecularly Imprinted Polymers for Selective Determination of Envi- ronmental Pollutants—A Review,” Analytica Chimica Acta, Vol. 622, No. 1-2, 2008, pp. 48-61. doi:10.1016/j.aca.2008.05.057 [16] J. Matsui, I. A. Nicholls, T. Takeuchi, K. Mosbach and I. Karube, “Metal Ion Mediated Recognition in Molecularly Imprinted Polymers,” Analytica Chimica Acta, Vol. 335, No. 1-2, 1996, pp. 71-77. doi:10.1016/S0003-2670(96)00356-X [17] P. K. Dhal, “Man-Made Mimics of Antibodies and Their Applications in Analytical Chemistry,” In: B. Sellergren, Ed., Molecularly Imprinted Polymers, Elsevier Science, Amsterdam, 2001, pp. 185-201. [18] F. Lanza and B. Sellergren, “Method for Synthesis and Screening of Large Groups of Molecularly Imprinted Po- lymers,” Analytical Chemistry, Vol. 71, No. 11, 1999, pp. 2092-2096. doi:10.1021/ac981446p [19] A. Martin-Esteban and J. L. Tadeo, “Selective Molecu- larly Imprinted Polymer Obtained from a Combinatorial Library for the Extraction of Bisphenol A,” Combinato- rial Chemistry & High Throughput Screen, Vol. 9, No. 10, 2006, pp. 747-751. doi:10.2174/138620706779026024 [20] B. Dirion, Z. Cobb, E. Schillinger, L. I. Andersson and B. Sellergren, “Water-Compatible Molecularly Imprinted Po- lymers Obtained via High-Throughput Synthesis and Ex- perimental Design,” Journal of the American Chemical Society, Vol. 125, No. 49, 2003, pp.15101-15109. doi:10.1021/ja0355473 [21] N. Perez-Morel and A. G. Mayes, “Comparative Study of Imprinted Polymer Particles Prepared by Different Po- lymerisation Methods,” Analytical Chimica Acta, Vol. 504, No. 1, 2004, pp. 15-21. doi:10.1016/S0003-2670(03)00533-6 [22] C. He, Y. Long, J. Pan, K. Li and F. Liu, “Application of Molecularly Imprinted Polymers to Solid Phase Extrac- tion of Analytes from Real Samples,” Journal of Bio- chemical and Biophysical Methods, Vol. 70, No. 2, 2007, pp. 133-150. doi:10.1016/j.jbbm.2006.07.005 [23] E. Caro, R. M. Marce, F. Borrull, P. A. G. Cormack and D. C. Sherrington, “Application of Molecularly Imprinted Polymers to Solid Phase Extraction of Compounds from Environmental and Biological Samples,” Trends in Ana- lytical Chemistry, Vol. 25, No. 2, 2006, pp. 143-154. doi:10.1016/j.trac.2005.05.008 [24] F. Augusto, E. Carasek, R. G. C. Silva, S. R. Rivellino, A. D. Batista and E. Martendal, “New Sorbents for Extrac- Copyright © 2011 SciRes. AJAC  R. GARCIA ET AL. Copyright © 2011 SciRes. AJAC 25 tion and Microextraction Techniques,” Journal of Chro- matography A, Vol. 1217, No. 16, 2010, pp. 2533-2542. doi:10.1016/j.chroma.2009.12.033 [25] M. T. Muldoon and L. H. Stanker, “Molecularly Im- printed Solid Phase Extraction of Atrazine from Beef Liver Extracts,” Analytical Chemistry, Vol. 69, No. 5, 1997, pp. 803-808. doi:10.1021/ac9604649 [26] J. Matsui, K. Fujiwara, S. Ugata and T. Takeuchi, “Solid-Phase Extraction with a Dibutylmelamine-Imp- rinted Polymer as Triazine Herbicide-Selective Sorbent,” Journal of Chromatography A, Vol. 889, No. 1-2, 2000, pp. 25-31. doi:10.1016/S0021-9673(00)00339-3 [27] J. Matsui, K. Fujiwara and T. Takeuchi, “Atrazine-Se- lective Polymers Prepared by Molecular Imprinting of Trialkylmelamines as Dummy Template Species of Atra- zine,” Analytical Chemistry, Vol. 72, No. 8, 2000, pp. 1810-1813. doi:10.1021/ac9911950 [28] C. Cacho, E. Turiel, A. Martín-Esteban, C. Pérez-Conde and C. Cámara, “Clean-Up of Triazines in Vegetable Ex- tracts by Molecularly-Imprinted Solid-Phase Extraction Using a Propazine-Imprinted Polymer,” Analytical and Bioanalytical Chemistry, Vol. 376, No. 4, 2003, pp. 491- 496. doi:10.1007/s00216-003-1915-0 [29] F. Chapuis, V. Pichon, F. Lanza, B. Sellergren and M.-C. Hennion, “Retention Mechanism of Analytes in the Solid- Phase Extraction Process Using Molecularly Imprinted Polymers: Application to the Extraction of Triazines from Complex Matrices,” Journal of Chromatography B, Vol. 804, No. 1, 2004, pp. 93-101. doi:10.1016/j.jchromb.2003.12.033 [30] B. Mhaka, E. Cukrowska, B. T. S. Bui, O. Ramströmc, K. Haupt, H. Tutu and L. Chimuka, “Selective Extraction of Triazine Herbicides from Food Samples Based on a Com- bination of a Liquid Membrane and Molecularly Im- printed Polymers,” Journal of Chromatography A, Vol. 1216, No. 40, 2009, pp. 6796-6801. doi:10.1016/j.chroma.2009.08.003 [31] L. Chimuka, M. van Pinxteren, J. Billing, E. Yilmaz and J. Å. Jönsson, “Selective Extraction of Triazine Herbicides Based on a Combination of Membrane Assisted Solvent Extraction and Molecularly Imprinted Solid Phase Ex- traction,” Journal of Chromatography A, Vol. 1218, No. 5, 2011, pp. 647-653. doi:10.1016/j.chroma.2010.12.019 [32] K. Tang, S. Chen, X. Gu, H. Wang, J. Dai and J. Tang, “Preparation of Molecularly Imprinted Solid Phase Ex- traction Using Bensulfuron-Methyl Imprinted Polymer and Clean-Up for the Sulfonylurea-Herbicides in Soy- bean,” Analytica Chimica Acta, Vol. 614, No. 1, 2008, pp. 112-118. doi:10.1016/j.aca.2008.03.018 [33] F. G. Tamayo, J. L. Casillas and A. Martin-Esteban, “Hi- ghly Selective Fenuron-Imprinted Polymer with a Ho- mogeneous Binding Site Distribution Prepared by Pre- cipitation Polymerisation and Its Application to the Clean- Up of Fenuron in Plant Samples,” Analytica Chimica Acta, Vol. 482, No. 2, 2003, pp. 165-173. doi:10.1016/S0003-2670(03)00213-7 [34] Y. Lv, Z. lin, W. Feng, X. Zhou and T. Tan, “Selective Recognition and Large Enrichment of Dimethoate from Tea Leaves by Molecularly Imprinted Polymers,” Bio- chemical Engineering Journal, Vol. 36, No. 3, 2007, pp. 221-229. doi:10.1016/j.bej.2007.02.023 [35] A. Sánchez-Ortega, M. C. Sampedro, N. Unceta, M. A. Goicolea and R. J. Barrio, “Solid-Phase Microextraction Coupled with High Performance Liquid Chromatography Using On-Line Diode-Array and Electrochemical Detec- tion for the Determination of Fenitrothion and Its Main Metabolites in Environmental Water Samples,” Journal of Chromatography A, Vol. 1094, No. 1-2, 2005, pp. 70- 76. doi:10.1016/j.chroma.2005.07.089 [36] A. Sánchez, S. Millán, M. C. Sampedro, N. Unceta, E. Rodríguez, M. A. Goicolea and R. J. Barrio, “Quantifica- tion of Fenitrothion and Its Main Metabolites in Poplar Leaves by Isotope Dilution Gas Chromatography-Mass Spectrometry Coupled with Solid-Phase Microextrac- tion,” Journal of Chromatography A, Vol. 1177, No. 1, 2008, pp. 170-174. doi:10.1016/j.chroma.2007.10.097 [37] L. A. Pereira and S. Rath, “Molecularly Imprinted Solid- Phase Extraction for the Determination of Fenitrothion in Tomatoes,” Analytical and Bioanalytical Chemistry, Vol. 393, No. 3, 2009, pp. 1063-1072. doi:10.1007/s00216-008-2511-0 [38] L. A. de Barros, I. Martins and S. Rath, “A Selective Molecularly Imprinted Polymer-Solid Phase Extraction for the Determination of Fenitrothion in Tomatoes,” Ana- lytical and Bioanalytical Chemistry, Vol. 397, No. 3, 2010, pp. 1355-1361. doi:10.1007/s00216-010-3629-4 [39] H. G. Kang, S. H. Jeong, J. H. Cho, D. G. Kim, J. M. Park and M. H. Cho, “Chlropyrifos-Methyl Shows Anti- Androgenic Activity without Estrogenic Activity in Rats,” Toxicology, Vol. 199, No. 2-3, 2004, pp. 219-230. doi:10.1016/j.tox.2004.02.025 [40] Z. Xu, G. Fang and S. Wang, “Molecularly Imprinted Solid Phase Extraction Coupled to High-Performance Liquid Chromatography for Determination of Trace Di- chlorvos Residues in Vegetables,” Food Chemistry, Vol. 119, No. 2, 2010, pp. 845-850. doi:10.1016/j.foodchem.2009.08.047 [41] A. P. Vonderheide, B. Boyd, A. Ryberg, E. Yilmaz, T. E. Hieber, P. E. Kauffman, S. T. Garris and J. N. Morgan, “Analysis of Permethrin Isomers in Composite Diet Sam- ples by Molecularly Imprinted Solid-Phase Extraction and Isotope Dilution Gas Chromatography-Ion Trap Mass Spectrometry,” Journal of Chromatography A, Vol. 1216, No. 22, 2009, pp. 4633-4640. doi:10.1016/j.chroma.2009.03.077 [42] C. Cacho, L. Schweitz, E. Turiel and C. Pérez-Conde, “Molecularly Imprinted Capillary Electrochromatography for Selective Determination of Thiabendazole in Citrus Samples,” Journal of Chromatography A, Vol. 1179, No. 2, 2008, pp. 216-223. doi:10.1016/j.chroma.2007.11.097

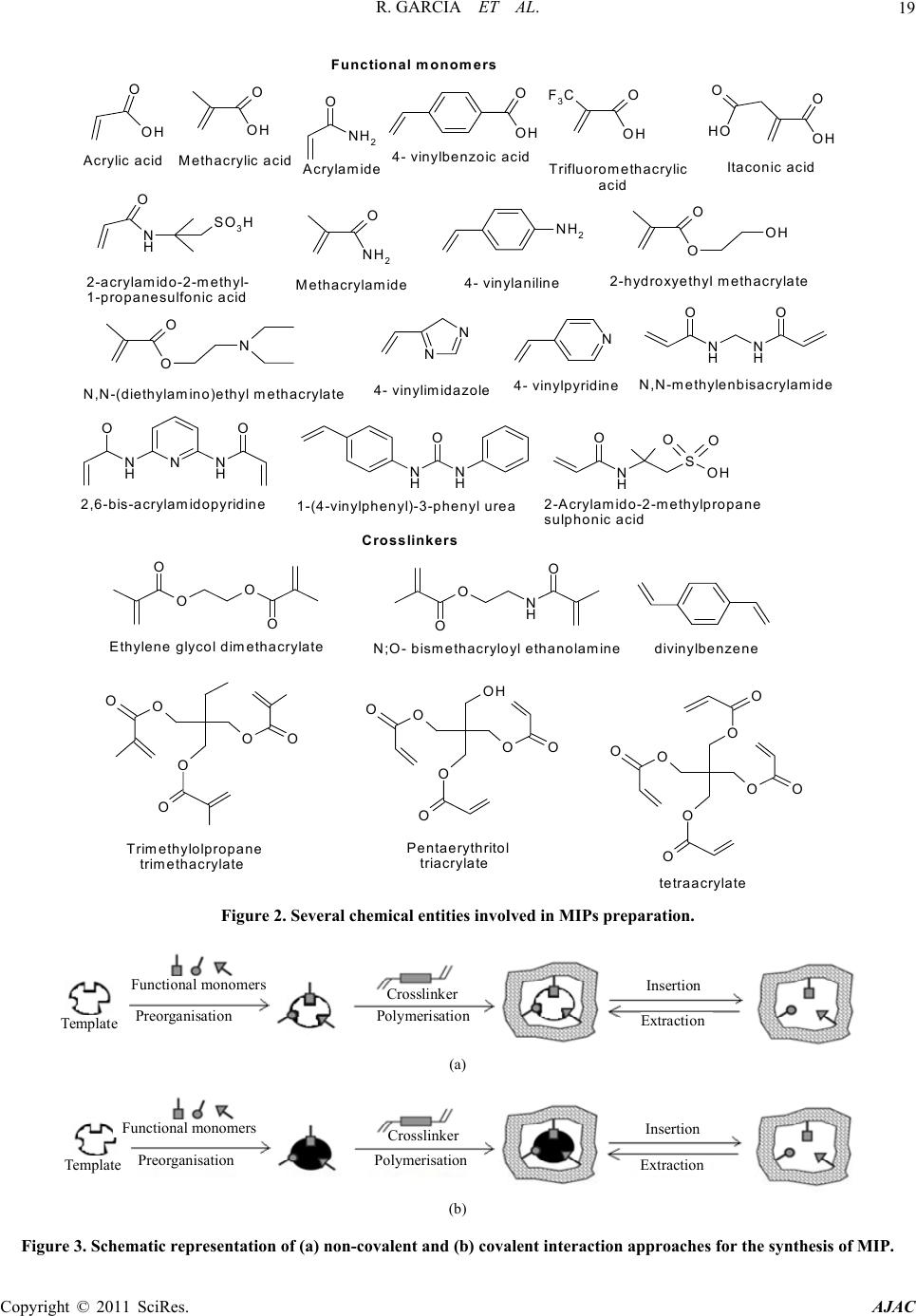

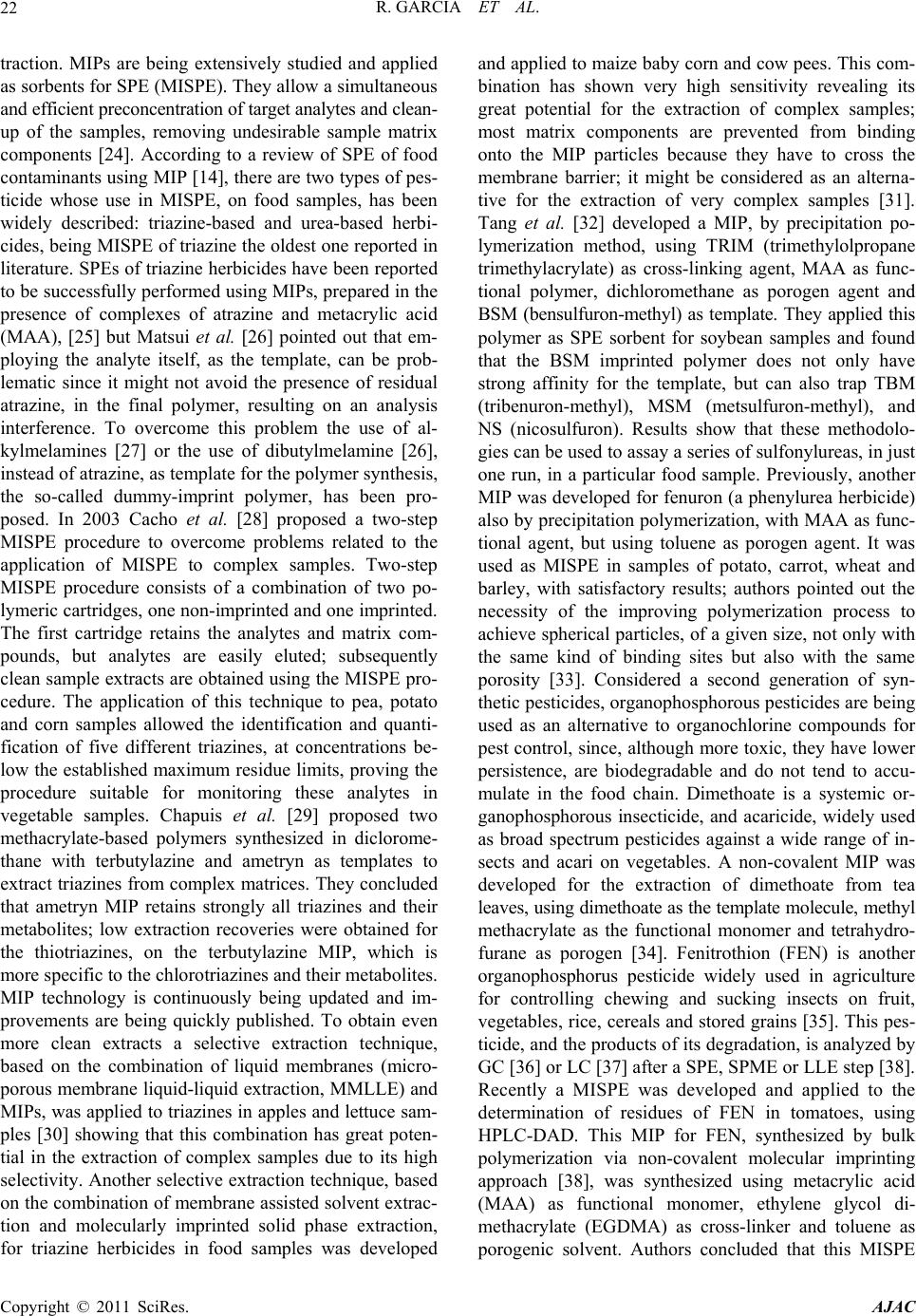

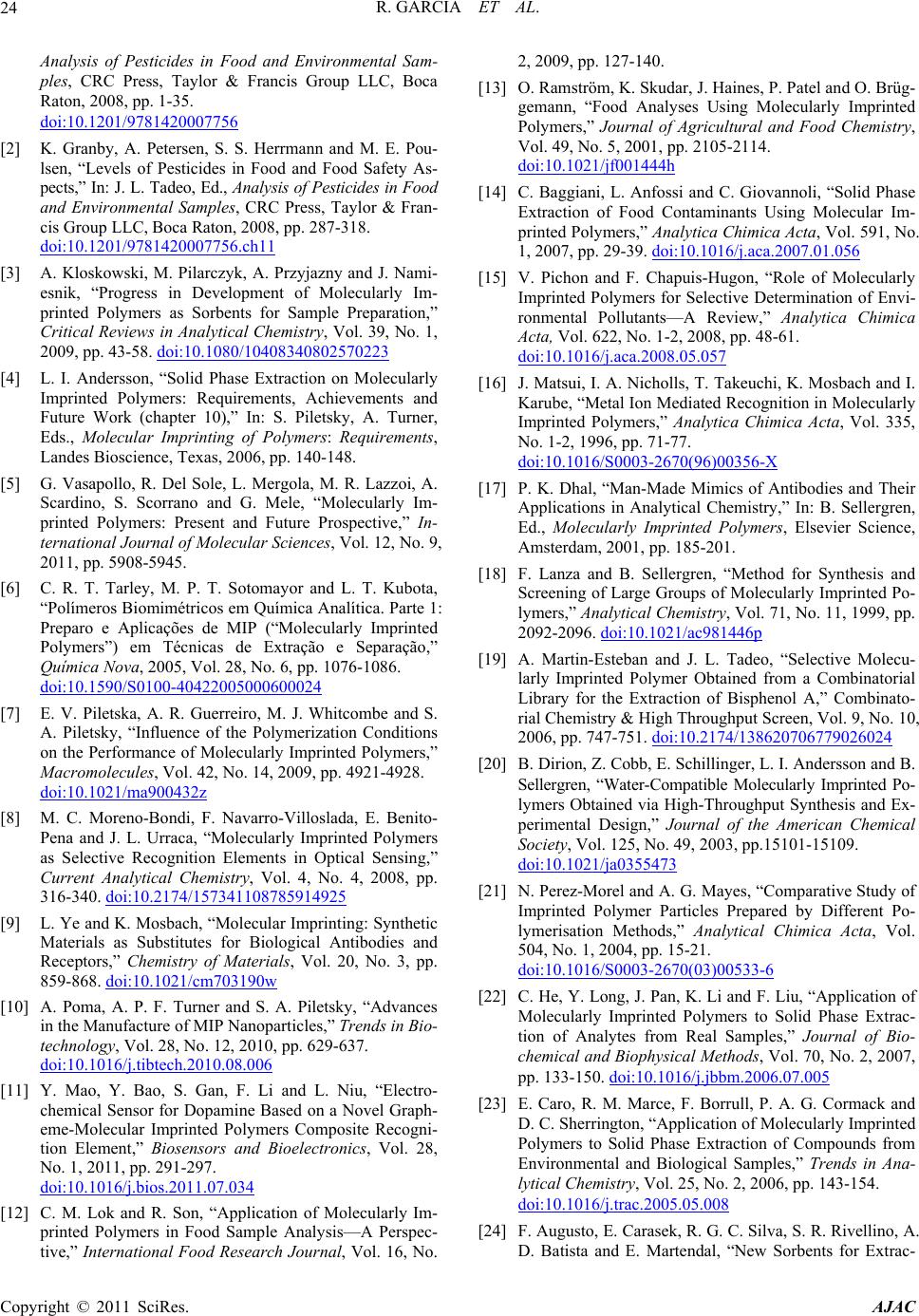

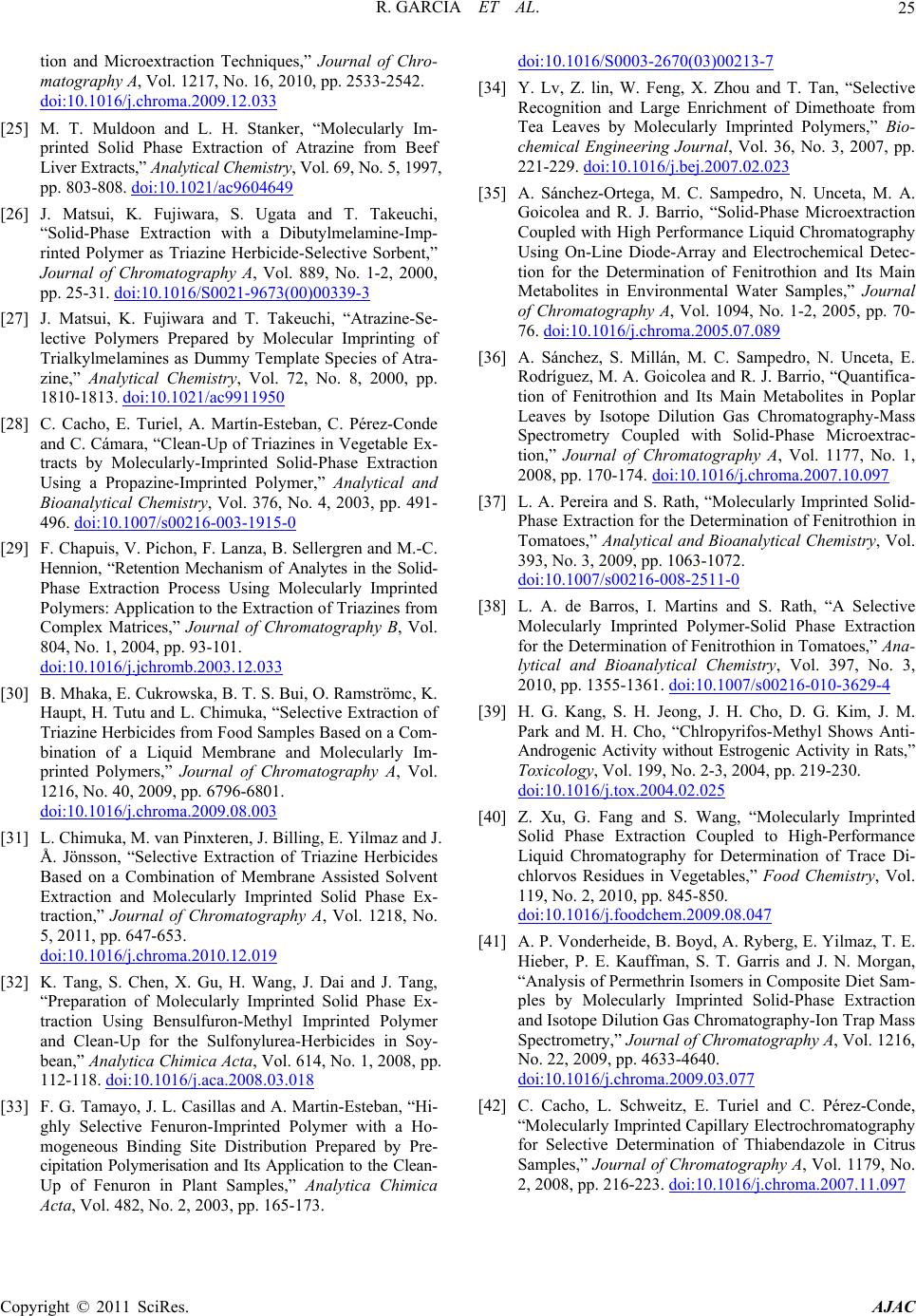

|