Open Journal of Safety Science and Technology, 2011, 1, 79 -88 doi:10.4236/ojsst.2011.13008 Published Online December 2011 (http://www.SciRP.org/journal/ojsst) Copyright © 2011 SciRes. OJSST Total Ergonomics and Its Impact in Musculoskeletal Disorders and Quality of Work Life and Productivity Naser Sadra Abarqhouei1*, Hasan Hossaini Nasab2 1Institute of Higher Education and Applied Science, Jihad of Agriculture, Yazd, Iran 2Faculty of Industrial Engineering, University of Yazd, Yazd, Iran E-mail: *nasersadra@yahoo.com Received September 6, 2011; accepted November 2, 2011; accepted November 10, 2011 Abstract Studies have indicated the application of ergonomics in improving the quality of work life, reducing muscu- loskeletal disorders and increasing productivity. On the other hand, there are large differences between de- veloping and developed countries in applying ergonomics knowledge, the need of applying the science of culture, especially in developing countries and the third world is vital, but the culture implementation and pay evaluation of total ergonomics (micro and macro) is low . Therefore, this study has tried using the stu- dies of society and culture dominated by manufacturing service, a comprehensive and integrated model for ergonomics interventions to be developed and used in an educational establishment and the effects of ergo- nomic interventions in a field study in comparison with conditions before the intervention using question- naire “body mapping” and “quality of work life” to evaluate . Study results showed increased productivity, improved work life quality and reduced musculoskeletal disorders . So a comparison of performance than the base year indicated lower costs and increased revenue and expanded with less manpower in data analysis questionnaire “quality of work life” and “body mapping” which showed that significant difference in confi- dence interval between the sample and control population is ninety-nine percent and there is reduction of musculoskeletal disorders and increase in quality of work life. Those indices indicated the positive effect of interventions ergonomics. Keywords: Micro Ergonomics, Macro Ergonomics, Quality of Work Life, Musculoskeletal Disorders, Productivity 1. Introduction Ergonomic studies have shown systems with weak de- signing, neglected ergonomic principles and have brought staff and workers disorders. Not considering to the ergo- nomic principles at work can provide spiritual and phy- sical tensions, low productivity and unsuitable work life quality and effective execution of ergonomic programs and increasing ergonomic awareness [1]. Nowadays im- proving productivity has been recognized as one of the most important cultural and socio-economic develop- ment alternatives as access to success in speeding pro- ductivity improvement is one of main conditions of ac- cess to suitable place in world competition and improv- ing people’s life [2]. Based on the fourth and fifth country development program, getting into real economic fact and continuous growth, at least 8% of Gross Domestic Product (GDP) is annually increasing the productivity in econo mic growth. This has been forecast to one third at the end of the fifth program and improving judiciary and administrative sys- tem for increasing movement and efficiency, improving service delivery to people, assuring staff livelihood, in- creasing indices of work and life environment and spiri- tual and physical hygiene. These legal necessities have made sensitive execution organizations and economic directors of country and provinces by using different tools and methods to think about providing important princi- ples in the fourth and fifth development programs in their economic units and sectors. Since results of different re- searches have shown logical and positive impact on ap- plying productivity and total ergonomic knowledge, effi- cient development, maintaining human rights, welfare, social security, relative increase of per capita income, thought innovation and so on1, undoubtedly making cul- 1Refer to Section 2 (research topic literature).  N. S. ABARQHOUEI ET AL. 80 ture and using ergon omics in Iran can help the coun try to achieve important goals in cultural and socio-economic programs which have been determined for achieving vi- sion of country. Unsuitable work life created under un- suitable work with humans provides imbalance between social and psychic conditions of staff of organization, only not considering goals of organization, but also causes de- crease in productivity, increase in absence, displacing and leaving work (Figure 1) and finally causes low self- confidence in labor force. Such conditions affect on qua- lity and as a result work life in organizations and pro- duction centers, make work life unsuitable and repeat events and insecurity [3]. 2. Review of Research Literature The goal of applying ergonomics is to provide a logical and suitable relationship among staff and their work. Ergonomics can study workers psychology and physiolo- gy at work with a complicated system among humans, tool and environment [1]. Improving productivity is an easy method for encouraging management in costs, pro- gramming and using ergonomic intervention and it can be more effective for a person without ergonomic infor- mation or a person not working on staff health and safety section, productivity provides a common language among stockholders [4]. In spite of many studies in recent dec- ades about ergonomics, many factors in organizations cause musculoskeletal disorders and ergonomic costly diseases [5,6], which show that ergonomic changes have not achieved the useful effectiveness in producing envi- ronment [7], thus all attempts of ergonomic researchers should be coordinated in decreasing ergonomic risk fac- tors and as a result improving quality of work life prac- tically and usefully. The conducted researches show that distributing ergonomics knowledge among staff is for helping and better execution of service and production programs. The results of conducted study show that ergo- nomic uses in designing tools will provide much effect on psychic health, work satisfaction, increasing efficien- cy, security and health [8] and as a resu lt it will improve work life. An efficient and effective system, which is the base of a productive system, depends on the manner of service delivery by human operators. We cannot imagine that human force is an island among service and production processes [9]. In an efficient and effective system, more attention should be given to human force and it should be tried to decrease human errors meanwhile pr oviding staff health and safety, and it can be done by choosing suitable persons and training, designing equipments, work envi- ronment and tools by considering physical and spiritual needs and characters of humans, providing methods and logical agenda [10]. It is clear that by achieving these Figure 1. Effects of unsuitable work on human body . goals and providing work welfare for human force work- ing at service and producing systems, we can observe increased productivity indices and quality of work life in service and production organizations. The concept of quality of life refers to Aristotle era (385 years B.C.). At that era, Aristotle consider ed “good life” or “doing work well” in meaning of being happy. The word of quality of life was used for the first time in 1920 in the book “Eco- nomics and Welfare” [11]. In 1985 , in northwest of Eng- land, life quality researches were conducted for the first time. These researches provided a complete definition of life quality: a person understands from his or her situa- tions with respect to living value system and culture and relationship of these captures with in tended g oals, exp ec- tation, standards and priorities [11]. Having a healthy and quality life with acceptable life expectancy and without disease an d inability is a general right and pre-condition for achieving sustainable deve- lopment of any country [12]. Potential ability of macro-ergonomics in considerable improvement of organizational functioning involving hy- giene, safety, job satisfaction, quality of work life and productivity has be en considered recently. As it was said before, introducing and clear show of this potential abi- lity will cause wide support by us ing and develop ing ma- cro ergonomics technology [13]. For achieving the suit- able situation, it is necessary that considerable changes one made in field of ergonomic research and training and making culture by moving from a safety and hygiene pa- ttern of ergonomics to a work pattern of ergonomics without missing safety and health goals [14]. In this re- spect, Dempsey (2007) conducted a research under the title of “ergonomic interventions for preventing muscu- loskeletal disorders” and understood many obstacles in way of this study [4]. For optimum design of system with the goal of facili- tating recognition and access the needs of consumers, it seems necessary to integrate human factors in start of design cycle till work life [15]. Human factors engineer- ing specialists worry about design and relationship be- tween system items for improving health, safety, comfort ability, quality of production and decrease in design pro- blems. The global attention towards human factors engi- neering is increasing human life quality [16]. If directors are satisfied that improving ergonomics meanwhile providing professional hygiene and safety rules simultaneously can help in achieving strategies and Copyright © 2011 SciRes. OJSST  N. S. ABARQHOUEI ET AL.81 goals of organizations, its acceptance among directors will be easier [14,17]. Thus, relating ergonomics with organizational strategies can associate management with a positive motivation for executing ergonomics. The ge- neral strategies used in model design include: 1) Micro ergonomics strategy concentrated on system of humans, machine, environment and work and its goal is to improve work or computer for preventing danger in daily performance of system. 2) Macro ergonomics strategy focused on organization and its goal is socio-technical system optimization and study of effect of organization structure on safety and human behavior [18,13]. Macro ergonomic is integrated from general principles of quality management [19] and focuses on needed con- ditions for improving a system. Macro ergonomic effects include: Effect on number, training and satisfaction of em- ployees, Effect on quality and equipment survival, Effect on em p ow ering physical environm e nt , Effect on quality of work life, Effect on economic production, It’s not only an analysis method, but also a method for designing socio-technical systems by delivering system- atic characters (common cross of technical fields and organization) [19]. It is clear that these two strategies focus on human and system and relationship which will get shape between these two strategies, and will affect on strategies and integration of system. In organizational systems, close relationship with low level labor force of organization is considered, only im- portant thing is that relationship among different levels of an organization can cause exact transmission of ergo- nomic information to superior directors and as a result it helps in better determination of production strategies. In stage of providing process, close relationship among di- fferent levels of organization management with zero level staff of organization, all ergonomic physiolo gy and physical factors are considered and in feedback stage, all information related to ergonomic risk factors in all or- ganization levels are transferred to organization superior directors and this recognition makes directors consider more programming for improving process of service de- livery and motivation indices of staff including leaving work and also other indices including leaving work due to disease and delays and stop at work are decreased by considering ergonomic factors [4]. In this respect, staff participation and management support can have impor- tant role among different levels of organization for exe- cuting ergonomic go als. Participatory ergonomics is a growing branch in macro- ergonomics and designing organization and management, and from beginning about three decades ago it has had growing attraction. In this field, to improve work envi- ronment conditions, productivity and quality, model of participatory ergonomics in a small industry was de- signed and executed in Iran [20]. On the other side, per- formance evaluation is one of the main duties of each or- ganization and is one of performance management di- mensions that in the past has been execute via using fi- nancial indices [21]. Efficient directors by relying on control systems and performance measurement in deter- mining outlines, making strategic decisions and access to suitable goals conqu er on problems. In these two decades some issues as determining factors of competitive advan- tage have been considered including organizational learn- ing, creating knowledge and innovation capacity [22,23] and so organization should try for finding total indices of performance measurement, with more focus on soft per- formance (human) indices because the weakness or em- powerment of mentioned indices, are not shown in bal- ance-sheet [23]. One of soft performance indices not shown in balance- sheet is effect of ergonomics use in organizations. Since in present era, human resources are considered as key factor for organizations success, we can deduce that po- wer sustainability o f an o rganization d epends o n ph ysical and psychic health of its staff [24]. By correct use of control systems and measuring performance organizatio- nal obstacles can be captured that prevent appearing or- ganization members ability [25]. In this respect, many valid ergonomics evaluation methods have been used with the goal of analyzing work environment (such as RULA [26], Strain Index [27], REBA [28] etc.). The considerable point is studies of these uses have been shaped in industries environment [29-31], but the reality is that industrial companies with related interior methods or prepared rules at national level like refusal or accep- tance measurements are used for evaluation, as a result the number of research articles which study methods of using and evaluatin g ergonomics is v ery less [32]. On the other hand, conducted studies certify this reality that us- ing ergonomic is effective in improving quality of work life, decrease in musculoskeletal disorders and increase in productivity and in attention to high difference of us- ing ergonomics among developed and developing coun- tries [9], it’s necessary to make a culture of using this science specially in developing countries and the third world and since models of making culture, launching and evaluating integrated ergonomics, are very few [32], it is necessary to design total and integrated model based on the following goals: 1) Measuring ergonomics effect on productivity, de- crease in musculoskeletal disord er and increase in quality of work life in organizations via designing and using a Copyright © 2011 SciRes. OJSST  N. S. ABARQHOUEI ET AL. 82 comprehensive and integrated model with logics of “mo- nitoring”, “insisting” and “sustainability” in culture mak- ing and using based on management and knowledge su- pports, staff participation, evaluation, recognition and en- couragement and communication and information net- work. 2) Providing basic field for performing applied ergo- nomic researches. 3) Helping in ergonomics culture extension in world. 4) Delivering performance evaluation model which can help to distribute culture of using ergonomics in the third world countries and advanced and developing coun- tries. 3. Materials and Methods This research is applied and analysis-descriptive study and by conducted studies and researches in field of dif- ferent models of evaluation, emphasis solving models weak points by using concepts and goals of total ergo- nomics knowledge, as by using this model we can exe- cute and evaluate ergonomics in different processes and work and to measure its effect on productivity, improv- ing work life and musculoskeletal disorders decrease in organizations. Delivering model of interventions and evaluating total ergonomics and its effect on organiza- tional productivity is done by studying and using con- ducted concepts and researches in performance evalua- tion field, micro and macro-ergonomics, relationship be- tween macro-ergonomics, management and organiza- tional designing and productivity. In this research by de- fining and recognizing society studies and launching er- gonomics based on designed model and using analysis- descriptive statistics and questionnaire, delivered model is practically used towards determined goal in frame of a case study and necessary statistical tests are done. 3.1. Designing and Introducing Model By considering issues in introduction and reviewing re- search literature, model designing is done based on five principles including management support, knowledge su- pport, staff participation, evaluation, recognition, encour- agement and communication and information network with logics of insistence and sustainability in culture making and launching total ergonomics and is delivered in frame of Figure 2. 3.2. Method of Model Use The EO model was used in the experimental training center. This center, using more that 220 teachers and employees and 1000 students in different related courses Figure 2. Model of interventions and evaluation process of total ergonomics. like accounting and computer, became interested to exe- cute interventions programs and ergonomic evaluation for performance improvement, and after several sessions got the responsibility for facilitating ergonomic use me- thod in different sections management and supervision on project and guiding persons in process. Project under title “ergonomic interventions” at two stages i.e. micro and macro ergonomic interventions in framework of de- signed model, planning and is executed. 3.3. Evaluation of the Total Ergonomic Interventions In this research, studying musculoskeletal disorders us- ing body mapping standard questionnaire [33] is deter- mined and analyzed. This questio nnaire seeks user ’s dis- order in five quality dimensio ns form non ergono mic and ergonomic chairs in 28 questions according to body divi- sion to 28 parts. It’s necessary to mention that used qu ality dimensions in body mapping questionnaire is integrate from SER- VQUAL2 model that for recogn ition and classification of people opinions has had the most use in management [34]. For studying the quality of work life in sample population (before and after the total ergonomic inter- ventions), several questionnaires were prepared and de- livered with the issue of quality of working life. These questionnaires were taken by Allameh (1999) from the National Institute of Occupational Safety and Health (NIOSH), based on the Dalton work life quality [35] an d the present study was based on these questionnaires by 2Servqual model is one of the most famous service quality measuring methods mention e d i n 1 98 5 . Copyright © 2011 SciRes. OJSST  N. S. ABARQHOUEI ET AL.83 summarizing and considering the following arguments: 1) Questionnaire with Islamic culture governing on county has been desig ne d. 2) Number of mentioned questions in this question- naire is more than other questionnaires (77 five-choice questions). 3) Quality dimensions are as five-choice in answer- sheet coordinated with Servqual model which is total questionnaire and used in such researches. 4. Results and Discussion The first stage of project inclu des process of using macro- ergonomics. The major goal at the first stage was to im- prove different systems and processes of service delivery to students and other trainees including stakeholders and EO centers staff in view of macro-ergonomics. Systems and processes like labs, students participation for deliver- ing suggestions and performing work, evaluating process of service delivery to students, increasing quality of de- livering classes, encouraging staff, alternatives for deli- vering recreational-welfare services, optimizing service and production section, human resources management and human force optimization process were considered in this study. Macro ergonomics interventions process was started by conducting a three-day workshop and 30 directors and staff participated in it. The workshop was held for finding a view to EO and regulating different goals for achieving a special vision of EO. A question- naire was prepared and participants wanted to mention an EO vision and at least three main goals for achieving an understandable vision. The questionnaire were dis- tributed, completed and collected, and then by summa- rizing mentioned issues in workshop, EO vision was de- termined at two items: 1) EO as the biggest and most important skill and higher education center at regional and national level. 2) Advancing EO in producing and processing products in framework of training pilots. Then as in Table 1, delivered goals for achieving vi- sion were summarized and approved. For impressive use of staff and students in Ergonomic Interventions Program (EIP) vi a future workshop was used. Future Workshop (FW) is a socio-pedagogic method for identification of a common problem, development of a vision, ideas and action plan among a group of con- cerned people. Later on it was spread successfully to the Scandinavian countries and is now widely used as par- ticipatory intervention method [10]. Future Workshop is a well-structured process with five def ined phas es: 1) Preparation phase 2) Experience phase 3) Fantasy phase 4) Strate gy phase 5) Act i on phase/Foll ow up. This workshop started its work in the framework of Table 1. Major goals for achieving vision. 1 Recognizing new technologies in related section and transferring th e m to students, stakeholders and official experts in related section. 2 Improving quality of welfare cultural programs for studen ts and staff by improving methods and new investments. 3 Human resource management (optimizing human force) by applying, maintaining, training and encouraging staff. 4 Improving c hain of studies of students in discontinuous expertise till professional PhD. 5 Increasing participation of par ents and students for mater ial, intellectual and thinking help to EO. 6 Providing necessary background for delivering innovation in performance a n d t r a i n in g p rogram. 7 Applying and participation of stu dents at EO production and routine activities. 8 Improving culture of cooperation and p articipation of students and staff of EO. 9 Developing training courses and admitting more students. 10Cooperation with international and big training centers. above phases (Figure 3) and studied the problems during four months and suggested solutions for solving them. The most suggested approaches are delivered for attract- ing participation of persons and using their potential ca- pacities for solving problem and executive policies and programs delivered in future workshop (Table 2). The delivered suggestions at macro-ergonomics inter- ventions stage for ergonomic culture development and extension and also continuous improvement of processes and dangers and ergonomic risk factors in EO subsec- tions were executed. EO superior management agreed with suggestion of execution of a process of micro ergo- nomic interventions for improving work situation and productivity increase as the second stage of ergonomic intervention process. Also this stage was started with two-day workshop like the first stage. 35 persons among staff participated in workshop. The go al of workshop was to provid e ergono- mic awareness among participants and teaching methods of recognizing ergonomic risk factors related to improv- ing environment and work situation. Workshop was started by introducing list of ergonomic inspection for increas- ing productivity, safety and comfort ability [36]. The project supervisor showed contents of list of ergonomic inspection including 79 inspections and explained to par- ticipants how to use it at their work place. Participants were divided into 7 different groups and each group stu- died 79 factors and tried to understand why and how to study factors and according to work experience, how to adjust to their work and explain it. Also they wanted to Copyright © 2011 SciRes. OJSST  N. S. ABARQHOUEI ET AL. Copyright © 2011 SciRes. OJSST 84 Figure 3. Activity diagram of ergonomics workshop for managers and leaders of instructional groups. Table 2. Summarizing delivered executive policies and programs at future workshop. Row Approved executive policies and programs titles 1 Organizing official place with the goal of decreasing musculoskeletal and physic stress via: Extracting Iranian anthropometry and using it in designing theater salon, conference salon, computer salon, classes an d et c. Recognizing ergonomic r i sk factors, evaluating them and determining solution for problems. Determining students and staff safety agendum and executing students i nsurance. Programming and executing ergon omic training courses for scientific jury members and staff. Forecasting seasonal comm o n sessions a n d discussing about safety standards. Introducing successful pat t e r n s a n d e n c o u r a ging about considering ergonomic suggestions. Empowering and increasing super vis ion on ergonomic agendum execution. 2 Considering percent of EO income for active staff and students in delivering suggestions and EO income generation. 3 Encouraging staff and students for providing cooperation culture and reminding more to EO. 4 Providing necessary backgrounds to students for executing applied researches needed for related section. 5 Empowering applied scientific relations with related section via opening relation office with industry at EO. 6 Programming for resear ch scientific relations among EO and applied scie nt ifi c ce nt ers in and out of country. 7 Preparing agendum and work plan of university and family cooperation society (university and parents soci ety). 8 Programming for using applied research findings for student's educational programmi ng. 9 Approving and establishing conference salon for using different trainings b y considering ergonomi c principles. 10 Students’ skill based activities towards defining income generating projects and designs. 11 Making relations with research centers and common execution of research projects. 12 Equipping labs to modern tools and establishing specialized labs. 13 Supporting innovations regarding related section in fram ework of growth centers. 14 Providing data bank of world scientific findings in related section. 15 Approving establishment of theater salon by considering ergonomic principles. 16 Providing scientific soc ie t ie s and student foundation at EO. 17 Programming for exchanging students with other countries.  N. S. ABARQHOUEI ET AL. Copyright © 2011 SciRes. OJSST 85 write down the experiences about each studied point and if they have any executive suggestion regarding these activities, then different group persons were gathered and showed acquired results summary to each other and dis- cussed about decisions for suggested activities and their priority and also suggested solutions for solving prob- lems. After wor kshop, members of committee were cho- sen for preparing agenda or steering committee by pro- ject supervisor, project coordinator and EO superior ma- nager. In this committee three persons were chosen as EO superior director agents and then steering committee had a meeting and during some sessions discussed and ap- proved duties and activities of steering committee and work teams, the most important actions done and defined at this stage for work teams, action groups and ergono- mic group and steering committee are delivered in Table 3. For measuring musculoskeletal disorders of sample society users’ opinions were taken about intended chairs and tables thus after using them every two hours, they wanted to determine amount of disorder in each body part in five quality dimensions (without disorder, with less disorder, very less disorder, with much disorder, intolerable disorder) in body mapping 28 part question- naire by writing from one to five. Of 77 distributed questionnaires accidently among so- ciety persons, 65 questionnaires were completed and returned and of 133 distributed questionnaires among society persons with ergonomic interventions, 107 ques- tionnaires were completed and returned then body map- ping questionnaire data was summarized that has been shown in Table 4. For measuring ergonomic interventions effect on qua- lity of work life and recognizing sample society opinion (before and after ergonomic interventions) and classify- ing their opinion questionnaire of work life quality was used [35]. This questionnaire seeks person’s opinion in 77 questions and in five qualitative dimensions. It’s ne- cessary to mention that used qualitative dimensions in this questionnaire is integrated from servqual model which has had the most use in management for recog- nizing and classifying p erson’s opin ion. Person’s opinion was taken before and after ergonomic interventions in five qualitative dimensions (very less, less, averag e, high, very high) thus before executing ergonomic interventions program of sample society was chosen and then ques- tionnaire was distributed among 58 individuals of sample society and 53 individuals of control society. Of which, 51 and 47 questionnaires were completed and returned. After ergonomic interventions (after 2 years) 57 and 54 questionnaires were distributed among sample and con- trol society individuals that 49 and 45 questionnaires Table 3. Executed projects and designs at micro ergonomic stage. Sr. no. Plans and project titles implemented at micro ergonomics stage 1 Designing and executing necessary projects for facilitating trainings execution su ch as teaching classes at suppor ted forms. 2 Enriching staff work and basis of EO training and different executive sections by combining parallel and similar works. 3 Extracting Iranian static anthropometry and using it for optimizing and d esigning approved project. 4 Recognizing ergonomic risk f ac t o rs, evaluating them and choosing solution for solving er go nomic problems. 5 Holding ergonomic training courses for scientific jury members and s t a f f once in every three month. 6 Introducing successful p atterns and researches and encouraging staff for considering ergonomic suggestions. 7 Preparing students and staff safety agendum and executing student insurance. 8 Forecasting seasonal common sessions and disc us si ng about safety standards. 9 Designing and installing turn-taking system and food pre-purchase. Table 4. Numbers calculated by collecting the community opinions with the help of sample and control community body mapping questionnaire qualitative dimensions. After ergonomic intervention (Sample community) Before ergonomic intervention (Control community) Fi ni Ni Fi ni Ni Qualitative dimensions 24.85107265820 65 1304 No Discomfort 2.2621072424.0865 265 Less Discomfort 1.35 1071442.9165 189 Partial Discomfort 0.4 10743 1.52365 99 Much Discomfort 0.13110714 0.49265 32 Intolerable pain Ni = Response frequency to qualitative dimension; i; ni = Community mem- bers undertaking questionnaire with performed ergonomic interventions and the control community (sample numbers); Fi = Response frequency to qualitative dimension. were returned and after summarizing data of question- naire, necessary computations were done. The results have been given in Table 5. Total ergonomic evaluation in this research was done by two methods: 1) Studying musculoskeletal disorders and work life quality via body mapping questionnaire and work life quality study question naire [35]. 2) Studying comparison performance before and after ergonomic intervention in different fields such as train- ing, sports, culture and finance (number of students, num- ber of delivered articles, getting research-scientific ho- nors).  N. S. ABARQHOUEI ET AL. Copyright © 2011 SciRes. OJSST 86 Table 5. Conclusion of statistical data about the quality of work life, before and after the total ergonomic intervention. Sample and control populations (Before ergonomic interventions) Sample and control populations (After ergonomic interventions) ni Fi ni Fi Qualitative dimensions sample control sample control sample control sample control Very less 51 47 18.16 11.65 49 45 11.2 8.84 less 51 47 16.84 29.86 49 45 12.37 22.53 Average 51 47 25 26.94 49 45 23.71 34.6 High 51 47 17 12.1 49 45 26.1 13.7 Very high 51 47 6 2,45 49 45 9.62 3.33 Sum - - 83 83 - - 83 83 ni = Sample size; Fi = Response frequency to qualitative dimension/person. 4.1. Significant Difference Test of Qualitative Dimensions For analyzing qualitativ e dimensions of con trol and sam- ple society, t-test and Chi-Square test were used in the framework of contingency table for comparing signifi- cant difference between quality of work life and muscu- loskeletal disorders and the frequency of their qualitative dime nsions [37] . In attention to test results given in Table 6, there is a significant difference with 99% confidence among all qualitative dimensions of musculoskeletal disorders of sample and control society (P < 0.05 and null hypothesis is refused against alternative hypothesis) shows positive effect of ergonomic interventions in sample population. Results of statistical data test related to quality of work life, given in Table 7 show there is no significant differ- ence between control and sample society (P > 0.05) but results of test between data after ergonomic intervention show that there is a significant difference with 99% con- fidence between quality of wo rk life of control and sam- ple population (P < 0.05 and null hypothesis is refused against alternative hypothesis) which shows positive effect of ergonomic intervention in sample society. Tests results certify this reality that ergonomic interventions had positive effect in increasin g the quality of work life. 4.2. Comparative Results before and after Total Ergonomics Intervention Some of the most important 3-year results3 due to total ergonomic interventions to base year (time of start of ergonomic interventions; 2007) have been summarized in Table 8. In this research, ergonomic interventions process was started with macro-ergonomic interventions and then at the second stage simultaneously focus was moved to Table 6. Statistical comparisons of qualitative data of mus- culoskeletal disorders of control and sample community. Test no. Society and time of testing P value Sig (2-tailed) χ2 Test result Control society before intervention 1 Sample society before intervention 0.591544 Without difference Sample society after intervention 2 Sample society after intervention 8.39996E-07 Meaningful difference Control society before intervention 3 Control society after intervention 4.22546E-16 Meaningful difference Sample society after intervention 4 Control society after intervention 8.53115E-24 Meaningful difference Table 7. Comparison of statistical data of work life quality (before and after the ergonomic intervention in sample and control population). Levine’s Test for Equality of Variances T-test for Equality of Means Qualitative dimensions F Sig.t df Sig. (2-tailed) Equal variances assumed 4.482 0.036–7.094 170 0.000 No Discomfort Equal variances not assumed –6.610 106.9740.000 Equal variances assumed 16.497 0.0003.510 170 0.001 Less Discomfort Equal variances not assumed 3.076 88.0270.003 Equal variances assumed 1.166 0.2825.077 170 0.000 Partial discomfort Equal variances not assumed 4.989 127.7520.000 Equal variances assumed 22.796 0.0006.212 170 0.000 Much Discomfort Equal variances not assumed 5.681 100.6110.000 Equal variances assumed 23.031 0.0003.187 170 0.002 Intolerable pain Equal variances not assumed 2.85393.9590.005 3Due to considering magazine rules in pages number, some of the most important results are delivered.  N. S. ABARQHOUEI ET AL.87 Table 8. Comparison of achievements before and after total ergonomic intervention. Sr. no. Achievement Titles 1 Acquiring EO preferred title among 220 state applied scientific training centers at the third festival of applied scientific comprehensive university in country. 2 500% increase of delivering articles in scientific assembles and foreign and internal re search scientific publications. 3 Getting permit for launching 18 new courses of studies a t higher-diploma and expertise as compared to base year. 4 Preparing frame of university and patterns cooperation society for the first time in higher education of country. 5 Establishing theater salon by cons ide rin g e rgonomic principles and using Iranian anthropometry. (In this project, studying anthropometry has been performed in field of ergonom ic interventions.) 6 Choosing one of EO lecturer s as pr eferred researcher at the third festival of technology and knowledge. 7 Establishing and using multi-apply conference salon by considering ergonomic principles. 8 Optimizing human force due to 50% decrease in human force. 9 15% annual saving of energy cost including gasoil and electricity. 10 Executing paperless system in o ff ic ia l writings and data packet. 11 280% EO income increase in 2009 as compared to base year. 12 30% annual increase in personnel income as compared to base year. 13 Establishing student scientific society with 400 members. 14 Acquiring distinguished researcher title in related section. 15 600% increase in number of students. micro ergonomic intervention and necessary program- ming was done. Micro ergonomic interventions in im- provements were touched more and were deduced sooner than macro ergonomic changes. It can be deduced that staff behavior and administra- tive process and their working method, is not an easy work among administrative personnel and needs more time as compared to engineering and physical changes for getting results. The most important result of macro-ergonomic chan- ges is organizational culture change, defined as depend- ent to values governing the organization including those which are not written and customary rules, this culture change is not a sort-term activity but is a calm and con- tinuous improvement process that needs long-term co- operation of staff and management simultaneously. As it was said that major goal of ergonomic interventions is optimizing system at micro and macro levels. Fortu- nately, conducted analysis in this research show s po sitiv e effects of total ergonomic interventions. 5. References [1] M. Shaliza, K. Shahrul, M. Mohzani, O. Zalinda and S. Khairanum, “Application of Quality Function Deploy- ment in Identifying Ergonomics Programs for Malaysian, The Effect of Ergonomics Applications in Work System on Mental Health of Visual Display Terminal Workers Manufacturing Industries,” Proceedings in International Conference on Technology Management, 4-5 December 2006, University of Technology Tun Hussien Onn, Ma- laysia, 2006, pp. 275-277. [2] A. Kazemi, “Productivity and Its Analysis in Organiza- tions,” Organization of Study and Determining Humanis- tics Sciences Books of Universities (Samt), Tehran, 1981. [3] N. S. Abarquoei and S. Ahmad, “Place and Role of Hu- man Factors Engineering in Agricultural Sector Produc- tivity,” The 1st National Conference of New Technolo- gies in Agriculture and Natural Resources, 4-5 March 2009, Rasht, 2008, pp. 2455-2459. [4] P. G. Dempsey, “Effectiveness of Ergonomics Interven- tions to Prevent Musculoskeletal Disorders: Beware of What You Ask,” International Journal of Industrial Er- gonomics, Vol. 37, No. 2, 2007, pp. 169-173. doi:10.1016/j.ergon.2006.10.009 [5] S. E. Mathiassen, “On the Evolution of Task-Based Ana- lysis of Manual Materials Handling, and Its Applicability in Contemporary Ergonomics,” Applied Ergonomics, Vol. 37, No. 1, 2006, pp 33-43. doi:10.1016/j.apergo.2004.11.004 [6] P. Leigh, S. B. Markowitz, M. Fahs, C. Shin and P. J. Landrigan, “Occupational Injury and Illness in the United States, Estimates of Costs, Morbidity, and Mortality,” Archives of Internal Medicine, Vol. 157, No. 14, 1997, pp. 1557-1568. doi:10.1001/archinte.1997.00440350063006 [7] G. Pransky, K. Benjamin, C. Hill-Fotouhi, J. Himmel- stein, K. E. Fletcher, J. N. Katz and W. G. Johnson, “Out- comes in Work-Related Upper Extremity and Low Back Injuries: Results of a Retrospective Study,” American Journal of Industrial Medicine, Vol. 37, No. 4, 2000, pp. 400-409. doi:10.1002/(SICI)1097-0274(200004)37:4<400::AID-AJ IM10>3.0.CO;2-C [8] M. Shaliza, S, Kamaruddin, O. Zalinda and M. Mohzani, “The Effect of Ergonomics Applications in Work System on Mental Health of Visual Display Terminal Workers,” European Journal of Scientific Research, Vol. 31, No. 3, 2009, pp. 341-354. [9] P. A. Scott, “Global Inequality, and the Challenge for Ergonomics to Take a More Dynamic Role to Redress the Situation,” Applied Ergonomics, Vol. 39, No. 4, 2008, pp. 495-499. doi:10.1016/j.apergo.2008.02.014 [10] P. A. Scott, “Ergonomicd in Developing Regions, Needs and Applications,” CRC Press, Boca Raton, 2009. doi:10.1201/9781420079128 [11] R. Ford, “Change Your Life Quality (Intellectual Way for Access to Personal Ability and Financial Independence),” Translated by Mehdi Garacheh Daghi, Tehran, 2008. [12] T. M. Reza, T. Fard, M. Tagi, A. Khalili, Hossein, K. Copyright © 2011 SciRes. OJSST  N. S. ABARQHOUEI ET AL. Copyright © 2011 SciRes. OJSST 88 Shaei and Safdar, “Re-Designing Environment and Proc- esses for Increasing Productivity and Safety,” 1st Inter- national Conference of Ergonomy and Human Factors, 7-8 May 2008, Tehran, pp. 24-25. [13] W. Hendrick and M. K. Brain, “Macroergonomics The- ory, Methods and Applications,” IEA, Mahwah, 2002. [14] J. Dul and W. P. Neumann, “Ergonomics Contributions to Company Strategies,” Applied Ergonomics, Vol. 40, No. 4, 2009, pp. 745-752. doi:10.1016/j.apergo.2008.07.001 [15] L. Cullen, “Human Factors Integration—Bridging the Gap between System Designers and End-Users: A Case Study,” Safety Science, Vol. 45, No. 5, 2007, pp. 621- 629. doi:10.1016/j.ssci.2007.01.002 [16] Human Factors and Ergonomics Society (HFES), Human Factors and Ergonomics Society Strategic Plan. Human Factors and Ergonomics Directory and Yearbook, 1999- 2000. Human Factors and Ergonomics Society, Santa Monica, p. 89. [17] P. W. Neumann, M. Ekman and J. Winkel, “Integrating Ergonomics into Production System Development—The Volvo Powertrain Case,” Applied Ergonomics, Vol. 4, No. 2, 2009, pp. 452-459. [18] N. Meshkati, “An Etiological Investigation of Micro- and Macroergonomic Factors in the Bhopal Disaster: Lessons for Industries of Both Industrialized and Developing Countries,” International Journal of Industrial Ergonom- ics, Vol. 4, No. 2, 1989, pp. 161-175. doi:10.1016/0169-8141(89)90042-5 [19] P. Carayon, “Human Factors of Complex Sociotechnical Systems,” Applied Ergonomics, Vol. 37, No. 4, 2006, pp. 525-535. doi:10.1016/j.apergo.2006.04.011 [20] M. Motamedzadeh, “Designing and Participatory System Establishment, Its Effect on Organization Productivity and Quality Improvement and Its Comparison with Cus- tomary Ergonomics by Guiding Prof. Shahnavaz,” Ph. D Thesis, Tarbiat Moddares University, Tehran, 2003. [21] W. O. Wing, B. L. Guo, W. Li and D. Yang, “Reducing Conflict in Balanced Scorecard Evaluations,” Accounting, Organizations and Society, Vol. 32, No. 4-5, 2007, pp. 363-377. [22] H. I. Lee, W. C. Chen and C. J. Chang, “A Fuzzy AHP and BSC Approach for Evaluating Industry in Taiwan,” Expert Systems with Applications, Vol. 34, No. 1, 2006, pp. 96-107. [23] B. Andersen, B. Henriksen and W. Aarseth, “Professional Practice Holistic Performance Management: An Inte- grated Framework,” International Journal Productivity and Performance Management, Vol. 55, No. 1, 2006, pp. 61-78. doi:10.1108/17410400610635507 [24] Ö. F. Sarı, “Effects of Employee Trainings on the Occu- pational Safety and Health in Accommodation Sector,” Procedia—Social and Behavioral Sciences, Vol. 1, No. 1, 2009, pp. 1865-1870. doi:10.1016/j.sbspro.2009.01.329 [25] S. Robert, “Performance Evaluation and Control Systems for Executing Strategy,” Translated by Mojtaba Asadi, Aryana in Dastrial Research Group, Tehran, 2006. [26] L. McAtamney and N. E. Corlett, “RULA: A Survey Method for the Investigation of Work-Related Upper Limb Disorders,” Applied Ergonomics, Vol. 24, No. 2, 1993, pp. 91-99. doi:10.1016/0003-6870(93)90080-S [27] J. S. Moorea and A. Garg, “The Strain Index: A Proposed Method to Analyze Jobs for Risk of Distal Upper Ex- tremity Disorders,” American Industrial Hygiene Asso- ciation Journal, Vol. 56, No. 5, 1995, pp. 443-458. doi:10.1080/15428119591016863 [28] S. Hignett and L. McAtamneyb, “Rapid Entire Body Assessment (REBA),” Applied Ergonomics, Vol. 31, No. 2-3, 2000, pp. 201-205. doi:10.1016/S0003-6870(99)00039-3 [29] P. Drinkaus, R. Sesek, D. Bloswick, T. Bernard, B. Walton and B. Joseph, “Comparison of Ergonomic Risk Assessment Outputs from Rapid Uppe r Limb Assessment and the Strain Index for Tasks in Automotive Assembly Plants,” Work, Vol. 21, No. 2, 2003, pp. 165-172. [30] S. Bao, N. Howard, P. Spielholz and B. Silverstein, “Quantifying Repetitive hand Activity for Epidemiologi- cal Research on Musculoskeletal Injuries—Part II: Com- parison of Different Methods of Measuring Force Level and Repetitiveness,” Ergonomics, Vol. 49, No. 4, 2006, pp. 381- 392. doi:10.1080/00140130600555938 [31] T. Jones and S. Kumar, “Comparison of Ergonomic Risk Assessments in a Repetitive High-Risk Saw Mill Occu- pation: Saw-Filer,” International Journal of Industrial Ergonomics, Vol. 37, No. 9-10, 2007, pp. 744-753. doi:10.1016/j.ergon.2007.05.005 [32] C. Berlin, R. Örtengren, D. Lämkull and L. Hanson, “Corporate-Internal vs. National Standard—A Compari- son Study of Two Ergonomics Evaluation Procedures Used in Automotive Manufacturing,” International Jour- nal of Industrial Ergonomics, Vol. 39, No. 6, 2009, pp. 940-946. [33] F. Tayarri and J. I. Smith, “Occupational Ergonomics: Principles and Application,” Chapman & Hall, London, 1997. [34] J. Van Lwaarden, T. Van Der Wiele, L. Bell and R. Miller, “Applying SERVQUAL to Websites: An Explo- ratory Study,” International Journal of Quality Manage- ment, Vol. 20. No. 8, 2003, pp. 919-935. [35] M. Allameh, “Developing Work Life Quality Pattern of Walton Based on Islamic Values,” Ph.D Thesis, Tarbiat Moddares University, Tehran, 1999. [36] M. Helander, “A Guide to the Ergonomics of Manufac- turing,” Taylor & Fra n cis, Boca Raton, 199 5 . [37] A. Rezai and S. A. Meibodi, “Statistics and Probability,” Daneshkahi Jahad of Isfahan Technology University, Is- fahan, 2005.

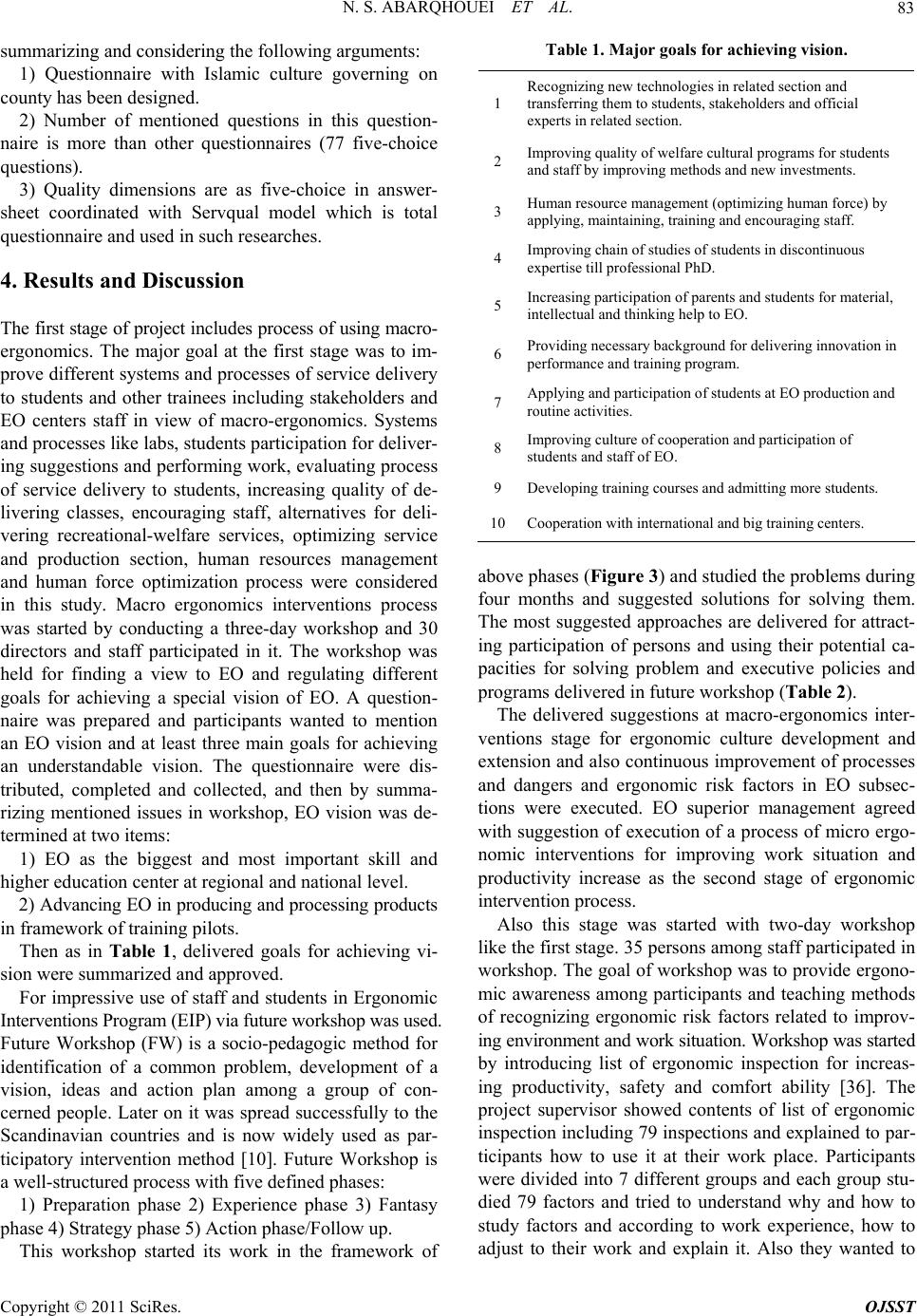

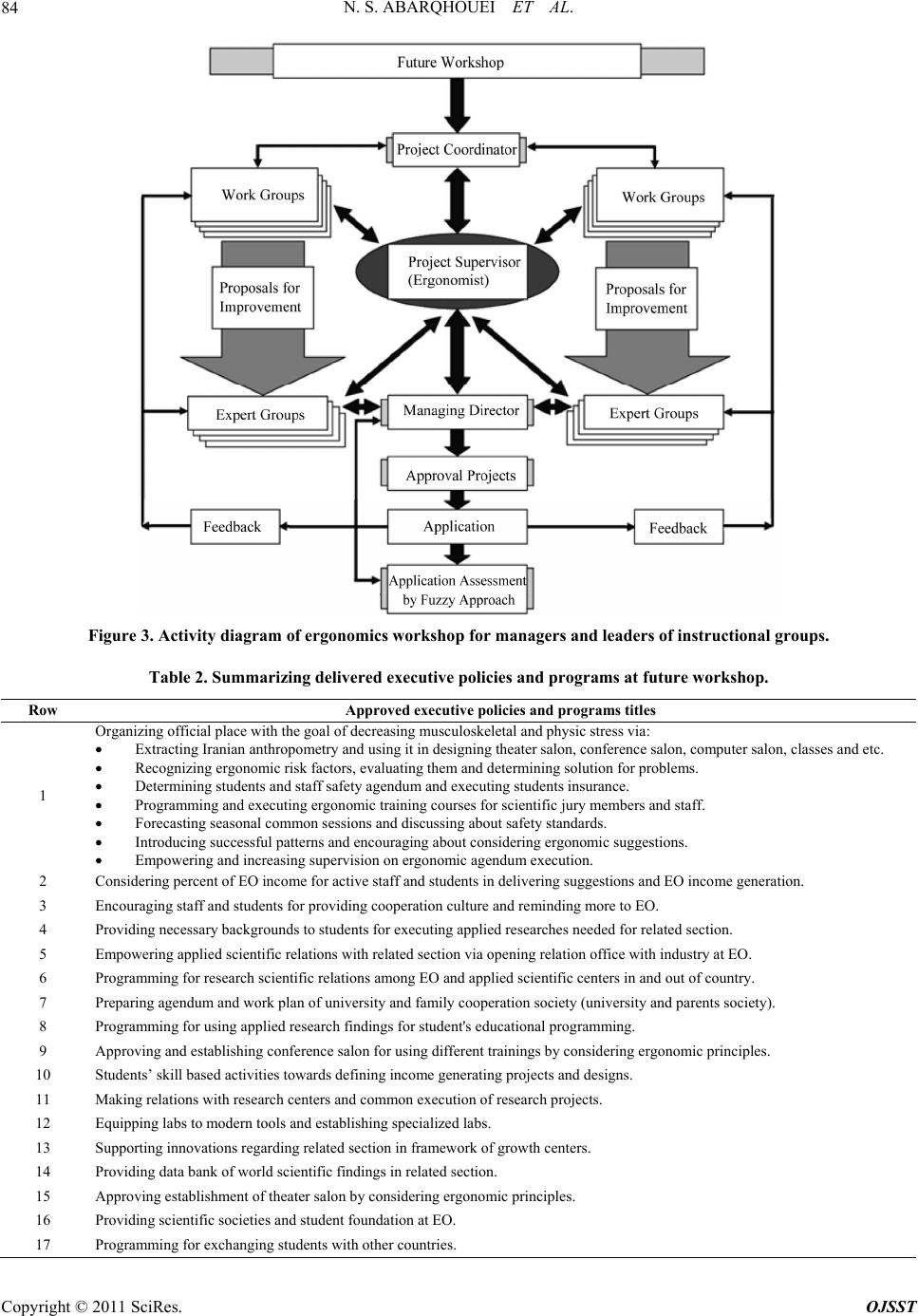

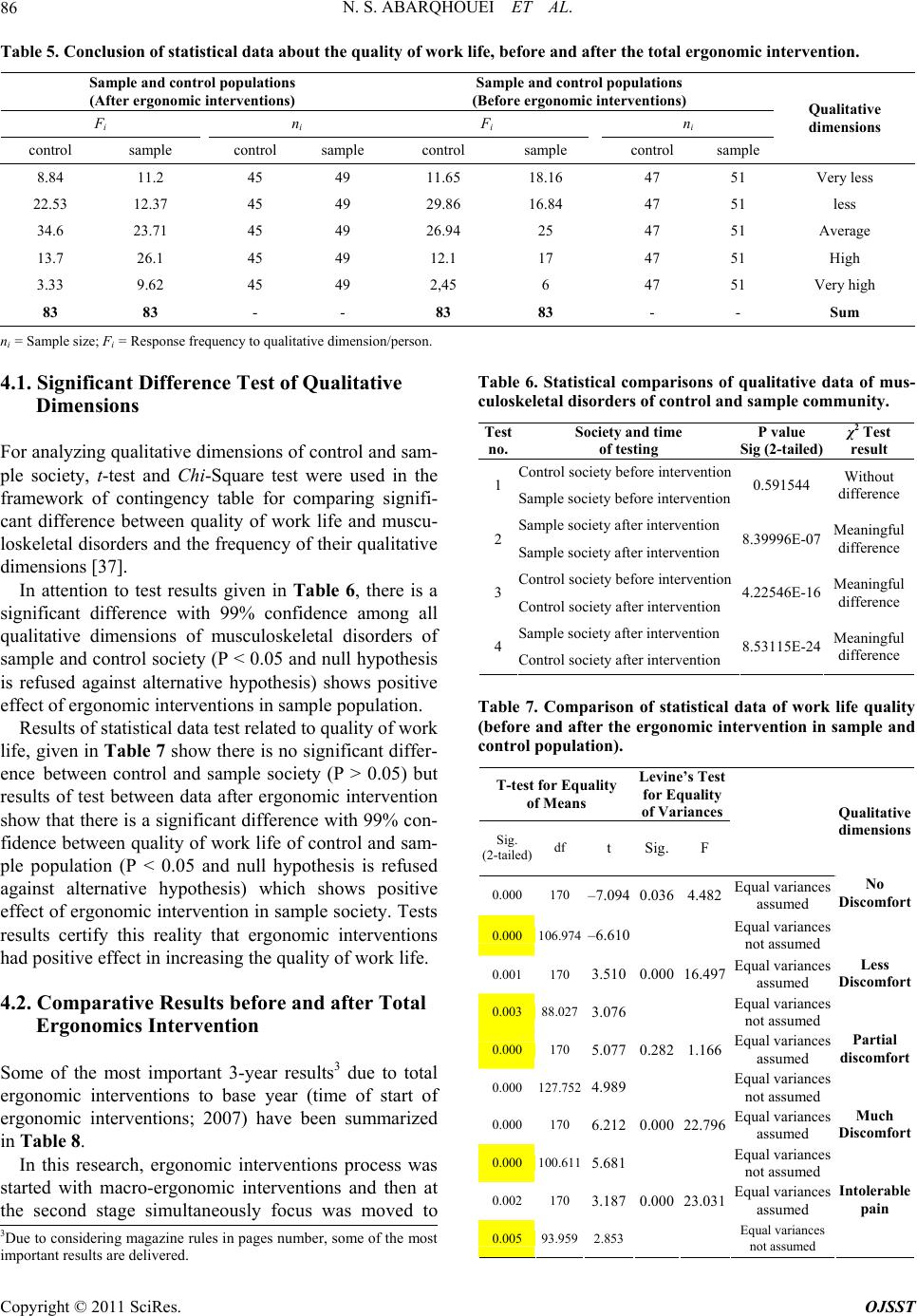

|