Applied Mathematics, 2011, 2, 1539-1545 doi:10.4236/am.2011.212219 Published Online December 2011 (http://www.SciRP.org/journal/am) Copyright © 2011 SciRes. AM Minimax Multivariate Control Chart Using a Polynomial Function Johnson Ademola Adewara1, Kayode Samuel Adekeye2, Osebekwin Ebenezer Asiribo3, Samuel Babatope Adejuyigbe4 1Distance Learning Institu te, University of Lagos, Akoka, Nigeria 2Department o f Mat hematical Sci en ces, Redeemer’s University, Redemption City, Nigeria 3Department of Stat i s t i c s, University of Agriculture, Abeoku ta, Nigeria 4Department of Mechanical Engineering, University of Agriculture, Abeokuta, Nigeria E-mail: adewaraja@yahoo.com, samadek_2017@yahoo.co.u k, asiribo@yahoo.com Received September 15, 2011; revised November 4, 2011; accepted Nov ember 12, 2011 Abstract Minimax control chart uses the joint probability distribution of the maximum and minimum standardized sample means to obtain the control limits for monitoring purpose. However, the derivation of the joint prob- ability distribution needed to obtain the minimax control limits is complex. In this paper the multivariate normal distribution is integrated numerically using Simpson’s one third rule to obtain a non-linear polyno- mial (NLP) function. This NLP function is then substituted and solved numerically using Newton Raphson method to obtain the control limits for the minimax control chart. The approach helps to overcome the prob- lem of obtaining the joint probability distribution needed for estimating the control limits of both the maxi- mum and the minimum statistic for monitoring multivariate process. Keywords: Minimax, Non-Linear Polynomial, Process, Maximum and Minimum 1. Introduction Multivariate statistical process control (MSPC) is parti- cularly important in the industries where data are col- lected on more than one variable. In practice, most of the quality characteristics to be controlled and monitored are not independent. The reason is that most of the variables involved are interconnected, that is, they are correlated. Hence, to monitor these interconnected or correlated va- riables is not simple but rather complex, especially for manufacturing processes. The use of multiple univariate control charts does not deliver a useful solution in th is si- tuation. The problems are that, the overall probability of signaling a false “out-of-control” situation is not contro- lled and more seriously the correlation among the vari- ables are ignored. In recent years, multivariate statistical process control (MSPC) procedures have enjoyed wide application in in- dustry. This has resulted from expanded capability to monitor the key variables of a process with sensor and measurement technolog y, and th e wid espread av ailab ility of computers and statistical software programs that in- corporate multivariate SPC cap ability. Simultaneously, there have been many new technical developments that have made multivariate SPC more useful. For example, many authors have investigated me- thods of monitoring multivariate co ntinuous data. [1] de- veloped the multivariate T2 statistic for quality control purposes. Multivariate generalizations of the CUSUM procedure have been studied by [2] and [3] developed and investigated multivariate exponenti a l ly wei ght ed mov- ing averages to identify quality problems. The use of multivariate exponentially weighted moving averages in monitoring multivariate data have been enhanced by [4]. Monitoring principal components of multivariate data has been studied by [5]. [6] discussed multivariate mini- max control chart and he us ed the joint probab ility distri- bution function of the minimum and maximum stan- dardized sample means to derive the control limits to make decision if the process is in or out of control. However, the derivation of the joint probability d istribution needed to obtain the minimax control limits as discussed by [6] is complex. In this paper we propose a Non-Linear Poly- nomial function (NLP) approach to multivariate minimax control chart to monitor con tinuous data as an alternative approach to the use of joint probability for both the ma-  J. A. ADEWARA ET AL. 1540 ximum ([] ) and minimum ([1] ) limits used by [6]. The minimax control limits derived by [6] is modified and the multivariate normal distribution is integ rated nu- merically using Simpson’s one third rule to obtain a non- linear polynomial (NLP) function. This NLP function is then substituted and solved numerically using Newton Raphson method to obtain the control limits for the mi- nimax control chart. 2. Non Linear Polynomial Function Polynomia ls are popu lar in curve an d surface rep resenta- tions and many critical problems arising in Computer Aided Geometric Design such as surface integration, are reduced to finding the zero set of a system of nonlinear polynomial equations () 0fx (2.1) where 12 (, ) n ff f and each i is a polynomial of independent variables 12 (, ,) l XX X . Several root-finding algorithms for multivariate polynomial sys- tems (2.1) have been used in practice. Newton type methods, which are classified as local solution techni- ques, have been applied to many problems since they are quadratically convergent and produce accurate results. They, however, require good initial approximations of the roots of the systems, and fail to provide full assur- ance that all roots have been found. These limitation s can be overcome by global solution technique, which can be categorized into three different types as proposed by [7]. The different types are algebraic and hybrid methods, homotropy methods, and subdivision methods. Among these techniques, the subdivision methods have been widely used in practice because of their performance and efficiency. The Interval Projected Polyhedral (IPP) algo- rithm proposed by [7] and [8] is one example, and it has been successfully applied to various problems. One par- ticular interest is locating zeros of a univariate applica- tion of polynomial [9]. It is a critical problem in diverse fields such as control theory and many literature has been devoted to it (see e.g. [10]). Most of the root finding algorithms, however, experi- ence difficulties in dealing with roots with high multi- plicity such as performance deterioration and lack of ro- bustness in numerical computation. For example, the IPP algorithm, which belongs to the su bdivision class of me- thods, slows down drastically and suf fers from prolifera- tion of boxes that are assumed to enclose roots. More- over, since a root with high multiplicity is unstable with respect to small perturbation , round-off errors dur ing flo- ating point arithmetic may change the topological aspect in such a way that a cluster of roots could be formed around the root. Solving univariate polynomials with multiple roots is an important but difficult task. [9] collated nine methods to bound multiple roots of polynomials and compared them rigorously. He also proposed a new hybrid algo- rithm which gives numerically nearly optimal bounds for multiple roots of univariate polynomials. Even though these methods work well in most cases, it is not easy for a user to control the size of th e bound of a root in general. [11] used the Sturm sequences to compute all roots of a univariate polynomial, but his approach relies on the di- vision of polynomials to compute Sturm sequences. So, it is not numerically robust unless exact arithmetic or symbolic computation is used. This paper focuses on the particular case where the ,1,,iQ in 111 1 (, ,) (, ,) N QQ N xfs s fs s are functions polynomials. Thus, we write () fs where f is a nonlinear function : Q CC and 1Q f constitute the com- ponent of f. The source separation problem consists of recovering the sources 1 s from the observation 1,, Q x for all i,() i Cs , where stands for the set of polynomials in variables 1 ()Cs ,, s and with coefficients in C. This restriction is partly justified by th e difficulty to tackle the nonlinear case because of its gene- rality. In addition, polynomials constitute an important class of nonlinear models which may represent accept- able approximations of certain nonlinearities. Finally, an important reason to deal with this model is the following: Consider the case where the multidimensional source vector belongs to a finite set . Although seemingly restrictive, this situation is highly interesting since it occurs in digital communications, where the emitted source sequences belong to a finite alphabet depending on the modulation used. (1)( ) ,,na saa An important observation is that if s and A is finite, all instantaneous mixtures of the sources can be expressed as polyno mial mixtures. This follo ws immedi- ately from the fact that any function on a finite set can be interpolated by a polynomial in a way similar to La- grange polynomial interpolation [12]. It follows that po- lynomial mixtures constitute the general model of non- linear mixtures in the case of sources belonging to a fi- nite alphabet. The Model 111 1 (, ,) (, ,) N QQ N xfs s fs s (2.2) is a polynomial, and in order to be able to resort to alge- Copyright © 2011 SciRes. AM  J. A. ADEWARA ET AL.1541 braic techniques, we will restrict the separator to the class of polynomial func tions in 1,, Q x, that is, , ii Cx . 2.1. Simpson One Third Rule The Simpson’s 1/3rd rule is a numerical method for find- ing the integral ()d b a xx within some finite limits a and b. Simpson’s 1/3rd rule approximates () x with a polynomial of degree two p(x), i.e., a parabola between the two limits a and b, and then finds the integral of that bounded parabola, and is used to represent the approxi- mate integral ()d b a xx . The integral of the approxi- mated function is the area under the parabola bounded by the points a and b by the positive side of the x axis. The quadratic function has three points common to the function f(x), as follows: The end points of the approxi- mate quadratic function p(x) is the same as the function f(x) at points a and b. p(x) takes the same value of the function f(x) at point ()mab 2. Thus three points are fixed each in equal interval amb and a parabola is drawn through these three points f(a), f(m), f(b). The area under the parabola through these points bounded by a and b with the positive side of the X axis is found and used as the approximated integral value. The iterative formula below can be used to find the integral of a function f(x) using Simpson’s 1/3rd rule. 012 () () () 3 SI h fxfx fx (2.3) 2.2. Newton Raphson Method The Newton-Raphson method is based on the principle that if the initial guess of the root of f (x) = 0 is at i , then if one draws the tangent to the curve at () i x, the point 1 () i where the tangent crosses the x-axis is an improved estimate of the root. Using the definition of the slope of a function, at x = xi 1 () 0 () tan ii fx fx x (2.4) Form Equation (2.4) we have 1() () i ii i x xx x (2.5) Equation (2.4) is called the Newton-Raphson formula for solving nonlinear equations of the form ()0fx . So starting with an initial guess, i , one can find the next guess, 1i by using Equation (2.5). One can re- peat this process until one finds the root within a desir- able tolerance. Algorithm The steps of the Newton-Raphson method to find the root of an equation () 0fx are: Step 1. Evaluate () x symbolically Step 2. Use an initial guess of the root, i xi, to estimate the new value of the root , 1i as 1() () i ii i x xx x Step 3. Find the absolute relative approximate error as 1 1 *100 ii i xx x Step 4. Compare the absolute relative approximate error with the pre-specified relative error tolerance, ,If s , then go to Step 2, or else stop the algo- rithm. Also, check if the number of iterations has ex- ceeded the maximum number of iterations allowed. If so, one needs to terminate the algorithm and notify the user. 2.3. Minimax Control Chart The Minimax control chart developed by Sepulveda [6], and as discussed in [13] is similar to the charts propo sed by [14] and [15]. The minimax control chart uses the mi- nimum and maximum standardized sample means to make the decision if the process should be considered in control or out of control. However, the minimax chart uses both lower and upper control limits on both the ma- ximum and minimum standardized sample means. This is facilitated by the development of the capability to de- termine the value of the joint density function of the maximum and min imu m stan dar dized s ampl e means . Th is not only facilitates a method for setting the control limits, but also allows for the comparison of the performance of the minimax chart relative to other charts through com- putation of the out-of-cont rol a verage run lengt h. Minimax control chart is used to standardize all p means and to monitor the maximum and the minimum of those standardized sample means. To do this, the sample average vector 2 1 (, ,, ) XX X is calculated and its elements are standardized using the expression: ()nX Z (2.6) where is the population mean and is the stan- dard deviation. The vector [], 1,2,, i Zi p is now defined as the standardized sample mean vector. The maximum sample mean () is defined as the maximum of the elements of the vector Z, that is, [] ( ),max i Z Also, the minimum standardized sam- Copyright © 2011 SciRes. AM  J. A. ADEWARA ET AL. 1542 )ple mean [1] ( is defined as the minimum of the ele- ments of the vector Z. The control limits that was proposed by [6] is modi- fied to solve for both upper and lower of maximum and upper and lower of minimum as given in the expression below: :()d1 :()d :1( )d :1( )d UCf Zz f Zz UCf Zz f Zz [] [] [1] [1] p p L LCL L LCL (2.7) 3. Results The data for this research work were collected from the production line of a manufacturing company that pro- duces soft drinks. The samples were drawn from the lines on each variable of the production. The data are secon- dary and multivariate in nature. The data had five vari- ables which are: X1 = Contents in ml, X2 = Brev brix, X3 = pressure, X4 = Gas volume (CO2) and X5 = Tempera- ture. Thus, 12 ,,, n XX X . We assumed that the variables are normally distributed since we are dealing with continuous data. The multivariate normal distribu- tion was integrated numerically using Simpson’s one third rule. Simpson’s rule is a numerical method that approximates the value of a definite integral by using quadratic polynomials. This approach was applied to the multivariate normal distribution to obtain a non-linear polynomial (NLP) function. This (NLP) function over- comes the problem of obtaining the joint prob ability dis- tribution needed for the control limits of both the maxi- mum ([] ) and the minimum ([1] ) statistic. This method was used to determine the position of the five control limits of the chart stated in Equation (2.4). In other to obtain the control limits, an algorithm was deve- loped and implemented on C language to fit the polyno- mial function in the form Z = 0.0024x5 + 0.000005x4 – 0.0444x3 – 0.00006x2 + 0.3805x + 0.4988. Using the ob- tained polynomial equation, the algorithm in 2.2.1 was then used to obtain the control limits for both the mini- mum a nd t he ma x imum st a t ist i c s. T he nu m e ric a l s olut ion for the control limits using the developed algorithm is presented in the Appendix. The control limits for mini- mum and maximum statistics for the five variables under consideration are presented in Table 1. Using the obtained control limits in Table 1, the pro- cess under study was tested for stability. To test for the stability of the process, Equ ation (2.6) was used to trans- form the data to obtain the minimum and the maximum Table 1. The upper and lower control limit for both maxi- mum and minimum statistics. UCL[p] LCL[p] UCL[1] LCL[1] 2.4185 1.954 3.0306 2.7195 –2.9458 –1.3148 –3.877 –3.3942 Table 2. The maximum and the minimum values. Maximum0.0187250.0214260.021987 0.022794 0.0357959 Minimum0.005012–0.00226–0.03127 –0.03031–0.00954 values for the five variables. The obtained minimum and maximum values are presented in Table 2. 4. Discussion of Result The values in Table 2 are arranged from the lowest to the highest. Thus minimum of Z[p] is 0.018725, and ma- ximu m of Z[p] is 0.0357959. Also the minimum of Z[1] is –0.031271 and the maximum of Z[1] is 0.005012. Com- paring these values with the control limit in Table 1, the result shows that the minimum and maximum values obtained are within the con trol limits. Hen ce, the produ c- tion process under consideration can be adjudged as be- ing stable. 5. Conclusions Minimax multivariate control chart is another sensitive multivariate control chart that has upper and lower con- trol limits for both maximum and the minimum statistics for monitoring a multivariate process. The paper has ad- dressed the use of numerical solution for obtaining the control limits of the minimax con trol chart as an alterna- tive to the use of joint probabilit y distribution. 6. References [1] H. Hotelling, “Multivariable Quality Control—Illustrated by the Air Testing of Sample Bombsights,” In: C. Ei- senhart, M. W. Hastay and W. A. Wallis, Eds., Tech- niques of Statistical Analysis, McGraw Hill, New York, 1947, pp. 111-184. [2] W. H. Woodall and M. M. Ncube, “Multivariate Cusum Quality Control Procedures,” Technometrics, Vol. 27, No. 3, 1985, pp. 285-292. doi:10.2307/1269710 [3] C. A. Lowry, W. H. Woodall, C. W. Champ and S. E. Rigdon, “A Multivariate Exponentially Weighted Moving Average Control Chart,” Technometrics, Vol. 34, No. 1, 1992, p. 46. doi:10.2307/1269551 [4] G. C. Runger, J. B. Keats, D. C. Montgomery and R. D. Scranton, “Improving the Performance of the Multivari- ate Exponentially Weighted Moving Average Control Chart,” Quality and Reliability International, Vol. 15, No. Copyright © 2011 SciRes. AM  J. A. ADEWARA ET AL. Copyright © 2011 SciRes. AM 1543 3, 1996, pp. 161-166. doi:10.1002/(SICI)1099-1638(199905/06)15:3<161::AID -QRE215>3.0.CO;2-V [5] C. M. Mastrangelo, G. C. Runger and D. C. Montgomery, “Statistical Process Monitoring with Principal Compo- nents,” Quality and Reliability International, Vol. 12, No. 3, 1996, pp. 203-210. doi:10.1002/(SICI)1099-1638(199605)12:3<203::AID-Q RE12>3.0.CO;2-B [6] A. Sepulveda, “The Minimax Control Chart for Multi- variate Quality Control,” Dissertation, Department of In- dustrial and Systems Engineering, Virginia Polytechnic Institute and State University, Blacksburg, 1996. [7] N. M. Patrikalakis and T. Maekawa, “Shape Interrogation for Computer Aided Design and Manufacturing,” Springer- Verlag, Heidelberg, 2002. [8] E.C. Sherbrooke and N. M. Patrikalakis, “Computation of the Solutions of Nonlinear Polynomial Systems,” Com- puter Aided Geometric Design, Vol. 10, No. 5, 1993, pp. 379-405. doi:10.1016/0167-8396(93)90019-Y [9] S. M. Rump, “Ten Methods To Bound Multiple Roots of Polynomials,” Journal of Computational and Applied Mathematics, Vol. 156, No. 2, 2003, pp. 403-432. doi:10.1016/S0377-0427(03)00381-9 [10] .M. McNamee, “A Bibliography On Roots of Polynomi- als,” Journal of Computational and Applied Mathematics, Vol. 47, No. 3, 1993, pp. 391-394. doi:10.1016/0377-0427(93)90064-I [11] H. S. Wilf, “A Global Bisection Algorithm for Comput- ing the Zeros of Polynomials in the Complex Plane,” Journal of the Association for Computing Machinery, Vol. 25, No. 3, 1978, pp. 415-420. doi:10.1145/322077.322084 [12] A. C. David, L. John and O. Donal, “Ideals, Varieties and Algorithms: An Introduction to Computational Algebraic Geometry and Commutative Algebra,” Springer, 2nd Edi- tion, Berlin, 1996. [13] J. Rehmert, “A Performance Analysis of the Minimax Multivariate Quality Control Chart,” M.Sc. Dissertation, Department of Industrial and Systems Engineering, Vir- ginia Polytechnic Institute and State University, Blacks- burg, 1997. [14] A. J. Hayter and K. L. Tsui , “Identification and Quantifi- cation in Multivariate Quality Control Problems,” Jour- nal of Quality Technology, Vol. 26, 1994, pp. 197-208. [15] N. H. Timm, “Multivariate Quality Control Using Finite Intersection Tests,” Journal of Quality Technology, Vol. 28, 1996, pp. 233-243.  J. A. ADEWARA ET AL. 1544 Appendix: Numerical Solution The numerical solutions for the control limits is 554 352 ( )0.00245100.4446100.38050.4988ZxXX XXX The multiple integral of Equation (2.6) is solved below: 554 352 665 4532 0.00245100.4446100.38050.4988 d 0.0024510 0.444610 0.38050.4988 65432 XXX X XXXXX x 665 4532 766554 3 2 0.0024510 0.444610 0.38050.4988d 65432 0.00245 100.4446 100.38050.4988 766554433212 XXXXX XXXXXX 766554 3 2 867 65543 0.00245 100.4446 100.38050.4988d 766554433212 0.00245 100.4446 100.38050.4988 768657 546435324123 XXXXXX XXXXXX 9687 565 0.00245 100.4446100.38050.4988 76896578546743563245 1234 4 XXX X X The possible solutions for the numerical algorithm of the multiple integral are given below. 7.5249 4.2219 4.8351 4.2219 4.8351 2.9458 i i 35 24 3.1708 102.0783 100.95),: x roots 0.24197 2.5085 0.24197 2.5085 2.4185 8.0042 4.6104 8.0042 4.6104 i i i i 799857 76 7.9366 102.9763105.2857 101.6667 10 xx x 7.5651 4.223 4.7726 4.223 4.7726 1.3148 i i 35 24 3.1708 102.0783 100.05),: x roots 2 2 5.8498101.2355 , 5.8498 101.2355 1.1954 8.0048 4.6049 8.0048 4.6049 i roots i i i Copyright © 2011 SciRes. AM  J. A. ADEWARA ET AL. Copyright © 2011 SciRes. AM 1545 79 98 57 12*3.141592654(7.9366 102.9763 105.285710 xx 7.4507 4.2262 4.928 4.2262 4.928 3.877 i i 76 3524 1.6667103.1708 102.0783 10))0.95),: xx root 0.36978 3.1125 0.36978 3.1125 3.0306 8.0031 4.6195 8.0031 4.6195 i i i i 79 98 57 1(2*3.141592654(7.9366 102.9763 105.2857 10 xx 74962 4.2229 4.8741 4.2229 4.8741 3.3942 i i 76 3524 1.6667 103.1708 102.078310))0.05,: xx roots 0.30276 2.8096 0.30276 2.8096 2.7195 8.0037 4.614 8.0037 4.614 i i i i

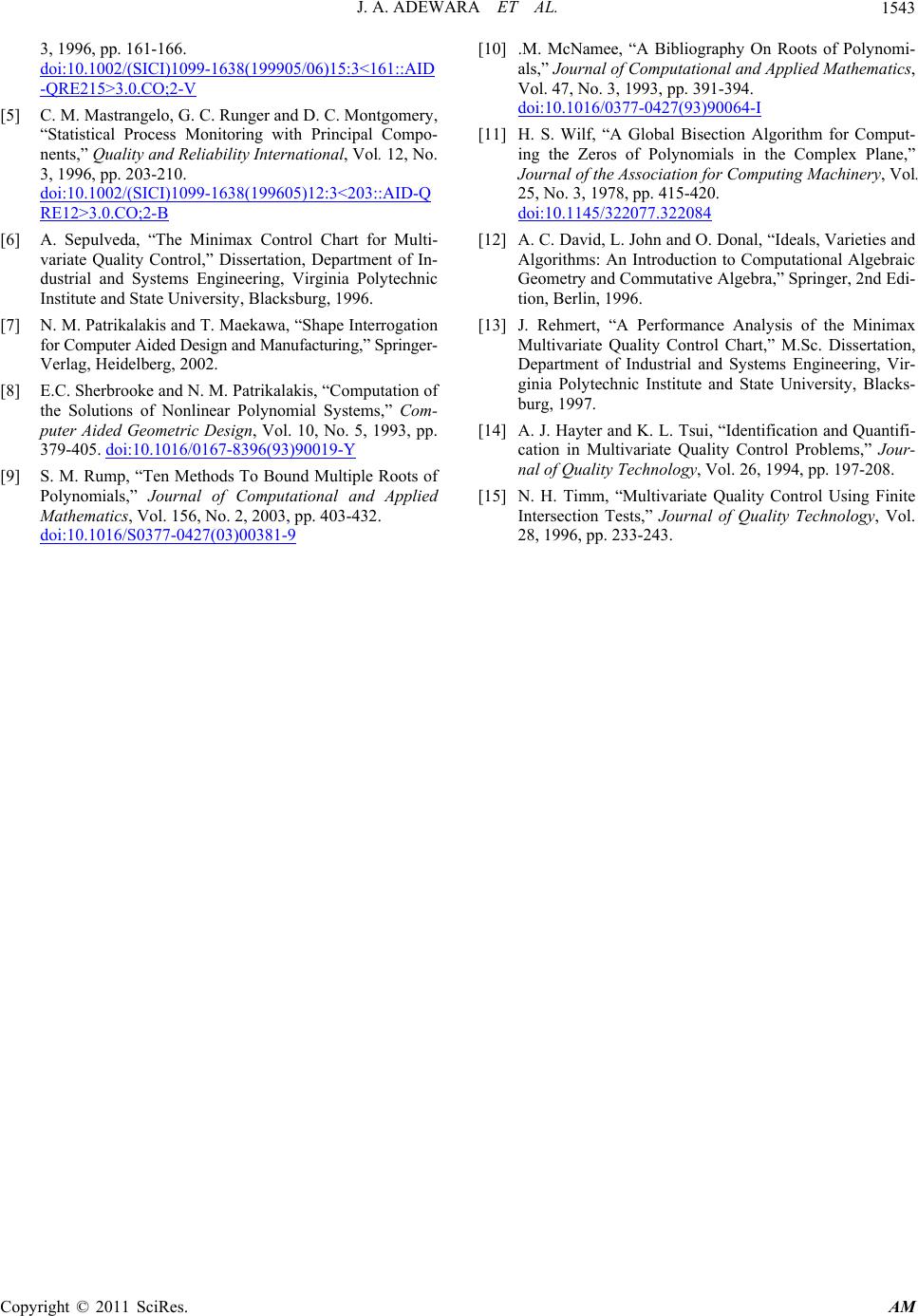

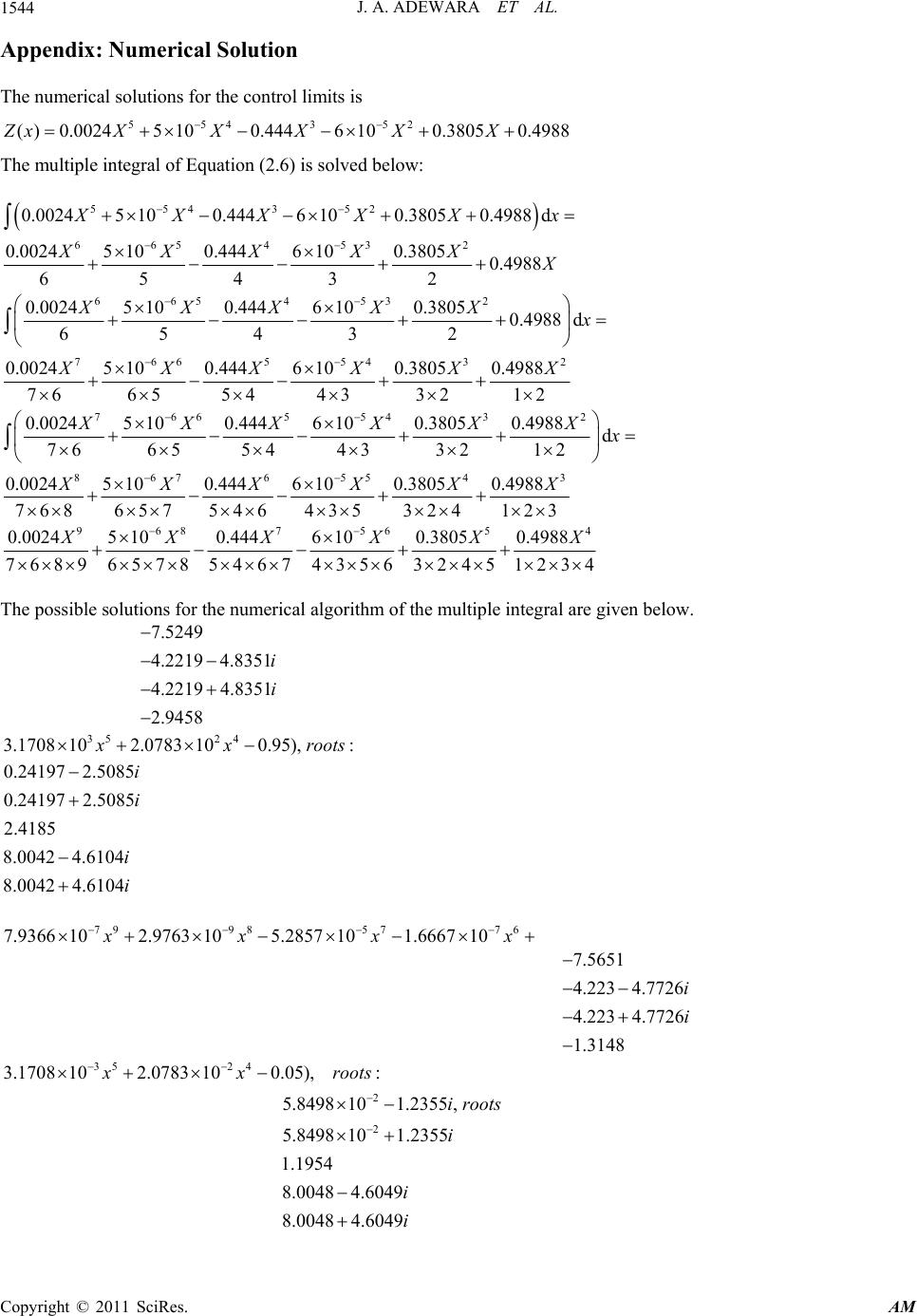

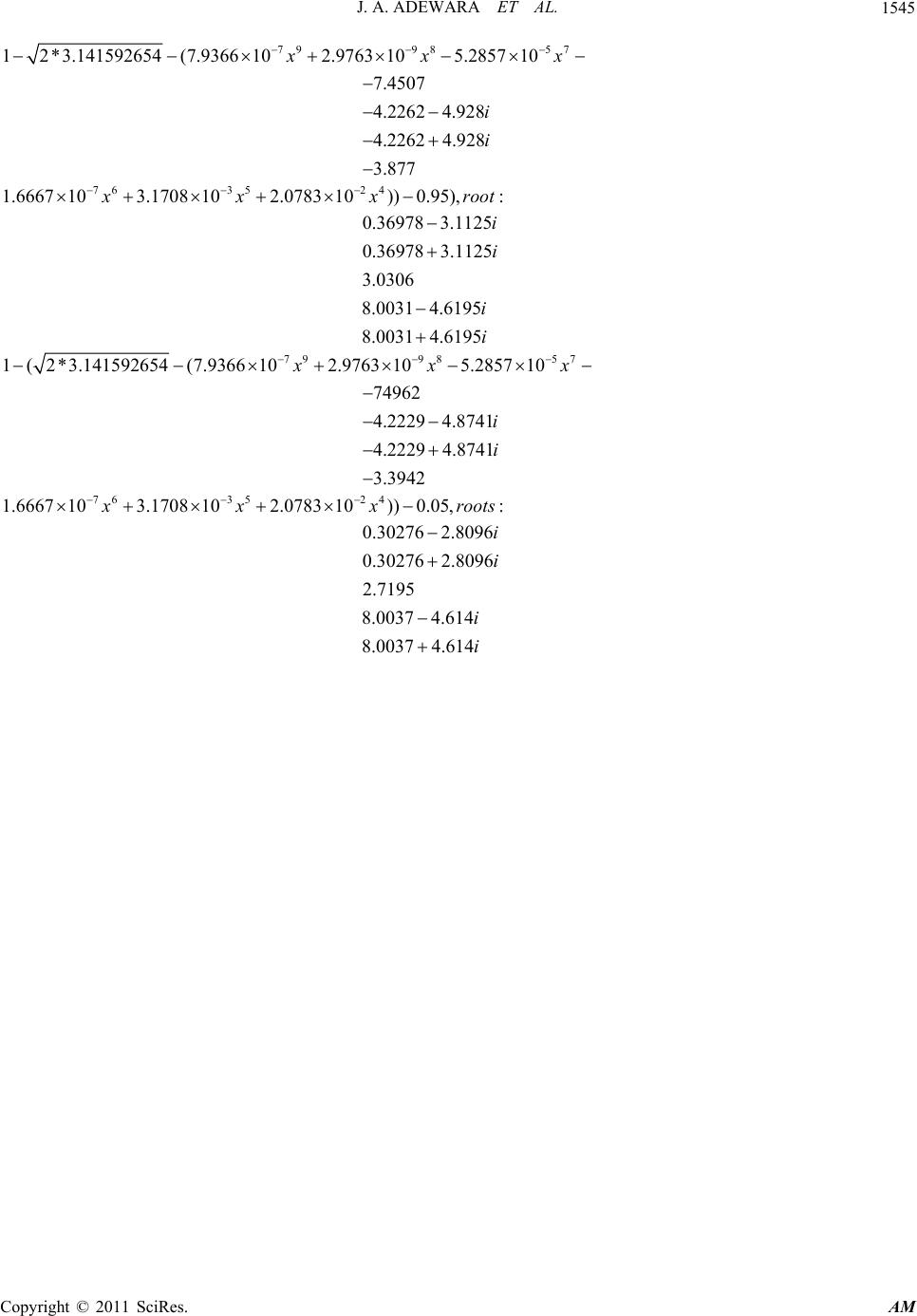

|