Paper Menu >>

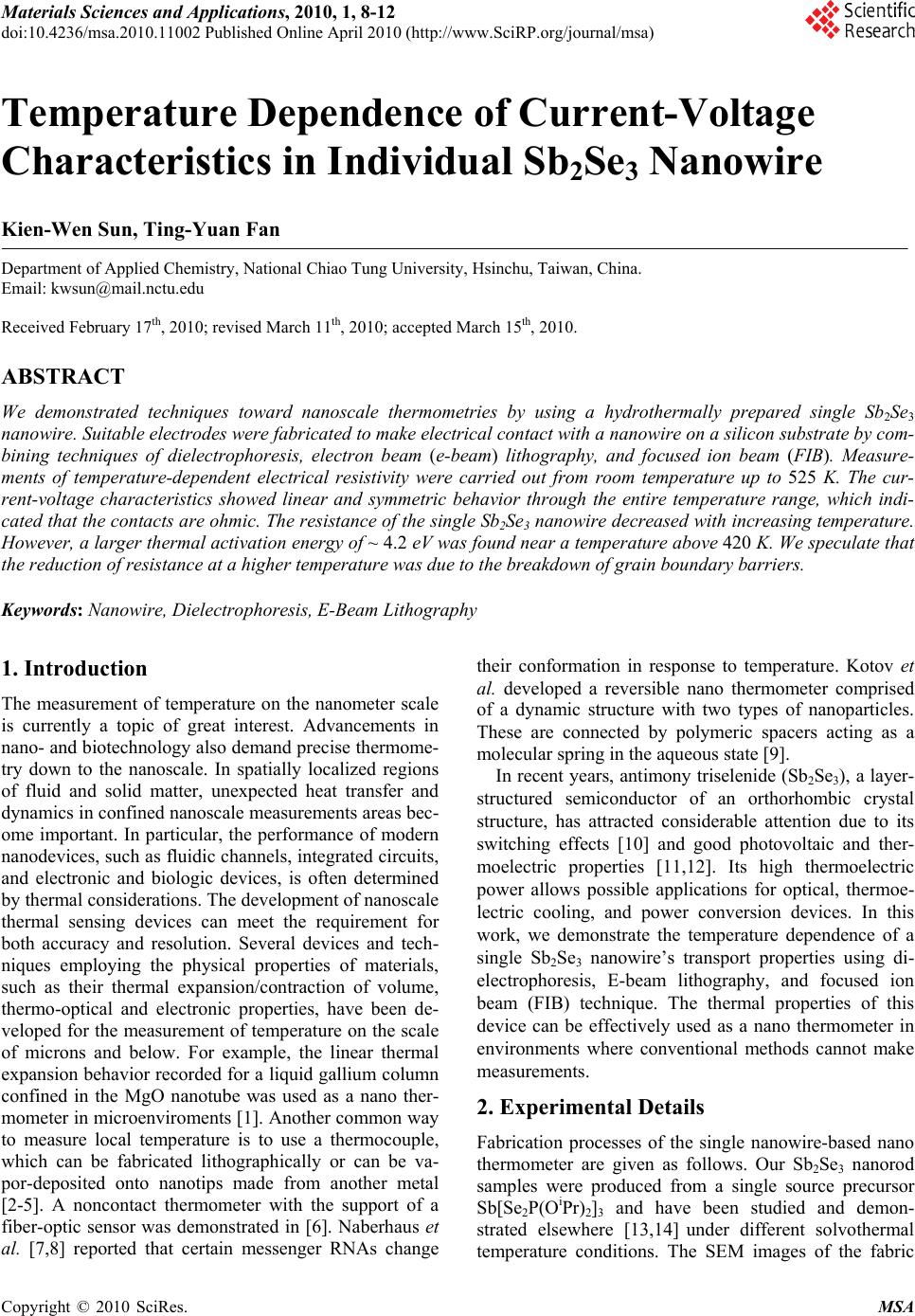

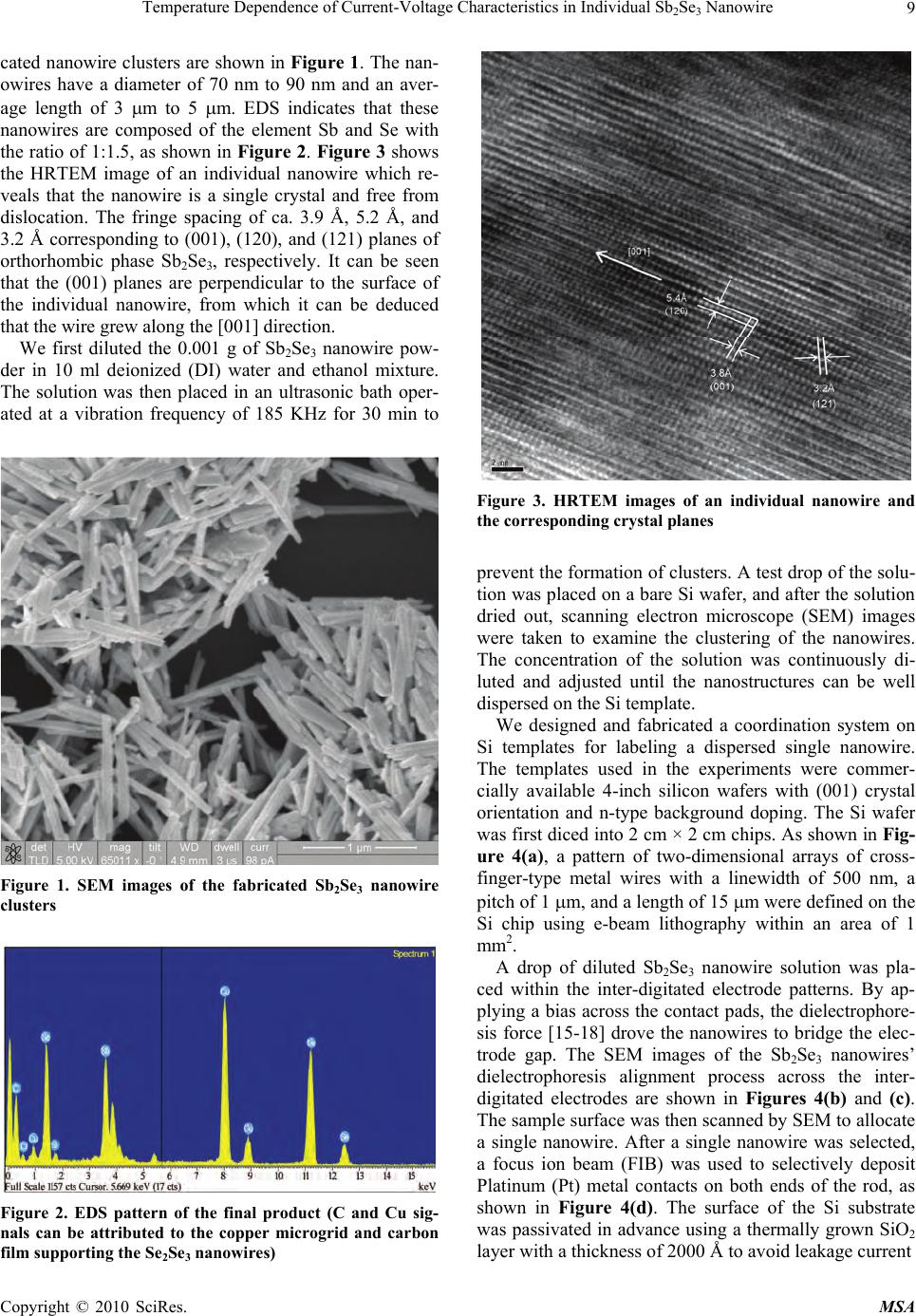

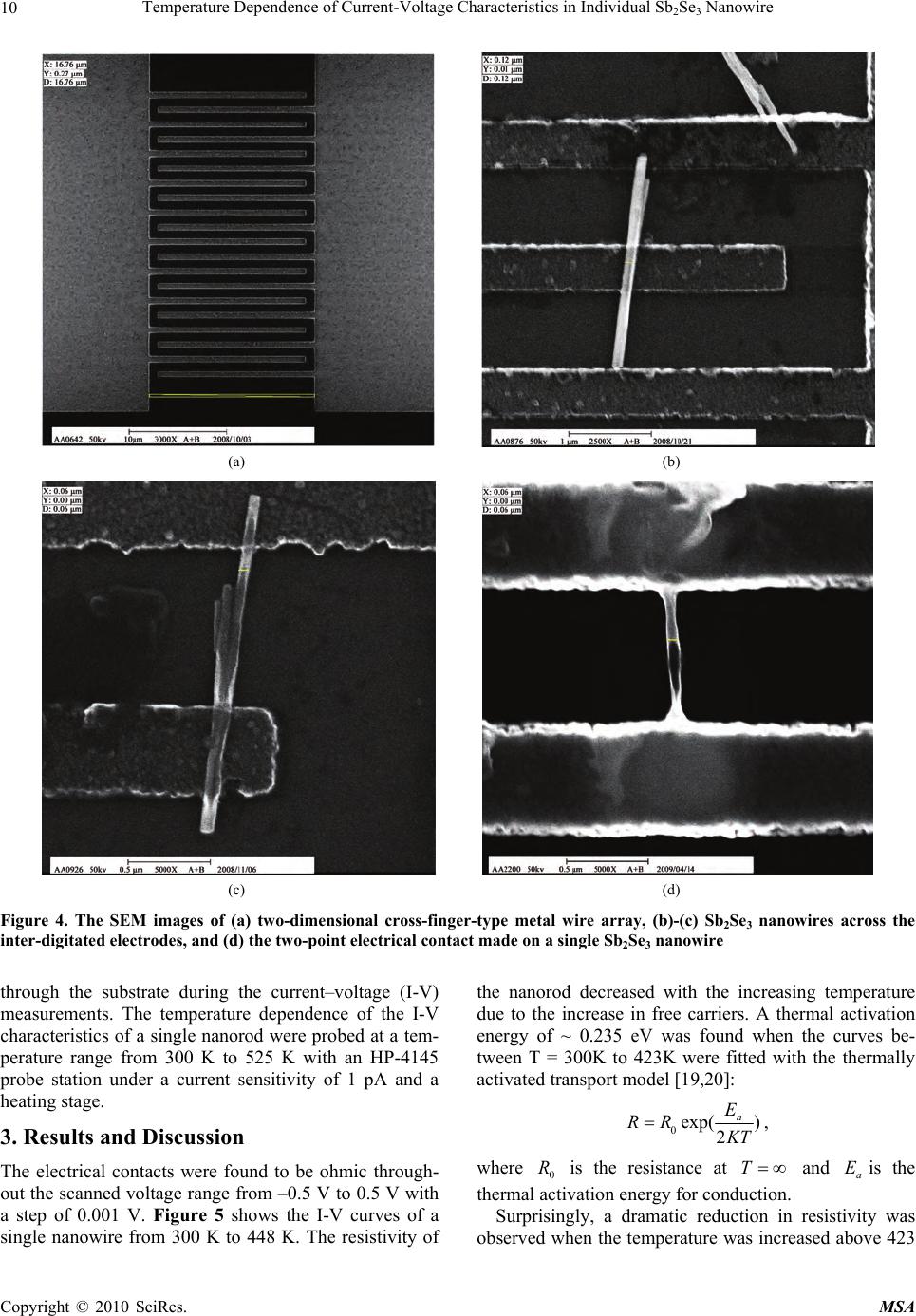

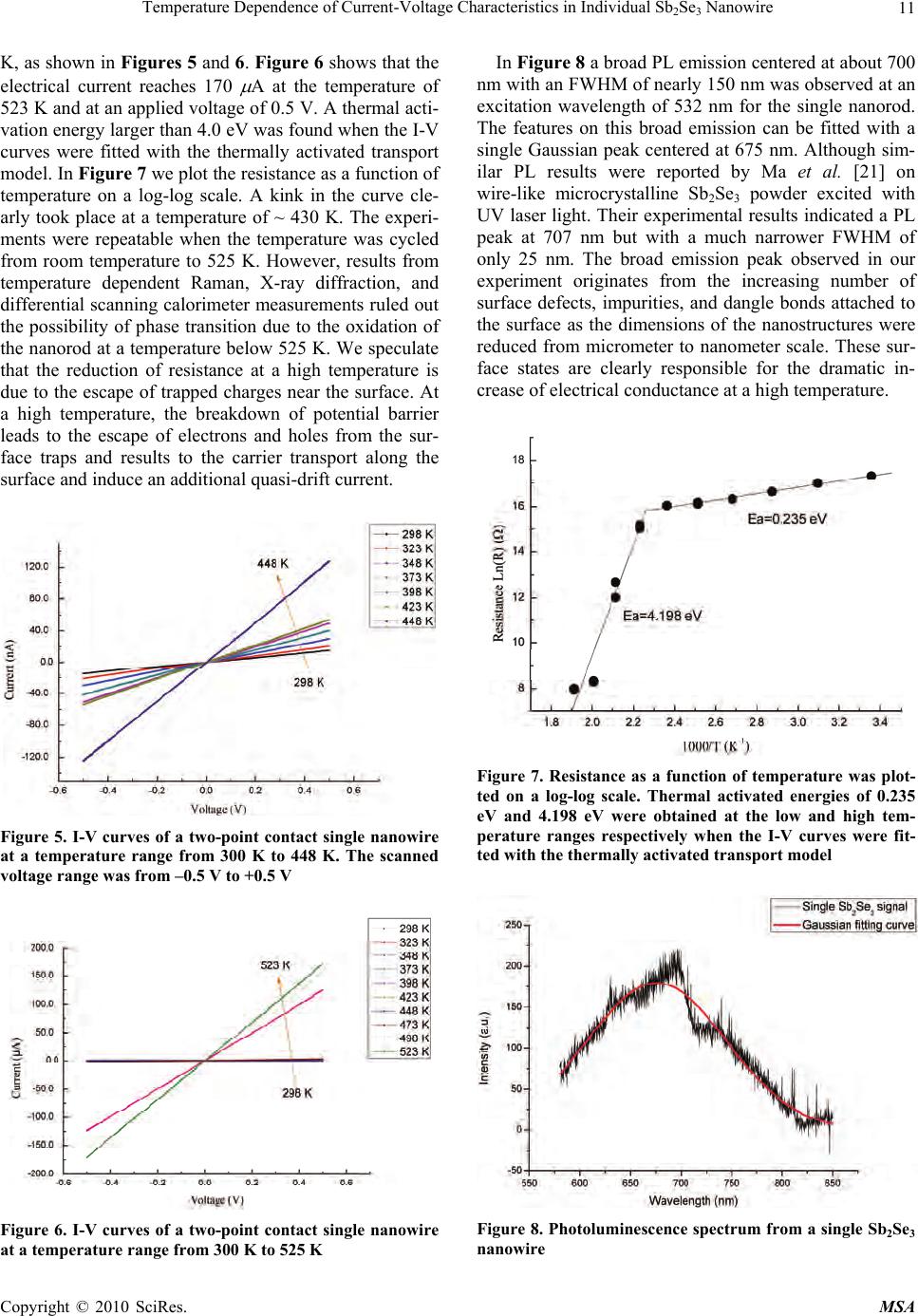

Journal Menu >>

Materials Sciences and Applicatio ns, 2010, 1, 8-12 doi:10.4236/msa.2010.11002 Published Online April 2010 (http://www.SciRP.org/journal/msa) Copyright © 2010 SciRes. MSA Temperature Dependence of Current-Voltage Characteristics in Individual Sb2Se3 Nanowire Kien-Wen Sun, Ting-Yuan Fan Department of Applied Chemistry, National Chiao Tung University, Hsinchu, Taiwan, China. Email: kwsun@mail.nctu.edu Received February 17th, 2010; revised March 11th, 2010; accepted March 15th, 2010. ABSTRACT We demonstrated techniques toward nanoscale thermometries by using a hydrothermally prepared single Sb2Se3 nanowire. Suitable electrodes were fabrica ted to make electrica l conta ct with a nano wire on a silico n substra te by com- bining techniques of dielectrophoresis, electron beam (e-beam) lithography, and focused ion beam (FIB). Measure- ments of temperature-dependent electrical resistivity were carried out from room temperature up to 525 K. The cur- rent-voltage characteristics showed linear and symmetric behavior through the entire temperature range, which indi- cated that the contacts are ohmic. The resistance of the single Sb2Se3 nanowire decreased with increasing temperature. However, a larger thermal activation energy of ~ 4.2 eV was found near a temperature above 420 K. We speculate that the reduction of resistance at a higher temperature was due to the breakdown of grain boundary barriers. Keywords: Nanowire, Dielectrophoresis, E-Beam Lithography 1. Introduction The measurement of temperature on the nanometer scale is currently a topic of great interest. Advancements in nano- and biotechnology also demand precise thermome- try down to the nanoscale. In spatially localized regions of fluid and solid matter, unexpected heat transfer and dynamics in confined nanoscale measurements areas bec- ome important. In particular, the performance of modern nanodevices, such as fluidic channels, integrated circuits, and electronic and biologic devices, is often determined by thermal considerations. The development of nanoscale thermal sensing devices can meet the requirement for both accuracy and resolution. Several devices and tech- niques employing the physical properties of materials, such as their thermal expansion/contraction of volume, thermo-optical and electronic properties, have been de- veloped for the measurement of temperature on the scale of microns and below. For example, the linear thermal expansion behavior recorded for a liquid gallium column confined in the MgO nanotube was used as a nano ther- mometer in microenviroments [1]. Another common way to measure local temperature is to use a thermocouple, which can be fabricated lithographically or can be va- por-deposited onto nanotips made from another metal [2-5]. A noncontact thermometer with the support of a fiber-optic sensor was demonstrated in [6]. Naberhaus et al. [7,8] reported that certain messenger RNAs change their conformation in response to temperature. Kotov et al. developed a reversible nano thermometer comprised of a dynamic structure with two types of nanoparticles. These are connected by polymeric spacers acting as a molecular spring in the aqueous state [9]. In recent years, antimony triselenide (Sb2Se3), a layer- structured semiconductor of an orthorhombic crystal structure, has attracted considerable attention due to its switching effects [10] and good photovoltaic and ther- moelectric properties [11,12]. Its high thermoelectric power allows possible applications for optical, thermoe- lectric cooling, and power conversion devices. In this work, we demonstrate the temperature dependence of a single Sb2Se3 nanowire’s transport properties using di- electrophoresis, E-beam lithography, and focused ion beam (FIB) technique. The thermal properties of this device can be effectively used as a nano thermometer in environments where conventional methods cannot make measurements. 2. Experimental Details Fabrication processes of the single nanowire-based nano thermometer are given as follows. Our Sb2Se3 nanorod samples were produced from a single source precursor Sb[Se2P(OiPr)2]3 and have been studied and demon- strated elsewhere [13,14] under different solvothermal temperature conditions. The SEM images of the fabric  Temperature Dependence of Current-Voltage Characteristics in Individual SbSe Nanowire9 2 3 cated nanowire clusters are shown in Figure 1. The nan- owires have a diameter of 70 nm to 90 nm and an aver- age length of 3 m to 5 m. EDS indicates that these nanowires are composed of the element Sb and Se with the ratio of 1:1.5, as shown in Figure 2. Figure 3 shows the HRTEM image of an individual nanowire which re- veals that the nanowire is a single crystal and free from dislocation. The fringe spacing of ca. 3.9 Å, 5.2 Å, and 3.2 Å corresponding to (001), (120), and (121) planes of orthorhombic phase Sb2Se3, respectively. It can be seen that the (001) planes are perpendicular to the surface of the individual nanowire, from which it can be deduced that the wire grew along the [001] direction. We first diluted the 0.001 g of Sb2Se3 nanowire pow- der in 10 ml deionized (DI) water and ethanol mixture. The solution was then placed in an ultrasonic bath oper- ated at a vibration frequency of 185 KHz for 30 min to Figure 1. SEM images of the fabricated Sb2Se3 nanowire clusters Figure 2. EDS pattern of the final product (C and Cu sig- nals can be attributed to the copper microgrid and carbon film supporting the Se2Se3 nanowires) Figure 3. HRTEM images of an individual nanowire and the corresponding crystal planes prevent the formatio n of clusters. A test drop of the solu- tion was placed on a bare Si wafer, and after the solution dried out, scanning electron microscope (SEM) images were taken to examine the clustering of the nanowires. The concentration of the solution was continuously di- luted and adjusted until the nanostructures can be well dispersed on the Si template. We designed and fabricated a coordination system on Si templates for labeling a dispersed single nanowire. The templates used in the experiments were commer- cially available 4-inch silicon wafers with (001) crystal orientation and n-type background doping. The Si wafer was first diced into 2 cm × 2 cm chips. As shown in Fig- ure 4(a), a pattern of two-dimensional arrays of cross- finger-type metal wires with a linewidth of 500 nm, a pitch of 1 m, and a length of 15 m were defined on the Si chip using e-beam lithography within an area of 1 mm2. A drop of diluted Sb2Se3 nanowire solution was pla- ced within the inter-digitated electrode patterns. By ap- plying a bias across the contact pads, the dielectrophore- sis force [15-18] drove the nanowires to bridge the elec- trode gap. The SEM images of the Sb2Se3 nanowires’ dielectrophoresis alignment process across the inter- digitated electrodes are shown in Figures 4(b) and (c). The sample surface was then scanned by SEM to allocate a single nanowire. After a single nanowire was selected, a focus ion beam (FIB) was used to selectively deposit Platinum (Pt) metal contacts on both ends of the rod, as shown in Figure 4(d). The surface of the Si substrate was passivated in advance using a thermally grown SiO2 layer with a thickness of 2000 Å to avoid leakage current Copyright © 2010 SciRes. MSA  Temperature Dependence of Current-Voltage Characteristics in Individual Sb2Se3 Nanowire Copyright © 2010 SciRes. MSA 10 (a) (b) (c) (d) Figure 4. The SEM images of (a) two-dimensional cross-finger-type metal wire array, (b)-(c) Sb2Se3 nanowires across the inter-digitated electrodes, and (d) the two-point electrical contact made on a single Sb2Se3 nanowire through the substrate during the current–voltage (I-V) measurements. The temperature dependence of the I-V characteristics of a single nanorod were probed at a tem- perature range from 300 K to 525 K with an HP-4145 probe station under a current sensitivity of 1 pA and a heating stage. 3. Results and Discussion The electrical contacts were found to be ohmic through- out the scanned voltage range from –0.5 V to 0.5 V with a step of 0.001 V. Figure 5 shows the I-V curves of a single nanowire from 300 K to 448 K. The resistivity of the nanorod decreased with the increasing temperature due to the increase in free carriers. A thermal activation energy of ~ 0.235 eV was found when the curves be- tween T = 300K to 423K were fitted with the thermally activated transport model [19,20]: 0exp( ) 2a E RR K T , where is the resistance at T and is the thermal activation energy for conduction. 0 R a E Surprisingly, a dramatic reduction in resistivity was observed when the te mperature was increased above 423  Temperature Dependence of Current-Voltage Characteristics in Individual SbSe Nanowire11 2 3 K, as shown in Figures 5 and 6. Figure 6 shows th at the electrical current reaches 170 A at the temperature of 523 K and at an applied voltag e of 0.5 V. A th ermal acti- vation energy larger than 4.0 eV was found when the I-V curves were fitted with the thermally activated transport model. In Figure 7 we plot the resistance as a function of temperature on a log-log scale. A kink in the curve cle- arly took place at a temperature of ~ 430 K. The experi- ments were repeatable when the temperature was cycled from room temperature to 525 K. However, results from temperature dependent Raman, X-ray diffraction, and differential scanning calorimeter measurements ruled out the possibility of phase transition due to the oxidation of the nanorod at a temperature below 525 K. We speculate that the reduction of resistance at a high temperature is due to the escape of trapped charges near the surface. At a high temperature, the breakdown of potential barrier leads to the escape of electrons and holes from the sur- face traps and results to the carrier transport along the surface and induce an additional quasi-drift current. Figure 5. I-V curves of a two-point contact single nanowire at a temperature range from 300 K to 448 K. The scanned voltage range was from –0.5 V to +0.5 V Figure 6. I-V curves of a two-point contact single nanowire at a temperature range from 300 K to 525 K In Figure 8 a broad PL emission centered at about 700 nm with an FWHM of nearly 150 nm was observed at an excitation wavelength of 532 nm for the single nanorod. The features on this broad emission can be fitted with a single Gaussian peak centered at 675 nm. Although sim- ilar PL results were reported by Ma et al. [21] on wire-like microcrystalline Sb2Se3 powder excited with UV laser light. Their experimental results indicated a PL peak at 707 nm but with a much narrower FWHM of only 25 nm. The broad emission peak observed in our experiment originates from the increasing number of surface defects, impurities, and dangle bonds attached to the surface as the dimensions of the nanostructures were reduced from micrometer to nanometer scale. These sur- face states are clearly responsible for the dramatic in- crease of electrical conductance at a high temperature. Figure 7. Resistance as a function of temperature was plot- ted on a log-log scale. Thermal activated energies of 0.235 eV and 4.198 eV were obtained at the low and high tem- perature ranges respectively when the I-V curves were fit- ted with the thermally activated transport model Figure 8. Photoluminescence spectrum from a single Sb2Se3 nanowire Copyright © 2010 SciRes. MSA  Temperature Dependence of Current-Voltage Characteristics in Individual Sb2Se3 Nanowire Copyright © 2010 SciRes. MSA 12 4. Summary In conclusion, we demonstrated a novel nano thermome- ter based on a single Sb2Se3 nanorod, which can be used for the temperature measurement of a temperature range from 300 K to 525 K, in a micrometer size environment. The temperature dependence of the nano thermometer’s transport characteristics shows a dramatic reduction in electrical resistivity (by more than two orders of magni- tude) at a temperature near 525 K. The nonlinear electri- cal behavior of the nanowire is attributed to the grain boundary barrier mechanisms. 5. Acknowledgement This work was supported by the National Science Coun- cil of Republic of China under contract No. NSC 96- 2112-M-009-024–MY3, and NSC 96-2120-M-009-004-, and the MOE ATU program. REFERENCES [1] Y. B. Li, Y. Bando, D. Golberg and Z. W. Liu, “Ga-Filled Single-Crystalline MgO Nanotube: Wide-Temperature Range Nanothermometer,” Applied Physics Letters, Vol. 83, 2003, pp. 999-1001. [2] W. Haeberle, M. Pantea and J. K. H. Hoerber, “Nanome- ter-Scale Heat-Conductivity Measurements on Biological samples,” Ultramiscroscopy, Vol. 106, 2006, pp. 678- 686. [3] H. H. Roh, J. S. Lee, D. L. Kim, J. Park, K. Kim, O. Kwon, S. H. Park, Y. K. Choi and A. Majumdar, “Novel Nanoscale Thermal Property Imaging Technique: The 2 ω Method. II. Demonstration and Comparison,” Journal of Vacuum Science and Technology, Vol. B24, 2006, pp. 2405-2411. [4] L. Chow, D. Zhou and F. Stevie, “Fabrication of Nano- scale Temperature Sensors and Heaters,” U. S. Patent 6905736, 14 June 2005. [5] Y. Okamura and T. Kohler, “Fabrication of Nanoscale Thermoelectric Devices,” U. S. Patent 6969679, 29 No- vember 2005. [6] H. Aizawa, T. Katsumata, S. Komuro, T. Morikawa, H. Ishizawa and E. Toba, “Fluorescence Thermometer Based on the Photoluminescence Intensity Ratio in Tb Doped Phosphor Materials,” Sensors and Actuators, Vol. A126, 2006, pp. 78-82. [7] S. Chowdhury, C. Maris, F. H.-T. Allain and F. Narber- haus, “Molecular Basis for Temperature Sensing by an RNA Thermometer,” European Molecular Biology Or- ganization Journal, Vol. 25, 2006, pp. 2487-2497. [8] T. Waldminghaus, A. Fippinger, J. Alfsmann and F. Nar- berhaus, “RNA Thermometers are Common in α- and γ-proteobacteria,” Biological Chemistry, Vol. 386, 2005, pp. 1279-1286. [9] J. Lee, A. O. Govorov and N. A. Kotov, “Nanoparticle Assemblies with Molecular Springs: A Nanoscale Ther- mometer,” Angewandte Chemie, Vol. 117, 2005, pp. 7605-7608. [10] N. S. Platakis and H. C. Gatos, “Threshold and Memory Switching in Crystalline Chalcogenide Materials,” Physi- ca Status Solidi, Vol. A13, 1972, pp. K1-K4. [11] J. Black, E. M. Conwell, L. Sigle and C. W. Spencer, “Electrical and Optical Properties of Some M2 Ⅴ-B N3 Ⅵ-B Semiconductors,” Journal of Physics and Chemistry of Solids, Vol. 2, 1957, pp. 240-251. [12] K. Y. Rajapure, C. D. Lokhande and C. H. Bhosele, “Ef- fect of the Substrate Temperature on the Properties of Spray Deposited Sb-Se Thin Films from Non-Aqueous Medium,” Thin Solid Films, Vol. 311, 1997, pp. 114-118. [13] H.-W. Chang, B. Sarkar and C. W. Liu, “Synthesis of Sb2Se3 Nanowires via a Solvothermal Route from the Single Source Precursor Sb[Se2P(OiPr)2]3,” Crystal Growth & Design, Vol. 7, 2007, pp. 2691-2695. [14] Y.-F. Lin, H.-W. Chang, S.-Y. Lu and C. W. Liu, “Prepa- ration, Characterization, and Electrophysical Properties of Nanostructured BiPO4 and Bi2Se3 Derived from a Structur- ally Characterized, Single-Source Precursor Bi[Se2P(OiPr)2]3,” Journal of Physical Chemistry C, Vol. 111, 2007, p. 18538. [15] K. Yamamoto, S. Akita and Y. Nakayama, “Orientation of Carbon Nanotubes Using Electrophoresis,” Japanese Journal of Applied Physics, Vol. 35, 1996, pp. L917- L918. [16] K. Yamamoto, S. Akita and Y. Nakayama, “Orientation and Purification of Carbon Nanotubes Using Ac Electro- phoresis,” Journal of Physic s D: Applied Physics, Vol. 31, 1998, pp. L34-L36. [17] W. B. Choi, Y. W. Jin, H. Y. Kim, S. J. Lee, M. J. Yun, J. H. Kang, Y. S. Choi, N. S. Park, N. S. Lee and J. M. Kim, “Electrophoresis Deposition of Carbon Nanotubes for Triode-Type Field Emission Display,” Applied Physics Letters, Vol. 78, 2001, pp. 1547-1549. [18] J. Suehiro, G. Zhou and M. Hara, “Fabrication of a Car- bon Nanotube-Based Gas Sensor Using Dielectrophoresis and its Application for Ammonia Detection by Impedance Spectroscopy,” Journal of Physics D: Applied Physics, Vol. 36, 2003, pp. L109-L114. [19] S. M. Sze and K. K. Ng, “Physics of Semiconductor De- vice,” 3rd Edition, Wiley, New York, 2007, pp. 21-25. [20] R. Smith, “Semiconductors,” Cambridge University Press, London, 1980, pp. 18-19. [21] X. Ma, Z. Zhang, X. Wang, S. Wang, F. Xu and Y. Qian, “Large-Scale Growth of Wire-Like Sb2Se3 Microcrystal- lines via PEG-400 Polymer Chain-Assisted Route,” Journal of Crystal Growth, Vol. 263, 2004, pp. 491-497. |