Food and Nutrition Sciences

Vol. 2 No. 2 (2011) , Article ID: 4560 , 4 pages DOI:10.4236/fns.2011.22022

Controlled Drying Effect on the Quality of Sorghum Malts Used for the Chakpalo Production in Benin

![]()

1Département de Nutrition et Science Alimentaire, Faculté des Sciences Agronomiques, Université d’Abomey-Calavi, Cotonou, Bénin; 2Laboratoire de Microbiologie et de Contrôle de Qualité des Denrées Alimentaires, Ecole Supérieure des Techniques Biologiques et Alimentaires, Université de Lomé, Lomé, Togo.

Email: yoffou_250@yahoo.fr

Received December 15th, 2010; revised February 20th, 2011; accepted February 26th, 2011.

Keywords: Sorghum, Malts, Shell Drier, Quality

ABSTRACT

Traditionally, sorghum malts used for the chakpalo production are dried under the sun in not controlled conditions in Benin. In order to improve drying operation in a rural approach, a shell drier was tested and the quality of the dried malts was evaluated. The germinated capacity, thousand kernel weight, moisture, protein and fat contents of the red sorghum used for malting were respectively 94%, 27.81%, 11.65%, 11.4% and 3.57%. The quality of the dried malt in the shell drier and those of the dried malt directly under the sun was compared. The results showed that the speed of malt drying was higher in the shell drier than under the sun. Indeed, the moisture contents of the dried malts directly under the sun and in the shell drier after 12 hours were respectively 12.56% and 7.66%. The microbiological quality of the dried malts in the shell drier was better. There were free of faecal coliforms. The results of this study indicate that the controlled drying of sorghum malts by using a shell drier improved the drying speed and the microbiological characteristics of the dried malts. Shell drier would be easy to use in the rural areas to dry sorghum malt.

1. Introduction

In Africa, drying is often a significant unit operation involved in several food technology processes. Drying is mainly used to preserve food products for longer periods. It has been established as the most efficient preservation technique for many tropical crops.

The principal raw material used in African traditional breweries is the sorghum, which plays a crucial role in the food safety of the semi-arid tropical areas [1]. Sorghum is quantitatively the world’s fifth largest most important cereal grain, after wheat, maize, rice and barley [2]. It is often transformed in malts used in the manufacture of various types of foodstuffs and fermented beverages. Drying is the last stage of the cereals malting process. Its principal objective is to stop the growth of the green malt at the end of the germination process and to produce a shelf-stable product complete with active enzymes by reducing moisture content and water activity [3]. The drying temperature suitable for retention of high amylase activity and other endogenous hydrolytic enzymes is approximately 50˚C [4].The sorghum malts are usually dried at 50˚C during 24 hours [5-7]. There are traditionally dried under the sun. The sun drying reduced to 16% the α-amylasic activity of sorghum malts [8].

Moreover drying reduces the microbial growth in the germinated green malt because relative humidity of the grain becomes too low to permit proliferation of microorganisms. However, the levels of microorganisms in dried malt depend mainly on the drying conditions. Thus, dried malt carries complex microbial population that essentially consists of bacteria, yeast and filamentous fungi (moulds) [9]. Some bacteria (coliforms) and moulds could be harmful to humans if consumed [9]. Microbial contamination could alter physical, chemical and sanitary characteristics of malts. From these data, the malts drying need to be controlled.

In Benin, the traditionally obtained sorghum malt after steeping, germination and drying is used to prepare many fermented product such as chakpalo, gowé and tchoukoutou [10-13]. After the germination, the germinated sorghum grains are spread over mat, plastic sack, or leaf to be dried directly under sun and thus are exposed to various bad weather (wind, dust...), insects and microorganisms. So, there is a need to develop attempts of technological approaches in order to improve this last unit operation and the quality of the final product.

The present work was taken up to assess the effect of controlled drying on the quality of sorghum malts by testing the aptitude of the shell drier to improve the drying operation and the micro-biological quality of the sorghum malts.

2. Material and Methods

2.1. Materials

The malt was produced starting from the local red variety of sorghum grain (Sorghum vulgare (L.) Moench) often used by the chakpalo producers.

2.2. Malting

Sorghum grains were steeped in water and dirt (weed seeds, dust and other) were removed after floating to the water surface. After soaking for 12 to 24 h at the room temperature, grains were drained and left in baskets for 10 to 12 h in order to allow shoots initiation (pregermination). Then, there were spread out in thin layer (3 - 5 cm thickness), covered and germinated during 72 h. From time to time, grains were watered. The obtained green malt was then separated into two equal portions of known weights. One portion was sun-dried and the other dried in a shell drier. For the sun drying, the green malt (6 kg) was spread over trays and exposed directly to the sun at ambient temperature depending on solar intensity during 12 h according to the traditional technology practiced by the processors.

The second portion (6 kg) was loaded and dried between 45 and 50˚C in a shell solar drier with thermal supplement for 12 h. Two kilograms of green malt were spread over each of the three trays put in the drier.

After drying, both of the two dried malts (sun-dried and dried in the shell drier) were separately packaged in polyethylene bags.

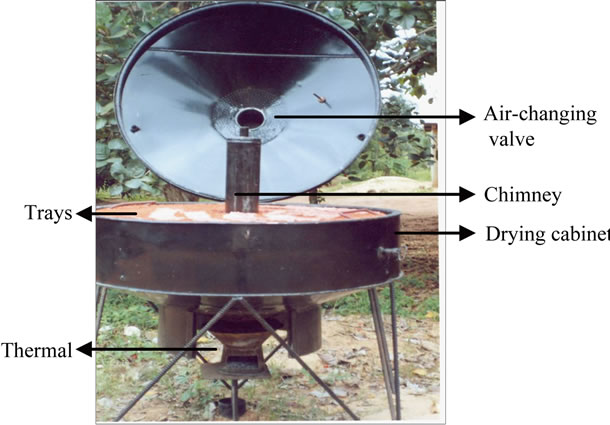

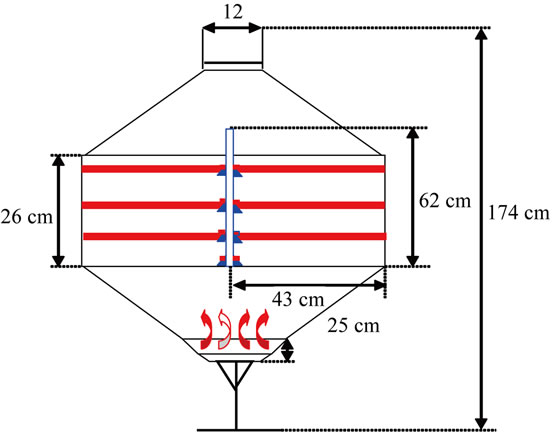

2.3. Shell Drier Description

The shell drier (Figure 1 and Figure 2) is an indirect solar drying system with integral natural convection [14]. The thermal supplement allows making drying independent of the ambient climatic conditions, controlling the drying temperature and maintaining it in an interval in order to preserve the malt enzymes essential to brewing. The drier consists of an upper cone, a cylindrical dehydration chamber and a bottom cone. The upper cone is truncated at the top and is topped by a cap that can slide to allow adjustment of the airflow section. The cylindri-

Figure 1. Shell drier with supplement thermal.

Figure 2. Operation principle of a shell drier to thermal supplement.

cal dehydration chamber can hold two trays in which the product to be dried is loaded. The bottom cone is identical to the upper one but is positioned in the opposite orientation and drilled with a number of regularly distributed holes. The absorber is unglazed, resulting in high heat losses to the ambient. So, most of the solar energy gain by the conical absorber is used to make the airflow through the product, and drying is mainly by aeration [15,16]. The thermal supplement increased the temperature inside the drier and reduces drying period.

2.4. Physicochemical Analysis

Thousand kernel weight, moisture, protein and fat contents were determined according to AOAC methods [17]. Germination activity was determined using triplicate samples (50 seeds each) in open Petri dishes lined with Whatman no. 4 filter paper. Water (4 ml) was added, and the dishes were placed in a germinator at 28˚C. Seeds that developed roots and shoots were counted after 72 h and the percentage was recorded.

2.5. Microbiological Analysis

10 g sample was diluted in sterile (90 ml) peptone water and then homogenized. Appropriate decimal dilutions were prepared for bacterial analysis according to ISO method. Total Mesophilic Aerobic Bacteria were enumerated on Plate Count Agar (PCA) after incubation at 30˚C for 72 h. Yeasts and Moulds were enumerated on Oxytetracycline Glucose Agar (OGA) after incubation at 25˚C for 5 days. Total and Faecal Coliforms were counted on Violet Red Bile Agar (VRBA) after incubation at 30˚C and 44˚C respectively for 48 h. Escherichia coli was carried on Rapid E. Coli after incubation at 44˚C for 24 h. Baird Parker Agar (BPA) was used for Staphylococci count after incubation at 37˚C for 48 h. Sulfitoreducers Anaerobes were enumerated on Bacto Sulfite Agar (BSA) after incubation at 37˚C for 48 h.

3. Results and Discussion

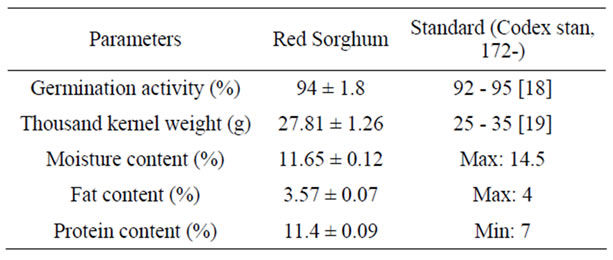

3.1. Physicochemical Characteristics of the Sorghum Grains

The malt’s physicochemical characteristics depend mainly on the raw material used. Results about sorghum physicochemical parameters are given in Table 1. These results were compared to the Codex standards.

Moisture content of the sorghum used (11.65%) was lower than the maximum value required by the Codex standards for the sorghum kernels [20]. Proteins and fat contents, respectively 11.4% and 3.57% were also in conformity with the Codex standards for the sorghum grains which require a minimal proteins content of 7% and a maximum fat content of 4%. The thousand kernel weight (27.81 g) was between the values (25 to 35 g) reported by Serna-saldivar et al. [19] for the sorghum.

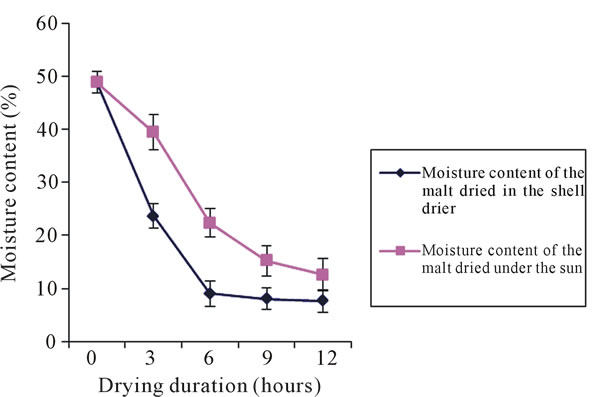

3.2. Moisture Content Variation during the Malt Drying

Figure 3 shows the changes in moisture content during sorghum malts drying in the shell drier between 45 and 50˚C and sorghum malts drying directly under the sun. The moisture content of the dried malts under the sun decreased from 48.81% to 22.36% and those dried in the shell drier from 48.81% to 9.04% after 6 h of drying. A

Table 1. Physicochemical parameters of sorghum grains.

Figure 3. Variation of the moisture content during sorghum malts drying.

moisture content of about 11% is considered safe and guarantees longer shelf life for the malt after drying [21]. More than 80% of the free water was eliminated after 6 h of drying in the shell drier while only 54 % of the water was eliminated during sun drying. After the first six hours of drying, the drying speed decreased considerably during the six other hours and the moisture content decreased from 9.04% to 7.66% for the dried malt using the shell drier and from 22.36% to 12.56% for the dried malt directly under the sun. This little reduction of the drying speed showed that the major part of the free water contained in the malt was evaporated. The free water constitutes the water available in the malt and easy to be evaporated. In contrast, linked water represents the water closely related to the biochemical components of the product and whose elimination requires high temperatures and can attack the chemical structure of the germinated sorghum. Sorghum malt can be dried in the shell drier during 6 h to preserve the enzymes with a final moisture content of 9.04% sufficient for its conservation.

3.3. Microbiological Characteristics of the Dried Malts

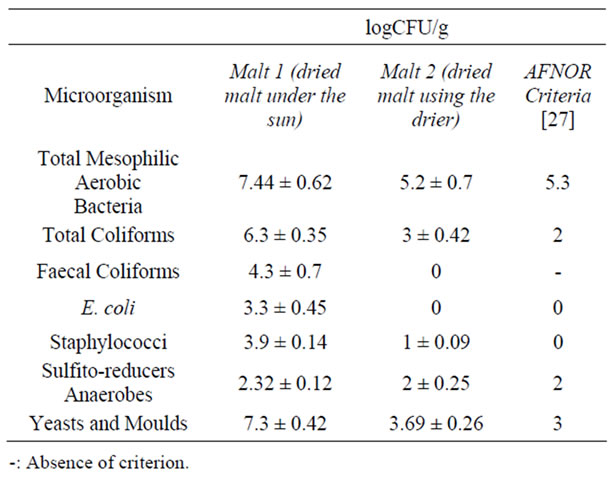

The dried malt under the sun (malt 1) and the dried malt using the shell drier (malt 2) were analyzed in microbeological aspects. Results were shown in Table 2.

Total Mesophilic Aerobic Bacteria, Total Coliforms, Faecal Coliforms, E. coli, Yeast and Moulds, Staphylococci and Sulfito-reducers Anaerobes counts were respectively 7.44 logCFU/g, 6.3 logCFU/g, 4.3 logCFU/g, 3.3 logCFU/g, 7.3 logCFU/g, 3.9 logCFU/g, 2.32 logCFU/g in malt 1 and 5.2 logCFU/g, 3 logCFU/g, 3.69 logCFU/g, 1 logCFU/g, 2 logCFU/g in malt 2. The microorganisms counts were higher in malt 1 than malt 2 due to the sun drying conditions which allow an exposition of the malt to the ambient air and consequently to microorganisms. Moreover, the drying temperature (50˚C)

Table 2. Dried malts microbiological characteristics.

used during the controlled drying process lowers the moisture content to a point where growth of moulds is inhibited or at least stopped [22]. The high level of yeasts and moulds enumerated in malt 1, when compared to the malt 2’s, confirmed this finding. Food products containing 10% or less of free moisture are not subjected to spoiling by microorganisms as their activity is suspended for want of moisture. Additionally, moulds can grow on a dry surface and on feeds containing 12% - 13% moisture content [23]. It is for this reason that the crops were dried to a final moisture content less than 14% (wet basis) allowing their preservation for a period of one year without deterioration [24].

The malt 1 microbial counts were in the same range with those obtained by Lefyedi [25] in which a Total Aerobic count of 8.11 logCFU/g, Yeast count of 6.93 logCFU/g, Moulds of 5.79 logCFU/g, and Coliforms of 5.73 logCFU/g, were obtained from sorghum malts dried in a forced-draft oven at 50˚C for 24 h. The hygienic conditions during malting could have an effect on the malt quality too. Ilorri et al. [26] obtained Total Bacterial counts of 6.3 logCFU/ml and 6.49 logCFU/g in malt samples made from two sorghum varieties.

Malt 1 had a Total Coliforms count (6.3 logCFU/g) greater than malt 2 (3 logCFU/g). Coliforms grow optimally at moisture contents of about 18% and temperatures of about 35˚C and therefore the temperature and moisture content during malt 2 drying will be unfavourable for their growths. Thaoge et al. [27] found the presence of coliforms at levels of 4 - 5.73 logCFU/g in South African sorghum malts. There were not Faecal Coliforms and E. coli in the malt 2 contrary to malt 1 where their levels were respectively 4.3 logCFU/g and 3.3 logCFU/g. The E. coli are important member of the coliform group and could cause gastroenteritis and urinary tract infection [28] as well as diarrhea in infant [29]. So, the malt production of the microbiological quality good would be important.

A typical Southern African sorghum malt specification for Total Bacterial count is lower than 7.3 logCFU/g [25]. The Total Mesophilic Aerobic Bacteria counts of the malt 1 samples exceed the specification and are therefore regarded as unacceptably high contrary to those of the malt 2. According to AFNOR criteria’s, the tolerable microbial load for the cereals products requiring a cooking before consumption (100˚C/3 min) is about 5.3 log CFU/ g for the Total Mesophilic Aerobic Bacteria, 3 log CFU/g for Yeasts and Moulds, 2 logCFU/g for Coliforms, 2 logCFU/g for Sulfito-reducers Anaerobes [30]. Total Mesophilic Aerobic Bacteria and Sulfito-reducers Anaerobes counts of the malt 2 were accordance with AFNOR’s criteria. Yeast and Moulds counts were very near to values recommended by criteria AFNOR. The microbiological characteristics of the malt dried in shell drier were acceptable.

The shell drier could be used for the malt controlled drying at small scale. Indeed, it can reduce malt’s moisture content and contaminations due to wind blown debris, rain, insect infestation, rodents, birds and microorganisms contrary to sun drying. The shell drier constructed from mostly locally available materials is simple, low capital and running costs. Shell drier disadvantage is its low capacity for large scale application. It is a multi-purpose solar dryer which can be used to dry the fruits and vegetables too.

4. Conclusion

The physico-chemical and sanitary qualities of malts could be improved by controlled drying in shell drier. Sun drying involved an exposure to microorganisms and the high final moisture content of the malt was not interesting for its conservation. The sorghum malt could be dried in the shell drier during 6 h allowing a final moisture content about 9.04%. The dried malts in the shell drier had better microbiological characteristics than the dried malts directly under the sun. The shell drier could be used in the sorghum malt production units at small scale.

5. Acknowledgements

Financial support provided by the Institut National des Recherches Agricoles du Bénin (INRAB) is gratefully acknowledged.

REFERENCES

- R. C. Agu and G. H. Palmer, “Enzymic Breakdown of Endosperm Proteins of Sorghum at Different Malting Temperatures,” Journal of the Institute of Brewing, Vol. 102, No. 6, 1996, pp. 415-418.

- FAO, United Nations Food and Agriculture Organization, “Le sorgho et les mils dans la nutrition humaine,” Rome, 1995, p. 198.

- L. Novellie and P. de Schaepdrijver, “Microorganisms in the Production of Food,” In: M. R. Adam, ed., Progress in Industrial Microbiology, Elsevier, Amsterdam, 1986, p. 73.

- J. S. Hough, D. E. Briggs and R. Stevens, “Malting and Brewing Science,” Chapman and Hall, London, 1971, p. 104.

- T. Beta, L. W. Rooney and R. D. Waniska, “Malting Characteristics of Sorghum Cultivars,” Cereal Chemistry, Vol. 72, No. 6, 1995, pp. 533-538.

- V. Subramanian, N. S. Rao, R. Jambunathan, D. S. Murty and B. V. S. Reddy, “The Effect of Malting on the Extractability of Proteins and Its Relationship to Diastatic Activity in Sorghum,” Journal of Cereal Science, Vol. 21, No. 3, 1995, pp. 283-289. doi:10.1006/jcrs.1995.0031

- M. A. Igyor, A. C. Ogbonna and G. H. Palmer, “Effect of Malting Temperature and Mashing Methods on Sorghum Wort Composition and Beer Flavour,” Process Biochemistry, Vol. 36, No. 11, 2001, pp. 1039-1044. doi:10.1016/S0032-9592(00)00267-3

- C. I. Owuama and I. Asheno, “Studies on Malting Conditions for Sorghum,” Food Chemistry, Vol. 49, No. 3, 1994, pp. 257-260. doi:10.1016/0308-8146(94)90169-4

- F. G. Priest and L. Campbell, “Brewing Microbiology,” 2nd Edition, Chapman and Hall, London, 1996, pp. 114-119.

- V. Ballogou, “Production de céréales maltées prêtes à l’emploi pour la fabrication de boissons locales,” Mémoire de maîtrise, Université d’Abomey-Calavi (Bénin); Faculté des Sciences et Techniques (FAST), 2005, p. 70.

- P. P. A. Kayodé, A. Adegbidi, D. J. Hounhouigan, A. R. Linnemann and R. J. M. Nout, “Quality of Farmers VarieTies of Sorghum and Derived Foods as Perceived by Consumers in Benin,” Ecology of Food and Nutrition, Vol. 44, No. 4, 2000, pp. 271-294.

- L. Michodjehoun-Mestres, D. J. Hounhouigan, J. Dossou and C. Mestres, “Physical, Chemical and Microbiological Changes during Natural Fermentation of Gowé, a Sprouted or Non-Sprouted Sorghum Beverage from West-Africa,” African Journal of Biotechnology, Vol. 4, No. 6, 2005, pp. 487-496.

- G. Vieira-Dalodé, L. Jespersen, D. J. Hounhouigan, P. L. Moller, C. M. Nago and M. Jakobsen, “Lactic Acid Bacteria and Yeasts Associated with Gowé Production from Sorghum in Bénin,” Journal of Applied Microbiology, Vol. 103, No. 2, 2007, pp. 1364-5072.

- GERES, “Appui à la filière séchage des aliments,” Séchoirs familiaux et artisanaux pour la zone sahélienne, Marseille, 1993, p. 13.

- M. Fournier and A. Guinebault, “The ‘shell’ DryerModeling and Experimentation,” Renewable Energy, Vol. 6, No. 4, 1995, pp. 459-463. doi:10.1016/0960-1481(94)E0015-W

- A. Fudholi, K. Sopian, M. H. Ruslan, M. A. Alghoul and M. Y. Sulaiman, “Review of Solar Dryers for Agricultural and Marine Products,” Renewable and Sustainable Energy Reviews, Vol. 14, No. 1, 2010, pp. 1-30. doi:10.1016/j.rser.2009.07.032

- Association of Official Analytical Chemists (AOAC) “Official Methods of Analysis,” 13th Edition, Washington, D.C., 1984.

- D. E. Briggs, C. A. Boulton, P. A. Brookes and R. Steven, “Native African Beers,” Brewing Science and Pratice, Boca Raton, Cambridge: CRC Press Woodhead Publishing Ltd, 2004, pp. 589-605.

- S. Serna-salvidar and L. W. Rooney, “Structure and Chemistry of Sorghum and Millets,” In: D. A. V. Dendy, Ed, Sorghum and Millets: Chemistry and technology, American Association of Cereal Chemists, Minnesota; USA, 1995, p. 406.

- Codex Stan, Norme codex pour le sorgho en grains, 1989.

- L. Mugode, “Free Amino Nitrogen Improvement in SorGhum Malt Brewing,” Food Science and Technology, University of Pretoria, South Africa, 2007, p. 100.

- R. C. Agu and G. H. Plamer, “Development of MicroOrganisms during the Malting Sorghum,” Journal of the Insttitute of Brewing, Vol. 105, 1999, pp. 101-106.

- L. W. Whitlow and W. M. Hagler Jr., “Mycotoxins in Feeds,” Feedstuffs, Vol. 74, No. 28, 2002, pp. 1-10.

- L. M. Bal, S. Satya and S. N. Naik, “Solar Dryer with Thermal Energy Storage Systems for Drying Agricultural Food Products: A Review,” Renewable and Sustainable Energy Reviews, Vol. 14, No. 8, 2010, pp. 2298-2314. doi:10.1016/j.rser.2010.04.014

- M. L. Lefyedi, “Control of Microbial Proliferation on Sorghum during Malting,” Food Science, University of Pretoria, 2007, p. 118.

- M. O. Ilori, B. Fessehatzion, O. Olajuyigbe, G. O. Babalola and J. O. Ogundiwin, “Effect of Malting and Brewing Processes on the Microorganisms Associated with Sor Ghum Grains and Malt,” Master Brewers Association of the Americas Quarterly, Vol. 28, 1991, pp. 45-49.

- M. L. Thaoge, M. R. Adams, M. M. Sibara, T. G. Watson, J. R. N. Taylor and E. M. Goyvaerts, “Production of ImProved Infant Porridges from Pearl Millet Using a Lactic Acid Fermentation Step and Addition of Sorghum Malt to Reduce Viscosity of Porridges with High Protein, Energy and Solids (30%) Content,” World Journal of Microbiology and Biotechnology, Vol. 19, 2003, pp. 305-310. doi:10.1023/A:1023614526667

- M. J. Pelczar, C. S. Chane and R. K. Noel, “Microbiology,” 5th Edition, McGraw-Hill Publishing Company, New Delhi, 1993, p. 272.

- L. S. Alice, “Microbiology and Pathology,” 11th Edition, C. V. Mosby Company, 1976, pp. 202-203.

- C. M. Bourgeois, J. F. Mescle and J. Zucca, “MicrobiologieAlimentaire: Aspect Microbiologique de la Sécurité et de la Qualité des Aliments,” Collection Sciences et Technique Agroalimentaire, Technique et Documentation. Londre, Paris, 1996.