Paper Menu >>

Journal Menu >>

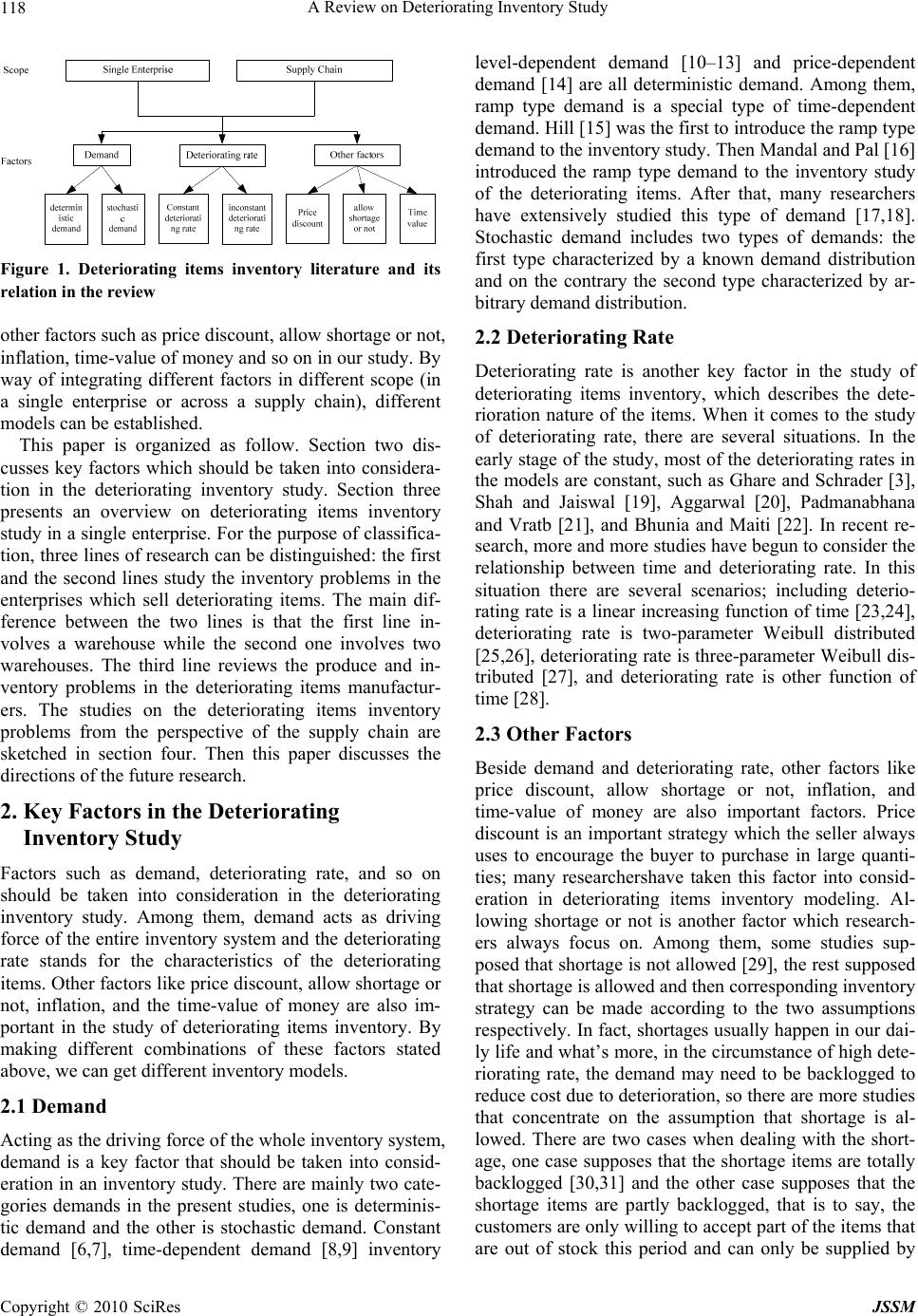

J. Service Science & Management, 2010, 3: 117-129 doi:10.4236/jssm.2010.31015 Published Online March 2010 (http://www.SciRP.org/journal/jssm) Copyright © 2010 SciRes JSSM 117 A Review on Deteriorating Inventory Study Ruxian Li1, Hongjie Lan1*, John R. Mawhinney2 1School of Economics and Management, Beijing Jiaotong University, Beijing, China; 2Business School, Duquesne University, Pittsburgh, USA. Email: *hjlan@bjtu.edu.cn Received September 2nd, 2009; revised October 21st, 2009; accepted November 29th, 2009. ABSTRACT To provide a comprehensive introduction about the deteriorating items inventory management research status, this pa- per reviews the recent studies in relevant fields. Compared with the extant reviews (Raafat 1991; S.K.Goyal 2001), this paper reviews the recent studies from a different perspecti ve. First, this paper proposes some key facto rs which should be considered in the deteriorating inventory studies; then, from the perspective of study scope, the current literatures are distinguished into two categories: the studies based on an enterprise and those based on supply chain. Literatures in each category are reviewed according to the key factors mentioned above. The literature review framework in this paper provides a clear overview of the deteriorating inventory study field, which can be used as a starting point for further study. Keywords: Deteriorating Items, Inventory Model, Literature Review 1. Introduction Deteriorating items are common in our daily life; how- ever, academia has not reached a consensus on the defini- tion of the deteriorating items. According to the study of Wee HM in 1993 [1], deteriorating items refers to the items that become decayed, damaged, evaporative, ex- pired, invalid, devaluation and so on through time. Ac- cording to the definition, deteriorating items can be clas- sified into two categories. The first category refers to the items that become decayed, damaged, evaporative, or expired through time, like meat, vegetables, fruit, medi- cine, flowers, film and so on; the other category refers to the items that lose part or total value through time be- cause of new technology or the introduction of alterna- tives, like computer chips, mobile phones, fashion and seasonal goods, and so on. Both of the two categories have the characteristic of short life cycle. For the first category, the items have a short natural life cycle. After a specific period (such as durability), the natural attributes of the items will change and then lose useable value and economic value; for the second category, the items have a short market life cycle. After a period of popu larity in the market, the items lose the original economic value due to the changes in consumer preference, product upgrading and other reasons. The inventory problem of deteriorating items was first studied by Whitin [2], he studied fashion items deterio- rating at the end of the storage period. Then Ghare and Schrader [3]concluded in their study that the consump- tion of the deteriorating items was closely relative to a negative exponential function of time. They proposed the deteriorating items inventory model as stated below: () () () dI t I tft dt In the function, stands for the deteriorating rate of the item, () I t refers to the inventory level at time t and then () f t is the demand rate at time t. This inventory model laid found ations for the follow-up study. Raafat [4] and Goyal and Giri [5] made comprehensive literature reviews on deteriorating inventory items in 1991 and 2001 respectively. From a different perspective, this paper reviews the recent trends in deteriorating inventory studies. Figure 1 presents the factors used to analyze and organize this review. From the perspective of scope, we make a dis- tinction between the studies which focus on the deterio- rating items inventory study in a single enterprise from those studies whose focus is on studying the deteriorating items inventory problems across a supply chain. The former is the focus of the early stage in the deteriorating items study and the latter now is attracting more and more attention from the researchers. From the perspective of the factors which should be taken into consideration in deteriorating items inventory study, we involve the im- portant factors such as demand, deteriorating rate and  A Review on Deteriorating Inventory Study Copyright © 2010 SciRes JSSM 118 Figure 1. Deteriorating items inventory literature and its relation i n the re view other factors such as price discount, allow shortage or not, inflation, time-value of money and so on in our study. By way of integrating different factors in different scope (in a single enterprise or across a supply chain), different model s can b e e s tablished. This paper is organized as follow. Section two dis- cusses key factors which should be taken into considera- tion in the deteriorating inventory study. Section three presents an overview on deteriorating items inventory study in a single enterprise. For the purpose of classifica- tion, three lines of research can be distinguished: the first and the second lines study the inventory problems in the enterprises which sell deteriorating items. The main dif- ference between the two lines is that the first line in- volves a warehouse while the second one involves two warehouses. The third line reviews the produce and in- ventory problems in the deteriorating items manufactur- ers. The studies on the deteriorating items inventory problems from the perspective of the supply chain are sketched in section four. Then this paper discusses the directions of the future research. 2. Key Factors in the Deteriorating Inventory Study Factors such as demand, deteriorating rate, and so on should be taken into consideration in the deteriorating inventory study. Among them, demand acts as driving force of the entire inventory system and the deteriorating rate stands for the characteristics of the deteriorating items. Other factors like price discount, allow shortage or not, inflation, and the time-value of money are also im- portant in the study of deteriorating items inventory. By making different combinations of these factors stated above, we can get different inventory models. 2.1 Demand Acting as the driving force of the whole inventory system, demand is a key factor that should be taken into consid- eration in an inventory study. There are mainly two cate- gories demands in the present studies, one is determinis- tic demand and the other is stochastic demand. Constant demand [6,7], time-dependent demand [8,9] inventory level-dependent demand [10–13] and price-dependent demand [14] are all deterministic demand. Among them, ramp type demand is a special type of time-dependent demand. Hill [15] was the first to introduce the ramp type demand to the inventory study. Th en Mand al and Pal [16] introduced the ramp type demand to the inventory study of the deteriorating items. After that, many researchers have extensively studied this type of demand [17,18]. Stochastic demand includes two types of demands: the first type characterized by a known demand distribution and on the contrary the second type characterized by ar- bitrary dem and dist ri b ut i o n. 2.2 Deteriorating Rate Deteriorating rate is another key factor in the study of deteriorating items inventory, which describes the dete- rioration nature of the items. When it comes to the study of deteriorating rate, there are several situations. In the early stage of the study, most of the deteriorating rates in the models are constant, such as Ghare and Schrader [3], Shah and Jaiswal [19], Aggarwal [20], Padmanabhana and Vratb [21], and Bhunia and Maiti [22]. In recent re- search, more and more studies have begun to consider the relationship between time and deteriorating rate. In this situation there are several scenarios; including deterio- rating rate is a linear increasing function of time [23,24], deteriorating rate is two-parameter Weibull distributed [25,26], deteriorating rate is three-parameter Weibull dis- tributed [27], and deteriorating rate is other function of time [28]. 2.3 Other Factors Beside demand and deteriorating rate, other factors like price discount, allow shortage or not, inflation, and time-value of money are also important factors. Price discount is an important strategy which the seller always uses to encourage the buyer to purchase in large quanti- ties; many researchershave taken this factor into consid- eration in deteriorating items inventory modeling. Al- lowing shortage or not is another factor which research- ers always focus on. Among them, some studies sup- posed that shortage is not allowed [29], the rest supposed that shortage is allowed and then corresponding inventory strategy can be made according to the two assumptions respectively. In fact, shortages usu ally happen in our dai- ly life and what’s more, in the circumstance of high dete- riorating rate, the demand may need to be backlogged to reduce cost due to deterioration, so there are more studies that concentrate on the assumption that shortage is al- lowed. There are two cases when dealing with the short- age, one case supposes that the shortage items are totally backlogged [30,31] and the other case supposes that the shortage items are partly backlogged, that is to say, the customers are only willing to accept part of the items that are out of stock this period and can only be supplied by  A Review on Deteriorating Inventory Study Copyright © 2010 SciRes JSSM 119 the seller in the next period. There are some different considerations in dealing with the backlogging function. In some of the studies, the backlogging function was as- sumed to be closely relative to the amount of demand backlogged [32], therefore the more the amount of de- mand backlogged, the smaller the demand to accept backlogging would be. While in our real life, for deterio- rating items with short life time, the waiting time for the next replenishment is the main factor for deciding whether the backlog will be accept or not and when we are willing to accept the backlog, what is the accepting proportion? It is easy for us to know that the willingness of a customer to wait for backlogged items during a shortage period declines with the length of the waiting time. In order to reflect this phenomenon, some studies [33–35] developed inventory models in which the back- logging rate is a function of waiting time. Trade credit is another factor. Trade credit (permissible delay in payment) is a widely used business strategy. To suppliers, trade credit helps to expand sale but it also adds to the risk of bad debts at the same time. To buyers, trade credit provides a very big advantage, due to the fact that they do not have to pay the seller immediately after receiving the items, but instead can delay their payment until the end of the allowed period. The buyer pays no interest during the agreed time for payment, but it in- creases the risk of deterioration cost when large amounts are purchased. However, both sellers and buyers need to reach trade-off between the advantages and disadvan- tages they can get from this inv entory policy. At present, there are three kinds of trade credit, in the first case, the length of th e credit period is fixed [36–38 ], in the second case, the length of the credit period is closely relative to the ordering quantity [39–41]. In the third case, the sell- ers provide trade credit to part of the ordering quantity and the purchase cost of the rest quantity should be paid immediately after receiving the items. Inflation and time value of money have also attracted attention of researchers. Taking the two factors into con- sideration is of vital importance. With the integration of the global economy, the economic relationships among countries are closer and the mutual influences are deep. Currency’s purchasing power will change from time to time and inflation should not be neglected. Many re- searchers [14,44–47] have made complementally com- prehensive consideration in deteriorating items modeling. 3. Deteriorating Items Inventory Study in a Single Enterprise Inventory cost is an important part of the enterprise op- eration cost. For deteriorating items, especially those with high deteriorating rate, deterioration is a key characteris- tic and its impact on modeling of inventory systems can- not be neglected. So the deterioration rate should be tak- en into consideration in the development of inventory strategy. For different kinds of enterprises, the emphasis on the deteriorating items inventory study is different. For the seller of deteriorating items, the current studies can be divided into two types; the first type emphasizes the inventory strategies for the retailer of the deteriorat- ing items, the second type focuses on the inventory pol- icy under a two-warehouse system. For the manufactures of deteriorating items, the current emphasis is on devel- oping an optimal production-inventory strategy. So, this paper has divided the present studies on deteriorating items inventory for a single enterprise into three catego- ries as stated above. 3.1 Deteriorating Inventory Strategy The sellers of deteriorating items such as retailers must frequently assess the replenishment strategy for deterio- rating items. Deteriorating items have a shorter life time compare with other items. In order to avoid the loss due to damage or expiration, it is of vital importance to de- velop a proper inventory strategy. Many researchers have conducted extensive studies on the deteriorating inven- tory strategy. Compared with normal inventory models, besides demand, deteriorating rate is another key factor that impacts significantly on an inventory management system. So when discussing models below, this paper will mainly concentrate on demand and de terior ating rate, and other factors, such as price discount, inflation, and so on, will also be taken into consideration. 3.1.1 Deterministic Demand Sarker, Jamal and Wang [48], Chang [49], Chung and Liao [50], Huang and Liao [51]), ZHANG, DAI and HAN [42], ZHANG, DAI, HAN and LI [52] all devel- oped inventory models in which both the demand and deteriorating rate are constant. In their research, the buyer is allowed a delay period to pay for the items purchased. The purpose of their studies is to help the buyers to make economic inventory strategy decisions under the influ- ence of trade credit. Although the constant demand as- sumption helps to simplify the prob lem, it is far from the actual situation where demand is always in change. In order to make research more practical, many researchers have studied other forms of demand. Among them, time-dependant demand has attracted considerable atten- tion. WANG Sheng-dong and WANG jun-ping [53] de- veloped a model to determine optimal ordering policy for deteriorating items under inflation, partial backlogging, and time-dependant demand. The effect of the time value of money was also considered in the paper. Panda, et al. [54] discussed an inventory model for a seasonal product. In the model, the demand rate is represented by a ramp-type time dependent function and the deteriorating rate is a constant. With the assumption that shortages are not allowed, the paper aimed to develop an optimal re- plenishment policy for retailer. In addition, Papachristos and Skouri [55], Chu and Chen [56], Khanra and Chaud-  A Review on Deteriorating Inventory Study Copyright © 2010 SciRes JSSM 120 huri [57], Yang [58], Dye et al. [59] all conducted re- search on deteriorating items inventory under the premise that the demand is time-dependent. Besides time, the inventory level is another factor that has a close relationship with demand. For some item types, the demand rate may fluctuate with the on-hand stock level. It is a common phenomenon that a large amount of goods displayed in the supermarket will lead the customers to buy more, so the demand is closely de- pendant on the inventory level. Gupta and Vrat [60] first proposed an inventory model in 1986 in which demand rate is stock-dependent. Then Mandal and Phaujdar [61] developed a production-inventory model for deteriorating items with the assumption that demand is a linear func- tion of inventory level. Padmanabhan and Vrat [62] de- veloped an EOQ model for deteriorating items with stock-dependant demand, they proposed three models: completely backlogging, partial backlogging and without backlogging, for the purpose of maximizing profit. In this paper, the backlogging function was assumed to be closely relative to the amount of demand backlogged. As we discussed before, in real life it is more common that the willingness of a customer to wait for a backlog during a shortage period declines with the length of the waiting time, that is to say, the longer the waiting time is, th e less likely the customers willing to wait. Then in 2005, Dye and Ouyang [63] extend Padmanabhan’s model (Padma- nabhan and Vrat, 1995) by proposing a time-proportional backlogging rate. While the opportunity cost due to lost sales was not taken into consideration in Padmanabhan’s model, Chung-Yuan Dye took consid erable consideration in his improved model. Hou [64] established an inventory model for deteriorating items with stock-dependent de- mand rate and shortages under inflation and time dis- counting. There are also some who studied other types of demand, like price-dependent demand [65–67], infla- tion-dependent demand [68] and so on. In fact, the real situation is complex and the demand is always affected by several factors such as time, inventory level, price, and so on. Balkhi and Benkherouf [69], Pal et al [70], Hsu et al [71] combined several of the factors together and considered the impact of the combination on the demand, in this premise the optimal inventory strat- egy was discussed. WEN et al [72] developed an inven- tory model in which the demand is affected by time and inflation. The aim of the paper is to determine the optimal replenishment strategy including the replenishment time and order quantities which minimize the present value of the total cost. All the models discussed above have the characteristics of a constant deteriorating rate. While the constant rate simplifies the problems, it cannot reflect the real situatio n of the deterioration; in fact the deteriorating rate varies with time. Wee and Law [73] proposed a deteriorating inventory model which took into consideration the time-value of money and price-dependent demand. Pa- pachristos and Skouri [74] considered a model where the demand rate is a function of the selling price and the backlogging rate is a time-dependent function. Both of them assumed that the deteriorating rate is two-parameter Weibull distributed. Dye et al [75] developed an inven- tory model for deteriorating items with price-dependent demand. In the model the deterioration rate is a function of time and shortages are allowed. The unsatisfied de- mand is partially backlogged and the backlogging rate is a negative exponential rate of the waiting time. The aim of the model was to maximize the profit, and according to the model, the inventory strategy, including price, eco- nomic ordering quantity and so on, can be determined. Then Dye et al [76] took the time-value of money into consideration and extended their earlier research. Chang, et al [77] established an EOQ model for deteriorating items. In the model the supplier provided trade credit to the purchaser on the cond ition that the order qu antity was greater than or equal to the predetermined quantity. The paper proposed Taylor’s series approximation to obtain the optimal order quantity and replenishment time. Liao [78] then amended the solution for the model proposed by Chun-Tao Chang, etc and developed an alternative approach to determine the optimal ordering policy. HUANG Wei-lai and HUANG song [79]studied the eco- nomic order quantity problem with deteriorating items taking time-value of money into consideration. In the problem, the deteriorating rate was two-parameter Wei- bull distributed and the demand rate is linear function of the inventory level. An optimal order quantity mod e l with deteriorating items based on the minimization of total cost was established, taking account of time value of money. 3.1.2 Stochastic Demand In fact, with the growing uncertainty in the modern busi- ness environment, the assumption of deterministic de- mand is far from truth, so stochastic demand has attracted more and more attentions. It is common that when dealing with the stochastic demand, a large number of researchers make the assump- tion that the demand is Poisson distributed. S. KAL- PAKAM and S.SHANTHI [80,81] analyzed inventory systems with Poisson demands for deteriorating items. With the assumption of constant demand, in solving the model, Zhu [82] proposed a data processing method in which the demand was accumulated, making the model easily solved by computer and then enhancing the practi- cality of the model. Li et al. [83] introduced the three-parameter weibull function to describe the charac- teristics of deterioration. In this paper, demand is sup- posed to be closely relative to d eterioration, that is to say, the more items deteriorating, the less the demand will be. Beside this, shortages were allowed and totally back- logged. According to the model, the optimal inventory  A Review on Deteriorating Inventory Study Copyright © 2010 SciRes JSSM 121 policy including the replenishment time, order quantity can be determined. With the increasing complexity in the business envi- ronment, it is of vital importance for enterprises to take factors such as demand, price discounting, inflation, time-value of money, and so on into consideration in in- ventory decision making. The current studies have given considerable con sideration to the factors stated above and so they play an important role in the inventory deci- sion-making. 3.2 Two Warehouse Deteri orating Inventor y Study Two-warehouse inventory problem for deteriorating items is a main category in the current inventory study for deteriorating items. The storage capacity of an en- terprise is limited and in some real life situations, when the supplier provides a price discount for bulk purchases, or when the item is a seasonal product, or when the order cost is high, or the demand goes up quickly, or the cost of out-stock is high, the buyer may purchase a large amount of an item [84]. When the amount of the purchased items exceeds the storage capacity of the enterprise’s own warehouse (OW), the excess quantities have to be stored in a rented ware- house (RW). This is the real background of the two- warehouse inventory problem. There are some com- mon assumptions in the two-warehouse inventory problem. It is often believed that the storage capability of the OW is limited but the storage capability of the rented warehouse (RW) is unlimited, and that the RW often provides a better preserving facility than the OW. So compared with the OW, the inventory cost in RW is higher but the deterioration rate is lower. According to these assumptions, it is easy for us to understand that in order to reduce the inventory cost; it will be a good choice to consume the items in the RW first and store items in OW before RW (last in first out policy, LIFO). A large number of researchers have studied in this area according to the assumptions stated above, such as [85], yang, S.L. and Zhou, Y.W. [86], Benkherouf [87] and so on. Sarma [88] first studied the two-warehouse inventory problem for deteriorating items. In his study, the deterio- rating item was first stored in the OW and the excess quantity was stored in the RW. Then in the inventory model an infinite replenishment rate was considered and shortages were allowed. Then Pakkala and Achary [89] extended Sarma’s study to the situation of an infinite replenishment rate. Yang [90] considered a two-ware- house inventory problem for deteriorating items with constant demand rate and shortages under the circum- stances of inflation. Then Yang [91] extended the former study and considered partial backlogging in the two– warehouse inventory model, in which the backlogging rate is closely relative to the waiting time. Then Hui-Ling Yang compar ed th e two two-w ar ehou s e inven tory mod e ls based on the minimum cost approach and the result showed that the model 2 was less expensive than model 1 if partial backlogging and inflation are considered. QIU and LIANG [92]) developed a two-warehouse inventory model on the basis of minimum cost. In the model the factors such as a constant deteriorating rate and demand trade credit were taken into cons ideration. The numerical results can aid the manager to decide the order quantity, order cycle, and so on. All the two-warehouse inventory models discussed above have the characteristic of constant demand; in fact many other researchers have studied other types of de- mand, like time-dependent demand, etc. XU and LI [93] proposed an optimal inventory policy for a two-ware- house inventory model with time-dependent demand and constant deterioration rate. In the model, shortages are not allowed and according to the model the total order quantity and the quantity stored in the rented warehouse in a cycle time can be determined. Dey et al. [94] studied the two-warehouse inventory problem from the perspec- tive of retailers. In their study, the storage capability of OW which is always located at a busy market place is limited. So the excess items should be stored in a RW which may be located away from the market place. The paper assumed that the inventory cost in the RW is greater than OW and so the items are first stored in OW and only excess items are stored in RW. This is the same as we discussed before. In order to reduce the inventory cost, the RW was emptied first by transporting the stock from RW to OW in a continuou s release patt ern. That is to say, the demand of items was met at OW only. Then the paper developed two-warehouse inventory model with the consideration of inflation, time-dependent demand, par- tially backlogging, and time-value of money. Rong et al. [95] studied the sim ilar probl em as Dey et al. [94] did. As we stated at the beginning of 3.2, in order to reduce inventory cost, a considerable number of studies on two- warehouse inventory problems for deteriorating items follow the rule of LIFO (last in first out). But Lee [96] held a different opinion in this respect; he believed th at in the RW, especially in the public warehouse, the vendor of the warehouse carried a lower operating cost because of well equipment set ups, learning effect of trained workers, and economies of scale. What’s more, in the buyer’s market more and more warehouses have to offer valued added service with completive lower prices to attract customers. So the assumption that the holding costs are higher in the rented warehouses is not so reasonable. Be- sides all stated above, the researcher still believ ed that for deteriorating items, under the rule of LIFO, the cost of item deterioration and related opportunity cost may far exceed the cost saving benefit derived from the rent (on the condition that the holding costs in the rented ware- houses are really higher than those in the OW). So it may  A Review on Deteriorating Inventory Study Copyright © 2010 SciRes JSSM 122 be more reasonable to operate under the rule of FIFO. In his study, Chun Chen Lee reconsidered the LIFO model proposed by Pakkala and Achary [97] and then developed a FIFO model. Comparison of the two models showed that the FIFO model was less expensive than the LIFO model, on the condition that the mixed effects of deterio- ration and holding cost in RW are less than that of the OW. Niu and Xie [98]then amended the model proposed by Chun Chen Lee and so the modified LIFO model al- ways had a lower cost than the FIFO model proposed by Pakkala and Achary. It is a common phenomenon that seasonal or cyclical items are often purchased in large quantities and so the study of two-warehouse inventory is of important practi- cal significance for these items. 3.3 Production-Inventory Study for Deteriorating Items For deteriorating items manufacturing, decision makers should take inventory into consideration in production policy making. Proposing an efficient production-inventory decision is conducive to enhancing the competitiveness of enterprises [43]. Many researchers have extensively studied in this area, such as Goyal and Gunasekaran [99], Jiang and Du [100], Chen et al. [101], Gong and WANG [102], Maity et al. [103] and so on. With the assumption that the demand rate, production rate, and deteriorating rate are all constant, Jui-Jung Liao [104,105] established a production-inventory model for deteriorating items un- der the condition of the supplier providing the retailer with trade credit. Teng and Chang [106] established an economic production quantity (EPQ) model for deterio- rating items when the demand rate was dependant on both the stock level and the selling price per unit, and in which the deteriorating rate was constant. The paper also provided the necessary conditions to decide the optimal solution which maximized profit of the EPQ model. From the model, decision makers could get aid in developing the optimal price and in production run time decisions. In all the models stated above, shortages are not al- lowed. In conditions of shortages, each production- in- ventory cycle in the planning horizon can be described in more detail. Generally speaking, each production- inven- tory cycle can be divided into four stage, there are pro- duction starts——con sumption stage; production stops— —consumption stage; production stops——shortage stage, and production starts——shortage stage. The order of the four stages depends mainly on the shortage occur- ring at the beginning or the end of the cycle. Lin Hsinyi et al. [107] established a production——inventory model with constant production rate, demand rate and deterio- rating rate. Shortages are allowed and occur at the start of each cycle. So the production——inventory cycle can be divided into production stops——shortage stage; produc- tio n starts——shortage stage; product ion —— con su mpt io n stage; production stops——consumption stage. From the model, we can get the number of production-inventory cy- cles and the starting point of the four stages in every cy- cle. Incorporating these parameters with the known con- stant production rate, we can get the optimal produc- tion-inventory policy. Zhou et al. [108] also considered production-inventory problem in which each cycle of a production-inventory schedule starts with replenishment and ends with a shortage. In this model, time-dependent demand was taken into consideration. In the research of Sana et al. [109] and Zhou and Gu [110], shortages are allowed and occur at the end of a cycle. So the cycle con- sists of four stages as below: production starts——con- sumption stage; production stops——consumption stage; production stops——shortage stage and production st a rt s — —shortage stage. With the consideration of time variable demand and constant deteriorating rate, the optimal pro- duction-in ventory policy was studi e d. All the deteriorating rates in the models stated above are constant and some researchers have studied time- dependent deteriorating rates. With the time-varying de- mand and deteriorating rate, both Skouri and Papachris- tos [111] and Chen et al. [112] developed a produc- tion-inventory model in which the storages are allowed at the beginning of the cycle. In contrast, in Manna and Chaudhuri [114] and Balkhi’s research [113], shortages are also allowed but occur at the end of each cycle. Abad [116] studied the pricing an d lot-sizing problem for dete- riorating items under the conditions of finite production, partial backlogging, and lost sale. Teng et al [115]extend P.L. Abad’s model by adding the backlogging cost and the cost of lost goodwill. Then, the paper made a com- parison between Abad’s model [116] and Goyal’s model [117] in which shortages occur at the beginning of the cycle. The numerical results show that there is no domi- nant one between these two models. The paper also pro- vides certain conditions und er which one model had more net profit per unit time than the other. 4. Deteriorating Items Inventory in the Supply Chain With the integration of the global economy, there is more and more diversity and uncertainty in the market. In ord er to deal with the uncertainties in the market and respond quickly to the diverse and personal demand of customer, enterprises need to cooperate with each other in the form of an integrated supply chain. The traditional inventory theory can not adapt to the current situ ation any more, the inventory problem should be considered in the supply chain. The deterioration of the deteriorating items makes it is important for the relative firms in the supply chain to make the optimal inventory policy together to minimize the total inventory cost across the supply chain. In the fol- lowing part of the paper, we will discuss the current studies on the deteriorati ng item s inventory in t he supply chain.  A Review on Deteriorating Inventory Study Copyright © 2010 SciRes JSSM 123 4.1 Deterministic Deteriorating Items Inventory in the Supply Chain Yang and Wee [118,119] have conducted research on the inventory policy for deteriorating item in the supply chain including a single-vendor and multi-buyers. Yang and Wee [118] developed a multi-lot-size production and inventory model for deteriorating items with constant production and demand rates. In this paper, a supply chain including a single-vendor and multi-buyers was established and the supplier was dominant in the supply chain. The supplier delivered the goods in the form of JIT and the aim of the paper was to find the optimal produc- tion-inventory policy on the basis of minimizing the in- ventory cost in the supply chain. According to the nu- merical results, the optimal policy using the integrated approach can reduce the total cost for the producer and the buyer. However, the producer’s cost is higher in the form of supply chain integration than the independent decision without considering the buyer’s perspective. So in order to maintain the stability of the supply chain, the buyers have to supply some kinds of incentives to the supplier. Then Yang and Wee [119] established a col- laborative inventory system of single vendor and single buyer with the price-dependent demand, shortages are not allowed in the system. The paper developed different inventory models under the cases of vendor and buyer making decisions respectively; vendor and buyer making decisions together but no incentives are incorporated in the decisions; the two parties making decisions together and the vendor providing trade credit to the buyer. The numerical results showed that among the three cases, the profit in the first case was the smallest. The profit in the second case was the same with the one in the third case and the profit in the secon d and th ird case was larger than the one in the first case. As is well known to us all, the optimal solution for the whole system is not always bene- ficial to all the players in the system and in fact in the second case, the buyer’s profit was seriously damaged and so the buyer will refuse to cooperate with the sup- plier. While in the third case, the trade credit was incor- porated in the system and it helped to share profit be- tween the two parties. Compared to the first case, both vendor and buyer can get the extra profit and the supply chain was stable in this case. Compared to the deteriorating items inventory study in a single enterprise, the inventory studies in the supply chain have to emphasize how to maintain the stability of the whole system while achieving the minimum of in- ventory costs in the supply chain. Therefore, researchers focused on supply chain coordination mechanism in the deteriorating items inventory problem study. LI and HUANG [120] established a three-level supply chain including vendor, manufacture, and retailer in which the manufacture is dominant. The paper developed two dif- ferent models; in first case all the firms in the supply chain make decisions independently, and in the second the firms make decisions together. In the case of non-integrated decision-making, the manufacturer was the dominant member in the supply chain; the ordering policies of vendor and supplier were subject to the policy made by manufacturer, so the aim of the model is to mi- nimize the costs of the manufacturer. While in the case o f integration, the aim of the optimal production and inven- tory policy making is to minimize the costs of the whole supply chain. According to the numerical results, the costs in the case of integration is lower than that in the case of non-integration, but the optimal solution for the whole system is not beneficial to all the members in the supply chain. In order to realize integration in the supply chain, the paper introduced the cost sharing mechanism in the supply chain to guarantee the implementation of integration and win-win among members. Both An and Luo [121], Qin and Guo [122] stud ied the effect of quan- tity discount across the supply chain and their studies showed that quantity discount is a useful coordination method among supply chain members. In Qin and Guo’s study [122], quantity discoun t was used as a coordination mechanism to achieve the stability of supply chain. As the leader of the supply chain, the supplier develops an optimal discount price policy and shares the policy with the customer. Then the customer determines his unit selling price and sales volume. The numerical example showed that when the supplier determined the quantity discount, bot h t he s uppl i e r an d c ustomer’s profit increase. 4.2 Stochastic Deteriorating Items Inventory in the Supply Chain The studies on stochastic deteriorating items inventory in the supply chain at present are much le ss th an th e o n e s on the deterministic deteriorating items inventory. Du et al. [123] studied the deteriorating item stock replenishment and shipment po licy for v endor- managed inven tory (V MI) system with the assumption that the demand process fol- lows a typical Poisson process. This research is important to practical applications and we will discuss the paper in detail. In the circumstances of vendor-managed inventory, the vendor acts as a supply chain manager and plans inventory and shipment scheduling from the perspective of the whole supply chain rather than obey orders passively and arrange shipments respectively. The aim of VMI is to develop an inventory and shipment policy in which the vendor can meet the demand of the retailers and determine their own inventory replenishment policy at the same time. The pol- icy can realiz e the aim of minimizing the total costs in the supply chain. This is the so called integrated shipment which means that gathering the small amount of order quantities from downstream enterprises into a large quan- tity and then make integrated shipping scheduling. The  A Review on Deteriorating Inventory Study Copyright © 2010 SciRes JSSM 124 integrated shipment policy can reduce relative costs in the inventory and shipm ent delivery [124] . Du et al. [123] made a comprehensive study on the in- tegrated shipment policy under the circumstances of vendor-managed inventory for the deteriorating items. The paper established a supply chain system which in- cludes a manufacturer, a vendor, and many retailers lo- cated in different regions and the demand process follows a typical Poisson process. In the mode of VMI, the ven- dor is responsible for replenishing the retailers’ inventory and arranging the corresponding shipment schedules. The purpose of the study is to make a joint decision in those two areas stated above. There are three parameters (Q, q, T) in the integrated shipment policy, among them the Q stands for the order-up to level, q stands for planned shipments and T is the planned delivery period. The pol- icy operates as below: vendor delivery order quantities which accumulate during the predetermined replenish cycle T is shipped to the retailer at the end of the cycle. However, if the accumulated order quantity reaches the amount of q, which is also a predetermined parameter, before the end of the cycle, the vendo r will also, delivery items to the retailers. Every time a delivery is planned, the vendors have to decide whether the inventory for each item needs to be replenished, and if it needs replenish- ment, what is the replenishment amount. It must be guaranteed that the inventory level of the vendor is equal to or more than the order-up to level parameter Q after delivery. Integrated delivery is an importan t issu e which must be considered when implementing vendor-managed inven- tory. The studies on the integrated delivery problem for deteriorating items can aid the vendors to make relevant decisions about delivery and replenishment and so can help reduce the costs in the supply chain. 5. Conclusions The inventory problems for deteriorating items have at- tracted more and more attention and many researchers have conducted extensive studies in this area. In this pa- per, from a different perspective, we have tried to make a review on deteriorating inventory literatures after Raafat [4]’s and Goyal’s reviews [5]. According to the litera- tures discussed in this paper, we can draw some useful conclusions. Subsequent subsections present significant findings, the gaps identified in the research and future directions of the research in the relevant area. 5.1 Significant Findings 1) According to the research scope, the current studies can be divided into two categories, the first category stu- dies the deteriorating items inventory problems in a sin- gle enterprise and the second category studies the dete- riorating items inventory in supply chain. From the per- spective of quantity, there are much less studies in the second category compared with those belong to the first category. The study on deteriorating items inventory problems is a new research area compared with the in- ventory research on common items and so the total re- search amount is far less than the traditional one. 2) Also, studies in the single enterprise category are less complex than the second category of the integrated supply chain. Two situations are included: first, from the perspective of the number of key factors involved in the model, there are always fewer factors involved in the supply chain deteriorating inventory models. For example, in the first category inventory models, besides demand and deteriorating rate, other factors such as price discount, allow shortage or not, inflation, time-value of money and so on are always combined in the model; then in the sec- ond category, in order to simplify the situation, always less factors considered. 3) Then when it comes to a single factor, the models in supply chain circumstances always consider easier situa- tion of the same factor. Take demand for example, Many studies in the second category especially those under the circumstances of multi-echelon supply chain involve constant demand rate in the inventory model. Only few of the studies in the second categ ory take stochastic demand into consideration for it is really hard to deal with in these kinds of models. For the first category, constant demand is the focus of the early stage and now more and more studies begin to research other kinds of demand, such as time-dependent demand, inventory level- dependent de- mand, price-dependent demand, and even stochastic de- mand. 4) Deteriorating rate is another key factor in the study of deteriorating items inventory and there are also several kinds of deteriorating rate in the present study, such as constant deteriorating rate, deteriorating rate is a linear increasing function of time, deteriorating rate is two- pa- rameter Weibull distributed, and deteriorating rate is three-parameter Weibull distributed. Among them, con- stant deteriorating rate is the easiest one and the three-parameter Weibull distribution deteriorating rate is more complex. Some studies which belong to the first category have made extensive study in this factor and some studies even involve the three-parameter Weibull distribution deteriorating rate; the relatively complex one in the model. For the second category, constant deteriorat- ing rate is the most common one in model establishment. 5.2 Future Directions of the Research 1) As we all know, in order to respond quickly to the di- versity and uncertainty in the market, all the enterprises should be part of a supply chain and so it is more reason- able to consider inventory problems in a supply chain. The diversity and uncertainty that a supply chain will face are much more complex than a single enterprise so more fac- tors and more complex situation of a single factor should  A Review on Deteriorating Inventory Study Copyright © 2010 SciRes JSSM 125 be taken into consideration of deteriorating inventory problems in a supply chain. Only in this way, can the stud- ies supply practical measurem ent s to m anagers. 2) In practical situation, the information about inven- tory is not always precise, most of the time it is vague or imprecise. So it is more reasonable to develop some fuzzy, stochastic and dynamic research methods and this is also the future trend of the deteriorating inventory study. 3) Luckily, many researchers have studied inventory under fuzzy circumstances. Katagiri and Ishii [125] es- tablished inventory models for deteriorating items with fuzzy shortage cost and due to the fuzziness of relative parameters; the expected profit function in the study is represented with a fuzzy set. Chen and Ouyang [126] established a fuzzy inventory model for deteriorating items with permissible delay in payment. The study in- volved the fuzzy carrying cost rate, fuzzy interest paid rate, and fuzzy interest earned rate simultaneously in the model. With the assumption of constant demand and de- teriorating rate, Arindam Roy, Samarjit Kar and Mano- ranjan Maiti [127], Arindam Roy, Manas Kumar Maiti, Samarjit Kar and Manoranjan Maiti [128] established an EOQ model which involved imprecise parameters, such as fuzzy inventory cost, fuzzy storage area, and so on. The purpose of their research was to minimize the total inventory cost. It is recommended that more and more researchers be- gin to study deteriorating items inventory problems in supply chain with fuzzy, stochastic and dynamic research methods, only in this way, can the researches be applied to practice. It is hoped that this paper can provide an overview of the deteriorating items inventory in the re- cent years and so act as a cornerstone for future study in this field. 6. Acknowledgements This research was suppor ted by The Research on Process Optimization of Cold Chain Logistics Based on Food Safety of Foundation of Beijing Jiaotong University (2007XM018). REFERENCES [1] H. M. Wee, “Economic production lot size model for deteriorating items with partial back ordering [J],” Com- pute~& Industrial Engineering, Vol. 24, No. 3, pp. 449– 458, 1993 [2] T. M. Whitin, “Theory of inventory management,” Princeton University Press, Princeton, NJ, pp. 62–72, 1957 [3] P. M. Ghare and G. P. Schrader, “A model for an expo- nentially decaying inventory [J],” Journal of Industrial Engineering, Vol. 14, No. 5, 1963. [4] F. Raafat, survey of literature on continuously deteriorat- ing inventory model [J],” Journal of the Operational Re- search Society, Vol. 42, No. 1, pp. 27–37, 1991. [5] S. K. Goyal and B. C. Giri, “Recent trends in modeling of deteriorating inventory [J],” European Journal of Opera- tional Research, Vol. 134, No. 1, pp. 1–16, 2001 [6] K.-J. Chung and C.-N. Lin, “Optimal inventory replen- ishment models for deteriorating items taking account of time discounting [J],” Computers & Operations Research, Vol. 28, No. 1, pp. 67–83, 2001. [7] L. Benkherouf, A. Boumenir, and L. Aggoun, “A diffu- sion inventory model for deteriorating items [J],” Applied Mathematics and Computation, Vol. 138, No. 1, pp. 21– 39, 2003. [8] B. C. Giri, T. Chakrabarty, and K. S. Chaudhuri, “A note on a lot sizing heuristic for deteriorating items with time- varying demands and shortages [J],” Computers & Opera- tions Research, Vol. 27, No. 6, pp. 495–505, 2000. [9] J.-T. Teng, H.-J. Chang, C.-Y. Dye, and C.-H. Hung, “An optimal replenishment policy for deteriorating items with time-varying demand and partial backlogging [J],” Opera- tions Research Letters, Vol. 30, pp. 387–393, 2002. [10] K.-J. Chung, P. Chu, and S.-P. Lan, “A note on EOQ models for deteriorating items under stock dependent selling rate [J],” European Journal of Operational Re- search, Vol. 124, pp. 550–559, 2000 [11] B. C. Giri and K. S. Chaudhuri, “Deterministic models of perishable inventory with stock-dependent demand rate and nonlinear holding cost [J],” European Journal of Op- erational Research, Vol. 105, No. 3, pp. 467–474, 16 March 1998. [12] D. K. Bhattachaya, “On multi-item inventory [J],” Euro- pean Journal of Operational Research, Vol. 162, pp. 786– 791, 2005. [13] K.-S. Wu, L.-Y. Ouyang, and C.-T. Yang, “An optimal replenishment policy for non-instantaneous deteriorating items with stock-dependent demand and partial backlog- ging [J],” International Journal of Production Economics, Vol. 101, pp. 369–384, 2006. [14] H.-M. Wee and S.-T. Law, “Economic production lot size for deteriorating items taking account of the time-value of money [J],” Computers & Operations Research, Vol. 26, pp. 545–558, 1999. [15] R. M. Hill, “Inventory model for increasing demand fol- lowed by level demand,” Journal of the Operational Re- search Society, Vol. 46, pp. 1250–1259, 1995. [16] B. Mandal and A. K. Pal, “Order level inventory system with ramp type demand rate for deteriorating items,” Jour- nal of Interdisciplinary Mathematics, No. 1, pp. 49–66. 1998. [17] P. S. H. Deng, R. H.-J. Lin, and P. Chu, “A note on the inventory models for deteriorating items with ramp type demand rate [J],” European Journal of Operational Re- search, Vol. 178, No. 1, pp. 112–120, 2007. [18] K. Skouri, I. Konstantaras, S. Papachristos, and I. Ganas, “Inventory models with ramp type demand rate, partial backlogging and Weibull deterioration rate [J],” European  A Review on Deteriorating Inventory Study Copyright © 2010 SciRes JSSM 126 Journal of Operational Research, 2007. [19] Y. K. Shah and M. C. Jaiswal, “An order-level inventory model for a system with constant rate of deterioration,” Opsearch, Vol. 14, pp. 174–184, 1977. [20] S. P. Aggarwal, “A note on an order-level inventory model for a system with constant rate of deterioration,” Opsearch, Vol. 15, pp. 184–187, 1978. [21] G. Padmanabhana and P. Vratb, “EOQ models for per- ishable items under stock dependent selling rate [J],” European Journal of Operational Research, Vol. 86, No. 2, pp. 281–292, 19 October 1995, [22] A. K. Bhunia and M. Maiti, “An inventory model of dete- riorating items with lot-size dependent replenishment cost and a linear trend in demand [J],” Applied Mathematical Modelling, Vol. 23, pp. 301–308, 1999. [23] A. K. Bhunia and M. Maiti, “Deterministic inventory model for deteriorating items with finite rate of replen- ishment dependent on inventory level [J],” Computers & Operations Research, Vol. 25, No. 11, pp. 997–1006, 1 November 1998. [24] S. Mukhopadhyay, R. N. Mukherjee, and K. S. Chaudhuri, “Joint pricing and ordering policy for a deteriorating in- ventory [J],” Computers & Industrial Engineering, Vol. 47, pp. 339–349, 2004. [25] H.-M. Wee, “Deteriorating inventory model with quantity discount, pricing and partial backordering [J],” Interna- tional Journal of Production Economics, Vol. 59, pp. 511–518, 1999 [26] N. K. Mahapatra, “Decision process for multiobjective, multi-item production-inventory system via interactive fuzzy satisficing technique [J],” Computers and Mathe- matics with Applications, Vol. 49, pp. 805–821, 2005. [27] T. Chakrabarty, B. C. Giri, and K. S. Chaudhuri, “An EOQ model for items with weibull distribution deteriora- tion, shortages and trended demand: an extension of philip’s model [J],” Computers & Operations Research, Vol. 25, No. 7–8, pp. 649–657, July 1998. [28] P. L. Abad, “Optimal price and order size for a reseller under partial backordering [J],” Computers & Operations Research, Vol. 28, pp. 53–65, 2001. [29] F. W. Gu and S. Y. Zhou, “A replenishment policy for deteriorating items which are permissible delay in pay- ment [J],” Logistics Technology, Vol. 26, No. 9, pp. 48– 51, 2007. [30] M. K. Salameh, S. A. Fakhreddine, and N. Noueihed, “Effect of deteriorating items on the instantaneous replen- ishment model with backlogging [J],” Computers & In- dustrial Engineering, Vol. 37, pp. 261–264, 1999. [31] Y.-W. Zhou and H.-S. Lau, “An economic lot-size model for deteriorating items with lot-size dependent replenish- ment cost and time-varying demand [J],” Applied Mathe- matical Modelling, Vol. 24, pp. 761–770, 2000. [32] Y.-W. Zhou, H.-S. Lau, and S.-L. Yang, “A new variable production scheduling strategy for deteriorating items with time-va rying demand and pa rtial lost sale [J], ” Com- puters & Operations Research, Vol. 30, pp. 1753–1776, 2003. [33] K. Skouri and S. Papachristos, “A continuous review inventory model, with deteriorating items, time-varying demand, linear replenishment cost, partially time-varying backlogging [J],” Applied Mathematical Modelling, Vol. 26, pp. 603–617, 2002. [34] S.-P. Wang, “An inventory replenishment policy for dete- riorating items with shortages and partial backlogging [J],” Computers & Operations Research, Vol. 29, pp. 2043–2051, 2002. [35] C.-Y. Dye, “Joint pricing and ordering policy for a dete- riorating inventory with partial backlogging [J],” Omega, Vol. 35, pp. 184–189, 2007. [36] A. M. M. Jamal, B. R. Sarker, and S. J. Wang, “Optimal payment time for a retailer under permitted delay of pay- ment by the wholesaler [J],” International Journal of Pro- duction Economics, Vol. 66, pp. 59–66, 2000. [37] X. P. Song and X. Q. Cai, “On optimal payment time for retailer under permitted delay of payment by the whole- saler [J],” International Journal of Production Economics, Vol. 103, pp. 246–251, 2006. [38] L.-Y. Ouyang, K.-S. Wu, and C.-T. Yang, “A study on an inventory model for non-instantaneous deteriorating items with permissible delay in payments [J],” Computers & Industrial Engineering, Vol. 51, pp. 637–651, 2006. [39] K.-J. Chung and J.-J. Liao, “Lot-sizing decisions under trade credit depending on the ordering quantity [J],” Com- puters & Operations Research, Vol. 31, pp. 909–928, 2004. [40] K.-J. Chung and J.-J. Liao, “The optimal ordering policy in a DCF analysis for deteriorating items when trade credit depends on the order quantity [J],” International Journal of Production Economics, Vol. 100, pp. 116–130, 2006. [41] L.-Y. Ouyang, J.-T. Teng, S. K. Goyal, and C.-T. Yang, “An economic order quantity model for deteriorating items with partially permissible delay in payments linked to order quantity [J],” European Journal of Operational Research, 2008. [42] C. Zhang, G.-X. DAI, G.-H. Han, and M. Li, “Study on optimal inventory model for deteriorating items based on linear trade credit [J],” Journal of Qingdao University (Natural Science Edition), Vol. 20, No. 3, pp. 70–74, 2007. [43] X. W. Wen and L.-J. Zuo, “A review of development of deteriorating inventory theory research [J],” Journal of South China Agricultural University: Social Science Edi- tion, Vol. 6, No. 4, pp. 46–52, 2007. [44] H.-C. Liao, C.-H. Tsai, and C.-T. Su, “An inventory model with deteriorating items under inflation when a de- lay in payments is permissible [J],” International Journal of Production Economics, Vol. 63, pp. 207–214, 2000. [45] K.-J. Chung and S.-F. Tsai, “Inventory systems for dete- riorating items with shortages and a linear trend in de- mand-taking account of time value [J],” Computers & Operations Research, Vol. 28, pp. 915–934, 2001. [46] J.-M. Chen, “An inventory model for deteriorating items with time-proportional demand and shortages under infla- tion and time discounting [J],” International Journal of  A Review on Deteriorating Inventory Study Copyright © 2010 SciRes JSSM 127 Production Economics, Vol. 55, No. 1, pp. 21–30, 10 June 1998, [47] I. Moon, B. C. Giri, and B. Ko, “Economic order quantity models for ameliorating/deteriorating items under infla- tion and time discounting [J],” European Journal of Op- erational Research, Vol. 162, pp. 773–785, 2005. [48] B. R. Sarker, A. M. M. Jamal, and S. J. Wang, “Supply chain models for perishable products under inflation and permissible delay in payment [J],” Vol. 27, pp. 59–75, 2000. [49] C.-T. Chang, “An EOQ model with deteriorating items under inflation when supplier credits linked to order quantity [J],” International Journal of Production Eco- nomics, Vol. 88, pp. 307–316, 2004. [50] K.-J. Chung and J.-J. Liao, “The optimal ordering policy in a DCF analysis for deteriorating items when trade credit depends on the order quantity [J],” International Journal of Production Economics, Vol. 100, pp. 116–130, 2006. [51] K.-N. Huang and J.-J. Liao, “A simple method to locate the optimal solution for exponentially deteriorating items under trade credit financing [J],” Computers and Mathe- matics with Applications, Vol. 56, No. 4, pp. 965–977, August 2008. [52] C. Zhang, G.-X. Dai, G.-H. Han, and M. Li, “Study on inventory model for deteriorating items based on trade credit and cash discount [J],” Operations Research and Management Science, Vol. 16, No. 6, pp. 33–37,41, 2007. [53] S.-D. Wang and J.-P. Wang, “A multi-stage optimal in- ventory model for deteriorating items by considering time value and inflation rate [J],” Operations Research and Management Science, Vol. 14, No. 6, pp. 142–148, 2005. [54] S. Panda, S. Senapati, and M. Basu, “Optimal replenish- ment policy for perishable seasonal products in a season with ramp-type time dependent demand [J],” Computers & Industrial Engineering, Vol. 54, pp. 301–314, 2008. [55] S. Papachristos and K. Skouri, “An optimal replenishment policy for deteriorating items with time-varying demand and partial-exponential type-backlogging [J],” Operations Researh Letters, Vol. 27, pp. 175–184, 2000. [56] P. Chu and P. S. Chen, “A note on inventory replenish- ment policies for deteriorating items in an exponentially declining market [J],” Computers & Operations Research, Vol. 29, pp. 1827–1842, 2002. [57] S. Khanra and K. S. Chaudhuri, “A note on an order-level inventory model for a deteriorating item with time-de- pendent quadratic demand [J],” Computers & Operations Research, Vol. 30, pp. 1901–1916, 2003. [58] “A comparison among various partial backlogging inven- tory lot-size models for deteriorating items on the basis of maximum profit [J],” International Journal of Production Economics, Vol. 96, pp. 119–128, 2005. [59] C.-Y. Dye, H.-J. Chang, and J.-T. Teng, “A deteriorating inventory model with time-varying demand and short- age-dependent partial backlogging [J],” European Journal of Operational Research, Vol. 172, pp. 417–429, 2006. [60] R. Gupta and P. Vrat, “Inventory model with multi-items under constraint systems for stock dependent consump- tion rate [J],” Operations Research, Vol. 24, pp. 41–42. [61] B. N. Mandal and S. Phaujdar, “An inventory model for deteriorating items and stock-dependent consumption rate [J],” Journal of the Operational Research Society, Vol. 40, pp. 483–488, 1989. [62] G. Padmanabhan and P. Vrat, “EOQ models for perish- able items under stock dependent selling rate [J],” Euro- pean Journal of Operational Research, Vol. 86, No. 2, pp. 281–292, 19 October 1995. [63] C.-Y. Dye and L.-Y. Ouyang, “An EOQ model for per- ishable items under stock-dependent selling rate and time-dependent partial backlogging [J],” European Jour- nal of Operational Research, Vol. 163, pp. 776–783, 2005. [64] K.-L. Hou, “An inventory model for deteriorating items with stock-dependent consumption rate and shortages un- der inflation and time discounting [J],” European Journal of Operational Research, Vol. 168, pp. 463–474, 2006. [65] Z.-H. Peng and T. Peng, “Pricing and inventory model based on quantity discounts of deteriorating goods [J],” Journal of University of Shanghai For Science and Tech- nology, Vol. 26, No. 6, pp. 565–568,574, 2004. [66] J.-T. Teng, C.-T. Chang, and S. K. Goyal, “Optimal pric- ing and ordering policy under permissible delay in pay- ments [J],” International Journal of Production Economics, Vol. 97, pp. 121–129, 2005. [67] Y.-Y. Qin, H.-W. Tang, and C.-H. Guo, “On an inventory model for deteriorating items of price-sensitive demand and quantity discounts [J],” Operations Research and Management Science, Vol. 15, No. 4, pp. 22–26, 2006. [68] C. K. Jaggi, K. K. Aggarwal, and S. K. Goel, “Optimal orser policy for deteriorating items with inflation induced demand [J],” International Journal of Production Eco- nomics, Vol. 103, pp. 707–714, 2006. [69] Z. T. Balkhi and L. Benkherouf, “On an inventory model for deteriorating items with stock dependent and time-varying demand rates [J],” Computers & Operations Research, Vol. 31, pp. 223–240, 2004. [70] A. K. Pal, A. K. Bhunia, and R. N. Mukherjee, “Optimal lot size model for deteriorating items with demand rate dependent on displayed stock level (DSL) and partial backordering [J],” European Journal of Operational Re- search, Vol. 175, pp. 977–991, 2006. [71] P.-H. Hsu, H. M. Wee, and H.-M. Teng, “Optimal order- ing decision for deteriorating items with expiration date and uncertain lead time [J],” Computers & Industrial En- gineering, Vol. 52, pp. 448–458, 2007. [72] Z.-L. Wen, Y. Zhu, J. Li, and C.-M. Xu, “An inventory model for deteriorating items with backorder dependent lost rate and time value of money [J],” Journal of Guangxi University of Technology, Vol. 18, No. 3, pp. 28–32, 2007. [73] H.-M. Wee and S.-T. Law, “Replenishment and pricing policy for deteriorating items taking into account the time-value of money [J],” International Journal of Pro- duction Economics, Vol. 71, pp. 213–220, 2001.  A Review on Deteriorating Inventory Study Copyright © 2010 SciRes JSSM 128 [74] S. Papachristos and K. Skouri, “An inventory model with deteriorating items, quantity discount, pricing and time- dependent partial backlogging [J],” International Journal of Production Economics, Vol. 83, pp. 247–256, 2003. [75] C.-Y. Dye, T.-P. Hsieh, and L.-Y. Ouyang, “Determining optimal selling price and lot size with a varying rate of deterioration and exponential partial backlogging [J],” European Journal of Operational Research, Vol. 181, pp. 668–678, 2007. [76] C.-Y. Dye, L.-Y. Ouyang, and T.-P. Hsieh, “Inventory and pricing strategies for deteriorating items with short- ages: A discounted cash flow approach [J],” Computers & Industrial Engineering, Vol. 52, pp. 29–40, 2007. [77] C.-T. Chang, L.-Y. Ouyang, and J.-T. Teng, “An EOQ model for deteriorating items under supplier credit linked to ordering quantity [J],” Applied Mathematical Model- ling, Vol. 27, pp. 983–996, 2003. [78] J.-J. Liao, “A note on an EOQ model for deteriorating items under supplier credit linked to ordering quantity [J],” Applied Mathematical Modelling, Vol. 31, pp. 1690– 1699, 2007. [79] W.-L. Huang and S. Huang, “An inventory model for items with weibull distribution deterioration rate under stock-dependent demand [J],” Industrial Engineering and Management, Vol. 2, pp. 72–75,101, 2007. [80] S. Kalpakam and S. Shanthi, “A perishable system with modified base stock policy and random supply quantity [J],” Vol. 39, pp. 79–89, 2000. [81] S. Kalpakam and S. Shanthi, “A perishable inventory system with modified(S-1,S)policy and arbitrary process- ing times [J],” Computers & Operations Research, Vol. 28, pp. 453–471, 2001. [82] G.-P. Zhu, “Optimal inventory model for single perish- able item [J],” Journal of Ningxia University (Natural Sci- ence Edition), Vol. 22, No. 1, pp. 15–16, 2001. [83] L.-F. Li, P.-Q. Huang, and J. -W. Luo, “A study of inven- tory management for deteriorating items [J],” Systems Engineering, Vol. 22, No. 3, pp. 25–30, 2004. [84] X.-H. Xu and R.-J. Li, “A two-warehouse inventory model for deteriorating items with time-dependent de- mand [J],” Logistics Technology, No. 1, pp. 37–40, 2006. [85] Z. L. Yang, Z. Y. Wu, and S. L. Yang, “An economic model and its optimal solution for deteriorating items with two warehouses and parabollic demand [J],” Systems En- gineering Theory Methodology Applications, No. 4, pp. 376–378, 2005. [86] S. L. Yang and Y. W. Zhou, “Two-warehouse inventory model: Considering time-varying demand and price dis- counts [J],” Journal of Systems Engineering, Vol. 18, No. 6, pp. 498–505, 2003. [87] L. Benkherouf, “A deterministic order level inventory model for deteriorating items with two storage facilities [J],” International Journal of Production Economics, Vol. 48, No. 2, pp. 167–175, 24 January 1997. [88] K. V. S. Sarma, “A deterministic order level inventory model for deteriorating items with two storage facilities [J],” European Journal of Operational Research, Vol. 29, No. 1, pp. 70–73, April 1987. [89] T. P. M. Pakkala and K. K. Achary, “A deterministic in- ventory model for deteriorating items with two ware- houses and finite replenishment rate [J],” European Jour- nal of Operational Research, Vol. 57, No. 1, pp. 71–76, 25 February 1992. [90] H.-L. Yang, “Two-warehouse inventory models for dete- riorating items with shortages under inflation [J],” Euro- pean Journal of Operational Research, Vol. 157, pp. 344–356, 2004. [91] H.-L. Yang, “Two-warehouse partial backlogging inven- tory models for deteriorating items under inflation [J],” International Journal of Production Economics, Vol. 103, pp. 362–370, 2006. [92] H. Qiu and L. Liang, “A two-warehouse inventory model with delay in payment [J],” Systems Engineering, Vol. 25, No. 2, pp. 46–50, 2007. [93] X.-H. Xu and R.-J. Li, “A two-warehouse inventory model for deteriorating items with time-dependent de- mand [J],” Logistics Technology, No. 1, pp. 37–40, 2006. [94] J. K. Dey, S. K. Mondal, and M. Maiti, “Two storage inventory problem with dynamic demand and interval val- ued lead-time over finite time horizon under inflation and time-value of money [J],” European Journal of Opera- tional Research, Vol. 185, pp. 170–194, 2008. [95] M. Rong, N. K. Mahapatra, and M. Maiti, “A two ware- house inventory model for a deteriorating item with par- tially/fully backlogged shortage and fuzzy lead time [J],” European Journal of Operational Research, Vol. 189, pp. 59–75, 2008. [96] C. C. Lee, “Two-warehouse inventory model with dete- rioration under FIFO dispatching policy [J],” European Journal of Operational Research, Vol. 174, pp. 861–873, 2006. [97] T. P. M. Pakkala and K. K. Achary, “A deterministic in- ventory model for deteriorating items with two ware- houses and finite replenishment rate [J],” European Jour- nal of Operational Research, Vol. 57, No. 1, pp. 71–76, 25 February 1992. [98] N. Bo and J. X. Xie, “A note on ‘Two-warehouse inven- tory model with deterioration under FIFO dispatching policy’ [J],” European Journal of Operational Research, Vol. 190, pp. 571–577, 2008. [99] S. K. Goyal and A. Gunasekaran, “An integrated produc- tion-inventory-marketing model for deteriorating items [J],” Computers & Industrial Engineering, Vol. 28, No. 4, pp. 755–762, October 1995. [100] D. L. Jiang and W. Du, “A study on two-stage production systems of perishable goods [J],” Journal of Southwest Jiaotong University, Vol. 33, No. 4, pp. 430–435, 1998. [101] S.-J. Chen, S.-P. Chen, and X.-B. Liu, “A produc- tion-inventory model for deteriorating items [J],” Journal of Zhaoqing University, Vol. 23, No. 2, pp. 66–68, 2002. [102] Z.-J. Gontg and C.-Q. Wang, “A production-inventory arrangement model for deteriorating items in a linear in-  A Review on Deteriorating Inventory Study Copyright © 2010 SciRes JSSM 129 creasing market [J],” Logistics Technology, No. 10, pp. 6–8, 2005. [103] A. K. Maity, K. Maity, S. Mondal, a nd M. Maiti, “A che- byshev approximation for solving the optimal production inventory problem of deteriorating multi-item [J],” Mathematical and Computer Modelling, Vol. 45, pp. 149– 161, 2007. [104] J.-J. Liao, “On an EPQ model for deteriorating items un- der permissible delay in payments [J],” Applied Mathe- matical Modelling, Vol. 31, pp. 393–403, 2007. [105] J.-J. Liao, “An EOQ model with noninstantaneous receipt and exponentially deteriorating items under two-level trade credit [J],” International Journal of Production Eco- nomics, Vol. 113, pp. 852–861, 2008. [106] J.-T. Teng and C.-T. Chang, “Economic production quan- tity models for deteriorating items with price- and stock- dependent demand [J],” Computers & Operations Re- search, Vol. 32, pp. 297–308, 2005. [107] H. Lin, X. W. Wen, and Q. L. Da, “Optimal production policy for deteriorating items with backlogging demand in stochastic production process [J],” Journal of Southeast University (Natural Science Edition), Vol. 37, No. 4, pp. 731–736, 2007. [108] Y.-W. Zhou, H.-S. Lau, and S.-L. Yang, “A new variable production scheduling strategy for deteriorating items with time-va rying demand and pa rtial lost sale [J], ” Com- puters & Operations Research, Vol. 30, pp. 1753–1776, 2003. [109] S. Sana, S. K. Goyal, and K. S. Chaudhuri, “A produc- tion-inventory model for a deteriorating item with trended demand and shortages [J],” European Journal of Opera- tional Research, Vol. 157, pp. 357–371, 2004. [110] S.-Y. Zhou and F.-W. Gu, “An optimal produc- tion-inventory policy for deteriorating items [J],’ Logis- tics Technology, Vol. 26, No. 4, pp. 43–46, 2007. [111] K. Skouri and S. Papachristos, “Optimal stopping and restarting production times for an EOQ model with dete- riorating items and time-dependent partial backlogging [J],” International Journal of Production Economics, Vol. 81–82, pp. 525–531, 2003. [112] J.-M. Chen andn L.-T. Chen, “Pricing and production lot-size/scheduling with finite capacity for a deteriorating item over a finite horizon [J],” Computers & Operations Research, Vol. 32, pp. 2801–2819, 2005. [113] Z. T. Balkhi, “On a finite horizon production lot size in- ventory model for deteriorating items: An optimal solu- tion [J],” European Journal of Operational Research, Vol. 132, pp. 210–223, 2001. [114] S. K. Manna and K. S. Chaudhuri, “An EOQ model with ramp type demand rate, time dependent deterioration rate, unit production cost and shortages [J],” European Journal of Operational Research, Vol. 171, pp. 557–566, 2006. [115] J.-T. Teng, L.-Y. Ouyang, and L.-H. Chen, “A compari- son between two pricing and lot-sizing models with par- tial backlogging and deteriorated items [J],” International Journal of Production Economics, Vol. 105, pp. 190–203, 2007. [116] P. L. Abad, “Optimal pricing and lot-sizing under condi- tions of perishability, finite production and partial back- ordering and lost sale [J],” European Journal of Opera- tional Research, Vol. 144, pp. 677–685, 2003. [117] S. K. Goyal and B. C. Giri, “The production-inventory problem of a product with time varying demand, produc- tion and deterioration rates [J],” European Journal of Op- erational Research, Vol. 147, pp. 549–557, 2003. [118] P. C. Yang and H. M. Wee, “A single-vendor and multi- ple-buyers production -inventory policy fo r a deteriorating item [J],” European Journal of Operational Research, Vol. 143, pp. 570–581, 2002. [119] P. C. Yang and H. M. Wee, “An integrated multi-lot-size production inventory model for deteriorating item [J],” Computers & Operations Research, Vol. 30, pp. 671–682, 2003. [120] L.-F. Li and P.-Q. Huang, “Study of production-inventory cooperation for deteriorating items on supply chain [J],” Journal of Shanghai Jiaotong University, Vol. 39, No. 3, pp. 464–467, 2005. [121] Q. An and J.-W. Luo, “Study on coordination in supply chain inventory of perishable item with price discount [J],” Journal of Industrial Engineering, Vol. 21, No. 4, pp. 80–84, 2007. [122] Y. Y. Qin and C. H. Guo, “Discount pricing model for easy-deteriorated items under elastic demand [J],” Chi- nese Journal of Management, Vol. 4, No. 2, pp. 163–168, 2007. [123] S.-F. Du, L. Liang, J.-J. Zhang, and Z.-G. Lu, “Hybrid replenishment and dispatching policy with deteriorating item for VMI: Analytical model, optimization and simula- tion [J],” Chinese Journal of Management Science, Vol. 15, No. 2. pp. 64–69, 2007. [124] L.-W. Liu and J.-R. Yuan, “Inventory and dispatch Mod- els i n VMI systems [J],” Chinese Journal of Management Science, Vol. 11, No. 5, pp. 31–36, 2003. [125] H. Katagiri and H. Ishii, “Fuzzy inventory problems for perishable commodities [J],” European Journal of Opera- tional Research, Vol. 138, PP. 545–553, 2002. [126] L.-H. Chen and L.-Y. Ouyang, “Fuzzy inventory model for deteriorating items with permissible delay in payment [J],” Applied Mathematics and Computation, Vol. 182, pp. 711–726, 2006. [127] A. Roy, S. Kar, and M. Maiti, “A deteriorating multi-item inventory model with fuzzy costs and resources based on two different defuzzification techniques [J],” Applied Mathematical Modelling, Vol. 32, pp. 208–223, 2008. [128] A. Roy, M. K. Maiti, S. Kar, and M. Maiti, “An inventory model for a deteriorating item with displayed stock de- pendent demand under fuzzy inflation and time discount- ing over a random planning horizon [J],” Applied Mathe- matical Modelling, 2008. |