Paper Menu >>

Journal Menu >>

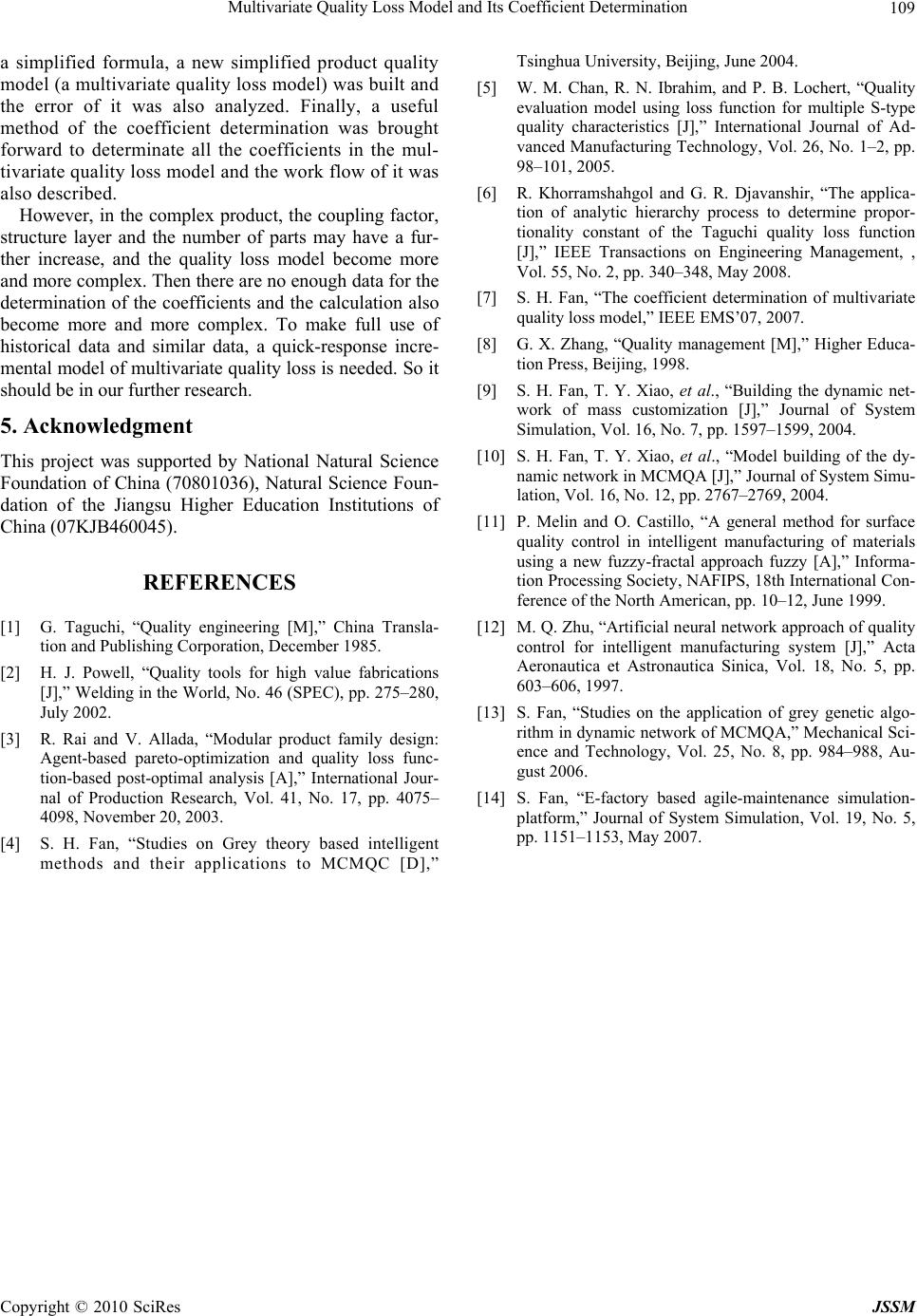

J. Service Science & Management, 2010, 3: 106-109 doi:10.4236/jssm.2010.31013 Published Online March 2010 (http://www.SciRP.org/journal/jssm) Copyright © 2010 SciRes JSSM Multivariate Quality Loss Model and its Coefficient Determination Shuhai Fan, Xia Cao Department of Industrial Engineering, Nanjing University of Technology, Nanjing, China. Email: fanshuhai@tsinghua.org.cn Received August 28th, 2009; revised October 10th, 2009; accepted November 27th, 2009. ABSTRACT In the ea rly 1970s, based on single ind ex deducted from absolut e quality deviants, Genichi Taguchi proposed th e qual- ity loss module. This module builds the foundation of his three-stage design theory, e.g. system design, parameter de- sign and tolerance design. In actual production process, nevertheless, it is multiple quality indices that influence the total quality. Consequently, the interaction of the quality indices should be imported into the module as a key factor. Accordingly, based on several indices of relative quality deviation, introduce a 2-order multivariate quality module at first. Next, extend the module to 3 or even higher orders. Then, improve the previous quality module by simplifying the 2-order module as a multivariate quality loss module. Finally, bring forward a significant solution to determinate all the coefficients in th e multivariate quality loss module and describe its work flow as well. Keywords: Quality Loss, Multiple Variables, Model Building 1. Introduction In the early 1970s, Dr. Genichi Taguchi, the famous quality management expert of Japan, carried on an inno- vation research into the theories and methods of quality management [1]. He established the famous “Taguchi Three-stage Design Methods”, the system design, the parameter design and the tolerance design. The core of his theory was his quality loss model [2,3]. And the qual- ity loss model was based on the absolute quality deviant, which suited for the single quality index. However, in the actual production process, many partial quality indices often affected the total quality in a coactions mode. After these interactions being considered, a multivariate quality loss mode can be brought forward [4]. To this many partial quality indices, Chan and Ibrahim studied a quality evaluation model using loss function for multiple S-type quality characteristics [5]. To determi- nate the coefficients of the multivariate quality loss mode, AHP method or tolerance method can be used [6,7]. 2. Model Building The total quality is a synthetic quality, which is often a coaction of some machining qualities and some assem- bling qualities of every part [1]. And it can be regarded as a function of every partial quality (including the ma- chining qualities and the assembling qualities): product1 2 ( ,,... ...,) hH QfQQQQ Assuming that f has continuous partial derivatives till 3-order in a neighborhood D of the origin, P0(0,0…0). There are H partial quality indices altogether, q1, q2, … qH. These partial quality indices are all continuous types; their values are very small and stand for relative quality deviants. When the values of q1, q2,…qH equal 0, it stands for no quality deviant (Here we use the relative quality deviants to get dimensionless. Thus a minor error can be avoided in the derivation process of Taguchi’s model.) [8]. Then the product quality can be expressed as follows: 12 12 12 12 1 2 ,1 ( ,...,...,)(0,0...,0)(0,0...,0) 1 (0,0...,0) 2! h hh H hHQ h h H QQh h hh fqq qqffq f qq R while, R2 is the 2-order remainder term. 123 123 12 3 21 ,, 1 1( ......) 3! hhh H QQQhHh hh hh h Rfqqqqqq (0 1) A brief proof is as follows: considering a single variant function ()Qt 12 ( )(,...,...,) hH Qt fqtqtqtqt , (1 1)t  Multivariate Quality Loss Model and Its Coefficient Determination Copyright © 2010 SciRes JSSM 107 ()Qt has continuous partial derivatives till 3-order for (1 1)t . Obeying the 2-order single variant Talylor’s formula with Lagrange remainder term, we get: 23 11 ( )(0)(0)(0)() 2! 3! Qt QQtQtQ tt ,(0 1) Let t=1, we get 11 (1)(0)(0)(0)( ) 2! 3! QQQ QQ (1) Follow the definition of ()Qt and the differential method of composite function. We get 1 1 ( )(,...,...,) h H QhHh h Qtfqt qtqtq 12 12 12 1 ,1 ( )(,...,...,) hh H QQhHh h hh Qtfqt qtqtqq 12 3 12 3 123 1 ,, 1 ( )(,...,...,) hhh H QQQhHh hh hhh Qtfqt qtqtqqq Then, when t =0, 1 (0) (0,...0,...,0) h H Qh h Qf q 1 12 12 2 ,1 (0) (0,...0,...,0) hh H QQh h hh Qf qq 123 123 123 ,, 1 (0) (0,...0,...,0) hh h H QQQh hh hhh Qf qqq while 12 (1)( ,...,...,) hH Qfqqqq, (0) (0,...,0...,0)Qf Substitute the results into (1) The expansion equation can get proved. To estimate the error term, we have: f has continuous partial derivatives till 3-order; in the neighborhood of (0,…,0,…0); the 3-order partial deriva- tive has a bound M. denote 22 22 12 1 ... H H h h qq qq , (0) then 123 123 3 212 ,, 1 (... ) 3! 3! H hhh H hhh MM Rqqqqqq 12 12 3 3 2 12 ,1 =(...) 3! 3! H Hhh hh MM qq qqq 12 12 3 22 ,1 3 222 12 1() 3! 2 (...) 3! H hh hh H Mqq MHq qq 3 33 23 1 =3! 3! H h h MM Hq H 2 2()Ro , (0) It is the general form that is used to describe the total quality index in the above formula. If the quality loss form index is adopted, the model can be much more sim- plified. Imply that when all the partial quality indices equal 0, the total quality index takes the minimum, 0. It is easy to see that the 0-order and 1-order derivative can be gotten rid of. Then a new product quality loss model can be built as follows: 212 1 2 112 2 product 11, Hn hhhhh h hhhh L Qwq wqq (2) Compared it with Taguchi’s model, we can see that (2) is actually the extended multivariate form of Taguchi’s quality loss model. Here, Qproduct is a target total quality index and de- scribed as the quality loss. All the n partial quality indi- ces influence Qproduct in a coaction mode, and qh is the relative quality deviant. Every partial quality deviant can be gotten by statistic. Here we use the relative partial quality deviant, and it can be expressed by the relative quality value of the deviant from the target value and severalfold tolerances. If the value of quality characteris- tic lies beyond the tolerance, it should be multiplied by a punishment factor. where, 2 2 1 H h h h wq , 1212 112 1, n hhh h hhh wqq are separately the self-action item and the inter-action item of the partial quality deviants. 2 h w is the self-action influence weight of the quality deviant 2h q; 12 hh w is the inter-action weight of deviant 12 hh qq . Compared with our expansion equation, it can be got- ten 22 2 11 (0,...,0,...0)(0,...,0,...0) 2! 2 hh hQ Q wf f 12 12 12 21 12 12 1(0,...,0,...0) 2! 1(0,...,0,...0) (0,...,0,...0) 2 =(0,...,0,...0) () hh hh hh hh hhQQ QQ QQ QQ wf ff f hh If necessary, we can also expand the product quality model further more to U-order.  Multivariate Quality Loss Model and Its Coefficient Determination Copyright © 2010 SciRes JSSM 108 12 12 12 () product ... 2,,...1 10, 0..., 0... !hh hu u u UH uQQQhhhU uhhh QfqqqR u () U U Ro When the quality model is expanded to 2-order, the inter-actions of partial quality indices have been fully considered. In fact, the impactions of items higher than 2-order are very little [10,11]. Thus for the simplification of computation and the actual requirement, further higher orders are never needed. The above work suits the small-is-better and the nomi- nal-is-best problems. The large-is-better problem can also be reformed into a small-is-better problem. 3. Coefficient Determination 3.1 The Tolerance Limits Method The quality loss model (2) can also be written as 2 product 11, Hn iiiij ij iiij Qwqwqq (3) the coefficients wij can be determined using the following method all these wij (i≤j) can constitute a upper triangular matrix like Figure 1. 1) Determine the elements in Diagonal for an arbitrary i (i=1,2,..., H), when all the qk=0, (k≠i) i is the toler- ance limit of defective for self quality and Ai is the self quality loss when defective happens. Then we have 22 product 11, () Hn iiiiijijiii iiij QAwqwqqw So 2 /( ) ii i i wA 2) Determine other elements for an arbitrary i,j (i,j=1,2,...,H, i≤j), when all the qk=0, (k≠i, k≠j), i ij is the tolerance limit of quality i for coaction quality i and j, j ij Figure 1. Upper triangular matrix of coefficients then, we can determine these coefficients is the tolerance limit of quality j for coaction quality i and j and Aij is the coaction quality loss when coaction defective happens. Then we have 02 11, 0, 20,20,0, ()( ) Hn productijiiiijij iiij ijij iiijjjijij ijij QAwqwqq ww w Thus we have 00,2 0,20,0, ()()/ ijij ijijiiijjjijij ij wAww where 002 /( ) ii ii wA , 002 /( ) j jj wA This coefficient determination process can be de- scribed in Figure 2. Remark: In some particular circumstances, 0, 00,0 , ij ij iijj we have a simplified form 000 00 / ijijijij w AAA 3.2 Other Methods To determinate the weight coefficients, the least square method can also be adopt. However linear neural net- works are more suitable [11–14]. The input weights of the trained neural network are just the weight coefficients of the model. 4. Conclusions Based on the quality loss model of Taguchi, the total quality model which is based on multivariate relative quality deviants was studied. A 2-order product quality model, which was based on several indices of relatively quality deviation, was built. Then, the model was suc- cessfully extended to 3 or even higher orders. To deduce w11 w12w13w14 w15 w16w17 w22 w23w24w25 w26 w27 w33 w34w35w36 w37 w44 w45w46w47 w55 w56w57 w66 w67 w77 Figure 2. From the diagonal elements to other elements  Multivariate Quality Loss Model and Its Coefficient Determination Copyright © 2010 SciRes JSSM 109 a simplified formula, a new simplified product quality model (a multivariate quality loss model) was built and the error of it was also analyzed. Finally, a useful method of the coefficient determination was brought forward to determinate all the coefficients in the mul- tivariate quality loss model and the work flow of it was also described. However, in the complex product, the coupling factor, structure layer and the number of parts may have a fur- ther increase, and the quality loss model become more and more complex. Then there are no enough data for the determination of the coefficients and the calculation also become more and more complex. To make full use of historical data and similar data, a quick-response incre- mental model of multivariate quality loss is needed. So it should be in our further research. 5. Acknowledgment This project was supported by National Natural Science Foundation of China (70801036), Natural Science Foun- dation of the Jiangsu Higher Education Institutions of China (07KJB460045). REFERENCES [1] G. Taguchi, “Quality engineering [M],” China Transla- tion and Publishing Corporation, December 1985. [2] H. J. Powell, “Quality tools for high value fabrications [J],” Welding in the World, No. 46 (SPEC), pp. 275–280, July 2002. [3] R. Rai and V. Allada, “Modular product family design: Agent-based pareto-optimization and quality loss func- tion-based post-optimal analysis [A],” International Jour- nal of Production Research, Vol. 41, No. 17, pp. 4075– 4098, November 20, 2003. [4] S. H. Fan, “Studies on Grey theory based intelligent methods and their applications to MCMQC [D],” Tsinghua University, Beijing, June 2004. [5] W. M. Chan, R. N. Ibrahim, and P. B. Lochert, “Quality evaluation model using loss function for multiple S-type quality characteristics [J],” International Journal of Ad- vanced Manufacturing Technology, Vol. 26, No. 1–2, pp. 98–101, 2005. [6] R. Khorramshahgol and G. R. Djavanshir, “The applica- tion of analytic hierarchy process to determine propor- tionality constant of the Taguchi quality loss function [J],” IEEE Transactions on Engineering Management, , Vol. 55, No. 2, pp. 340–348, May 2008. [7] S. H. Fan, “The coefficient determination of multivariate quality loss model,” IEEE EMS’07, 2007. [8] G. X. Zhang, “Quality management [M],” Higher Educa- tion Press, Beijing, 1998. [9] S. H. Fan, T. Y. Xiao, et al., “Building the dynamic net- work of mass customization [J],” Journal of System Simulation, Vol. 16, No. 7, pp. 1597–1599, 2004. [10] S. H. Fan, T. Y. Xiao, et al., “Model building of the dy- namic network in MCMQA [J],” Journal of System Simu- lation, Vol. 16, No. 12, pp. 2767–2769, 2004. [11] P. Melin and O. Castillo, “A general method for surface quality control in intelligent manufacturing of materials using a new fuzzy-fractal approach fuzzy [A],” Informa- tion Processing Society, NAFIPS, 18th International Con- ference of the North American, pp. 10–12, June 1999. [12] M. Q. Zhu, “Artificial neural network approach of quality control for intelligent manufacturing system [J],” Acta Aeronautica et Astronautica Sinica, Vol. 18, No. 5, pp. 603–606, 1997. [13] S. Fan, “Studies on the application of grey genetic algo- rithm in dynamic network of MCMQA,” Mechanical Sci- ence and Technology, Vol. 25, No. 8, pp. 984–988, Au- gust 2006. [14] S. Fan, “E-factory based agile-maintenance simulation- platform,” Journal of System Simulation, Vol. 19, No. 5, pp. 1151–1153, May 2007. |