Y. C. Xue et al. / Natural Science 2 (2010) 120-123

Copyright © 2010 SciRes. OPEN ACCESS

121

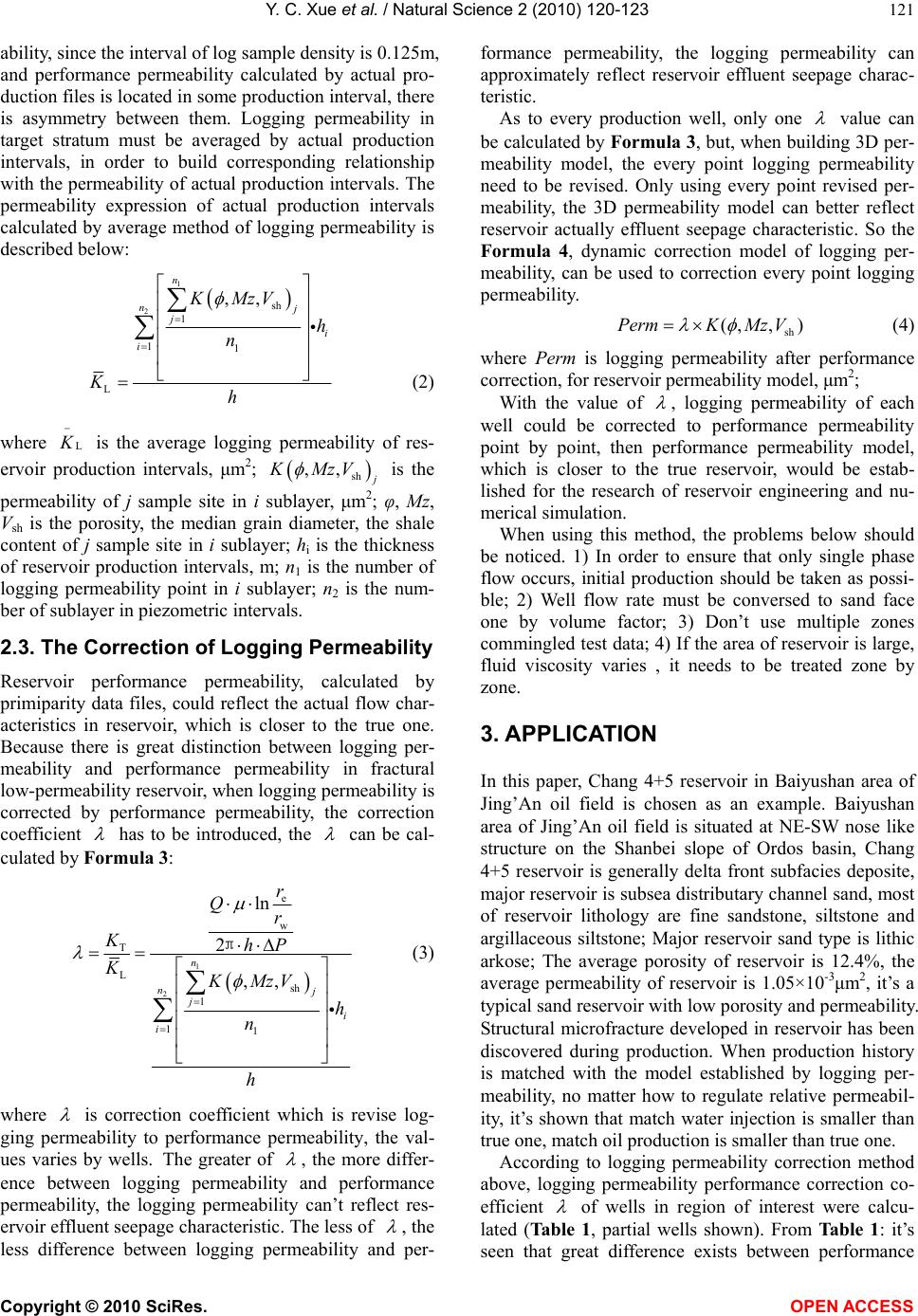

ability, since the interval of log sample density is 0.125m,

and performance permeability calculated by actual pro-

duction files is located in some production interval, there

is asymmetry between them. Logging permeability in

target stratum must be averaged by actual production

intervals, in order to build corresponding relationship

with the permeability of actual production intervals. The

permeability expression of actual production intervals

calculated by average method of logging permeability is

described below:

1

2sh

1

11

L

,,

n

nj

j

i

i

KMzV

h

n

Kh

(2)

where L

is the average logging permeability of res-

ervoir production intervals, μm2;

sh

,,

KMzV

is the

permeability of j sample site in i sublayer, μm2; φ, Mz,

Vsh is the porosity, the median grain diameter, the shale

content of j sample site in i sublayer; hi is the thickness

of reservoir production intervals, m; n1 is the number of

logging permeability point in i sublayer; n2 is the num-

ber of sublayer in piezometric intervals.

2.3. The Correction of Logging Permeability

Reservoir performance permeability, calculated by

primiparity data files, could reflect the actual flow char-

acteristics in reservoir, which is closer to the true one.

Because there is great distinction between logging per-

meability and performance permeability in fractural

low-permeability reservoir, when logging permeability is

corrected by performance permeability, the correction

coefficient

has to be introduced, the

can be cal-

culated by Formula 3:

1

2

e

w

T

L

sh

1

11

ln

2

,,

n

nj

j

i

i

r

Qr

KhP

KKMzV

h

n

h

π (3)

where

is correction coefficient which is revise log-

ging permeability to performance permeability, the val-

ues varies by wells. The greater of

, the more differ-

ence between logging permeability and performance

permeability, the logging permeability can’t reflect res-

ervoir effluent seepage characteristic. The less of

, the

less difference between logging permeability and per-

formance permeability, the logging permeability can

approximately reflect reservoir effluent seepage charac-

teristic.

As to every production well, only one

value can

be calculated by Formula 3, but, when building 3D per-

meability model, the every point logging permeability

need to be revised. Only using every point revised per-

meability, the 3D permeability model can better reflect

reservoir actually effluent seepage characteristic. So the

Formula 4, dynamic correction model of logging per-

meability, can be used to correction every point logging

permeability.

sh

(,, )PermKMz V

(4)

where Perm is logging permeability after performance

correction, for reservoir permeability model, μm2;

With the value of

, logging permeability of each

well could be corrected to performance permeability

point by point, then performance permeability model,

which is closer to the true reservoir, would be estab-

lished for the research of reservoir engineering and nu-

merical simulation.

When using this method, the problems below should

be noticed. 1) In order to ensure that only single phase

flow occurs, initial production should be taken as possi-

ble; 2) Well flow rate must be conversed to sand face

one by volume factor; 3) Don’t use multiple zones

commingled test data; 4) If the area of reservoir is large,

fluid viscosity varies , it needs to be treated zone by

zone.

3. APPLICATION

In this paper, Chang 4+5 reservoir in Baiyushan area of

Jing’An oil field is chosen as an example. Baiyushan

area of Jing’An oil field is situated at NE-SW nose like

structure on the Shanbei slope of Ordos basin, Chang

4+5 reservoir is generally delta front subfacies deposite,

major reservoir is subsea distributary channel sand, most

of reservoir lithology are fine sandstone, siltstone and

argillaceous siltstone; Major reservoir sand type is lithic

arkose; The average porosity of reservoir is 12.4%, the

average permeability of reservoir is 1.05×10-3μm2, it’s a

typical sand reservoir with low porosity and permeability.

Structural microfracture developed in reservoir has been

discovered during production. When production history

is matched with the model established by logging per-

meability, no matter how to regulate relative permeabil-

ity, it’s shown that match water injection is smaller than

true one, match oil production is smaller than true one.

According to logging permeability correction method

above, logging permeability performance correction co-

efficient

of wells in region of interest were calcu-

lated (Table 1, partial wells shown). From Table 1: it’s

seen that great difference exists between performance