Paper Menu >>

Journal Menu >>

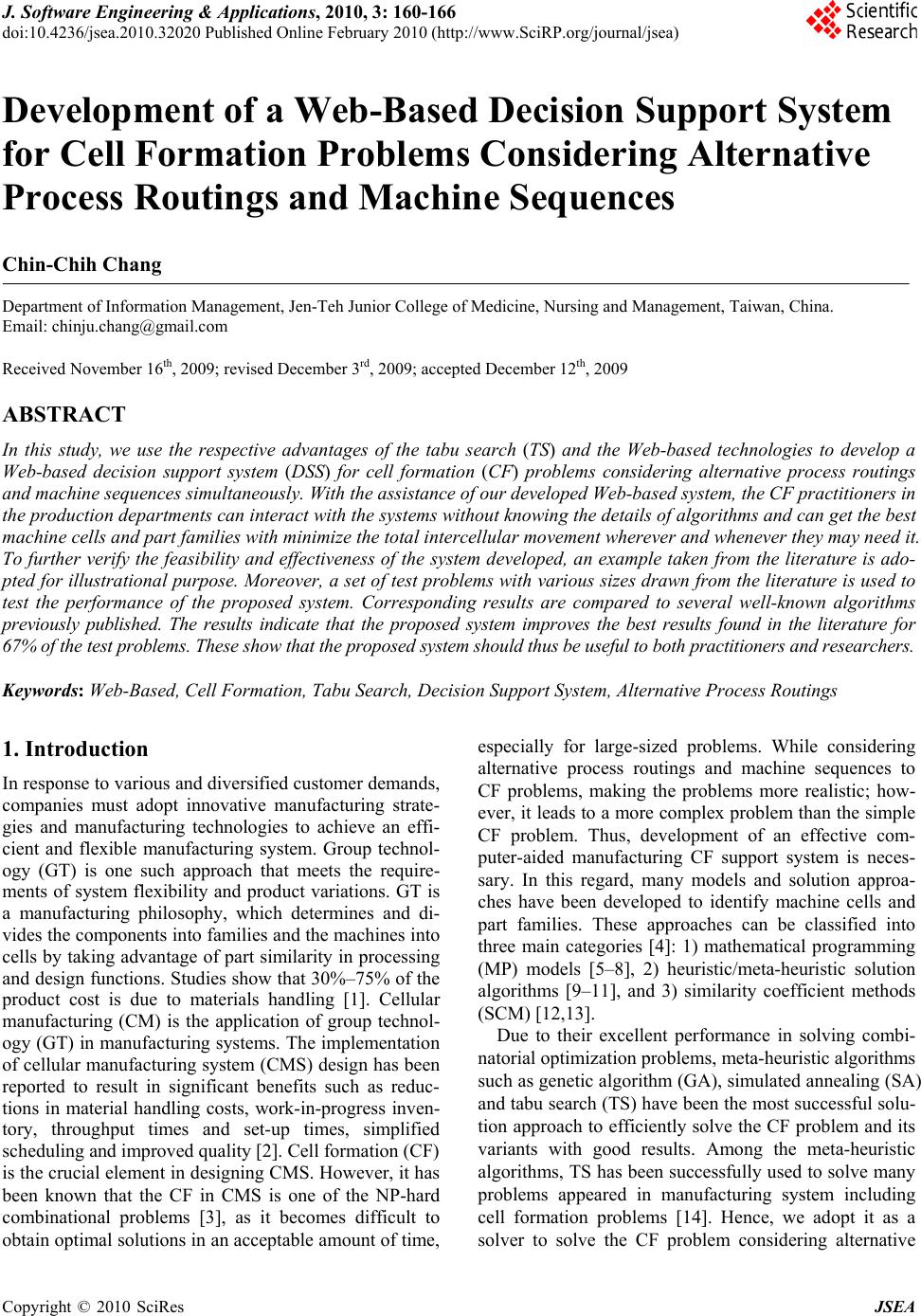

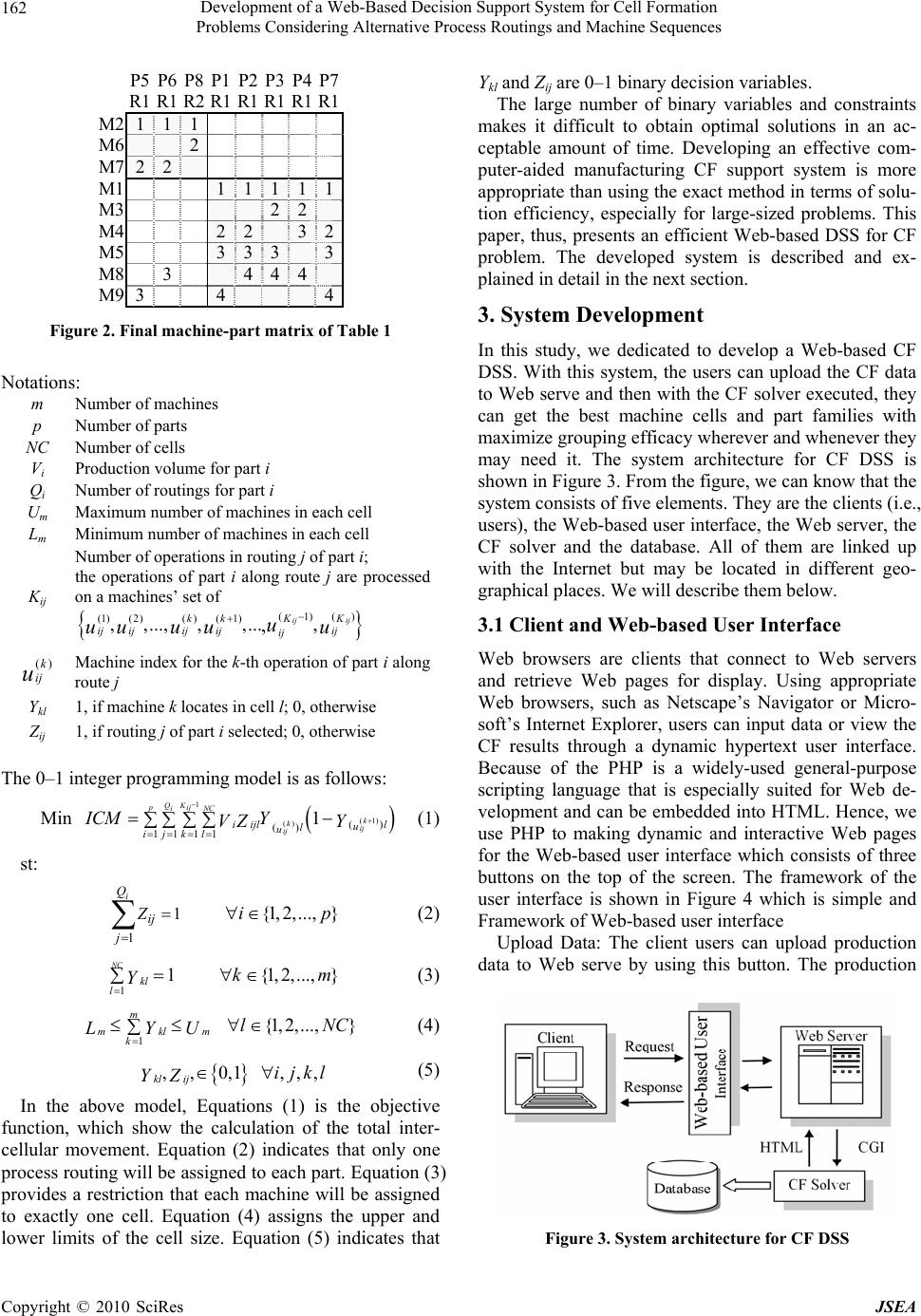

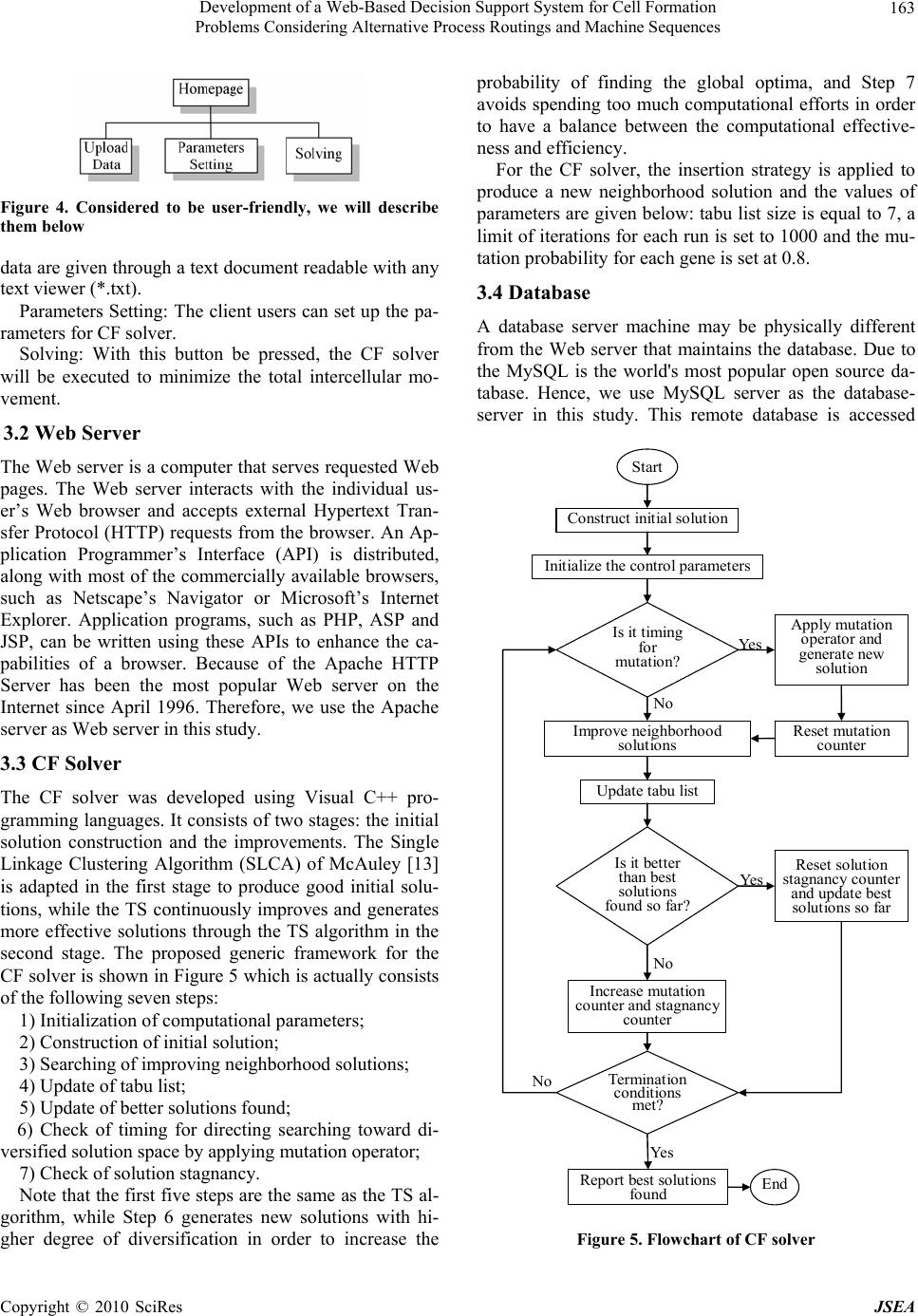

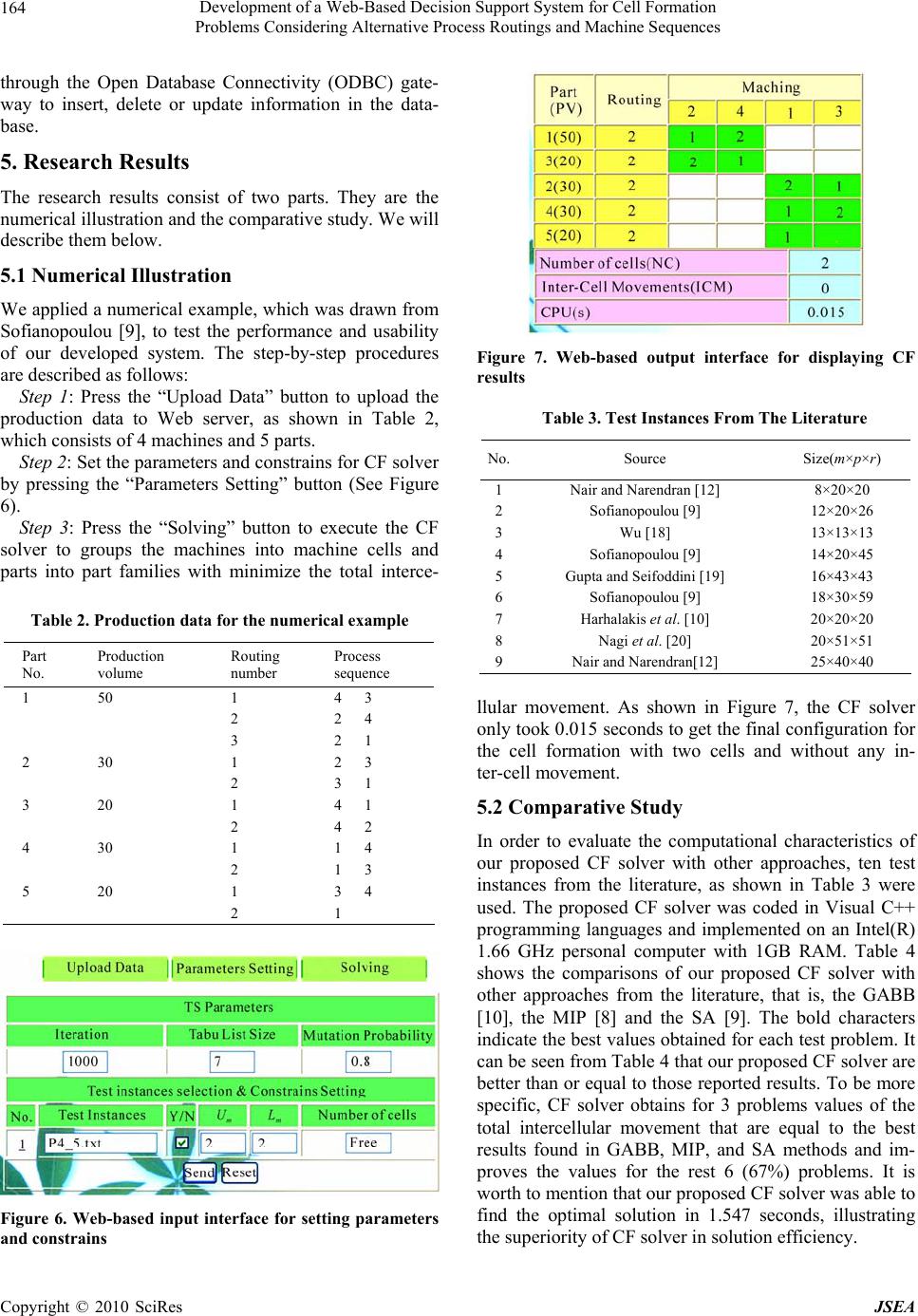

J. Software Engineering & Applications, 2010, 3: 160-166 doi:10.4236/jsea.2010.32020 Published Online February 2010 (http://www.SciRP.org/journal/jsea) Copyright © 2010 SciRes JSEA Development of a Web-Based Decision Support System for Cell Formation Problems Considering Alternative Process Routings and Machine Sequences Chin-Chih Chang Department of Information Management, Jen-Teh Junior College of Medicine, Nursing and Management, Taiwan, China. Email: chinju.chang@gmail.com Received November 16th, 2009; revised December 3rd, 2009; accepted December 12th, 2009 ABSTRACT In this study, we use the respective advantages of the tabu search (TS) and the Web-based technologies to develop a Web-based decision support system (DSS) for cell formation (CF) problems considering alternative process routings and machine sequences simultaneously. With the assistance of our developed Web-based system, the CF practitioners in the production departments can interact with the systems without knowing the details of algorithms and can get the best machine cells and part fa milies with minimize the to tal intercellu lar movemen t wherever and whenever th ey ma y need it. To further verify the feasibility and effectiveness of the system developed, an example taken from the literature is ado- pted for illustrationa l purpose. Moreover, a set of test problems with va rious sizes drawn from the literature is used to test the performance of the proposed system. Corresponding results are compared to several well-known algorithms previously published. The results indicate that the proposed system improves the best results found in the literature for 67% of the test problems. These show that the proposed syst em should t hus be usef ul to bot h practitioners and researchers. Keywords: Web-Based, Cell Formation, Tabu Search, Decision Support System, Alternative Process Routings 1. Introduction In response to various and diversified customer demands, companies must adopt innovative manufacturing strate- gies and manufacturing technologies to achieve an effi- cient and flexible manufacturing system. Group technol- ogy (GT) is one such approach that meets the require- ments of system flexibility and product variations. GT is a manufacturing philosophy, which determines and di- vides the components into families and the machines into cells by taking advantage of part similarity in processing and design functions. Studies show that 30%–75% of the product cost is due to materials handling [1]. Cellular manufacturing (CM) is the application of group technol- ogy (GT) in manufacturing systems. The implementation of cellular manufacturing system (CMS) design has been reported to result in significant benefits such as reduc- tions in material handling costs, work-in-progress inven- tory, throughput times and set-up times, simplified scheduling and improved quality [2]. Cell formation (CF) is the crucial element in de signing CMS. However, it has been known that the CF in CMS is one of the NP-hard combinational problems [3], as it becomes difficult to obtain optimal solutions in an acceptable amount of time, especially for large-sized problems. While considering alternative process routings and machine sequences to CF problems, making the problems more realistic; how- ever, it leads to a more complex problem than the simple CF problem. Thus, development of an effective com- puter-aided manufacturing CF support system is neces- sary. In this regard, many models and solution approa- ches have been developed to identify machine cells and part families. These approaches can be classified into three main categories [4]: 1) mathematical programming (MP) models [5–8], 2) heuristic/meta-heuristic solution algorithms [9–11], and 3) similarity coefficient methods (SCM) [12,13]. Due to their excellent performance in solving combi- natorial optimization problems, meta-heuristic algorithms such as genetic algorith m (GA), simulated annealing (SA) and tabu search (TS) have been the most successful solu- tion approach to efficiently solve the CF problem and its variants with good results. Among the meta-heuristic algorithms, TS has been successfully used to solve many problems appeared in manufacturing system including cell formation problems [14]. Hence, we adopt it as a solver to solve the CF problem considering alternative  Development of a Web-Based Decision Support System for Cell Formation 161 Problems Considering Alternative Process Routings and Machine Sequences process routings and machine sequences simultaneously in the development of our CF Web-based decision sup- port system (DSS). In addition, CF algorithms are usually expressed in mathematical terms, which may only be understood by domain experts, but not by most of the CF practitioners in the production departments. With the assistance of CF DSS, users can interact with the systems without know- ing the details of algorithms. Moreover, due to an in- creasing global competition, companies are now shifting to a geographically distributed manufacturing environ- ment. Besides, the information flow nowadays requires reliability, efficiency and security. With the emergence of information technology, the traditional way of com- munication of information flows between companies and between internal parties can now be replaced by the in- terconnected network [15]. The Internet provides an open environment for companies to connect with their busi- ness partners as well as to serve as a medium for internal information flows [16]. Moreover, manufacturing sys- tems have migrated to integrate with the Internet to pro- vide a remote access and control system with the charac- teristics of quick response and real line monitoring [17]. In this study, we use the respective advantages of the TS and the Web-based technologies to develop a Web- based DSS for CF problem considering alternative proc- ess routings and machine sequences simultaneously. An example taken from the literature is adopted for illustra- tional purpose. To further v erify the feasibility and effec- tiveness of the system developed, ten test problems with various sizes drawn from the literature are used to test the performance of our proposed CF so lver. Correspond- ing results are compared to several well-known algo- rithms previously published. The remainder of this article is organized as follows: Section 2 describes the problem definition including cell formation and the mathematical model; Section 3 details the implementation of our Web-based CF DSS; Section 4 verifies the performance of the proposed system and methodology; and Section 5 concludes the paper. 2. Problem Definition 2.1 Cell Formation In a simple CF problem, cell formation in a given 0–1 machine-part incidence matrix involves rearrangement of rows and columns of the matrix to create part families and machines cells, in which the cellular movement can be minimized and the utilizatio n of the machin es within a cell can be maximized. Two matrices shown in Figure 1 are used to illustrate the concept. Figure 1(a) is an initial matrix where no blocks can be observed directly. After rearrangement of rows and columns, two blocks can be obtained along the diagonal of the solution matrix in Figure 1(b). For those 1’s outside the diagonal blocks, they are called “exceptional elements”; while those 0’s inside the diagonal blocks are called “voids”. When parts have alternative process routings (APR) is called the generalized CF problem. Such as the case shown in Table 1, part #1 has two process routings R1 and R2. Kusiak [5] first described the problem and pre- sented an integer-programming model to solve the prob- lem. While introducing APR to CF problems, the group- ing of parts can be more effective due to the flexibility of the routes; however, it leads to a more complex problem than the simple CF problem. Under this circumstance, not only the formation of part families and machine cells must be determined but also the selection of routings for each part has to be determined to achieve decision objec- tives such as the minimizatio n of intercellular movement. For instance, Table 2 provides a feasible solution to the sample problem of Table 1 with a total intercellular mo- vement of 215. 2.2 Mathematical Model The decision objective of their research is to minimize the sum of total intercellular movement. The 0–1 integer programming model that they formulated is given below, and the notations are introduced first. Figure 1. Rearrangement of rows and columns of matrix to create cells: (a) initial matrix and (b) matrix after rear- rangement Table 1. Initial machine-part matrix where alternative process routings are allowed PV: Production Volume; PN: Part Number; RN: Routing Number; * Process Sequence Copyright © 2010 SciRes JSEA  Development of a Web-Based Decision Support System for Cell Formation 162 Problems Considering Alternative Process Routings and Machine Sequences P5 P6 P8 P1P2 P3 P4 P7 R1 R1 R2 R1R1 R1 R1 R1 M2 1 1 1 M6 2 M7 2 2 M1 11 1 1 1 M3 2 2 M4 22 3 2 M5 33 3 3 M8 3 4 4 4 M9 3 4 4 Figure 2. Final machine-part matrix of Table 1 Notations: m Number of machines p Number of parts NC Number of cells Vi Production volume for part i Qi Number of routings for part i Um Maximum number of machines in each cell Lm Minimum number of machines in each cell Kij Number of operations in routing j of part i; the operations of part i along route j are processed on a machines’ set of ()(1) (1) (2)() (1) , ,..., ,,..., ,ijij KK kk ij ijijijij ij u uu uuu {1,2,..., } ip m NC ()k ij u Machine index for the k-th operation of part i along route j Ykl 1, if machine k locates in cell l; 0, otherwise Zij 1, if routing j of part i selecte d; 0, otherwise The 0–1 integer programming model is as follows: Min (1) 1 (1) () () () 11111 QK pij iNC k kij ij ijl l iu l u ijkl Y ICM Z VY st: 1 1 i Q j ij Z (2) 11 NC kl lY (3) {1,2, ...,}k 1 m mkl m kU LY {1,2, ...,}l (4) ,,0,1 ,,, kl ijijkl YZ (5) In the above model, Equations (1) is the objective function, which show the calculation of the total inter- cellular movement. Equation (2) indicates that only one process routing will be assigned to each part. Equation (3) provides a restriction that each machine will be assigned to exactly one cell. Equation (4) assigns the upper and lower limits of the cell size. Equation (5) indicates that Ykl and Zij are 0–1 binary decision variables. The large number of binary variables and constraints makes it difficult to obtain optimal solutions in an ac- ceptable amount of time. Developing an effective com- puter-aided manufacturing CF support system is more appropriate than using the exact method in terms of solu- tion efficiency, especially for large-sized problems. This paper, thus, presents an efficient Web-based DSS for CF problem. The developed system is described and ex- plained in detail in th e next section. 3. System Development In this study, we dedicated to develop a Web-based CF DSS. With this system, the users can upload the CF data to Web serve and then with the CF solv er executed, they can get the best machine cells and part families with maximize grouping efficacy wherever and whenever they may need it. The system architecture for CF DSS is shown in Figure 3. From the figure, we can know that the system consists of five elements. They are the clients (i.e., users), the Web-based user interface, the Web server, the CF solver and the database. All of them are linked up with the Internet but may be located in different geo- graphical places. We will describe them below. 3.1 Client and Web-based User Interface Web browsers are clients that connect to Web servers and retrieve Web pages for display. Using appropriate Web browsers, such as Netscape’s Navigator or Micro- soft’s Internet Explorer, users can input data or view the CF results through a dynamic hypertext user interface. Because of the PHP is a widely-used general-purpose scripting language that is especially suited for Web de- velopment and can be embedded into HTML. Hence, we use PHP to making dynamic and interactive Web pages for the Web-based user interface which consists of three buttons on the top of the screen. The framework of the user interface is shown in Figure 4 which is simple and Framework of Web-based user interface Upload Data: The client users can upload production data to Web serve by using this button. The production Figure 3. System architecture for CF DSS Copyright © 2010 SciRes JSEA  Development of a Web-Based Decision Support System for Cell Formation 163 Problems Considering Alternative Process Routings and Machine Sequences Figure 4. Considered to be user-friendly, we will describe them below data are given through a text document readable with any text viewer (*.txt). Parameters Setting: The client users can set up the pa- rameters for CF solver. Solving: With this button be pressed, the CF solver will be executed to minimize the total intercellular mo- vement. 3.2 Web Server The Web server is a computer that serves requested Web pages. The Web server interacts with the individual us- er’s Web browser and accepts external Hypertext Tran- sfer Protocol (HTTP) requests from the browser. An Ap- plication Programmer’s Interface (API) is distributed, along with most of the commercially available browsers, such as Netscape’s Navigator or Microsoft’s Internet Explorer. Application programs, such as PHP, ASP and JSP, can be written using these APIs to enhance the ca- pabilities of a browser. Because of the Apache HTTP Server has been the most popular Web server on the Internet since April 1996. Therefore, we use the Apache server as Web server in this study. 3.3 CF Solver The CF solver was developed using Visual C++ pro- gramming languages. It cons ists of two stages: the initial solution construction and the improvements. The Single Linkage Clustering Algorithm (SLCA) of McAuley [13] is adapted in the first stage to produce good initial solu- tions, while the TS continuously improves and generates more effective solutions through the TS algorithm in the second stage. The proposed generic framework for the CF solver is shown in Figure 5 wh ich is actually consists of the following seven steps: 1) Initialization of co mputational parameters; 2) Construction of initial solution; 3) Searching of improving neighborhood solutions; 4) Update of tabu list; 5) Update of better solutions found; 6) Check of timing for directing searching toward di- versified solution space by applying mutation operator; 7) Check of solution stagnancy. Note that the first five steps are the same as the TS al- gorithm, while Step 6 generates new solutions with hi- gher degree of diversification in order to increase the probability of finding the global optima, and Step 7 avoids spending too much computational efforts in order to have a balance between the computational effective- ness and efficiency. For the CF solver, the insertion strategy is applied to produce a new neighborhood solution and the values of parameters are given below: tabu list size is equal to 7, a limit of iterations for each run is set to 1000 and the mu- tation probability for each gene is set at 0.8. 3.4 Database A database server machine may be physically different from the Web server that maintains the database. Due to the MySQL is the world's most popular open source da- tabase. Hence, we use MySQL server as the database- server in this study. This remote database is accessed Con struct initial solutio n Start Improve neighborhood solutions U p da te ta bu l ist Is it better than best solutions found so far? T erm i nat i on conditions met? Is ittiming for mutation? Reset solution st agna ncy cou nte r and update best solution s so far Apply mutation operator and gene ra te ne w solution Reset mutation counte r Repo rt best solutions foundEnd Yes N o Yes N o Yes N o In itia lize thecont rolparameter s Increasemutation counter and stagnancy cou nter Figure 5. Flowchart of CF solver Copyright © 2010 SciRes JSEA  Development of a Web-Based Decision Support System for Cell Formation 164 Problems Considering Alternative Process Routings and Machine Sequences through the Open Database Connectivity (ODBC) gate- way to insert, delete or update information in the data- base. 5. Research Results The research results consist of two parts. They are the numerical illustration and the comparative study. We will describe them below. 5.1 Numerical Illustration We applied a numerical example, which was drawn from Sofianopoulou [9], to test the performance and usability of our developed system. The step-by-step procedures are described as follows: Step 1: Press the “Upload Data” button to upload the production data to Web server, as shown in Table 2, which consists of 4 machines and 5 parts. Step 2: Set the parameters and constrains for CF solver by pressing the “Parameters Setting” button (See Figure 6). Step 3: Press the “Solving” button to execute the CF solver to groups the machines into machine cells and parts into part families with minimize the total interce- Table 2. Production data for the numerical example Part No. Production volume Routing number Process sequence 1 50 1 4 3 2 2 4 3 2 1 2 30 1 2 3 2 3 1 3 20 1 4 1 2 4 2 4 30 1 1 4 2 1 3 5 20 1 3 4 2 1 Figure 6. Web-based input interface for setting parameters and constrains Figure 7. Web-based output interface for displaying CF results Table 3. Test Instances From The Literature No.Source Size(m×p×r) 1Nair and Narendran [ 12] 8×20×20 2Sofianopoulou [9] 12×20×26 3Wu [18] 13×13×13 4Sofianopoulou [9] 14×20×45 5Gupta and Seifoddini [19] 16×43×43 6Sofianopoulou [9] 18×30×59 7Harhalakis et al. [10] 20×20×20 8Nagi et al. [20] 20×51×51 9Nair and Narendran[12] 25×40×40 llular movement. As shown in Figure 7, the CF solver only took 0.015 second s to get the final configuration for the cell formation with two cells and without any in- ter-cell movement. 5.2 Comparative Study In order to evaluate the computational characteristics of our proposed CF solver with other approaches, ten test instances from the literature, as shown in Table 3 were used. The proposed CF solver was coded in Visual C++ programming languages and implemented on an Intel(R) 1.66 GHz personal computer with 1GB RAM. Table 4 shows the comparisons of our proposed CF solver with other approaches from the literature, that is, the GABB [10], the MIP [8] and the SA [9]. The bold characters indicate the best values obtained for each test problem. It can be seen from Table 4 that our proposed CF solver are better than or equal to those reported results. To be more specific, CF solver obtains for 3 problems values of the total intercellular movement that are equal to the best results found in GABB, MIP, and SA methods and im- proves the values for the rest 6 (67%) problems. It is worth to mention that our prop osed CF solver was ab le to find the optimal solution in 1.547 seconds, illustrating the superiority of CF solver in solution efficien cy. Copyright © 2010 SciRes JSEA  Development of a Web-Based Decision Support System for Cell Formation 165 Problems Considering Alternative Process Routings and Machine Sequences Table 4. Performance of the proposed approach compared to other approaches Test instances Other approaches Proposed approach GABB[ 10] MIP[8] SA[9] CF solver No. Lm U m ICM ICM ICM NC ICM CPU (s) 1 2 4 13 - - 2 13 0.273 2 2 5 - - 29 3 29 0.500 3 2 6 - 1800 - 3 12600.360 4 2 5 - - 25 3 25 0.578 5 2 6 - 34979 - 3 274160.907 6 2 7 - - 34 3 32 0.774 7 2 5 18 - - 5 17 0.953 8 2 5 86 - - 5 82 1.789 9 2 4 39 - - 7 33 1.547 6. Conclusions Considering alternative process routings and machine sequences to cell formation (CF) problems makes the problems more realistic. New technologies, especially the World-Wide Web (WWW) technologies, have cre- ated many opportunities for research about Decision Support Systems (DSS). In this study, a Web-based CF DSS considering alternative process routings and ma- chine sequences simultaneously has been proposed. With the assistance of CF DSS, the CF practitioners in the production departments can interact with the systems without knowing the details of algorithms and can get the best machine cells and part families with minimize the total intercellular movement wherever and whenever they may need it. An example taken from the literature was adopted for illustrational purpose. To further verify the feasibility and effectiv eness of the system developed, a set of test problems with various sizes drawn from the literature have be used to test the performance of the CF solver. Corresponding results were compared to several well-known algorithms previously published. The results indicated that the proposed CF solver improved the best results found in the literature for 67% of the test prob- lems and the CPU times took by our proposed CF solver to find the optimal solutio n were in 1.547 second s. These show that our developed system should be very effective, efficient and practical. REFERENCES [1] S. Heragu, “Facilities design,” Massachusetts: PWS Publishing Company, Boston, 1997. [2] U. Wemmerlov and N. Hyer, “Research issues in cellular manufacturing,” International Journal of Production Re- search, Vol. 25, pp. 413–431, 1987. [3] A. Kusiak, “Intelligent manufacturing systems,” New Jersey: Prentice Hall, Englewood Cliffs, 1990. [4] Y. Yin and K. Yasuda, “Similarity coefficient methods applied to the cell formation problem: A taxonomy and review,” International Journal of Production Economics, Vol. 101, pp. 329–352, 2006. [5] A. Kusiak, “The generalized group technology concept,” International Journal of Production Research, Vol. 25, pp. 561–569, 1987. [6] M. S. J. Ameli and J. Arkat, “Cell formation with alterna- tive process routings and machine reliability considera- tion,” International Journal of Advanced Manufacturing Technology, Vol. 35, pp. 761–768, 2008. [7] F. Boctor, “A linear formulation of the machine-part cell formation problem,” International Journal of Production Research, Vol. 29, No. 2, pp. 343–356, 1991. [8] Y. Y. Won and K. C. Lee, “Group technology cell forma- tion considering operation sequences and production vol- umes,” International Journal of Production Research, Vol. 39, No. 13, pp. 2755–2768, 2001. [9] S. Sofianopoulou, “Manufacturing cells design with alter- native process plans and/or replicate machines,” Interna- tional Journal of Production Research, Vol. 37, pp. 707– 720, 1999. [10] M. Boulif and K. Atif, “A new branch-&-bound-enhanced genetic algorithm for the manufacturing cell formation problem,” Computers and Operations Research, Vol. 33, pp. 2219–2245, 2006. [11] T.-H. Wu, S.-H. Chung, and C.-C. Chang, “Hybrid simu- lated annealing algorithm with mutation operator to the cell formation problem with alternative process routings,” Expert Systems with Applications, Vol. 36, pp. 3652– 3661, 2008. [12] G. J. Nair and T. T. Narendran, “CASE: A clustering algorithm for cell formation with sequence data,” Interna- tional Journal of Production Research, Vol. 36, pp. 157– 179, 1998. [13] J. McAuley, “Machine grouping for efficient production,” Production Engineer, Vol. 52, pp. 53–57, 1972. [14] S. Lozano, B. Adenso-Diaz, and L. Onieva, “A one-step Tabu search algorithm for manufacturing cell design,” Journal of the Operational Research Society, Vol. 50, pp. 509–516, 1999. [15] G. Y. Tian, G. Yin, and D. Taylor, “Internet-based manu- facturing: A review and a new infrastructure for distrib- uted intelligent manufacturing,” Journal of Intelligent Manufacturing, Vol. 13, No. 5, pp. 323–338, 2002. [16] J. Lee, “E-manufacturing systems: Fundamental and too- ls,” Robotics and Computer-Integrated Manufacturing, Vol. 9, No. 6, pp. 501–507, 2003. [17] C. S. Smith and P. K. Wright, “CyberCut: A world-wide web-based design-to-fabrication tool,” Journal of Intelli- gent Manufacturing, Vol. 15, No. 6, pp. 432–442, 1996. [18] N. Wu, “A concurrent approach to cell formation and assignment of identical machines in group technology,” Copyright © 2010 SciRes JSEA  Development of a Web-Based Decision Support System for Cell Formation Problems Considering Alternative Process Routings and Machine Sequences Copyright © 2010 SciRes JSEA 166 International Journal of Production Research, Vol. 36, pp. 2099–2114, 1998. [19] T. Gupta and H. Seifoddini, “Production data based simi- larity coefficient for machine-part grouping decisions in the design of a cellular manufacturing system,” Interna- tional Journal of Production Research, Vol. 28, pp. 1247– 1269, 1990. [20] R. Nagi, G. Harlarakis, and J. M. Proth, “Multiple rout- ings and capacity considerations in group technology ap- plications,” International Journal of Production Research, Vol. 28, pp. 2243–2257, 1990. |