Paper Menu >>

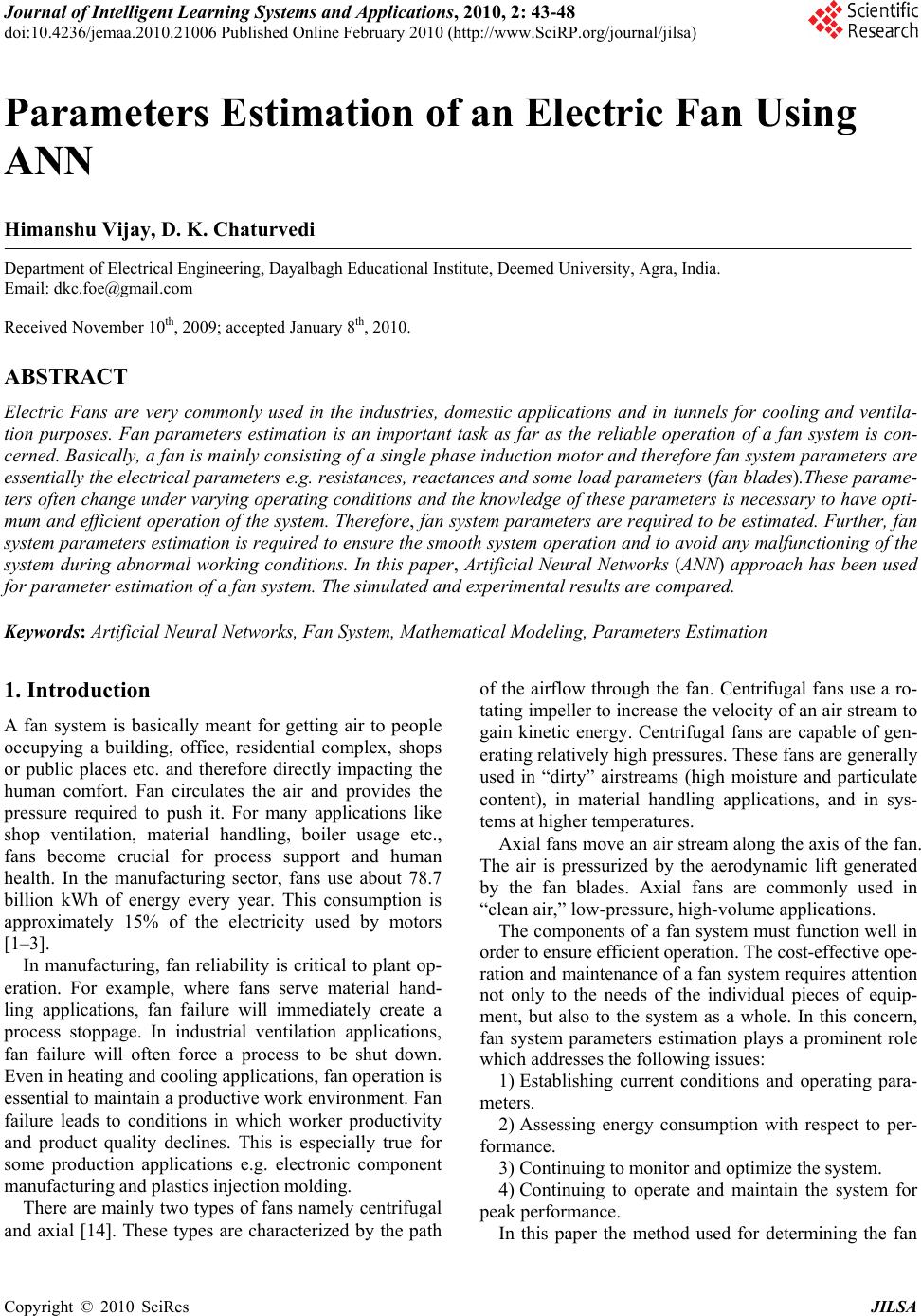

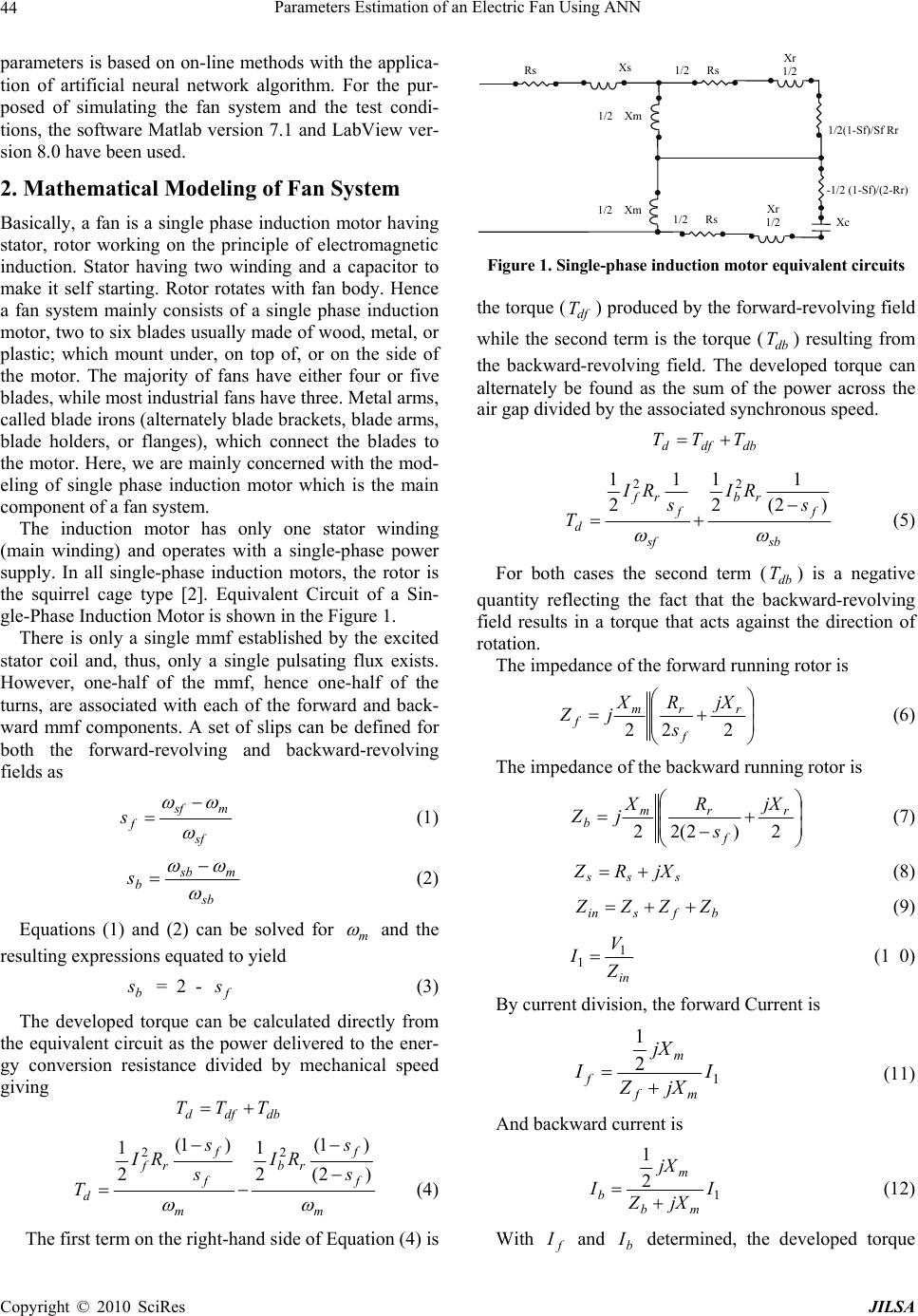

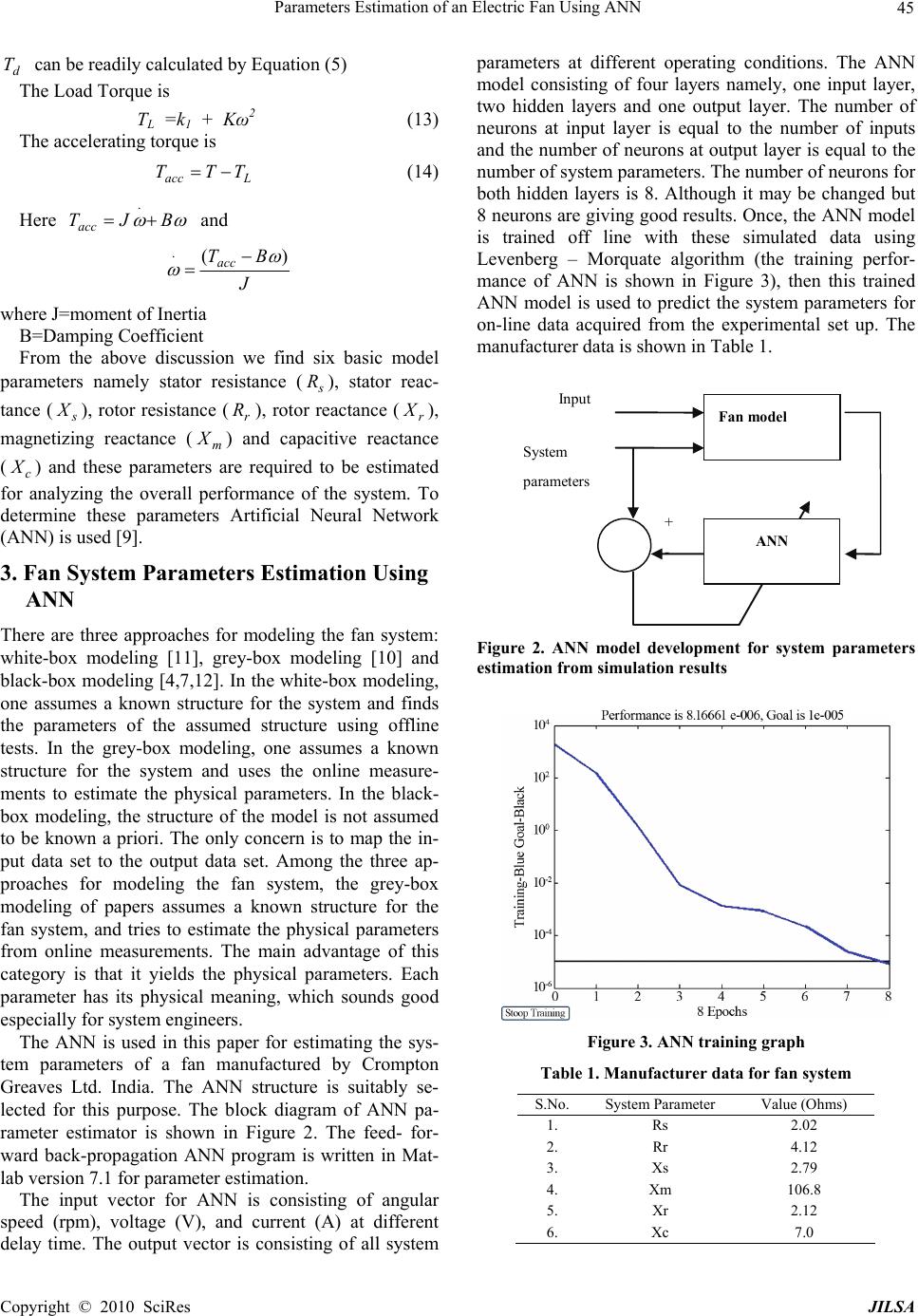

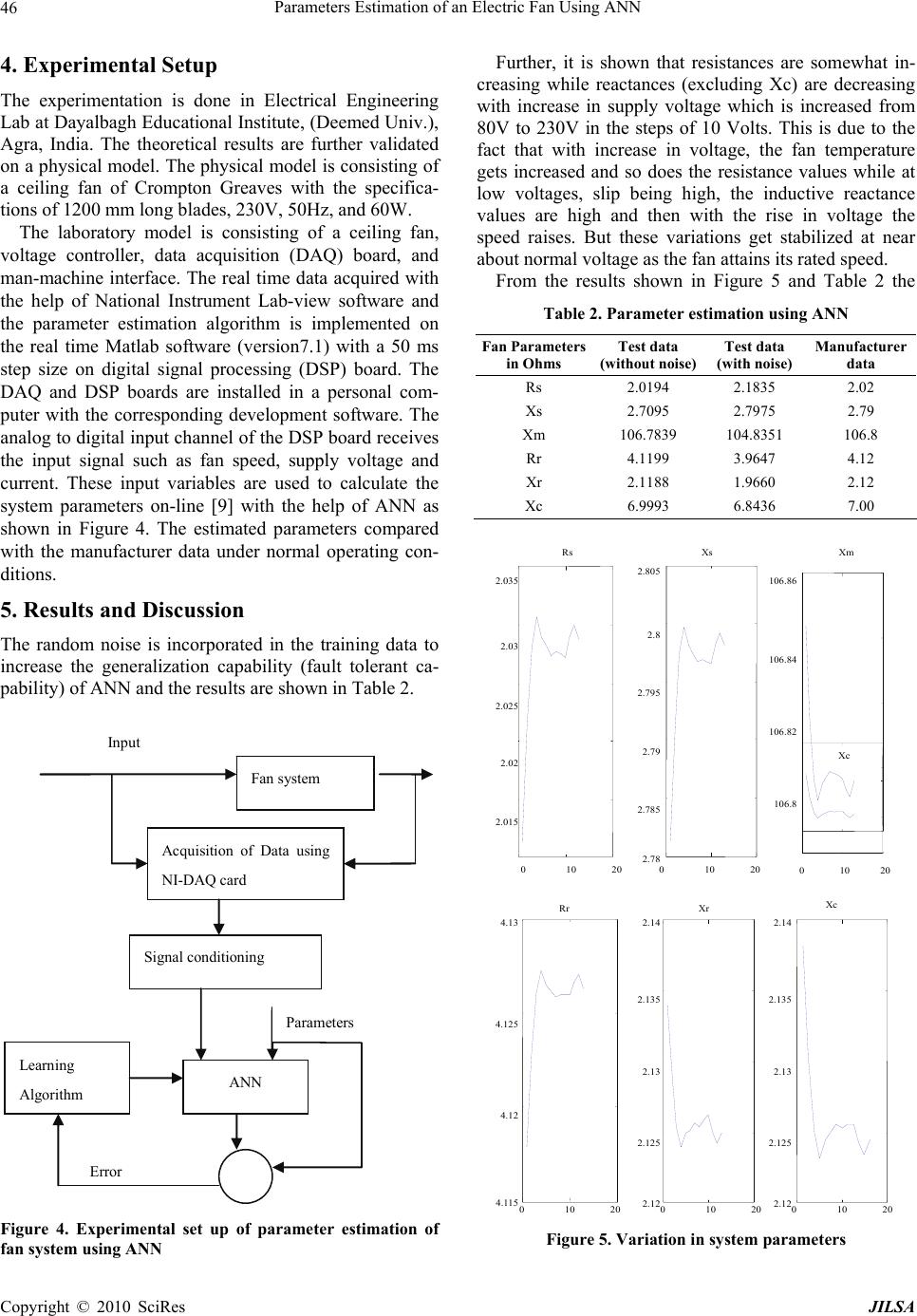

Journal Menu >>

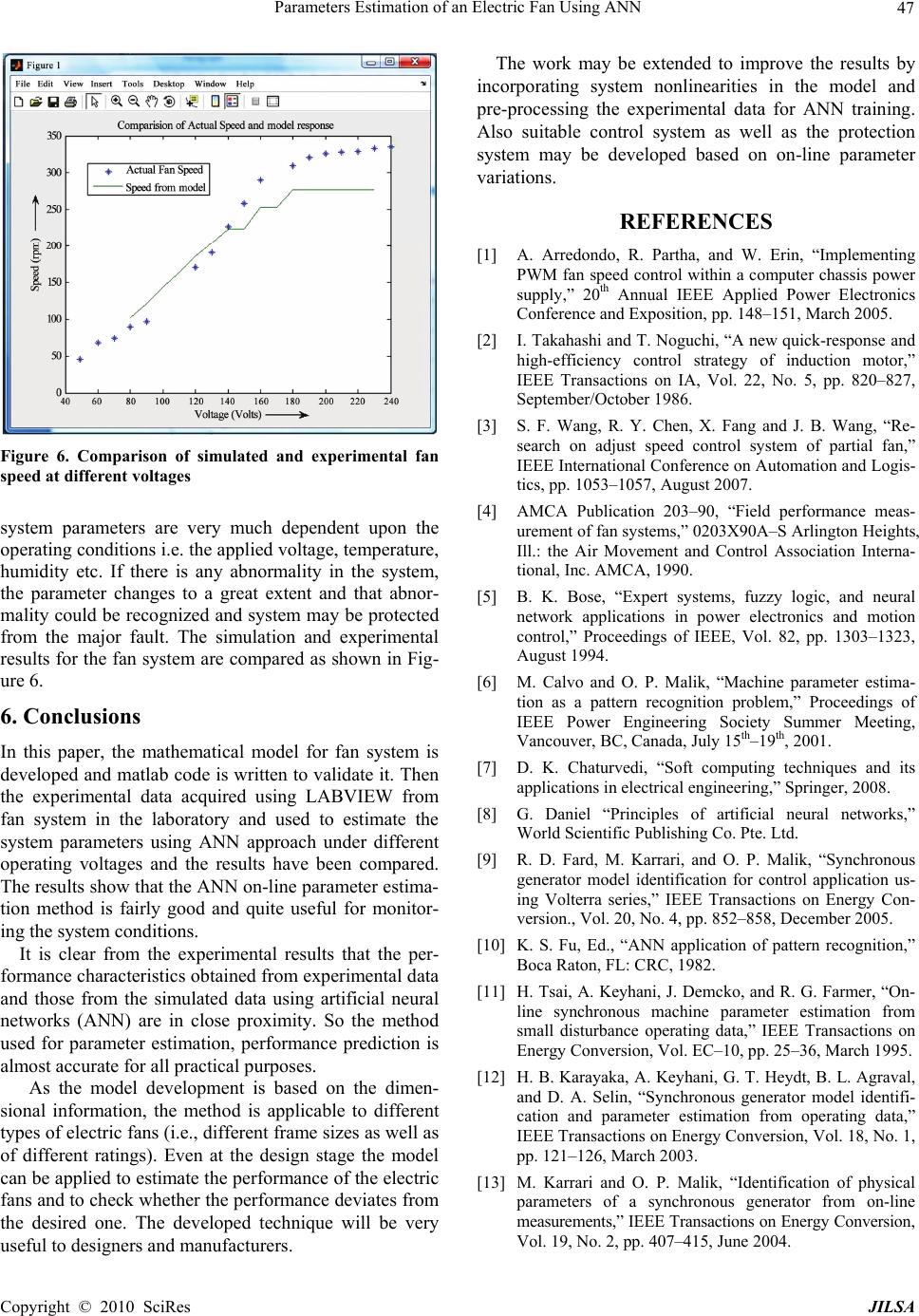

Journal of Intelligent Learning Systems and Applications, 2010, 2: 43-48 doi:10.4236/jemaa.2010.21006 Published Online February 2010 (http://www.SciRP.org/journal/jilsa) Copyright © 2010 SciRes JILSA 43 Parameters Estimation of an Electric Fan Using ANN Himanshu Vijay, D. K. Chaturvedi Department of Electrical Engineering, Dayalbagh Educational Institute, Deemed University, Agra, India. Email: dkc.foe@gmail.com Received November 10th, 2009; accepted January 8th, 2010. ABSTRACT Electric Fans are very commonly used in the industries, domestic applications and in tunnels for cooling and ventila- tion purposes. Fan parameters estimation is an important task as far as the reliable operation of a fan system is con- cerned. Basically, a fan is mainly consisting of a single phase induction motor and therefore fan system parameters are essentially the electrical parameters e.g. resistances, reactances and some load parameters (fan blades).These parame- ters often change under varying operating conditions and the knowledge of these parameters is necessary to have opti- mum and efficient operation of the system. Therefore, fan system parameters are required to be estimated. Further, fan system parameters estimation is required to ensure the smooth system operation and to avoid any malfunctioning of the system during abnormal working conditions. In this paper, Artificial Neural Networks (ANN) approach has been used for parameter estimation of a fan system. The simulated and experimental results are compared. Keywords: Artificial Neural Networks, Fan System, Mathematical Modeling, Parameters Estimation 1. Introduction A fan system is basically meant for getting air to people occupying a building, office, residential complex, shops or public places etc. and therefore directly impacting the human comfort. Fan circulates the air and provides the pressure required to push it. For many applications like shop ventilation, material handling, boiler usage etc., fans become crucial for process support and human health. In the manufacturing sector, fans use about 78.7 billion kWh of energy every year. This consumption is approximately 15% of the electricity used by motors [1–3]. In manufacturing, fan reliability is critical to plant op- eration. For example, where fans serve material hand- ling applications, fan failure will immediately create a process stoppage. In industrial ventilation applications, fan failure will often force a process to be shut down. Even in heating and cooling applications, fan operation is essential to maintain a productive work environment. Fan failure leads to conditions in which worker productivity and product quality declines. This is especially true for some production applications e.g. electronic component manufacturing and plastics injection molding. There are mainly two types of fans namely centrifugal and axial [14]. These types are characterized by the path of the airflow through the fan. Centrifugal fans use a ro- tating impeller to increase the velocity of an air stream to gain kinetic energy. Centrifugal fans are capable of gen- erating relatively high pressures. These fans are generally used in “dirty” airstreams (high moisture and particulate content), in material handling applications, and in sys- tems at higher temperatures. Axial fans move an air stream along the axis of the fan. The air is pressurized by the aerodynamic lift generated by the fan blades. Axial fans are commonly used in “clean air,” low-pressure, high-volume applications. The components of a fan system must function well in order to ensure efficient operation. The cost-effective ope- ration and maintenance of a fan system requires attention not only to the needs of the individual pieces of equip- ment, but also to the system as a whole. In this concern, fan system parameters estimation plays a prominent role which addresses the following issues: 1) Establishing current conditions and operating para- meters. 2) Assessing energy consumption with respect to per- formance. 3) Continuing to monitor and optimize the system. 4) Continuing to operate and maintain the system for peak performance. In this paper the method used for determining the fan  Parameters Estimation of an Electric Fan Using ANN 44 parameters is based on on-line methods with the applica- tion of artificial neural network algorithm. For the pur- posed of simulating the fan system and the test condi- tions, the software Matlab version 7.1 and LabView ver- sion 8.0 have been used. 2. Mathematical Modeling of Fan System Basically, a fan is a single phase induction motor having stator, rotor working on the principle of electromagnetic induction. Stator having two winding and a capacitor to make it self starting. Rotor rotates with fan body. Hence a fan system mainly consists of a single phase induction motor, two to six blades usually made of wood, metal, or plastic; which mount under, on top of, or on the side of the motor. The majority of fans have either four or five blades, while most industrial fans have three. Metal arms, called blade irons (alternately blade brackets, blade arms, blade holders, or flanges), which connect the blades to the motor. Here, we are mainly concerned with the mod- eling of single phase induction motor which is the main component of a fan system. The induction motor has only one stator winding (main winding) and operates with a single-phase power supply. In all single-phase induction motors, the rotor is the squirrel cage type [2]. Equivalent Circuit of a Sin- gle-Phase Induction Motor is shown in the Figure 1. There is only a single mmf established by the excited stator coil and, thus, only a single pulsating flux exists. However, one-half of the mmf, hence one-half of the turns, are associated with each of the forward and back- ward mmf components. A set of slips can be defined for both the forward-revolving and backward-revolving fields as sf msf f s (1) sb msb b s (2) Equations (1) and (2) can be solved for m and the resulting expressions equated to yield b s = 2 - (3) f s The developed torque can be calculated directly from the equivalent circuit as the power delivered to the ener- gy conversion resistance divided by mechanical speed giving dbdfd T T T m f f rb m f f rf d s s RI s s RI T )2( )1( 2 1 )1( 2 122 (4) The first term on the right-hand side of Equation (4) is Xc Xr 1/2 1/2 Xm Xs -1/2 (1-Sf)/(2-R r ) 1/2(1-Sf)/Sf Rr 1/2 Rs Rs 1/2 Xm1/2 Rs Xr 1/2 Figure 1. Single-phase induction motor equivalent circuits the torque (df T ) produced by the forward-revolving field while the second term is the torque () resulting from the backward-revolving field. The developed torque can alternately be found as the sum of the power across the air gap divided by the associated synchronous speed. db T dbdfd TTT sb f rb sf f rf d s RI s RI T )2( 1 2 11 2 122 (5) For both cases the second term () is a negative quantity reflecting the fact that the backward-revolving field results in a torque that acts against the direction of rotation. db T The impedance of the forward running rotor is 222 r f r m f jX s R X jZ (6) The impedance of the backward running rotor is 2)2(22 r f r m b jX s R X jZ (7) sss jXRZ (8) bfsinZZZZ (9) in Z V I1 1 (1 0) By current division, the forward Current is 1 2 1 I jXZ jX I mf m f (11) And backward current is 1 2 1 I jXZ jX I mb m b (12) With and determined, the developed torque f Ib I Copyright © 2010 SciRes JILSA  Parameters Estimation of an Electric Fan Using ANN 45 d T can be readily calculated by Equation (5) The Load Torque is TL =k1 + Kω2 (13) The accelerating torque is Lacc TTT (14) Here and BJTacc . J BTacc )( . where J=moment of Inertia B=Damping Coefficient From the above discussion we find six basic model parameters namely stator resistance (), stator reac- tance (), rotor resistance (), rotor reactance (), magnetizing reactance () and capacitive reactance () and these parameters are required to be estimated for analyzing the overall performance of the system. To determine these parameters Artificial Neural Network (ANN) is used [9]. s R s Xr Rr X m X c X 3. Fan System Parameters Estimation Using ANN There are three approaches for modeling the fan system: white-box modeling [11], grey-box modeling [10] and black-box modeling [4,7,12]. In the white-box modeling, one assumes a known structure for the system and finds the parameters of the assumed structure using offline tests. In the grey-box modeling, one assumes a known structure for the system and uses the online measure- ments to estimate the physical parameters. In the black- box modeling, the structure of the model is not assumed to be known a priori. The only concern is to map the in- put data set to the output data set. Among the three ap- proaches for modeling the fan system, the grey-box modeling of papers assumes a known structure for the fan system, and tries to estimate the physical parameters from online measurements. The main advantage of this category is that it yields the physical parameters. Each parameter has its physical meaning, which sounds good especially for system engineers. The ANN is used in this paper for estimating the sys- tem parameters of a fan manufactured by Crompton Greaves Ltd. India. The ANN structure is suitably se- lected for this purpose. The block diagram of ANN pa- rameter estimator is shown in Figure 2. The feed- for- ward back-propagation ANN program is written in Mat- lab version 7.1 for parameter estimation. The input vector for ANN is consisting of angular speed (rpm), voltage (V), and current (A) at different delay time. The output vector is consisting of all system parameters at different operating conditions. The ANN model consisting of four layers namely, one input layer, two hidden layers and one output layer. The number of neurons at input layer is equal to the number of inputs and the number of neurons at output layer is equal to the number of system parameters. The number of neurons for both hidden layers is 8. Although it may be changed but 8 neurons are giving good results. Once, the ANN model is trained off line with these simulated data using Levenberg – Morquate algorithm (the training perfor- mance of ANN is shown in Figure 3), then this trained ANN model is used to predict the system parameters for on-line data acquired from the experimental set up. The manufacturer data is shown in Table 1. Fan model Input System parameters + - ANN Figure 2. ANN model development for system parameters estimation from simulation results Figure 3. ANN training graph Table 1. Manufacturer data for fan system S.No. System Parameter Value (Ohms) 1. Rs 2.02 2. Rr 4.12 3. Xs 2.79 4. Xm 106.8 5. Xr 2.12 6. Xc 7.0 Copyright © 2010 SciRes JILSA  Parameters Estimation of an Electric Fan Using ANN 46 4. Experimental Setup The experimentation is done in Electrical Engineering Lab at Dayalbagh Educational Institute, (Deemed Univ.), Agra, India. The theoretical results are further validated on a physical model. The physical model is consisting of a ceiling fan of Crompton Greaves with the specifica- tions of 1200 mm long blades, 230V, 50Hz, and 60W. The laboratory model is consisting of a ceiling fan, voltage controller, data acquisition (DAQ) board, and man-machine interface. The real time data acquired with the help of National Instrument Lab-view software and the parameter estimation algorithm is implemented on the real time Matlab software (version7.1) with a 50 ms step size on digital signal processing (DSP) board. The DAQ and DSP boards are installed in a personal com- puter with the corresponding development software. The analog to digital input channel of the DSP board receives the input signal such as fan speed, supply voltage and current. These input variables are used to calculate the system parameters on-line [9] with the help of ANN as shown in Figure 4. The estimated parameters compared with the manufacturer data under normal operating con- ditions. 5. Results and Discussion The random noise is incorporated in the training data to increase the generalization capability (fault tolerant ca- pability) of ANN and the results are shown in Table 2. Input Acquisition of Data using NI-DAQ card Fan system Signal conditioning ANN Learning Algorithm Parameters Erro r Figure 4. Experimental set up of parameter estimation of fan system using ANN Further, it is shown that resistances are somewhat in- creasing while reactances (excluding Xc) are decreasing with increase in supply voltage which is increased from 80V to 230V in the steps of 10 Volts. This is due to the fact that with increase in voltage, the fan temperature gets increased and so does the resistance values while at low voltages, slip being high, the inductive reactance values are high and then with the rise in voltage the speed raises. But these variations get stabilized at near about normal voltage as the fan attains its rated speed. From the results shown in Figure 5 and Table 2 the Table 2. Parameter estimation using ANN Fan Parameters in Ohms Test data (without noise) Test data (with noise) Manufacturer data Rs 2.0194 2.1835 2.02 Xs 2.7095 2.7975 2.79 Xm 106.7839 104.8351 106.8 Rr 4.1199 3.9647 4.12 Xr 2.1188 1.9660 2.12 Xc 6.9993 6.8436 7.00 0 10 20 2.035 2.03 2.025 2.02 2.015 2.805 2.8 2.795 2.79 2.785 2.78 RsXs Xm 0 10 20 0 10 20 106.86 106.84 106.82 106.8 Xc RrXr 4.13 4.125 4.12 4.115 2.14 2.135 2.13 2.125 2.12 0 10 200 10 20 0 10 20 Xc 2.14 2.135 2.13 2.125 2.12 Figure 5. Variation in system parameters Copyright © 2010 SciRes JILSA  Parameters Estimation of an Electric Fan Using ANN 47 Figure 6. Comparison of simulated and experimental fan speed at different voltages system parameters are very much dependent upon the operating conditions i.e. the applied voltage, temperature, humidity etc. If there is any abnormality in the system, the parameter changes to a great extent and that abnor- mality could be recognized and system may be protected from the major fault. The simulation and experimental results for the fan system are compared as shown in Fig- ure 6. 6. Conclusions In this paper, the mathematical model for fan system is developed and matlab code is written to validate it. Then the experimental data acquired using LABVIEW from fan system in the laboratory and used to estimate the system parameters using ANN approach under different operating voltages and the results have been compared. The results show that the ANN on-line parameter estima- tion method is fairly good and quite useful for monitor- ing the system conditions. It is clear from the experimental results that the per- formance characteristics obtained from experimental data and those from the simulated data using artificial neural networks (ANN) are in close proximity. So the method used for parameter estimation, performance prediction is almost accurate for all practical purposes. As the model development is based on the dimen- sional information, the method is applicable to different types of electric fans (i.e., different frame sizes as well as of different ratings). Even at the design stage the model can be applied to estimate the performance of the electric fans and to check whether the performance deviates from the desired one. The developed technique will be very useful to designers and manufacturers. The work may be extended to improve the results by incorporating system nonlinearities in the model and pre-processing the experimental data for ANN training. Also suitable control system as well as the protection system may be developed based on on-line parameter variations. REFERENCES [1] A. Arredondo, R. Partha, and W. Erin, “Implementing PWM fan speed control within a computer chassis power supply,” 20th Annual IEEE Applied Power Electronics Conference and Exposition, pp. 148–151, March 2005. [2] I. Takahashi and T. Noguchi, “A new quick-response and high-efficiency control strategy of induction motor,” IEEE Transactions on IA, Vol. 22, No. 5, pp. 820–827, September/October 1986. [3] S. F. Wang, R. Y. Chen, X. Fang and J. B. Wang, “Re- search on adjust speed control system of partial fan,” IEEE International Conference on Automation and Logis- tics, pp. 1053–1057, August 2007. [4] AMCA Publication 203–90, “Field performance meas- urement of fan systems,” 0203X90A–S Arlington Heights, Ill.: the Air Movement and Control Association Interna- tional, Inc. AMCA, 1990. [5] B. K. Bose, “Expert systems, fuzzy logic, and neural network applications in power electronics and motion control,” Proceedings of IEEE, Vol. 82, pp. 1303–1323, August 1994. [6] M. Calvo and O. P. Malik, “Machine parameter estima- tion as a pattern recognition problem,” Proceedings of IEEE Power Engineering Society Summer Meeting, Vancouver, BC, Canada, July 15th–19th, 2001. [7] D. K. Chaturvedi, “Soft computing techniques and its applications in electrical engineering,” Springer, 2008. [8] G. Daniel “Principles of artificial neural networks,” World Scientific Publishing Co. Pte. Ltd. [9] R. D. Fard, M. Karrari, and O. P. Malik, “Synchronous generator model identification for control application us- ing Volterra series,” IEEE Transactions on Energy Con- version., Vol. 20, No. 4, pp. 852–858, December 2005. [10] K. S. Fu, Ed., “ANN application of pattern recognition,” Boca Raton, FL: CRC, 1982. [11] H. Tsai, A. Keyhani, J. Demcko, and R. G. Farmer, “On- line synchronous machine parameter estimation from small disturbance operating data,” IEEE Transactions on Energy Conversion, Vol. EC–10, pp. 25–36, March 1995. [12] H. B. Karayaka, A. Keyhani, G. T. Heydt, B. L. Agraval, and D. A. Selin, “Synchronous generator model identifi- cation and parameter estimation from operating data,” IEEE Transactions on Energy Conversion, Vol. 18, No. 1, pp. 121–126, March 2003. [13] M. Karrari and O. P. Malik, “Identification of physical parameters of a synchronous generator from on-line measurements,” IEEE Transactions on Energy Conversion, Vol. 19, No. 2, pp. 407–415, June 2004. Copyright © 2010 SciRes JILSA  Parameters Estimation of an Electric Fan Using ANN Copyright © 2010 SciRes JILSA 48 [14] G. Kenne, T. Ahmed-Ali, L. F. Lagarrigue, and H. Nkwawo, “Nonlinear systems parameters estimation us- ing radial basis function network,” Control Engineering Practice, Vol. 14, No. 7, pp. 819–832, 2006. [15] W. S. Meisel, Computer-Oriented Approaches to Pattern Recognition, Academic Press, New York, 1972. [16] D. Pitis, “Energy efficient single stage axial fan (ENEF),” IEEE Canada Electrical Power Conference, pp. 280–285, October 2007. [17] D. K. Chaturvedi, “Modeling and simulation of systems using matlab/simulink@,” CRC Press, U.K., 2009. |