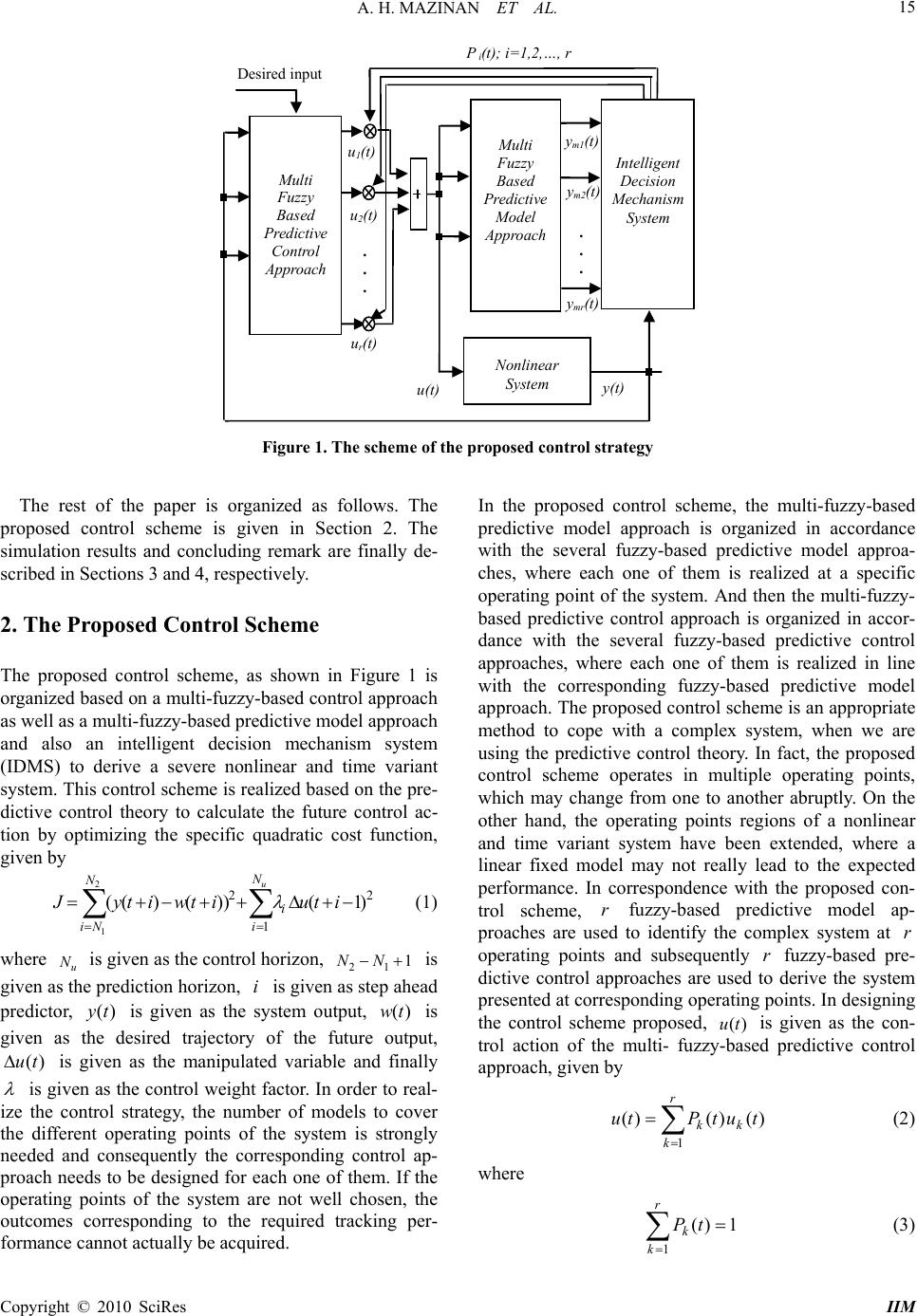

Intelligent Information Management, 2010, 2, 14-20 doi:10.4236/iim.2010.21002 Published Online January 2010 (http://www.scirp.org/journal/iim) Copyright © 2010 SciRes IIM A New Approach to Intelligent Model Based Predictive Control Scheme A. H. MAZINAN1, M. F. KAZEMI2 1Electrical Engineering Department, Islamic Azad University (IAU), South Tehran Branch, Tehran, Iran 2Electrical Engineering Department, Islamic Azad University (IAU), Lahijan Branch, Lahijan, Iran Emails: mazinan@azad.ac.ir, mfkazemi@iau-lahijan.ac.ir Abstract This paper describes a new approach to intelligent model based predictive control scheme for deriving a complex system. In the control scheme presented, the main problem of the linear model based predictive control theory in dealing with severe nonlinear and time variant systems is thoroughly solved. In fact, this theory could appropriately be improved to a perfect approach for handling all complex systems, provided that they are firstly taken into consideration in line with the outcomes presented. This control scheme is or- ganized based on a multi-fuzzy-based predictive control approach as well as a multi-fuzzy-based predictive model approach, while an intelligent decision mechanism system (IDMS) is used to identify the best fuzzy-based predictive model approach and the corresponding fuzzy-based predictive control approach, at each instant of time. In order to demonstrate the validity of the proposed control scheme, the single linear model based generalized predictive control scheme is used as a benchmark approach. At last, the appropriate tracking performance of the proposed control scheme is easily outperformed in comparison with previous one. Keywords: multi-fuzzy-based predictive control approach, multi-fuzzy-based predictive model approach, intelligent decision mechanism system 1. Introduction Nowadays, the linear model based predictive control theory has been widely used in so many applications, in the past two decades. This control theory guarantees that the future error signals will be approached to zero by optimizing the specific cost function, if the linear model approximation of a complex system could accurately be identified. Based on the matter presented here, a complex system cannot actually be dealt with, while we are using the linear model based predictive control theory. In order to improve the present results, a new control scheme is now proposed to derive a severe nonlinear and time variant system in accordance with this control theory. The advantage of the proposed scheme is to realize an intelligent control method in the absence of any linear models of the system. In the control scheme proposed, a multi-fuzzy-based predictive model-predictive control approach so called MFPMPC scheme in this paper is organized to cope with an industrial tubular heat ex- changer system as a severe nonlinear and time variant system. To realize the control scheme, at first, fuzzy-based predictive model approach and subsequently fuzzy-based predictive control approach need to be cor- respondingly realized at a specific operating point of the system. After that, the multi-fuzzy-based predictive model approach and then the multi-fuzzy-based predic- tive control approach are correspondingly implemented on the system to cover all the operating points. The rest of the proposed control algorithm is based on an intelli- gent decision mechanism system (IDMS) realization to choose the best fuzzy-based model approach and also the corresponding fuzzy-based predictive control approach, at each instant of time. In fact, the system behavior is fully covered via the IDMS, provided that the multi- fuzzy-based predictive model approach as well as the multi-fuzzy-based predictive control approach is suitably organized. It means that the best fuzzy-based predictive model approach and therefore the best fuzzy-based pre- dictive control approach are accurately identified by the IDMS, at each instant of time, while the system parame- ters are abruptly varied with respect to time [1–11]. Based on the control strategy, the new predictive control could be so flexible to derive a highly nonlinear system in association with the traditional linear model based predictive control theory.  A. H. MAZINAN ET AL. 15 u (t) u 1 (t) Desired input u 2 (t) Multi Fuzzy Based Predictive Control Approach y m1 (t) y m2 (t) . . . y m (t) Multi Fuzzy Based Predictive Model Approach Intelligent Decision Mechanism System u(t) y(t) Nonlinear System i (t); i=1,2,…, r . . . Figure 1. The scheme of the proposed control strategy The rest of the paper is organized as follows. The proposed control scheme is given in Section 2. The simulation results and concluding remark are finally de- scribed in Sections 3 and 4, respectively. 2. The Proposed Control Scheme The proposed control scheme, as shown in Figure 1 is organized based on a multi-fuzzy-based control approach as well as a multi-fuzzy-based predictive model approach and also an intelligent decision mechanism system (IDMS) to derive a severe nonlinear and time variant system. This control scheme is realized based on the pre- dictive control theory to calculate the future control ac- tion by optimizing the specific quadratic cost function, given by 2 1 2 1 2)1())()(( N Ni N i iituitwityJ u (1) where is given as the control horizon, u N1 12 NN )(tw is given as the prediction horizon, is given as step ahead predictor, is given as the system output, is given as the desired trajectory of the future output, is given as the manipulated variable and finally i )(ty )(tu is given as the control weight factor. In order to real- ize the control strategy, the number of models to cover the different operating points of the system is strongly needed and consequently the corresponding control ap- proach needs to be designed for each one of them. If the operating points of the system are not well chosen, the outcomes corresponding to the required tracking per- formance cannot actually be acquired. In the proposed control scheme, the multi-fuzzy-based predictive model approach is organized in accordance with the several fuzzy-based predictive model approa- ches, where each one of them is realized at a specific operating point of the system. And then the multi-fuzzy- based predictive control approach is organized in accor- dance with the several fuzzy-based predictive control approaches, where each one of them is realized in line with the corresponding fuzzy-based predictive model approach. The proposed control scheme is an appropriate method to cope with a complex system, when we are using the predictive control theory. In fact, the proposed control scheme operates in multiple operating points, which may change from one to another abruptly. On the other hand, the operating points regions of a nonlinear and time variant system have been extended, where a linear fixed model may not really lead to the expected performance. In correspondence with the proposed con- trol scheme, fuzzy-based predictive model ap- proaches are used to identify the complex system at operating points and subsequently fuzzy-based pre- dictive control approaches are used to derive the system presented at corresponding operating points. In designing the control scheme proposed, is given as the con- trol action of the multi- fuzzy-based predictive control approach, given by )(tu )()()( 1 tutPtu k r k k (2) where 1)( 1 r k ktP (3) Copyright © 2010 SciRes IIM  A. H. MAZINAN ET AL. 16 and is given as the number of the operating points of the system. Hereinafter, and are given as the appropriate weight and the control action of the local fuzzy-based predictive control approach, respec- tively. )(tP k)(tuk th k Realization of the fuzzy based predictive control ap- proach, the fuzzy based predictive model approach and finally the IDMS are now described in the proceeding sections. 2.1. The Fuzzy-Based Predictive Control Approach The fuzzy-based predictive control approach is given as one of the local controllers in the multi-fuzzy-based pre- dictive control approach, in the control scheme presented. The main concept in realizing the fuzzy-based predictive control approach is described by the following fuzzy rule base i jk i jmk i j FistuTHEN EisNtyandDisNtwIFiRule )( )()(: where is given as the rule number, is given as the fuzzy set number and finally , , are given as the input-output fuzzy sets. In this control strategy, denotes the desired trajectory of the future output, denotes the fuzzy-based predictive model approach output and finally denotes the manipulated variable of the fuzzy-based predictive control approach, which is directly related to the follow- ing future error signal i ) y j F (uk i j D th k i j E i j )t (Ntwth k )( Nt mk )()()( NtyNtwNte k mk (4) The fuzzy set of the fuzzy-based predictive control ap- proach is now shown in Figures 2(a) and 2(b). Moreover, the control action could easily be acquired by the fol- lowing )( 1 1 )( 1tu z tu kk (5) 2.1.1. Fuzzy Sets Tuning In the control scheme proposed, the fuzzy sets used in realizing the multi-fuzzy-based predictive control sche- me are tuned in an offline manner. In fact, the proposed tuning algorithm which is already based on the GA algo- rithm is realized for all the fuzzy-based predictive con- trol approaches. With this purpose, these fuzzy sets are first parameterized, as shown in Figure 3 using . In this way, some populations are chosen, while the first population has nine chromosomes ( ,,,iiicba 3,1,3,2,1; jid j 9,...,2,1; jVj ,,,{ 321 j jj ggg ), which is now realized by the following forms },,,,,,,114 1098765jj gggggggg jjjjjj j where we could have the following j j j j dg cg bg ag 110 17 14 11 j j j j j jjj j jj djd cjcjc bjbjb a j a j a dg cgcg bgbg agag 31 321 321 321 311 3928 3625 3322 (6) In such a way, with a specific mutation rate; 6.0 Pc , the 2nd population have five chromosomes and the 3rd population have three chromosomes. Also the 4th popula- tion has two chromosomes and the 5th populations have )(( Ntw ,))(Ntymk / 1 / 2 / 3 D/ 4 D/ 5 (a) 1 0 -5 0 5 1 F 2 F 3 ) k u( (b) Figure 2. (a) The input fuzzy sets used in the fuzzy- based predictive control approach; (b) The output fuzzy sets used in the fuzzy- based predictive control approach 1 0 )(k u 2312 cada 1 F 2 F 3 Figure 3. The fuzzy sets used in the tuning algorithm 0 70 1 0 Copyright © 2010 SciRes IIM  A. H. MAZINAN ET AL. 17 one chromosome. Obviously, the fuzzy sets parameters could be optimized to appropriate values by the superior genes. 2.2. The Fuzzy-Based Predictive Model Approach The fuzzy-based predictive model approach is realized as one of models in the multi-fuzzy-based predictive model approach. In case of this approach, )( tu is given as a valid input of the system, while τ is given as its delay. Also, is given as the fuzzy-based model output. The schematic of this approach is shown in Fig- ure 4. Here, the fuzzy-based model#N could be placed in sequence with the fuzzy-based model#(N-1) to provide the fuzzy-based predictive model approach. In fact, the prediction of model output could be improved, while the number of the present fuzzy-based models is increased. The fuzzy rule based for this approach is now given as follows )(tymk th k i jmk i jmk i j CistyTHEN BistyandAistuIFiRule )( )1()(: where is given as the rule number, is given as the fuzzy set number and finally , , are given as the input-output fuzzy sets, as shown in Figure 5. ij i j B i j Ai j C 2.3. The IDMS Realization In the control scheme proposed, the best fuzzy-based predictive model approach in the multi-fuzzy-based pre- dictive model approach is accurately identified by using the IDMS, at each instant of time. Now, by assuming only three fuzzy-based predictive model approaches, for simplicity, the IDMS can be summarized as follows Defining the specific performance indices; itJi);( 3,2,1 , for each one of the fuzzy-based predictive model approaches, correspondingly, given by 0 0 )()()( 0 2 )( 2 deetetJ i t ii (7) where )()()( tytyte ii (8) In the IDMS proposed, , and are given as the weighting factors on the instantaneous measures, the long term accuracy and the forgetting factor, respec- tively. Defining the input-output fuzzy sets, as shown in Figure 6. Defining the fuzzy rules based, which can be given by the following 3 3 3 3 3 2 3 1 2 2 2 3 2 2 2 1 1 1 1 3 1 2 1 1 )( )()()( :3# )( )()()( :2# )( )()()( :1# P JJJ P JJJ P JJJ ListPTHEN SistJANDListJANDListJIF Rule ListPTHEN ListJANDSistJANDListJIF Rule ListPTHEN ListJANDListJANDSistJIF Rule 3. Simulation Results In order to verify the applicability of the proposed con- trol scheme so called MFPMPC scheme in this paper, an industrial tubular heat exchanger system is used to con- trol [1–11]. To analyze the proposed control scheme in comparison with other control techniques which are fully investigated by the Authors in the several publications, this complex system is realized the same specification as these research works, where all the research papers could easily be found by the readers in detail. z -1 y m k (t+1) y m k (t +N -1) . . . z -1 Fuzzy Based Model#1 )( u Fuzzy Based Model#N Figure 4. The scheme of the fuzzy-based predictive model approach 0 70 /B/ 1 … A/B/C 5 … A/B/C 9 ))(),1(),(( NtyNtytu k m k m 1 0 Figure 5. The fuzzy sets used in fuzzy-based predictive model approach Copyright © 2010 SciRes IIM  A. H. MAZINAN ET AL. 18 i J i J i JLMS 1 0 0 1 )(i 1 0 i P i P i PLMS 0 1 )( i P Figure 6. The fuzzy sets used in the IDMS With this purpose, we have carried out the MFPMPC scheme for this system using the Simulink-Matlab pro- gramming language, while the multi-fuzzy-based predic- tive model approach is organized based on the three fuzzy-based predictive model approaches and subse- quently the multi-fuzzy-based predictive control ap- proach is correspondingly organized based on the three fuzzy-based predictive model approaches. In these simu- lations, the tracking performance of the MFPMPC scheme is given in Figure 7, while the single model lin- ear generalized predictive control entitled SLMGPC scheme is used as a benchmark approach here. At first, the desired trajectory of the future output is given as 60oC at 5 sec., while it is abruptly varied to 55oC and also 40oC at 54 sec. and 104 sec., respectively. In these simulations, the SLMGPC scheme is carried out by the following control parameters 3 31 12 u N NN (9) And the CARIMA model is also given by )( )( )1()()()( 1 11 q ke kuqBkyqA (10) 4;...1)( 1 1 1 pqaqaqA p p (11) pmqbqbbqB m m ;...)( 1 10 1 (12) where its coefficients are identified using the RLS algo- rithm, as tabulated in Table 1. Afterwards, the weight signals which are all resulted from the proposed IDMS is shown in Figure 8. In such a case, the multi-fuzzy-based Figure 7. The scheme of MFPMPC scheme tracking perfor- mance in comparison with the SLMGPC scheme predictive model approach outputs are given in Figure 9 as well. Hereinafter, the manipulated variable signals and the corresponding control actions are all given in Figures 10 and 11, respectively. Here the control actions are all multiplied by its weights, in these figures. As is easily obvious from the outcomes, the tracking performance of the MFPMPC scheme is quite outperformed with respect to its benchmark approach. Figure 8. The scheme of the MFPMPC weight signals, given by the proposed IDMS [The first diagram is related to , the second diagram is related to and the third diagram is finally related to ] )( 1tP )( 2tP )( 3tP Copyright © 2010 SciRes IIM  A. H. MAZINAN ET AL. 19 Figure 9. The scheme of the MFPMPC models outputs, given by the multi-fuzzy-based predictive model approach [The first diagram is related to , the second diagram is related to and the third diagram is finally related to ] m1 y(t) m2 y(t) m3 y(t) Figure 10. The scheme of the MFPMPC manipulated vari- ables [The first diagram is related to , the second- diagram is related to and the third diagram is fi- nally related to ] )( 1tu )( 2tu )( 3tu Figure 11. The scheme of the MFPMPC control actions [The first diagram is related to , the second diagram is related to , the third diagram is related to and finally the fourth diagram is finally related to ] )( 1tu )( 2tu )( 3tu )t(u 4. Conclusions A main problem in realizing the linear model based pre- dictive control theory to derive a severe nonlinear system has been thoroughly solved, in this paper. Based on the proposed control strategy so called MFMPMC scheme by the Authors, a nonlinear system must first be repre- sented via the multi-fuzzy-based predictive model ap- proach. And then the multi-fuzzy-based predictive con- trol approach is correspondingly realized to derive the nonlinear system presented. Table 1. The coefficients of the CARIMA model j a j b 1 -0.9933 0.2506e-3 2 -0.4342 0.3519e-3 3 0.0069 0.5283e-3 4 0.4219 0.1830e-3 Copyright © 2010 SciRes IIM  A. H. MAZINAN ET AL. Copyright © 2010 SciRes IIM 20 Besides, the intelligent decision mechanism system (IDMS) is used to identify the best fuzzy-based predic- tive model approach and the corresponding fuzzy-based predictive control approach, at each instant of time. The advantage of the proposed control scheme over other related control techniques is to realize the strategy in the absence of any linear model approximation of the com- plex system. It points out that the proposed MFPMPC scheme is the generalized version of the traditional model based predictive control theory. Also the present control structure aims us to develop it for all the highly nonlinear and time variant systems in both real and aca- demic environments. 5. References [1] A. H. Mazinan and M. F. Kazemi, “An efficient solution to load‐frequency control using fuzzy‐based predictive scheme in a two–area interconnected power system,” The 2nd International Conference on Computer and Automa- tion Engineering, 2010. [2] A. H. Mazinan and N. Sadati, “An intelligent multiple models based predictive control scheme with its applica- tion to industrial tubular heat exchanger system,” Applied Intelligence, Springer Publisher, DOI 10.1007/s10489- 009-0185-8, in press, 2009. [3] A. H. Mazinan and N. Sadati, “Fuzzy predictive control based multiple models strategy to a tubular heat ex- changer system,” Applied Intelligence, Springer Publisher, DOI 10.1007/s10489-009-0163-1, in press, 2009. [4] A. H. Mazinan and N. Sadati, “On the application of fuzzy predictive control based on multiple models strat- egy to a tubular heat exchanger system,” Transactions of the Institute of Measurement & Control, SAGE Publisher, DOI 10.1177/0142331209345153, in press, 2009. [5] A. H. Mazinan and A. H. Hosseini, ”Application of intel- ligent based predictive scheme to load-frequency control in a two-area interconnected power system,” Applied In- telligence, in press, 2009. [6] A. H. Mazinan and N. Sadati, “A comparative study on applications of artificial intelligence based multiple mod- els predictive scheme to industrial tubular heat exchanger system,” ISA Transactions, Elsevier Publisher, in press, 2009. [7] A. H. Mazinan, N. Sadati, and H. Ahmadi-Noubari, “A case study for fuzzy adaptive multiple models predictive control strategy,” in Proc. of IEEE World Symposium on Industral Electronics, pp. 1172–1177, 2009. [8] A. H. Mazinan and N. Sadati,”Fuzzy multiple models predictive control of tubular heat exchanger,” in Proc. of IEEE World Congress on Computational Intelligence, pp. 1845–1852, 2008. [9] A. H. Mazinan and N. Sadati, “Multiple modeling and fuzzy predictive control of a tubular heat exchanger sys- tem,” Transactions on Systems and Control, Vol. 3, pp. 249–258, 2008. [10] A. H. Mazinan and N. Sadati, “Fuzzy multiple modeling and fuzzy predictive control of a tubular heat exchanger system,” International Conference on Application of Electrical Engineering, pp. 77–81, 2008. [11] A. H. Mazinan and N. Sadati, “Fuzzy multiple modeling and fuzzy predictive control of a tubular heat exchanger system,” International Conference on Robotics, Control and Manufacturing Technology, China, pp. 93–97, April 2008.

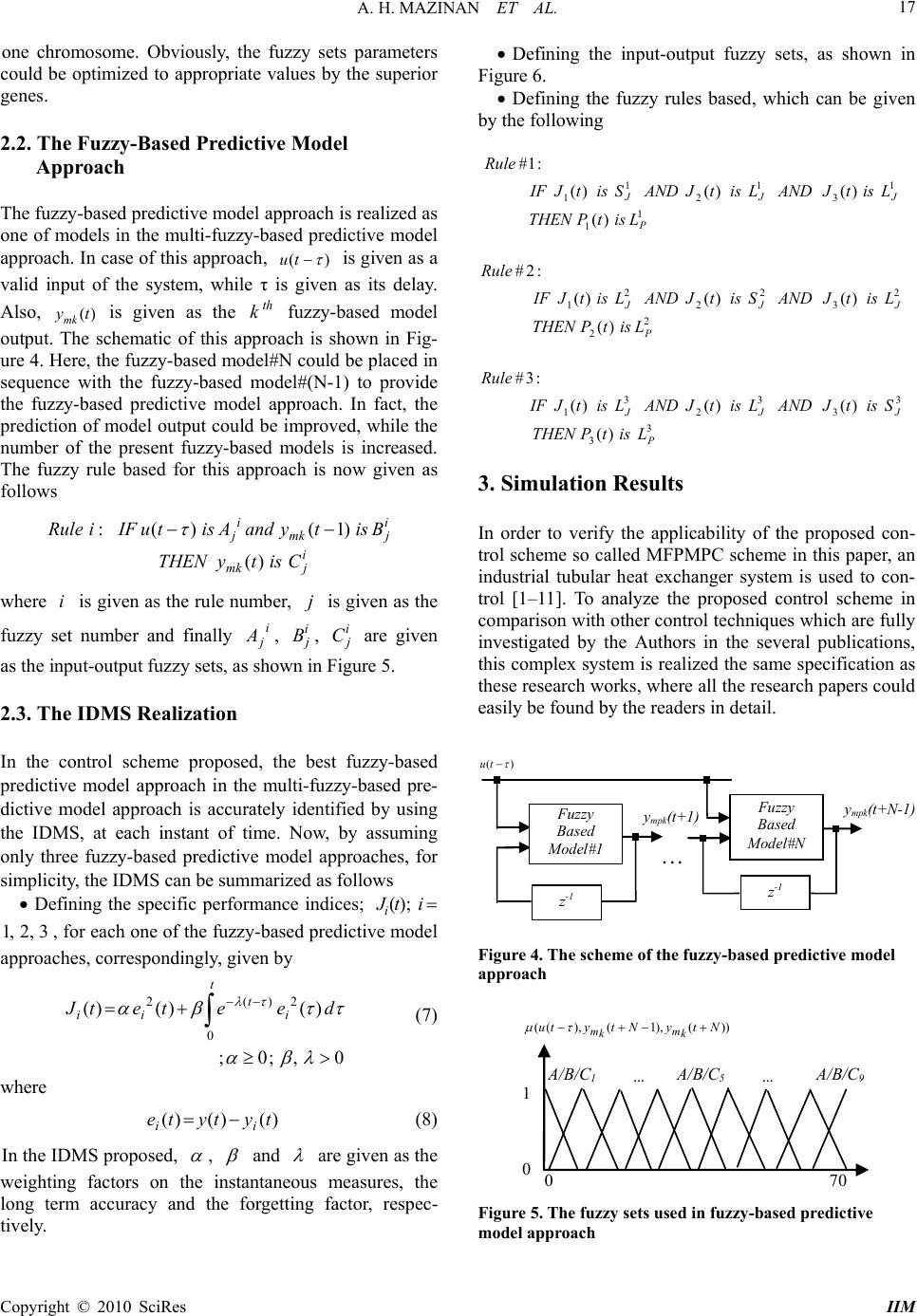

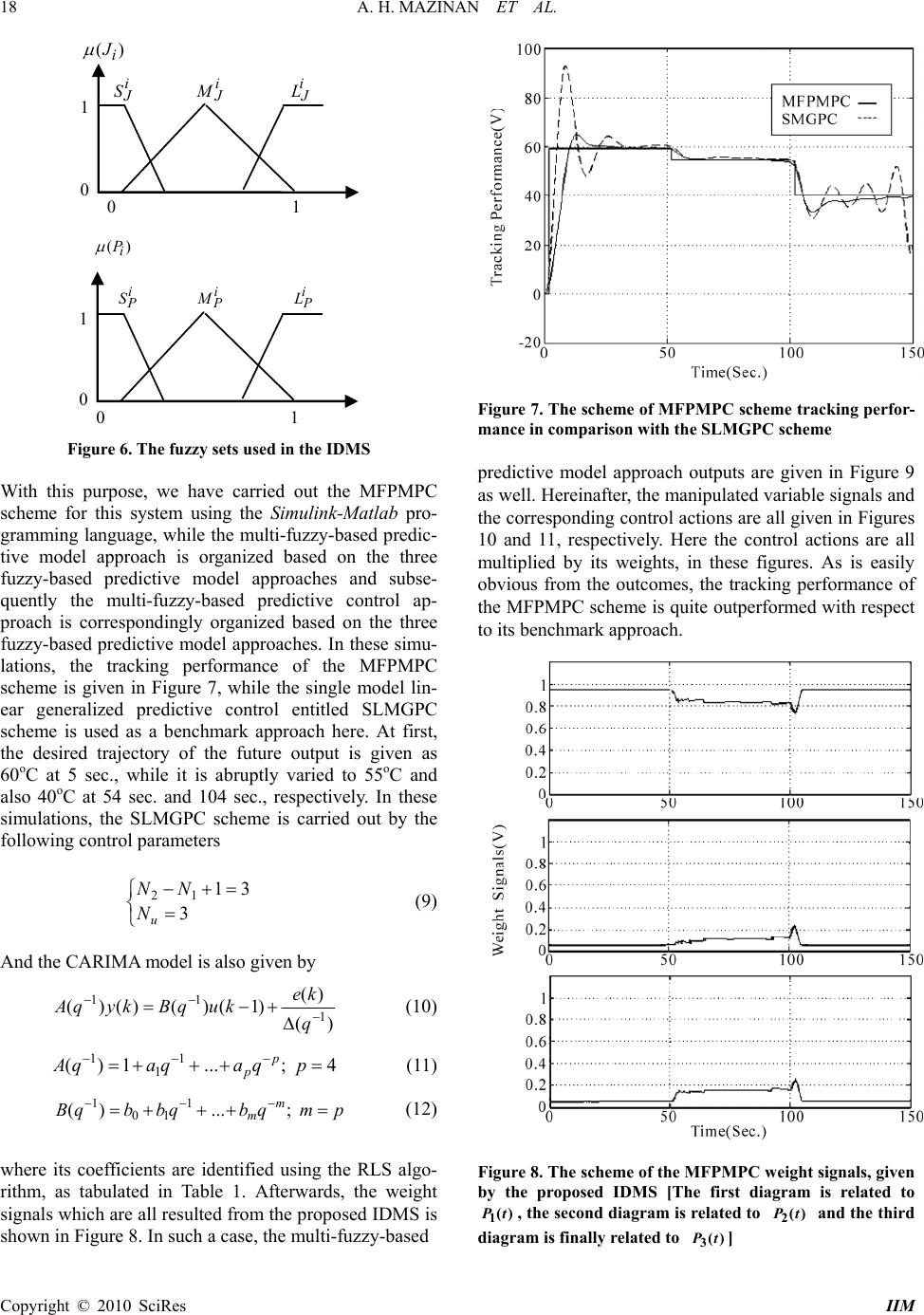

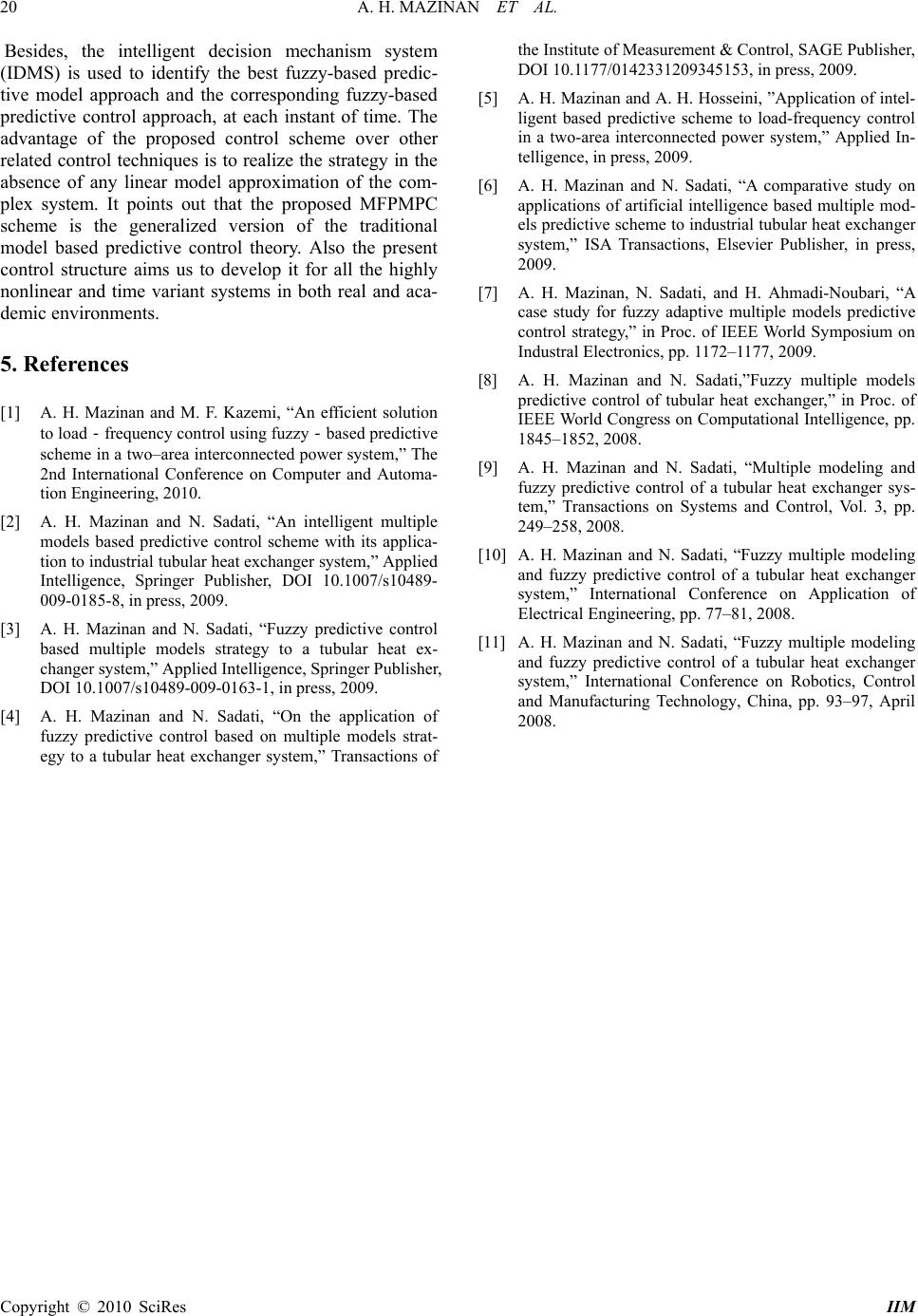

|