Engineering

Vol.5 No.1(2013), Article ID:26542,7 pages DOI:10.4236/eng.2013.51012

Study of the Process of Extraction and Refining of Pequi (Caryocar brasiliense Camb.) Oil

School of Engineering, Federal University of Grande Dourados, Dourados, Brazil

Email: *pierremartins@ufgd.edu.br

Received October 12, 2012; revised November 15, 2012; accepted November 30, 2012

Keywords: Cerrado Fruits; Processing Oils; Control Parameters

ABSTRACT

Pequi fruit is a characteristic of Central Brazil with high oil content. This study evaluated the extraction of oil from the fruit portions by chemical and physical methods and determined an optimal condition for neutralization and degumming of oil extracted by solvent pequi pulp. The solvent extraction of oil was better than the mechanical pressing method. The oil extracted by solvent of the pulp pequi had a higher yield compared to other portions of the fruit. The peels and impurities material of fruit has a negligible amount of oil. The oil extracted from the pulp has better commercial characteristics in relation to the oil obtained from almonds. The operating parameters (temperature and time) studied at the stage of degumming the crude oil were significant at the 5% significance. The Increase in temperature decreases the values of acidity and iodine of the degummed oil.

1. Introduction

The pequi (Caryocar brasiliense Camb.) is a native species in the Brazilian Cerrado region and its fruit, pequi, contains about 20% oil compared to fresh fruit rich in vitamin A. Thus, pequi oil production in pilot scale is a way to add value to regional raw material of the Cerrado’s Brazil and development of cooperatives of farmers and agribusinesses in the region.

There are two traditional methods for the extraction of vegetable oils: physical and chemical or solvent. The physical extraction of vegetable oil is carried out by mechanical pressing pressure constant, reducing the oil content in the cake pressed to 10% by weight of oil. In oil extraction solvent, the lipid fraction is removed by means of an apolar solvent, usually hexane, whose boiling point is 70˚C [1].

The literature suggests that the processes of extraction of oleaginous legumes (soybean, sunflower, etc.). Have the combination of two methods: pressing and solvent extraction. However, some studies of oil production plant designed to minimize changes or loss of functional activity of components of the raw material using the physical method of oil extraction at room temperature [2,3]. Thus, it is important to elucidate the possible qualitative and quantitative differences of extractive methods for mechanical pressing and solvent extraction portion of pequi fruit: pulp, almond hulls and waste fruit peeled.

Any sets quality standards for the marketing of crude vegetable oil in domestic market, such as the value of 5% for oleic acid content of free fatty acids and 10 meq/kg peroxide content [4]. The content of acidity (free fatty acids), peroxide and phosphorus characterize the quality of the oils. The melting point is the temperature at which the fat melts completely, by passing the liquid [1,5]. The moisture content of maximum acceptable vegetable oil refined, bleached and deodorized is in the range of 0.15% and 0.10% [5]. ANVISA [6] takes values up to 1% moisture content in crude oil.

The refining of crude oil is to keep the contents of acidity, peroxides and others in the acceptable range determined by the responsible legislation (national and/or international) ensuring the quality and characteristics of the identity of the merchant to the consumer. The chemical refining is what allows the processing of oil of any kind among the other refining methods used. The chemical or alkali refining includes degumming, neutralization, and washing and clarification (bleaching and filtration) and deodorization. The objective of this study was evaluate the chemical and physical methods of extracting oil from portions of pequi second income in oil content and their physical and chemical characteristics. Maybe to study the operating parameters of temperature and time of degumming crude oil and content of soda added to neutralize the oil degummed by results of free fatty acids and iodine value of the product.

2. Materials and Methods

2.1. Raw Material

The raw material used was matured pequi divided in their constituent parts: peel, pulp, almond and residual material. The fruits were purchased in the retail market in the Grande Dourados (Brazil). The fruits acquired were selected, washed, peeled and placed in polyethylene bags and stored at −18˚C. Pequi oil extracted from the pulp and the almods by the chemical method were stored in glass bottles covered with aluminum foil at refrigeration temperature (10˚C).

2.2. Equipment

The oil extraction solvent was realized in erlenmeyer closed and the separation of miscella (oil/solvent) in a rotary evaporator (model 803/804, Fisatom Scientific Equipment LTDA, Brazil). Tests of refining pulp pequi were realized on an experimental apparatus consisting of kitazato closed (vessel operation) coupled to a vacuum pump and placed on a hot plate with magnetic stirring. Temperature control was accomplished through a thermometer inserted in the vessel operation. A bar magnet located inside the kitazato held stirring of the material.

2.3. Experimental Methodology

2.3.1. Pequi

The fruits acquired were selected, washed, peeled and placed in polyethylene bags and stored at −18˚C. The frozen fruit pulp is removed manually with the stainless steel knives in small rectangular pieces (average area of 1.5 cm by 2.0 cm) of approximately 2 mm thick. The almond’s involucre, denominated of residual material (fruit portion formed by thorns with pulp) was cut into two halves, removing the almonds. The pieces of almond and pulp and residual material (fruit portion formed by thorns with pulp) are stored separately in polyethylene bags and stored at −18˚C. Next, an evaluation of the mass distribution of the fruit in its constituent parts (peel, pulp, almond and residual material) was realized.

2.3.2. Oil Extraction

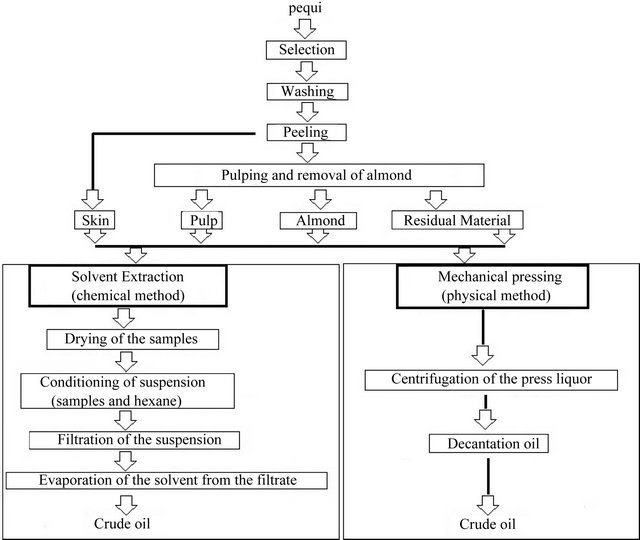

For extraction of the lipid fraction of the pequi portions were used chemical and physical methods separately. Initially were used the chemical method of solvent extraction, adapting the methodology and Mandarino and Roessing [3] for pequi. Before of chemical extraction, the samples were dried in a vacuum oven (model ET- 395/l, Tecnal, Brazil) at 70˚C and absolute pressure of 100 mmHg for 5 hours. Samples of dried peel, pulp, almond and residual material were placed in flasks containing hexane in a ratio of 3:1 by volume of solvent per mass of the sample for 7 days. The suspension of solvent and sample was filtered and miscella obtained was evaporated in a Rota evaporator (Model 803/804, Fisatom Scientific Equipment, Brazil) at 73˚C, 160 mmHg abs and 60 rpm until complete evaporation of the hexane. Thereafter, the extracted oil was placed in a vacuum oven (model ET-395/l, Tecnal, Brazil) at 70˚C and absolute pressure of 100 mmHg for 6 hours to remove the residual solvent. The physical method of pequi oil extraction was performed by mechanical pressing of the pulp in the experimental apparatus developed. The pressed material was centrifuged (centrifuge model Simplex II, ITR, Brazil) for 30 min to separate the lipid and aqueous phases. The separated material was stored in test tubes to the remaining impurities settling for a minimum of two days. Figure 1 shows a schematic diagram of the extractive methods applied.

2.3.3. Proximal Composition Pulp

For proximal composition of the pulp used was a 300 g mass of the sample. The pieces of frozen pulp were crushed in a mixer (Britania, Brazil). The proximal composition of the pulp was performed by analysis of moisture in the vacuum oven (70˚C/100 mmHg abs.) to constant weight, protein (method of semi-micro Kjeldahl), crude fiber (chemical hydrolysis with acid concentrates and soda), lipids (Soxhlet method), ash (muffle furnace at 550˚C), according to the norms of the AOAC [7]. Determination of carbohydrate is obtained by difference.

2.3.4. Characterization of Crude Oil

The crude oil was characterized by the following chemical and physical determinations: content of acidity (% oleic acid), iodine and peroxide, according to the AOCS method [8]; moisture content, using the vacuum oven (model TE-395/l, Tecnal, Brazil) and the AOCS method [8]; density by pycnometry using pycnometers 10 mL; melting point, using the PCM II determiner Tecnopon (Tecnopon Scientific Instrumentation, Brazil).

2.3.5. Refining of Crude Oil

The process of refining oil extracted by solvent pequi pulp was based on methodologies developed by Moraes et al. [9] and Paucar-Menacho et al. [10]. The process basically consists in the steps of degumming and neutralization of the crude oil. The adaptation of these methodologies, according to some parameters and steps of the refining process were evaluated by chemical analyzes of free fatty acid content and iodine value. Study parameters of operation of the refining steps were used:

a) Degumming: Operating temperature (60˚C and 80˚C) and time of agitation of the mixture (10 and 30 min);

b) Neutralization: The amount of sodium hydroxide solution (20% w/w) in excess over the free fatty acid

Figure 1. Flowchart of the steps of the methods of oil pequi extraction.

content of degummed oil (20% in excess and 40% in excess).

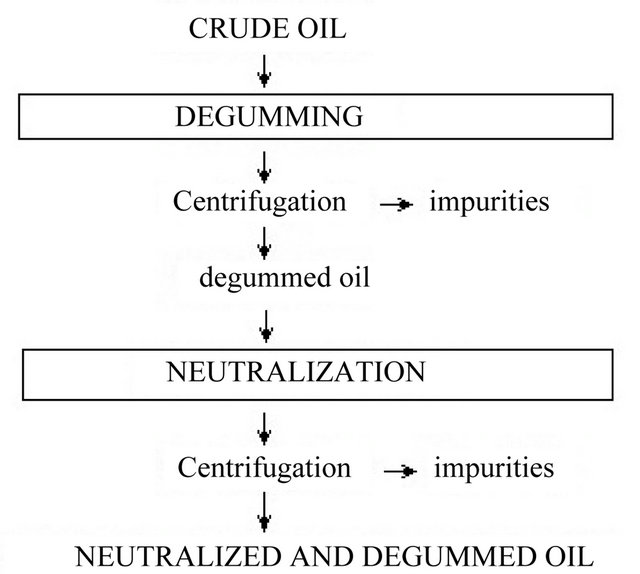

The flowchart in Figure 2 summarizes the main steps of the refining of vegetable oil.

The oil refining pequi initiated by degumming crude oil by the addition of concentrated phosphoric acid (85% w/w), a quantity of 1.0% in relation to the mass of oil, the mixture of oil and place under acid vigorous stirring (agitation level 5 of the heating plate) to a certain temperature range (80˚C to 60˚C) and retention time (10 to 30 min) under study. The process is conducted under vacuum (260 mmHg abs) and the stirring. This step terminated with the centrifugation (centrifuge model Simplex II, ITR, Brazil) of material for 20 min to separate the sludge and oil.

Tests degumming crude oil were performed using an experimental design 22, in according the Barros-Neto et al. [11], and the variables studied were the temperature and retention time or stirring time. The acidity content was used as a parameter of response to the statistical treatment.

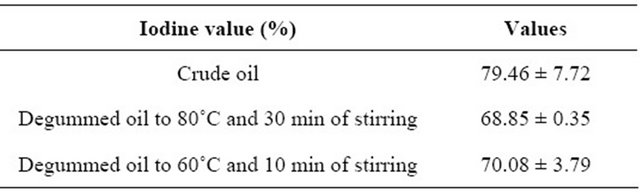

The iodine was used to evaluate the parameters of the tests in the study of the minimum conditions (60˚C and 10 min) and maximum (80˚C and 10 min) of operation.

The degummed oil obtained in the operating condition of smaller amounts of acid value was used in neutralization assays. The degummed oil was neutralized with a

Figure 2. Flowchart for obtaining vegetable oil degummed and neutralized.

solution of sodium hydroxide (20% w/w) with an excess amount of study (20% and 40% by weight) in relation the mass of free fatty acids in the sample. The process was performed under vacuum (260 mmHg abs), and with vigorous stirring (stirring at 5) at 60˚C for 20 min. After this time, stirring was ceased and the temperature rose to 80˚C, order to facilitate the separation of oil and soapstock. The mixture is cooled and the separated oily fraction by centrifugation for 20 min. The acidity content was used to evaluate the performance of the amount of sodium hydroxide added in excess in the neutralized oil.

3. Results and Discussion

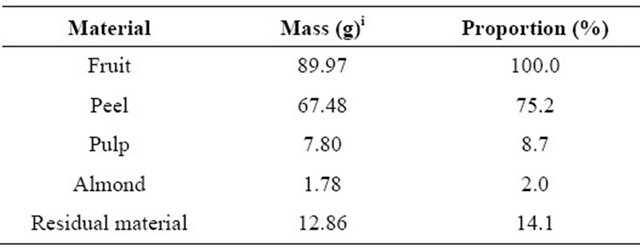

The evaluation results of the mass distribution of the fruit in its constituent parts or portions are shown in Table 1 and are in agreement with the results of Vera et al. [12] and Deus [13].

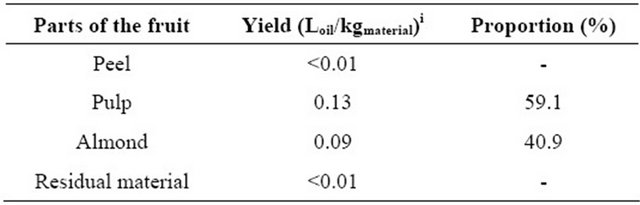

It is noted in Table 1 that the peel and residual material results significant mass of fresh fruit, which corresponds to 90% of its total mass. The fruit has a low income portions of their mass commercially used for oil production (pulp and almond), which represent 10% of fruit mass. However, the pulp and almond pequi have considerable economic interest because of its aromatic compounds and antioxidants associated with their lipid fraction, according to studies by Roesler et al. [14]. The solvent extraction was initially performed by his assured performance and ease of implementation, adapting the methodology and Mandarino and Roessing [3] applied to soybean oil for pequi. Table 2 shows the performance results of the oil obtained from the constituent parts of the fruit by the method of extraction with hexane.

In according the values in Table 2, the pulp showed the highest oil content and the peel and debris showed no significant amount. The pulp and almond are the potential sources of oil from the fruit, their productive portions corresponding to 10% by weight of fruit. The nut has an oil content displayed next to the pulp. But shows a marked disadvantage quantitative mass in relation to the pulp. It accounts for 2% by weight of the portion of the fruit pulp as corresponds to 8.7%, i.e. a mass of about four times lower or 20% of the mass production of the portion of the oil fresh fruit. The yield of the mass of material compared to liter of oil obtained is relatively low for the pulp, it requires from 7.7 kg of pulp to obtain

Table 1. Mass of fresh fruit pequi and the constituent parts.

iMedia of 50 fruit.

Table 2. Yield of oil obtained by solvent extraction parts of the pequi.

iVolume oil obtained by the mass of material.

1 liter of oil pequi. This mass ratio has an even lower to result almond, for using 11.11 kg of material to produce 1 liter of oil. The production of almond oil pequi can be justified by the difficulty of marketing this material in nature.

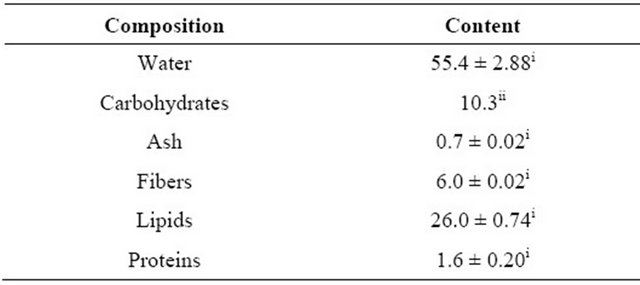

The chemical composition of pequi pulp is important because the pulp is the portion of greatest interest for the production of production pequi oil. The chemical composition of the proximal result is shown in Table 3.

The results in Table 3 are consistent with the Deus [13] and Vera et al. [12]. The method of Soxhlet extraction with hot solvent used for the determination of lipid was obtained a higher yield in relation to the cold extraction method and the results were shown in Table 2. Probably due to increased contact time of the material-solvent method proposed by Mandarino and Roessing [3] to give an oil content similar to that obtained by the Soxhlet extractor. The use of heating oil extraction for human consumption should be avoided because it degrades the unsaturated fatty acids, beneficial public health.

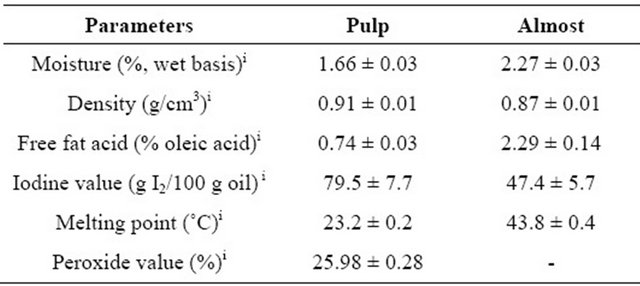

The results of the physical and chemical characteristics of the oil obtained in the solvent extraction of the pulp and almonds are shown in Table 4.

The pulp pequi presented an oil of better quality commercial and nutritional product in relation to the almond, according to the results in Table 4. The lower values of moisture and acidity and higher iodine value of the pulp oil represent, respectively, a product richer in lipids, more stable (less prone to oxidation) and higher content

Table 3. Composition proximal chemical pulp pequi (g/100g sample).

iMedia of three determinations; iiValor obtained by difference.

Table 4. Physical and chemical characterization of the pulp and almond oil pequi obtained with solvent extraction.

iMedia two determinations.

of unsaturated fatty acids (monounsaturated probably). These results are consistent with the values of the Deus [13] and the difference between the results of acidity and iodine value of the product of the pulp and almond may be related to their fatty acid compositions. The amount of the peroxide pulp oil obtained was found to be similar to Deus [13]. The amount of the peroxide found indicates that the oil has a degree of oxidation due to heating of the miscella (oil-solvent mixture) used in the extraction solvent. For commercial oils the peroxide must not exceed 0.01%, as Malacrida [15]. The moisture content is higher than recommended for commercial refined oils as Rossell and Pritchard [2], which can be associated with handling of material during the extraction process. The commercial refined vegetable oil has a negligible moisture content due to the refining steps occur under heat and vacuum and centrifugation, which dramatically reduces the moisture content of the crude oil. The step of deodorizing vegetable oil, for example, is performed at temperatures close to 100˚C and pressures up to 160 mmHg abs. The density value of crude oil from the pulp is consistent with the literature information [4]. The result of iodine value of crude oil (range 75 to 80 g I2/100 g oil) is that it presents a considerable content of unsaturated fatty acids, probably of monounsaturated fatty acids as Roesler et al. [14].

The identification of the melting point of the almond and pulp pequi oils important because the pulp oil solidified fully at ambient temperature (25˚C) as almond oil remained liquid. This fact prevented the extraction process by cold pressing of the pulp pequi, which is the largest and most productive portion of the fruit production of oil.

The physical method of extraction was not successful by pressing through the experimental apparatus developed. In presses of pequi pulp at ambient temperature was an insignificant amount of collected material. The pulp was heated in a water bath at 60˚C and pressed, however the obtained material is presented as a paste. After successive centrifugations and prolonged settling, the supernatant appeared as a dense fluid, such as “folder”. It was hoped that the degumming of this dense material would make a separation of the lipid content, but the result of tests degumming was the solidification of the “folder” in vessel operation. Thus, the extraction method of pressing needs to be improved in a later study in more detail.

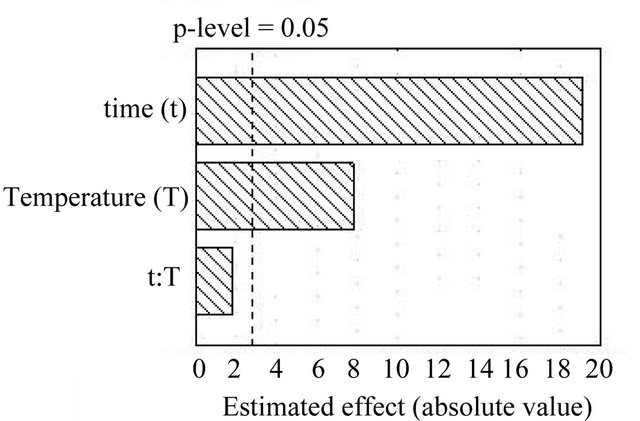

The material used for tests of refining the oil was pulp pequi. The amount of almond oil obtained was insufficient for studying the stages of its refinement. The refining of the pulp oil pequi initially studied degumming step in the screening of operating parameters: temperature and stirring time. The experimental design used 22 complete a significance level of 5% (p-level < 0.05) for statistical analysis of study parameters. Figure 3 shows the Paretto of acidity (% oleic acid) the degummed oil pequi pulp.

The operating parameters of the stirring time and temperature were significant at a significance level of 5%. However, the effect of shaking time found to be more important for the acid. The effect of heating temperature despite being significant at 5% is 2.5 times lower than that found for the stirring time. The first order interaction between the factors temperature and stirring time was not significant at the significance level arbitrated.

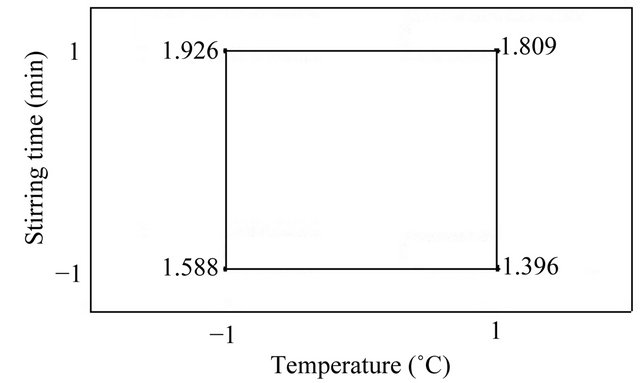

It was observed during the testing of degumming the oil after the addition of phosphoric acid to the crude oil. The mixture became hazy, forming a dark fraction dispersed homogeneously in the oil. With the heating and stirring the mixture of this fraction were grouped dark, forming a dark sludge. The increased temperature (60˚C to 80˚C) afforded a dark fraction greater aggregation and greater separation of oil and soap stock. The higher the stirring time also promoted increased sludge formation in the test with higher temperature (80˚C), but trials at 60˚C and 30 min fraction remained dispersed in the dark oil. The best operating condition degumming was one that showed the lowest values for the acid degummed oil. The results of the tests the acid degumming the oil of the pulp are presented in square coded response of Figure 4. The average acid value of each test are in their vertices: −1

Figure 3. Paretto diagram for acidity of degumming the oil pequi pulp.

Figure 4. Square response to the response for the acidity of the experimental design of degumming the oil pequi pulp, and the indices: −1 = tests at 60˚C and 10 min; +1 = test at 80˚C and 30 min.

represents the index values of 60˚C and 10 min values +1 and +1 is equal the 80˚C and 30 min for the variables to study the variables of temperature and time of agitation, respectively.

It can be observed in Figure 4, the best operating condition occurs at higher temperature (80˚C) and under stirring time (10 min). The oil obtained in this condition had a color closer to the crude oil, as the temperature increases promoted aggregation of fine particles of darkening, due to the sludge formed by the reaction of phosphoric acid with the oil. The reaction of phosphoric acid with the impurities present in the crude oil may have been increased with increasing temperature, decreasing acid content from this condition relative to the other. However, iodine index values shown in Table 5 indicate a higher degradation of unsaturated fatty acids of degummed oil with increased operating temperature.

The results of the tests of neutralization of degummed at 80˚C and 10 min are shown in Table 6 using the values of the acid.

The results in Table 6 show that the neutralization process was satisfactory, dramatically reducing the acidity of the contents of degummed oil. The condition of greater excess of sodium hydroxide produced the best results for the acidity of the oil, i.e., the lowest values of acidity. The temperature and time of agitation has not been studied, was used as the optimized values of the study Morais et al. [10]. These authors reported that the temperature was not a significant factor for the neutralization of crude fish degummed in the range of 60˚C to 80˚C. Therefore, we used the lowest temperature in the neutralization tests (60˚C) and a stirring time of 20 min to minimize the lipid hydrolysis.

The neutralized oil not presented impurities, which sedimented on centrifugation of the mixture oil-soda. The neutralized oil had a color next to the olive oil, but more orange.

Table 5. Iodine value of the crude and degummed oils pulp.

iMedia two determinations.

Table 6. Acidity oil pulp pequi neutralized.

iMedia two determinations.

4. Conclusion

The solvent extraction of oil pequi performance is satisfactory and higher than the physical method. The pulp and the almond portions are the constituents of the fruit which have oil for the production of food products. The peel and waste have a negligible contribution of oil in the fruit. The methodology used by mechanical pressing and centrifugation pequi pulp is not suitable, because it produces a lipid fraction separable. The optimum condition for the degumming crude oil is 80˚C and 10 min of agitation, it showed the lowest acidity and the color and transparency for the crude pulp pequi. The greater excess of sodium hydroxide produced in the neutralization step a refined oil content of less acidity. The neutralized oil did not require centrifugation wash, as showed no impurities. Partially refined oil is a transparency similar to olive oil.

REFERENCES

- E. Moretto and R. F. Alves, “Óleos e Gorduras Vegetais—Processamento e Análises,” 2th Edition, Editora da UFSC, Florianópolis, 1989. p. 179.

- J. B. Rossel and J. L. R. Pritchard, “Analysis of Oilseeds, Fats and Fatty Foods,” Elsevier Science Publishers Ltd., Amsterdam, 1991, pp. 261-327.

- J. M. G. Mandarino and A. C. Roessing, “Tecnologia Para a Produção do Óleo de Soja: Descrição das Etapas, Equipamentos, Produtos e Subprodutos,” Documentos 171. Embrapa, Londrina, PR Setembro, 2001, p. 40.

- “Regulamento Técnico Para Fixação de Identidade e Qualidade de Óleos e Gorduras Vegetais,” Diário Oficial da União, Brasília, Vol. 196, No. 13, 1999, pp. 82-87.

- R. D. O’brien, “Fats and Oils. Formulating and Processing for Applications,” Technomic Publishing Company, Inc., 1998, pp. 181-249.

- “Estabelece Critérios Para o Complemento Nutricional e dá Outras Providências,” Diário Oficial da União, Brasília, 1995.

- AOAC, “Official Methods of Analysis of AOAC International,” 16th Edition, AOAC International, Arlington, 1995.

- AOCS, “Official and Tentative Methods of American Oil Chemists’ Society (Additions and Revisions),” 3rd Edition, AOCS Press, Champaign, 1980.

- M. M. Moraes, L. A. A. Pinto, S. C. A. Ortiz, V. T. Crexi, R. L. Da Silva and J. D. Da Silva, “Study of Fish Oil Refining Process,” Revista do Instituto Adolfo Lutz, Vol. 60, No. 1, 2001, pp. 23-33.

- L. M. Paucar-Menacho, L. H. Silva, A. S. Santana and L. A. G. Gonçalves, “Refining of Rice Bran Oil (Oryza sativa L.) to Preserve γ-Orizanol,” Ciência e Tecnologia de Alimentos, Vol. 27, Suppl. 1, 2007, pp. 45-53.

- B. Barros-Neto, I. S. Scarminio and R. E. Bruns, “Como Fazer Experimentos. Pesquisa e Desenvolvimento na Ci- ência e na Indústria,” Editora Unicamp, 2002, p. 401.

- R. Vera, E. R. B. Souza, E. P. Fernandes, R. V. Ship, M. S. S. Jr., M. Caliari and P. A. Ximenes, “Caracterização Física e Química de Frutos do Pequizeiro (Cariocar brasiliense Camb.) Oriundos de Duas Regiões no Estado de Goiás, Brasil,” Pesquisa Agropecuária Tropical, Goi- ânia, Vol. 37, No. 2, 2007, pp. 93-99.

- T. N. Deus, “Extração e Caracterização de Óleo do Pequi (Caryocar brasiliense Camb.) Para Uso Sustentável em Formulações Cosméticas Óleo/Água (O/A),” Dissertação de Mestrado, Universidade Católica de Goiás, Goiânia, 2008, p. 75.

- R. Roesler, I. G. Malta, I. C. Carrasco, R. B. Holland, C. A. S. Sousa and G. M. Pastore, “Antioxidant Activity of Cerrado Fruits, “Ciência e Tecnologia de Alimentos,” Campinas, Vol. 27, No. 1, 2007, pp. 53-60.

- C. R. Malacrida, “Changes of Soybean Oil and Mix of the Oil Palm-Soya in Frying Potato Chips,” Brazilian Journal of Food Technology, Vol. 6, No. 2, 2003, pp. 245-249.

NOTES

*Corresponding author.