Food and Nutrition Sciences

Vol. 2 No. 6 (2011) , Article ID: 6618 , 7 pages DOI:10.4236/fns.2011.26084

Effect of Extrusion Cooking of White Yam (Dioscorea rotundata) and Bambara-Nut (Vigna subterranean) Blend on Some Selected Extrudate Parameters

![]()

1Federal Institute of Industrial Research Oshodi (FIIRO), Lagos, Nigeria; 2Department of Food Technology, University of Ibadan, Ibadan, Nigeria.

Email: toyinoluwole2@yahoo.com, *aaolapade@yahoo.com

Received May 6th, 2011; revised July 1st, 2011; accepted July 8th, 2011.

Keywords: Extrusion cooking, Yam, Bambara nut, Feed moisture

ABSTRACT

The effect of thermo-extrusion processing of white yam (Dioscorea rotundata) and bambara nut (Vigna subterranean) on some selected extrudate parameters of residence time, throughput and moisture content were investigated in this study. Both yam and bambara nut were processed into meals of 750 µm and 500 µm respectively. Extrusion was carried out following a three variable response surface methodology using a Box Behnken design. Blend of yam meal and Bambara nut meal at ratio 80:20 respectively was conditioned into 12.5, 15.0 and 17.5% moisture content (dry basis) and allowed to equilibrate for 4 h. Extrusion was carried out on a single screw extruder at 50, 60 and 70 rpm screw speed and 130˚C, 140˚C and 150˚C barrel temperatures. The study revealed that the extrusion time varied between 13.1 and 29.7 sec, throughput varied from 13.3 to 34.4 kg/h and product moisture ranged from 11.1 to 16.8% dry basis). All investigated extrudate parameters were significantly affected (p < 0.05) by the process variables of screw speed, barrel temperature and feed moisture content, and their interactions. The results were indicative that the second order polynomial was adequate to model the dependence of the extrudate parameters of residence time, throughput and moisture content on extrusion variables of barrel temperature, feed moisture content and screw speed.

1. Introduction

Yam (Dioscorea sp) is a widely distributed food crop in west Africa especially Nigeria, where more than half of world total production is obtained [1]. Yam is an important source of carbohydrate for human nutrition [2] but suffers a high degree of post harvest loss due to its high moisture content [3]. Bambara nut (Vigna subterranean) on its own is an indigenous African legume with high nutritional value especially protein of about 21% [4]. The usefulness of legume grain in developing high protein foods in meeting the need of the vulnerable groups is well recognized [5]. Supplementation of yam with inexpensive legume such as bambara will help in improving the nutritional quality of the products. Extrusion cooking is increasingly being used for production of food for human consumption [6,7]. Expanded snack foods, ready-toeat cereal and dry pet foods are manufactured from cereals and starches by high temperature short-time extrusion cooking [8]. Colonna and Mercier [9] also described extrusion cooking as an important technique for modification and manufacture of a wide variety of traditional and novel foods and food blends. Expanded volume of extruded starches is generally governed by extrusion cooking parameters such as extruder barrel temperature, screw speed, moisture content of the feed material [8,10, 11]. Ding et al. [7] observed that the independent process variables for extrusion process are screw speed, barrel temperature, feed moisture content, total mass flow rate and die configuration. These independent variables affect such system parameters like extrudate residence time distribution, energy requirement for the process, pressure profile along the barrel, pressure drop in the die [12]. It is widely recognized that both the relationship within the extruder and the effects of extrusion parameters on the properties of resulting extrudates are strongly dependent on the individual machine used [13]. There is little information on the extrusion cooking of combination of yam and bambara nut for food preparation. Consequently, in this study the effects of three process variables namely screw speed, feed moisture and barrel temperature were determined on some extrudate parameters of residence time, throughput and product moisture using yam-bambara nut blend. These parameters are critical in determining the efficiency of the extruder, the yield as well as the quality of the resulting extrudates particularly in terms of the moisture content. The moisture content of the extrudate will affect the degree of crispiness as well as the storage properties of the finished products.

2. Materials and Methods

2.1. Sources of Raw Materials

White yam (Dioscorea rotundata) was obtained from National Root Crop Research Institute Umudike, Abia State, Nigeria. Bambara nut was obtained from Mile 12 retail market in Lagos, Nigeria. A laboratory sized single screw extruder, (Komet 1993 Model, Germany) with length to diameter ratio of 3:1 and die opening of 8mm, which required a minimum of 0.2 kg feed input was used in this study.

2.2. Preliminary Processing of Raw Materials

The specie of Yam tubers (Dioscorea rotundata) used in this study was subjected to some preliminary operations such as peeling, washing and slicing (5 mm thick), pre-cooking for 10 min. and drying at 60˚C in an air oven tray drier (Model 1999, made in Germany) with an air flow of 8 cfu for 8 h. The dried sliced yam was milled into grits of 750 µm using Hammer mill. Bambara nut was soaked for 8 hours, manually dehulled, then dried at 60˚C for 8 h and milled into flour of 500 µm particle sizes. Blend of yam flour and bambara flour was prepared in ratio 4:1 (w/w) respectively.

2.3. Experimental Design

A response surface experimental design (Design Expert 8.0.4) for feed moisture content (12.5% - 17.5%), screw speed (50 - 70 rpm) and barrel temperature (130˚C - 150˚C) was employed in this study to determine the effect of the process variables on the residence time, throughput and moisture content of extrudates. The experimental design was a three variable Box Behnken design comprising three independent variables of barrel temperature (BT), screw-speed (SS) and feed moisture content (FM) tested at 3 levels coded (−1 to +1). The experiment required a total of seventeen extruder runs (Table 1).

2.4. Moisture Content Determination

The moisture content of the samples was determined according to AOAC [14] method to know the amount of water to be added to make required moisture content. Three replicates samples each weighing 10 g of the blend were dried at 103˚C ± 2˚C until constant weight was attained. The samples were cooled in a glass container with silica gel as desiccant. Moisture content was calculated as ratio of weight loss to the dry matter weight (dry basis). The desired moisture content levels in the blend were obtained by adding distilled water as calculated using equation below.

(1)

(1)

where A = Initial mass of the blend (kg)

Mi = Initial fraction of moisture content of the blend (db)

Mf = Desired fraction of moisture content of the blend (db)

Q = Mass of water to be added (kg)

2.5. Extrusion Processing

Blend of yam and bambara nut meals were prepared in ratio 80:20 (w/w) and conditioned by adding water to obtain moisture contents of 12.5%, 15.0% and 17.5% (db). The blends were packaged in separate polyethylene bags and allowed to equilibrate for 4 h before extrusion. The extruder barrel temperatures were stabilized using bambara flour. Extrusion cooking of the blends was carried out as shown in transformed matrix (Table 1). After steady state conditions were attained samples were collected in open pans, allowed to cool, then packaged in low density polyethylene bags and stored under refrigeration (10˚C). The dependent variables were investigated as follows:

2.6. Determination of Residence Time

Extrusion time was determined at every 5 min. interval of steady state operation following the method of previous workers [15]. A small amount of red food dye was added to the sample at the extruder feed port and the time required for the dyed extrudate to exit the die was measured using a stop watch. Three replicates were carried out for each run.

2.7. Determination of Throughput of Extrudates

Throughput was determined by using the method described by Chinnaswamy and Hanna [8]. The extrudate produced over a period of time was collected and weighed

Table 1. Matrix transformation of the experimental design runs and extrusion conditions.

in an open pan. The experiment was carried out five replicates for each run.

2.8. Determination of Product Moisture Content

Moisture content of the extrudate as it exited the die was determined according to AOAC [14] method. The experiment was carried out on three replicates for each run.

2.9. Data Analysis

The data generated in this study was subjected to response surface analysis and analysis of variance using Design Expert 8.0.4. Statistical package.

3. Results and Discussion

3.1. Residence Time (RT)

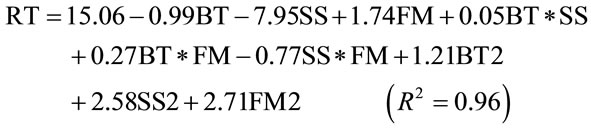

Mean value of RT of the extrudate observed in this study was 18.1 ± 6.3 sec. Highest RT of 29.7 ± 2.5 sec. was obtained at 130˚C barrel temperature, 50 rpm screw speed and 15% (db) feed moisture content while 150˚C barrel temperature, 70 rpm screw speed and 15.0% (db) feed moisture content produced least RT of 8.1 ± 0.8 sec. The observed difference in the RT values may be attributed to variations in screw speed and feed moisture content of the blends used in this study. It was observed that the faster screw speed and the lower feed moisture content led to reduction in residence time of the blend, while higher barrel temperature was associated with decrease in residence time. The results obtained in this study were consistent with the observations of Phillips et al. [16], who reported that feed moisture content was relatively more important than barrel temperature in influencing residence time of extrudate. Harper [13] associated residence time to the extruder geometry and dough characteristics. Statistical analysis of the collected data showed that the quadratic model significantly (p < 0.05) fit for prediction of RT. Mathematical expression of the relationship between the actual values of the variables and the response is shown in equation (1).

(1)

(1)

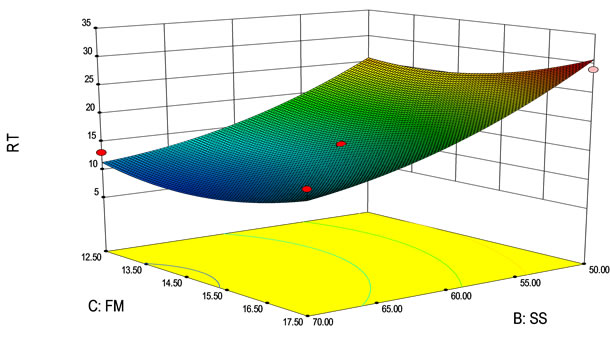

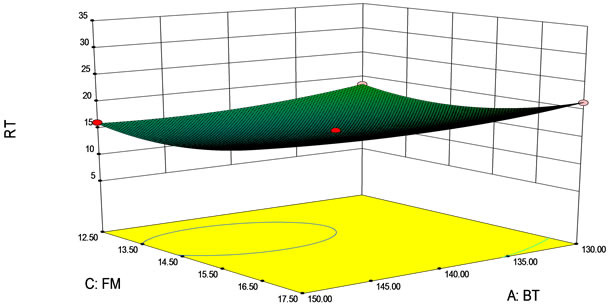

Coefficient of determination R2 of the model was 0.96. High coefficient of determination implies that as a result of application of the model, equation errors will be minimal. Significant model terms of the equation at p < 0.05 were screw speed, feed moisture content, interaction between SS and FM, and SS and BT, and 2nd orders of BT, SS and FM. Response surface plots of the RT as influenced by process variables are presented in Figures 1-3. These plots help to visualize the information about the fit model. Figure 1 indicates that minimum residence time was obtained at maximum screw speed for all feed moisture content used in this study. Though, RT increased with decrease in screw speed, the effect was more pronounced at higher feed moisture content of the blend. At maximum screw speed of 70 rpm, a slight reduction in RT was observed for increase in feed moisture content. Also Figure 2 revealed that SS had more pronounced effect on RT compared to FM. It can be seen in Figure 3 that RT marginally increased with increase in FM and BT. From economic production point of view, least ET will be desired.

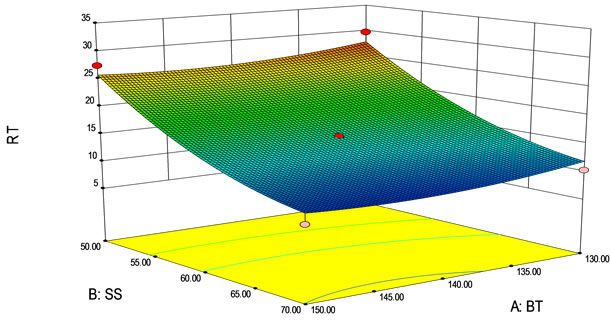

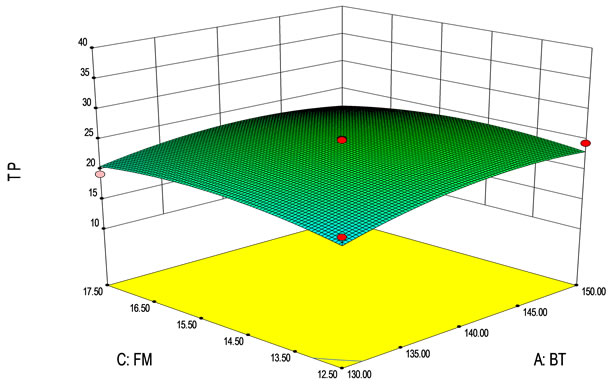

3.2. Throughput of Extrudate

Throughput of the extrusion cooking of yam-bambara blend varied between 13.3 and 34.4 kg/h with mean value of 23.3 ± 6.9 kg/h. The highest value for throughput 34.4 ± 0.7 kg/h was obtained at extrusion condition of 150˚C, 70 rpm and 15.0% for barrel temperature, screw speed and feed moisture content respectively, while 140 oC barrel temperature, 70 rpm screw speed and 12.5% feed moisture content produced the least throughput of 13.3 ± 0.3 kg/h. Throughput was observed to be positively correlated with barrel temperature, screw speed

Figure 1. Residence time (RT) of extrudate as influenced by feed moisture content (FM) and screw speed (SS).

Figure 2. Residence time (RT) of extrudate as influenced by barrel temperature (BT) and screw speed (SS).

Figure 3. Residence time (RT) of extrudate as influenced by barrel temperature (BT) and feed moisture (FM).

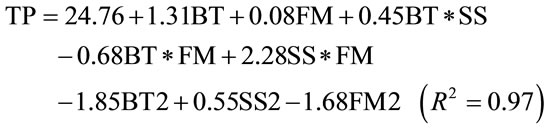

and feed moisture content. The results observed in this study ran contrary to the report of Maurice and Stanley [17], who reported that moisture content and not temperature affected throughput of soybean extrudate. The difference in our observation can be attributed to difference in the two materials used. Equation (2) presented the mathematical expression of the relationship between throughput and process variables.

(2)

(2)

Coefficient of determination R2 of the model was 0.97, which is an indication that the equation predicts the relationship between the response and process variables with high degree of accuracy. Screw speed had strongest and positive correlation with throughput followed by interaction between screw speed and feed moisture content.

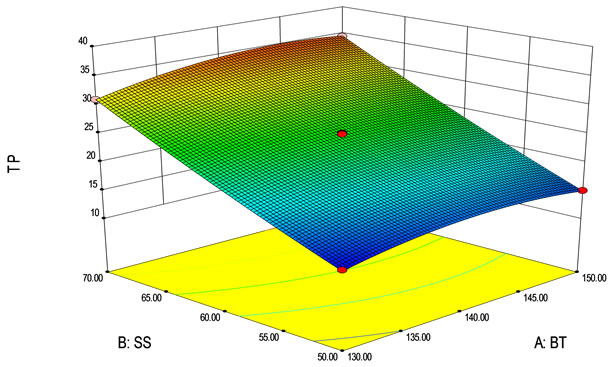

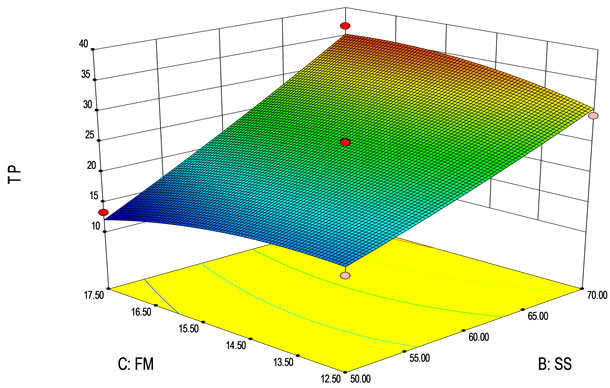

Response surface plots of interactions amongst the process variables as they affected throughput in this study are shown in Figures 4-6. Throughput gradually and rapidly increased with increase in screw speed (Figure 4) but marginally increased with increase in barrel temperature. Both feed moisture content and barrel temperature had marginal effect on throughput as shown in

Figure 4. Throughput (TP) of extrudate as influenced by barrel tempera-ture (BT) and screw speed (SS).

Figure 5. Throughput (TP) of extrudate as influenced by barrel tempera-ture (BT) and feed moisture content (FM).

Figure 6. Throughput (TP) of extrudate as influenced by screw speed (SS) and feed moisture content (FM).

Figure 5, whereas Figure 6 confirmed strongest effect of screw speed on throughput over other process variables used in this study. Throughput is a parameter that determines production efficiency in terms of production output per unit time. It is a process factor of interest particularly when considering pilot plant and commercial production of the extruded product.

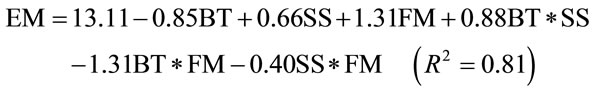

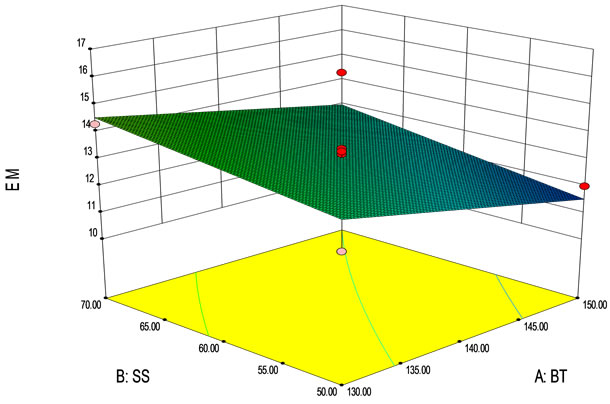

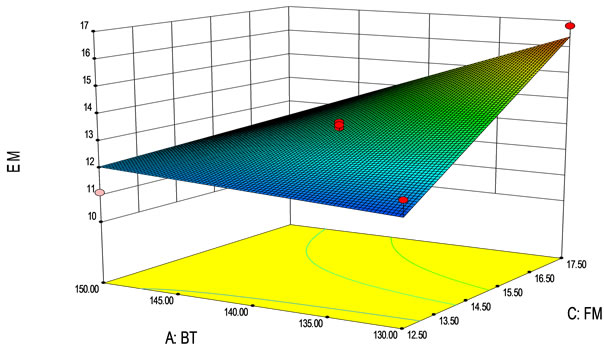

3.3. Extrudate Moisture Content

The values of extrudate moisture content observed in this study ranged from 11.1% to 16.8% (db) with mean value of 13.1% ± 1.7%. Highest value of 16.8% ± 0.4% was obtained at 130˚C barrel temperature, 60 rpm screw speed and 17.5% feed moisture content, while the least value of 11.1 ± 0.3 was observed at 150˚C, 60 rpm and 12.5% for barrel temperature, screw speed and feed moisture content respectively. The regression equation for predicting values of FM at any given values of process variables employed in this study is shown in equation (3).

(3)

(3)

High coefficient of determination R2 of the model was 0.81, which indicates that the equation will predict the values of EM with minimal error. The significant model terms are at p < 0.05 were feed moisture content, and interaction between feed moisture content and barrel temperature. Figures 7-9 present visual observations of interaction effects of process variables on the extrudate moisture content. Extrudate moisture was strongly affected by screw speed and barrel temperature (Figure 7), fed moisture content and barrel temperature (Figure 8) and feed moisture content and screw speed (Figure 9). The results obtained in this study were in agreement with previous observations that the product moisture content correlated positively with feed moisture content during extrusion cooking [16-19]. Reduction in moisture content of extrudate can be attributed to steam flash off during extrusion cooking.

4. Conclusions

The study had revealed that the process variables of

Figure 7. Extrudate moisture (EM) as influenced by screw speed (SS) and barrel temperature (BT).

Figure 8. Extrudate moisture (EM) as influenced by feed moisture content (FM) and barrel temperature (BT).

Figure 9. Extrudate moisture (EM) as influenced by screw speed (SS) and feed moisture content (FM).

screw speed, barrel temperatures and feed moisture generally had a significant effect at p < 0.05 on the extrudate parameters of residence time, throughput and product moisture content during extrusion. The regression equations generated in this study can be used to predict the values of the extrudate parameters provided the values of the process variables lie within the values investigated in this study. This is significant from the standpoint of pilot scale production where probably extruded products of specific properties different from those properties currently investigated in this study are desired by consumers.

5. Acknowledgements

The authors wish to thank the Managing Director of Tallum Nigeria Limited, Dr. S. Talabi for the support during this study.

REFERENCES

- J. M. Babajide and O. A.Onaderu, “Effect of Local Preservatives on the Sensory Properties of Dried Yam Slices ‘Gbodo’, flour and paste,” Nigerian Food Journal, vol. 27, no. 2, 2009, pp. 119-128.

- N. H. Akissoe, J. D. Hounhouigan, C. Mestres and M. Nago, “How blanching and drying affect the colour and functional characteristics of yam (Dioscorea cayenesis-rotundata) flours,” Food Chemistry, vol. 82, no. 2, 2003, pp. 257-264. doi:10.1016/S0308-8146(02)00546-0

- K. O. Falade, T. O. Olurin, E. A. Ike and O. C. Aworh, “Effect of Pretreatment and Temperature on Air Drying of Dioscorea alata and Dioscorea rotundata Slices,” Journal of Food Engineering, vol. 80, no. 4, 2007, pp. 1002-1010. doi:10.1016/j.jfoodeng.2006.06.034

- N. J. Enwere and Y.-C. Hung, “Some chemical and physical properties of bambara groundnut (Voandzeia subterranean Thours) Seed and Products,” International Journal of Food Science and Nutrition, vol. 47, no. 6, 1996, pp. 469-475. doi:10.3109/09637489609031875

- I. Nkama, “Traditional methods of production of high protein-energy food from grain legumes in north-Eastern states of Nigeria,” Annals of Borno, vol. 10, 1993, pp. 138-145.

- R. Ostergard, A. Bjork and J. Vainionpaa, “Effect of extrusion cooking on starch and dietary fibre in barley,” Food Chemistry, vol. 34, no. 3, 1989, pp. 215-227. doi:10.1016/0308-8146(89)90142-8

- Q. B. Ding, P. Ainsworth, A. Plunkett, G. Tucker and H. Manson, “The effect of extrusion cooking on the functional and physical properties of wheat based expanded snacks,” Journal of Food Engineering, vol. 73, no. 2, 2006, pp. 142-148. doi:10.1016/j.jfoodeng.2005.01.013

- R. Chinnaswamy and M. A. Hanna, “Optimum extrusion cooking conditions for maximum expansion of corn starch,” Journal of Food Science, vol. 53, no. 3, 1988, pp. 834-836. doi:10.1111/j.1365-2621.1988.tb08965.x

- P. Colonna and C. Mercier, “Macromolecular modification of mamoc starch components by extrusion cooking with and without lipids,” Carbohydrate Polymer, vol. 3, No. 2, 1983, pp. 87-128. doi:10.1016/0144-8617(83)90001-2

- C. Mercie, R. Charbonniere, J. de la Guermea and F. Grbuit, “Formation of amylase-lipid complexes by twin screw extrusion cooking of manioc starch,” Journal of Cereal Chemistry, vol. 57, no. 1, 1980, pp. 4-9.

- J. Owusu-Ansah, F. R. Van de Vaort and D. W. Stanley, “Physicochemical changes in corn starch as a function of extrusion variables,” Cereal Chemistry, vol. 60, no. 4, 1983, pp. 319-324.

- Y. K. Chang and A. A. El-Dash, “Effects of Acid Concentration and Extrusion Variables on Some Physical Characteristics and Energy Requirements of Cassava Starch,” Brazilian Journal of Chemical Engineering, vol. 20, no. 2, 2003, pp. 1-8. doi:10.1590/S0104-66322003000200006

- J. M. Harper, “Extrusion of Foods,” CRC Press, Boca Raton, 1981, pp. 101-115.

- AOAC, “Official methods of analysis,” 16th Edition, Association of Official Analytical Chemists, Washington DC, 1995.

- F. Hsieh, I. Peng and H. E. Huff, “Effect of salt, sugar and screw speed on processing and product variables of corn meal extruded with a twin screw extruder,” Journal of Food Science, vol. 55, no. 1, 1990, pp. 224-227. doi:10.1111/j.1365-2621.1990.tb06057.x

- A. Phillips, M. S. Chhinnan and M. B. Kennedy, “Effect of Feed Moisture and Barrel Temperature on Physical Properties of Extruded Cowpea Meal,” Journal of Food Science, vol. 49, no. 3, 1984, pp. 916-921. doi:10.1111/j.1365-2621.1984.tb13241.x

- T. J. Maurice and D. W. Stanley, “Texture Structure Relationship in Texturized Soy Protein. Influence of Process variable on extrusion texturization,” Canadian Institute of Food Science and Technology Journal, vol. 11, No. 1, 1978, p. 1.

- R. C. Miller, “Low Moisture Extrusion. Effects of Cooking Moisture on Product Characteristics,” Journal of Food Science, vol. 50, no. 1, 1985, pp. 249-252. doi:10.1111/j.1365-2621.1985.tb13321.x

- T. Aboagye and D. W. Stanley, “Thermoplastic Extrusion of Peanut Flour by Twin Screw Extruder,” Canadian Institute of Food Science and Technology, vol. 20, No. 3, 1987, pp. 148-153.