Open Journal of Social Sciences

Vol.06 No.02(2018), Article ID:82604,10 pages

10.4236/jss.2018.62011

Risk Analysis of Laundry Equipment Development Project with Interpretative Structural Modeling

Chengpeng Zhong1,2, Haoheng Ye1, Leqi Xie1

1School of Business Administration, South China University of Technology, Guangzhou, China

2Engineering, Alliance Laundry Equipment (Guangzhou) Ltd., Guangzhou, China

Copyright © 2018 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: January 21, 2018; Accepted: February 23, 2018; Published: February 26, 2018

ABSTRACT

This paper uses the method of expert voting to determine the top ten key risk factors, and then uses the interpretative structure model to find out the deep logic between the top ten risks. Ten key risk factors are attributable to five aspects of the project of washing equipment development: organization, initiative, planning, executing and controlling that more intuitively show the level of the relationship between the factors, which provides a theoretical foundation for risk management and risk response of washing equipment development project, to reduce the risk and failure.

Keywords:

Laundry Equipment Development Project, Risk Management, Key Risk Factors, Interpretative Structural Modeling, Causal Relationship, Deep Logic

1. Introduction

With the improvement of living standards, the washing amount of hotel and restaurant linens is growing, and washing industry has ushered in a new development opportunities. According to the ministry of commerce business information service enterprise statistics and the wash typical commission statistics data, by the end of 2016, washing and dyeing industry revenue has risen from 99.82 billion yuan in 2015 to 104.71 billion yuan in 2016, increased by 4.9%. One of the enterprises above designated size operating income rose from 57.13 billion yuan in 2015 to 60.67 billion yuan in 2016, increased by 6.2%. The size of the following corporate revenues from 42.7 billion yuan in 2015, rose to 44.04 billion yuan in 2016, up 3.2%. However, at present, the project management system of washing equipment development is still imperfect in China. Especially the risk management is rather weak. The control ability of risk determines the success or failure of the project of washing equipment development to a certain extent.

This paper establishes the interpretative structure model of risk factors of washing machine development project by using the interpretative structural model method (Interpretative Structure Model, referred to as ISM), to analyze the causal relationship between the key risk factors and find out the key factors that lead to the failure of the project of washing equipment development, for providing theoretical guidance for risk management of the washing equipment development project.

2. Literature Review

The first edition of “A Guide to the Project Management Body of Knowledge” is published by American PMI Association in 1996. The risk management is as one of the nine knowledge field, and it is retained in the later updated version; Qi Anbang professor, president of Management Committee of the International Project Management Association published the “Project Risk Management” in November 2010, that a comprehensive introduction to the basic process, the principle and method of project risk management [1] ; China’s first certified international senior project manager Mr. Shen Jianming put forward and established a relatively perfect and scientific risk management system model and method in his book “Project Risk Management” which published in September 2010 [2] . The risk analysis of the equipment development project includes the following steps: first, risk identification. One of the features of a project is uniqueness, so the risk of each project is not the same, but we can still learn from previous project risk levels to identify risks in the process of identifying risks, or consult industry experts to identify project risks. Second, risk analysis. Risk analysis is a qualitative and quantitative analysis of the identified risks, a comprehensive analysis and evaluation of the probability and impact of risk, risk ranking priority and impact on the project evaluation process. Third, risk control. Risk control includes the formulation of corresponding risk response schemes and the process of controlling and reducing the probability of risk during the entire implementation of the project. The ability of risk control plays a great role in the success or failure of the project [1] [2] [3] .

The interpretive structure model (ISM) refers to the application matrix and simple logic operation to describe the structural relationships among the components of a complex system. ISM technology uses directional graph, matrix and other tools to deal with the relationship between the problem elements, and explains it with text, to better clarify the level and overall structure of the problem, and improve the understanding and understanding of the problem [4] . The work steps of interpretative structural modeling method: 1) The formation of ISM implementation team construction; 2) A set of key issues; 3) Through repeated discussions, get the cause list of the key factors; 4) List the correlation factors; 5) Establish the adjacency matrix and reachable matrix; 6) Regional division; 7) Division of the level; 8) Extract the skeleton matrix and draw the interpretation structure model. The ISM is widely used, in medical field, application of interpretative structural model the whole process management of medical waste of extracted factors, determine the relationship and the division level, thus found to affect key factors of medical waste management in the whole process [5] ; in the high-tech field, ISM can carry out scientific analysis and evaluation of technological innovation capability of high-tech enterprises, to find out the ideas and methods to solve problems [6] ; in the manufacturing field, application of interpretive structural model to analyze the factors existing in the maintenance management of the comprehensive production obstacles, and puts forward countermeasures [7] ; project management, through the interpretative structural modeling method to establish a risk factor to explain the structure, it can directly reflect the level of the relationship between various factors, to provide guidance and reference for metro construction safety management [4] ; in the field of Internet software, identifying risk factors through the IT service management project implementation failure, and according to the degree of risk they are sorted and analyzed, and identify the risk factors resulting in failure, through the development of countermeasures in advance, In order to guarantee the success of project [8] [9] ; in agriculture, through the method of interpret structure model, analysis of agricultural logistics distribution center, and puts forward the logistics distribution center location is proposed in the medical field [10] ; from the Internet to the manufacturing industry, the interpretation structure model is widely used, the risk management and interpretation structure model method has also been a very good combination [11] .

3. Identify Risk Factors

Based on the previous washing equipment development project risk register analysis and through expert interview, this paper extracted the 21 risk factors which may cause the failure of washing equipment development project and formed a list of risk factors, and then, the risk factors are divided into five categories―group, initiating process, planning process, executing process and controlling process (Table 1).

In order to further determine the key risk factors, this paper uses the Delphi method to assess the importance of the risk factors that lead to the failure of the project. First, according to the principle of systems engineering, we set a set of commentary on the correlation between risk factors and project failure: X = {X1, X2, X3, X4} = {Very important, Important, General, Irrelevant} = {0.8, 0.6, 0.4, 0.2}. Then, on the basis of circular evaluation of ten washing industry experts, the number of each risk factor selected as the relevant comment set is aggregated, and the evaluation results are obtained, see table 1.

Then, creating the importance evaluation matrix R of risk factors which lead to project failure based on table 1, These risk factors belong to the degree of Xj of each item in the project failure, as in (1).

Table 1. Ranked list of TOP 10 key risk factors.

(1)

Among them, rij = dij/da, dij means the number of people of factor i select evaluation value j; da is the total number of participants to participate in the evaluation. At the end, through the calculation of Y = RXT = (y1, ∙∙∙, yi, ∙∙∙, yn)T, obtain the evaluation value Y of candidate risk factors’ importance of project, with the other calculation, to obtain the evaluation value yi of each candidate risk factor’s importance of project, the last column in table 1. According to the 2 - 8 law, we selected and removed the evaluation value yi < 0.6 of related candidate success factors, and the remaining 10 factors were the top ten key risk factors leading to the failure of the washing equipment development project. The top ten factors were named S1, S2, S3, ∙∙∙, S10 sort by score from high to low.

From table 1, S1 Indifference the project of Senior management, S2 Indistinct project goal, S3 Disagreed evaluation standard of project success and failure, it is also not hard to find these three elements are in initiating process stage of the project, project input has a significant impact on the project; Followed by S4 Unmatched product design and project requirement, S5 Lack of experienced member, S6 Imperfect process of project management, we can see that the problems appeared in initiating process, planning process and controlling process, that mainly reflect the project manager’s ability to control project. The S7 Project stakeholder frequently change requirement, the frequent change of project requirements is mainly due to the fact that the project has not identified the root causes of the stakeholders in the planning stage, and the quality of the project will have a great impact on the project. S8 Poor ability of project control, S9 Poor implement ability of project team, S10 Low efficiency of team work, these three factors have the same votes and they belong to the category of communication management, which is extreme important to the project implementation process.

4. Create the ISM of Risk of Laundry Equipment Development Project

4.1. Create Adjacency Matrix based on Key Risk Factors

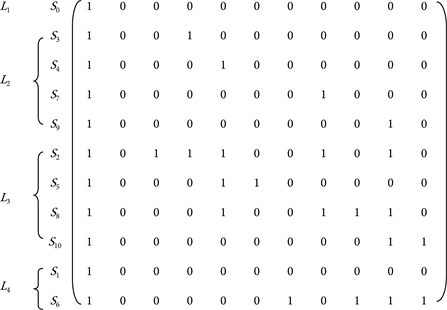

According to Table 1 ranked list of TOP 10 key risk factors and using the ISM to analyze the structure relationship of the risk factors, in order to make a complete structure of the relationship between risk factors and the risk factors lead to project results more clear, here introduces a risk factors S0 represents “washing equipment development project failure”, in this way, carries on the analysis on the relationship of 11 risk factors, The specification is as follows: Si has an influence on Sj, mark 1; Si has no influence on Sj, mark 0; (i, j = 0, 1, ∙∙∙, 10). For the factors influencing each other, the influence of the influential party is influenced. The result is as in table 2.

From table 2, we can get the 11 × 11 adjacency matrix A, after calculation of matrix A: A1 = A, A2 = A2, A3 = A3, ∙∙∙, according to the ISM calculation rule, for general, A1 ≠ A2 ≠ ∙∙∙ ≠ Ar−1 = Ar = Ar+1, and r £ 11-1, getting reachable matrix M = Ar = Ar.

Table 2. Relationship of key risk factors.

4.2. Grade Partition for Reachable Matrix

Reachable set: Element set which element Si is able to reach can be defined as reachable set of element Si, represented by R(Si), composing by the column which all matrix elements are “1” in the Si raw of reachable matrix.

Cause set: Element set which elements are able to reach element Si can be defined as cause set of element Si, represented by A(Si), composing by the raw which all matrix elements is “1” in the Si column of reachable matrix.

The highest element set: A multilevel hierarchical structure is a collection of elements that cannot reach other elements but can reach themselves. The set R(Si) contains only its own set of elements, while the previous focus, excluding the elements Si itself, includes the next level of elements that can reach it. If R(Si) = R(Si) ∩ A(Si), i = j, then R(Si) is the highest set of elements. After finding the top-level set of elements, you can remove the corresponding rows and columns from the reachable matrix, and then continue to search for the new superlative elements from the remaining matrix. By analogy, you can find the highest set of elements contained in all levels [5] . The first level can reach the set and the previous set, as in table 3.

Table 3. First grade of reachable set and cause set.

According to the theory of Grade Partition for Reachable Matrix and table 3, R(S0) = R(S0) ∩ A(S0), the same of S0 in first grade, cancel raw 0 and column 0, obtain the second grade of reachable set and cause set; the same of S3, S4, S7, S9, cancel raw 3, 4, 7, 9, and column 3, 4, 7, 9, obtain the third grade of reachable set and cause set; the same of S2, S5, S8, S10, cancel raw 2, 5, 8, 10, and column 2, 5, 8, 10, obtain the fourth grade of reachable set and cause set. The accessible matrix can be further obtained by the combination of the above and the previous set.

We know that S0 washing equipment development project failure is the highest factor; S3 Disagreed evaluation standard of project success and failure, S4 Unmatched product design and project requirement, S7 Project stakeholder frequently change requirement and S9 Poor implement ability of project team are the second-level factor set. S2 Indistinct project goal, S5 Lack of experienced member, S8 Poor ability of project control and S10 Low efficiency of team work are the third level factor set; S1 Indifference the project of Senior management and S6 Imperfect process of project management are the base lever set as same as root factor set, is the root factor set which lead to S0 washing equipment development project failure. A clear demonstration of the linkages between levels, the hierarchy of risk factors and the interconnections between various risk factors is of great significance to the creation of an interpretation structure model.

4.3. Create interpretative Structural Model

This paper establishes the risk interpretative structural model of laundry equipment development project as figure 1, factors Indifference the project of Senior management and Imperfect process of project management are the root of washing equipment development project failure. Senior management did not attach enough importance to the project’s commercial argumentation and the allocation of resources that bring the significant influence, in the process of project implementation will be a serious blow the morale of the project members, thus affecting the implementation of the project. The project management process is not perfect. The project management process is very important to the project. It is the cornerstone of the project operation and is an important premise to ensure the orderly progress of the project. Both root causes and trigger indistinct project goal; Lack of experienced member; Poor ability of project control; Low efficiency of team work; Disagreed evaluation standard of project success and failure; Unmatched product design and project requirement; Project stakeholder frequently change requirement; Poor implement ability of project team, these factors eventually lead to project failure. By using the interpretative structural modeling method, the structure relation between the risk factors of the washing equipment is analyzed, so that we can better prepare the risk response measures.

Figure 1. Risk interpretative structural model of laundry equipment development project.

5. Management Enlightenment

We can find that the washing equipment development project risk type and the structure of the relationship between risk factors, which cause the failure of washing equipment development project of the five factors, respectively, in the second, three and four layers in the model, the product design does not accord with the project requirements involve the project goal is not clear, the lack of experienced developers and project development capacity is low; Poor execution of the project is also the result of elements of the third tier. In addition, high-level management is the most fundamental factor in the lack of attention to the project and low project control ability.

1) Washing equipment due to the particularity of the industry, so the top management are integrated in product development strategy formulation with the characteristics of the industry, so early in the project, must maintain close communication with senior management, to ensure the project to get the attention of senior management personnel, during the project implementation, keep reporting to senior management, to ensure the project from beginning to end top managers are involved in the project.

2) Washing industry project management is still in its infancy, so the project manager should reflect the defects existing in the project process in a timely manner to senior management, so that top management to improve and arrange resources to improve the project management process, reduce the project failure caused by imperfect process.

3) Washing equipment of the customer experience is very important, so the project manager to communication with senior management or customers, to ensure that the input of the project is clear, training for project team members and ensure that team members possess the skills required to perform project. At the same time, the project manager must constantly improve the project management level to avoid the lack of project management and control ability due to lack of self-level.

6. Conclusions

This paper selects the top 10 key risk factors by using the Delphi method and explains the deep logic of the top ten key risk factors. Top ten key risk factors are attributable to five aspects of washing equipment development project: organization, initiation, planning, executing and controlling, so that it is more intuitive to reflect the level of the relationship between the factors, for providing scientific theoretical basis of risk management and risk responses of washing equipment development project, and that would be beneficial for reducing the project risk and project failure possibility.

Acknowledgements

Thanks a lot for the valuable discussions with you, professor Jiangping Wan.

Cite this paper

Zhong, C.P., Ye, H.H. and Xie, L.Q. (2018) Risk Analysis of Laundry Equipment Development Project with Interpretative Structural Modeling. Open Journal of Social Sciences, 6, 117-126. https://doi.org/10.4236/jss.2018.62011

References

- 1. Qi, A.B. (2010) Project Risk Management. Nankai University Press, Tianjing, 1-35.

- 2. Project Management Institute. (2013) Project Management Body of Knowledge (PMBOK Guide). 5th Edition, Publishing House of Electronics Industry, Beijing, 309-312.

- 3. Shen, J.M. (2010) Project Risk Management. 2nd Edition, China Machine Press, Beijing, 487-489.

- 4. Gou, M. and Zhao, J.X. (2014) Risk Analysis of Tunnel Boring Machine Based on ISM Method. Shenyang Jianzhu University Journal (Social Science Edition), 10, 390-393.

- 5. Chang, Y., Liu, X.D. and Yang, L. (2003) Analyze the Technological Innovation Ability of High-tech Enterprises by ISM Method. Science Research Management, 3, 41-47.

- 6. Liu, G.F. and Tian, T.T. (2016) Study on the Influence Factors of the Whole Process of Medical Waste Management Based on ISM. Manager Journal, No. 35, 7-8.

- 7. Poduval, P.S., Pramod, V.R. and Jagathy Raj, V.P. (2005) Interpretive Structural Modeling (ISM) and Its Application in Analyzing Factors Inhibiting Implementation of Total Productive Maintenance (TPM). International Journal of Quality & Reliability Management, 32, 308-331.

- 8. Wan, J.P., Cao, Y.H. and Hou, J.J. (2013) Case Study on H Corp. Software Project Risk Management with ISM. Technology and Investment, 4, 145-152.

- 9. Wan, J.P., Wang, Y.F. and Liu, Q.J. (2009) An Empirical Analysis of Risk Factors for IT Service Management Project Based on ISM. Science Research Management, No. 5, 487-489.

- 10. Huang, L.J., Yu, J. and Huang, X.W. (2012) Modeling Agricultural Logistics Distribution Center Location Based on ISM. Journal of Software, 7, 638-643.

- 11. Zhang, Y.L. and Yang, N.D. (2006) Project Risk Management Process and Integration under the Perspective of Knowledge Management. Industrial Engineering and Management, No. 6, 110-113.