Journal of Applied Mathematics and Physics

Vol.04 No.10(2016), Article ID:71673,28 pages

10.4236/jamp.2016.410197

The Third-Order Viscoelastic Acoustic Model Enables an Ice-Detection System for a Smart Deicing of Wind-Turbine Blade Shells

Eugen Mamontov1*, Viktor Berbyuk2

1Versati AB, Askim, Sweden

2Division of Dynamics, Department of Applied Mechanics, Chalmers University of Technology, Gothenburg, Sweden

Copyright © 2016 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: August 12, 2016; Accepted: October 28, 2016; Published: October 31, 2016

ABSTRACT

The present work is based on the third-order partial differential equation (PDE) of acoustics of viscoelastic solids for the quasi-equilibrium (QE) component of the average normal stress. This PDE includes the stress-relaxation time (SRT) for the material and is applicable at any value of the SRT. The notion of a smart deicing system (SDS) for blade shells (BSs) of a wind turbine is specified. The work considers the stress in a BS as the one caused by the operational load on the BS. The work develops key design issues of a prospective ice-detection system (IDS) able to supply an array of the heating elements of an SDS with the element-individual spatiotemporal data and procedures for identification of the material parameters of atmospheric-ice (AI) layer accreted on the outer surfaces of the BSs. Both the SDS and IDS flexibly allow for complex, curvilinear and space-time-varying shapes of BSs. The proposed IDS presumes monitoring of the QE components of the normal stresses in BSs. The IDS is supposed to include an array of pressure-sensing resistors, also known as force- sensing resistors (FSRs), and communication hardware, as well as the parameter- identification software package (PISP), which provides the identification on the basis of the aforementioned PDE and the data measured by the FSRs. The IDS does not have hardware components located outside the outer surfaces of, or implanted in, BSs. The FSR array and communication hardware are reliable, and both cost- and energy-efficient. The present work extends methods of structural-health/operational- load monitoring (SH/OL-M) with measurements of the operational-load-caused stress in closed solid shells and, if the prospective PISP is used, endows the methods with identification of material parameters of the shells. The identification algorithms that can underlie the PISP are computationally efficient and suitable for implementation in the real-time mode. The identification model and algorithms can deal with not only the single-layer systems such as the BS layer without the AI layer or two- layer systems but also multi-layer systems. The outcomes can be applied to not only BSs of wind turbines but also non-QE closed single- or multi-layer deformable solid shells of various engineering systems (e.g., the shells of driver or passenger compartments of ships, cars, busses, airplanes, and other vehicles). The proposed monitoring of the normal-stress QE component in the mentioned shells extends the methods of SH/OL-M. The topic for the nearest research is a better adjustment of the settings for the FSR-based measurement of the mentioned components and a calibration of the parameter-identification model and algorithms, as well as the resulting improvement of the PISP.

Keywords:

Non-Equilibrium Deformable Solid System, Quasi-Equilibrium Mechanical Variable, Average Normal Stress, Pressure-Sensing Resistor, Acoustics of Viscoelastic Solids, Third-Order Partial Differential Equation, Shell of a Blade of a Wind Turbine, Atmospheric Ice, Smart Deicing, Structural-Health/Operational-Load Monitoring, Identification of Material Parameters

1. Introduction

In cold weather, a layer of atmospheric ice (AI) is accreted on the outer surfaces of the blade shells (BSs) of a wind turbine. As is well known, this layer can cause unexpected downtime and increased maintenance cost of the turbine, thereby resulting in reduced efficiency of the energy production by the turbines.

Remark 1.1. All of the cold-climate areas can be found within the Köppen-Geiger climate classification system (http://en.wikipedia.org/wiki/Köppen_climate_classification). The climates associated with the freezing temperatures comprise various weather conditions, from the hot summer continental climate (see also http://en.wikipedia.org/wiki/Humid_continental_climate) with the minimum temperatures in the coldest months down to −10˚C to the tundra climate (see also http://en.wikipedia.org/wiki/Tundra) with the minimum temperatures in the coldest months down to −50˚C.

The coldest climate is the ice cap climate (see also http://en.wikipedia.org/wiki/Ice_cap_climate) with the winter temperatures below −50˚C in the Arctic (see also http://en.wikipedia.org/wiki/Polar_climate and http://en.wikipedia.org/wiki/Climate_of_the_Arctic). The minimum temperatures during a year can vary between −50˚C and −90˚C (http://en.wikipedia.org/wiki/Polar_climate and http://en.wikipedia.org/wiki/Climate_of_Antarctica).

Thus, the temperatures dealt with in connection with deicing of the BSs are in the interval from 0˚C down to the aforementioned values depending on a specific climate.

□

Note that all of the physical-quantity values are specified below in the SI without indication of the corresponding units, with the exception of the cases where the units are not the SI ones (such as the temperature values in Remark 1.1).

The accreted AI is generally of different qualities. It can be continuous or porous, more specifically, hexagonal crystalline or low-density amorphous, clear, frozen dense snow, soft or hard rime, glaze, etc. In terms of continuum mechanics, these qualities are distinguished with values of the material parameters of the AI (e.g., [1] , [2] ).

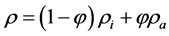

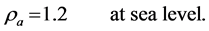

According to [2] , the AI (including porous and continuous ice) is regarded as porous medium where pores are filled with air. The corresponding (volumetric) density of the AI mass  is expressed as follows

is expressed as follows

(1.1)

(1.1)

where  is the AI porosity, i.e., the volume fraction occupied by air (

is the AI porosity, i.e., the volume fraction occupied by air ( ),

), is the mass density of a continuous, non-porous ice, and

is the mass density of a continuous, non-porous ice, and  is the mass density of air. All of these parameters present the equilibrium values. Note that

is the mass density of air. All of these parameters present the equilibrium values. Note that

(1.2)

(1.2)

(1.3)

(1.3)

As follows from (1.1),

(1.4)

(1.4)

The mass densities of the seasonal and dense snows are below and above 300, respectively.

Nowadays, BSs are usually fabricated of composite materials. As is well known (e.g., [3] ), they are viscoelastic.

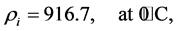

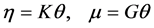

Viscoelasticity is also a property of AI. A viscosity of a medium presents the product of the corresponding elastic modulus and the relaxation time  of the quasi-eq- uilibrium (QE) component of the Cauchy stress matrix to its equilibrium value. More specifically, if

of the quasi-eq- uilibrium (QE) component of the Cauchy stress matrix to its equilibrium value. More specifically, if  and

and  are the bulk and shear moduli of an isotropic material, then parameters

are the bulk and shear moduli of an isotropic material, then parameters

(1.5)

(1.5)

are the volume (or compressional) and shear viscosities. The stress relaxation exists in any material medium, in gases, liquids, and solids, no matter if the medium is spatially non-homogeneous or spatially homogeneous. Also note that, for the sake of simplicity, the stress-relaxation time (SRT)  is assumed to be a scalar rather than a matrix. Also, the same value of it is used in expressions (1.5) for both the viscosities. The physical picture for the viscosities of solids and the relevant theoretical-physics modeling approach are available (e.g., [4] , §34). Many aspects of theoretical analysis and ex- perimental study of viscoelastic materials are described in [5] and [6] .

is assumed to be a scalar rather than a matrix. Also, the same value of it is used in expressions (1.5) for both the viscosities. The physical picture for the viscosities of solids and the relevant theoretical-physics modeling approach are available (e.g., [4] , §34). Many aspects of theoretical analysis and ex- perimental study of viscoelastic materials are described in [5] and [6] .

The fact that ice is viscoelastic rather than purely elastic (i.e., inviscid) was re- cognized more than a century ago [7] - [10] . This line of research was continued in [11] . It appeared that solid ice has high values of viscosity. For instance, the experimental data in ( [11] , the last column of Table 3) show that the ice shear viscosity values are in the interval . The shear-viscosity values for glaciers obtained for a number of the Swiss glaciers are

. The shear-viscosity values for glaciers obtained for a number of the Swiss glaciers are  ( [10] , Table 1). This is confirmed with the fact that ( [12] , p. 305) values of the viscosity of polycrystalline ice vary in the range

( [10] , Table 1). This is confirmed with the fact that ( [12] , p. 305) values of the viscosity of polycrystalline ice vary in the range .

.

Basing on the pioneering work of J. C. McConnel published in 1891, the ex- perimental data of ( [10] , Table 2) show that the ice viscosity rapidly increases from  to

to

The following remark indicates a possible interval of the AI SRT.

Remark 1.2. The aforementioned experimental values for ice show that shear viscosity

In the case of polycrystalline ice (e.g., [12] ), the range of the SRT values is even wider. Indeed, as already noted, values of the viscosity of polycrystalline ice vary from about

According to Remark 1.2, the SRT values for continuous or polycrystalline ice can vary in five-six orders. The latter feature practically means that the corresponding viscoelastic acoustic model must be relevant at any value of the material SRT.

The AI layer accreted on it the outer surface of a BS is different at different locations on the surface and at different time points. More specifically, the AI landscape varies in both the space and time.

To prevent the losses mentioned at the beginning of this section, one usually applies deicing methods. The most common of them is heating. However, by now, all of the deicing techniques are based on a priori assumptions on the AI-layer parameters over the BS surface. In the case of heating, this often results in under-heating, i.e., reduced reliability of the deicing, or over-heating that damages the BS-material and, thus, reduce the cost-efficiency of the deicing.

The notion of a smart deicing system (SDS) presumes that the system is smart in the sense that is cost- and energy-efficient, safe to the BS material, and reliable. As noted above, the AI layer is space-time varying. The BS, which the AI landscape is accreted on, has a complex, curvilinear shape, which is generally space-time varying as well, due to the action of the operational load (e.g., [14] ). To be able to smartly remove the above spatiotemporal landscape of the AI, an SDS must provide the heat levels, which are individual to the landscape regions and specific time points. Consequently, these levels should be determined on the basis of the spatiotemporal landscape of the AI-layer material parameters including the layer thickness. To provide this landscape, each heating element (e.g., [15] ) should be accompanied by an appropriate sensor, which is located near, but outside the area of, the heating element and measures a mechanical variable that allows to identify the mentioned parameters of the AI layer. The heating elements can be implanted in each of the three blades of a wind-turbine rotor in such a way that they are distributed over the BS surface uniformly (say, one element per four square meters), whereas the sensors can be attached to the inner surface of the BS at their aforementioned locations. Thus, an SDS is supposed to consist of a sufficiently large array of the identical heating elements (e.g., square- or disk-shaped) and com- munication hardware that controls the array. Similarly, a related IDS is supposed to consist of the corresponding sensor array and communication hardware that controls this array. Both the controls can be implemented by a personal computer (PC).

To meet temporal variations of the AI landscape, both the SDS and IDS should operate in the real-time mode. Both the SDS and IDS have components implanted in, or attached to, the BSs. The BSs are rigidly attached to a wind-turbine rotor, which is in general rotating, and, as follows from the published review works, both the SDS and IDS must not have components located outside the body of a wind turbine. Therefore, both the systems must be located inside the rotating rotor but accessible to a remote operator at any time. For this reason, both the controls should be wireless. Moreover, the controlling PC must also identify the parameters of the spatiotemporal AI layer from the measurement data obtained by the sensors in the IDS, determine on the basis of them the heat levels individual to the heating elements in the SDS, and send the level data to the corresponding elements. The first of the three tasks should be implemented in the parameter-identification software package (PISP) installed on the PC.

The main questions to be answered in the IDS design are the following:

・ How can one design an IDS in order to enable it, firstly, to be relevant to an SDS for the BSs of a wind turbine, secondly, to be reliable, cost- and energy-efficient, and, thirdly, to supply the prospective PISP with the data measured by the ISD sensors?

・ What are the parameter-identification procedures that can be implemented in the PISP?

The purpose of the present work is answering these questions by development of design issues of an IDS relevant to an SDS for the wind-turbine BSs and procedures for identification of the AI-layer parameters on the basis of acoustics of viscoelastic solids. The work is underlain by the previous works of the authors [16] and [1] . Each of them considers a thin curvilinear deformable solid layer associated with the BS and develops a procedure for identification of the material parameters of the layer. Paper [16] deals with a one-layer shell separating its interior and exterior, for instance, the non-QE deformable solid shells of various engineering systems (e.g., the shells of driver or passenger compartments of ships, cars, busses, airplanes, and other vehicles) or BS of a wind turbine. Paper [1] deals with the two-layer system of the BS layer and the AI layer accreted on the BS-layer outer surface.

Both works [16] and [1] consider the stress in a layer system as the one caused by the operational load on the system. The works describe the QE component of the average normal stress (ANS) with a third-order partial differential equation (PDE) of acoustic of viscoelastic solids. The deviatoric (or shear) stress is neglected for compactness of the model. The equation is introduced in [16] , takes into account the stress-relaxation function (in the exponential approximation) in the integrand of the Boltzmann super- position integral, includes the stress-relaxation time (SRT) of the layer material, and is relevant at any value of the SRT. The latter property enables application to viscoelastic materials, in particular, AI (see Remark 1.2).

The parameter-identification procedures in papers [16] and [1] presume structural- health/operational-load monitoring (SH/OL-M) (e.g., [17] ) with the help of the sensors located on the layer-system inner surface, i.e., the surface not affected by the environ- ment. However, these papers consider a use of accelerometers as the sensors. This restricts application of the procedures to the QE systems only. In contrast to that, the present work regards a use of the sensors, which enable application of the parameter- identification procedures to general, non-QE layer systems. Also, papers [16] and [1] consider homogeneous conditions at the layer-system outer surface, i.e., the one af- fected by the environment, but do not include the operational-load-caused source term in the above equation. The present work overcomes these limitations as well.

The answer to the first question in the above bullet list is developed in terms of methods of SH/OL-M and with the emphasis on monitoring stress in BSs in Section 2. The answer to the second question in the mentioned list is developed in Appendixes A-C. Appendix A deals with the identification of the material parameters of a one- layer system. Appendix B shows how this identification approach is generalized for multilayer systems. Appendix C exemplifies this generalization in the case of the BS/AI-layer system, which comprises two layers. Section 3 summarizes the obtained results and presents the concluding remarks. The section "Notations", which also includes the list of the used abbreviations, completes the work.

2. Design Issues of an IDS, Which Is Relevant to an SDS for the BSs of a Wind Turbi

Wind turbines are driven by irregular wind under irregular weather conditions, more specifically, by the air flows at the outer surface of the BS/AI-layer. Practical techniques for measurement of the wind effect are still unknown, even if the outer surface of the BS is free from AI. The absence of the techniques deprives some of the most common acoustic methods. For example, structural dynamics (e.g., [18] ) and lookup tables (e.g., [19] ) cannot be applied because the data on the wind effect on the BS/AI-layer, which are necessary parts of the input data for these approaches, cannot be measured.

The only practical techniques are the ones, which do not use measurements of the above wind effect. These techniques comprise methods of SH/OL-M. They are based on the data measured by sensors and used in works [1] and [16] . Methods of SH/OL-M apply various sensors, such as accelerometers or strain gauges (e.g., [20] ).

In a deformable solid system, an acoustic signal, which is measured at a spatial point of the system and can be regarded in SH/OL-M, is the QE component of one or another mechanical variable at the point. Until now, the settings for measurements of the QE components of the accelerations or strains in the non-QE systems are unknown.

The settings for measurements of the QE component of the stresses in the non-QE systems are unknown either. However, the remark below proposes the corresponding idea.

Remark 2.1. If a non-QE deformable solid system includes a cavity filled by air, which remains at equilibrium and at the atmospheric pressure, then the QE component of the stress in the wall of this cavity can be measured by an appropriate pressure/ normal-stress sensor as the difference between the values of the normal stresses in the solid wall and air in the cavity. □

An example of the non-QE systems noted in Remark 2.1 is the BS of an operating wind turbine. Indeed, the BS is a hollow solid body where the cavity is isolated from the external air. Other examples are the non-QE closed deformable solid hells and interiors of driver or passenger compartments of ships, cars, busses, airplanes, and other vehicles.

The sensors that can provide the measurements indicated in Remark 2.1 are the pressure-sensing resistors also known as the force-sensing resistors (FSRs). They are used in SH/OL-M. For example, in the wireless array of FSRs of the Honeywell Tech- nology Center ( [21] , Sections 3.2.3 and 3.2.4), the FSRs are identical. Each of them is a small-area thin planar resistor, which includes the film sensitive to the pressure or, more precisely, normal-stress difference at the opposite planar surfaces of the film, or to the related force.

The difference of the normal stresses at the opposite planar surfaces of an FSR,

where

Remark 2.2. The operating-temperature interval of the FlexiForce Standard Model A301 FSR is from

The sensing region of this device is a disk with the diameter

According to the sensor data sheet [23] , the power consumed by one sensor together with the related electrical circuit, which includes one MCP6004 amplifier, does not exceed

The operating-temperature intervals noted in Remark 2.2 include a considerable part of the temperature values discussed in Remark 1.1. The interval of the measured pressure is also rather wide. Is it possible to measure the QE component of the normal stress in the BS/AI-layer system with FSRs? In order to answer this question, one can take a closer look at key aspects of the aerodynamics of the operation of a wind-turbine rotor.

The main aerodynamic effect, by which the operating rotor extracts the energy, is the pressure drop between the air domains directly in front of, and directly behind, the BS of a rotor. More specifically, the picture is the following.

If there is no wind, the BS as well as the air domains at the inner and outer surfaces of the BS are at equilibrium, and their pressures are the same and equal to the at- mospheric pressure.

If there is a wind and the wind-turbine rotor operates, then:

・ the air domain at the outer surface, which is directly in front of the BS, is at the above-atmospheric pressure,

・ the air domain at the outer surface, which is directly behind the BS, is at the below- atmospheric pressure, and

・ the BS is not at equilibrium,

whereas the pressure at the inner surface of the BS remains atmospheric. Con- sequently, in the course of the operation, there is always the pressure difference between the BS inner surface not affected by a wind and the BS outer surface affected by a wind. This difference manifests the presence of the stress distributed along the thickness of the BS.

This stress can be measured as follows. Assume that the working planar surface of an FSR is attached to the inner surface of the BS. Consequently, the opposite planar surface of the FSR contacts the equilibrium atmospheric-pressure air in the interior of the BS. Then, according to the well-known continuity of the QE component of the stress at, and normal to, the interface between two solids (e.g., [24] , (1.48)), the normal stress at the FSR/BS interface is equal to the QE component of the stress at the interface. Similarly, according to the well-known continuity of the QE component of the stress at, and normal to, the interface between a solid and air, the QE component of the stress at, and normal to, the opposite planar surface of the FSR, i.e., the FSR/air interface, is equal to zero (e.g., [24] , (1.49)). Since the FSR measures the normal-stress difference between its surfaces (see the text on (2.1)), it in fact measures the QE component of the mentioned stress in the BS at the FSR/BS interface.

The above part of the present section can be summarized as follows.

A sensor, which can measure the QE component of the normal stress in a non-QE closed deformable solid shell such as a BS of a wind turbine, is an FSR with its working planar surface attached to the BS inner surface and its opposite planar surface con- tacting the equilibrium air in the BS cavity. An array of the FSRs can be wirelessly connected to, and controlled by, a PC.

This picture is equally applicable to a more general case where the layer system measured by FSRs includes not only the BS layer but also the AI layer that can be accreted on the BS outer surface. The corresponding parameter-identification pro- cedures are developed in Appendixes A-C.

The above settings can be implemented in a hardware configuration that includes an electronic communication subsystem for the sensor array. The components of it are standard manufactured (or off-the-shelf) products, very small and light, reliable, high- speed, inexpensive, and providing flexible scaling. Importantly, the sensor array and communication subsystem does not presume parts placed outside the BS.

To be specific, the present section considers a wind-turbine rotor that has three identical blades. The blade length is assumed to be of 50 (i.e., similar to the one of a fiberglass-reinforced epoxy blade of the Siemens SWT-2.3-101 wind turbine [25] ). As one can estimate, the area of the BS layer of this blade is about 400. In order to sense the AI landscape discussed in Section 1, one should, near but outside the area of each heating element of an SDS (see Section 1), attach the FSRs, one per, say, four square meters. Thus, the area of 400 is covered with 100 sensors (see Row 1 of Table 1). As is noted above in this section, all of the sensors are attached to the inner surface of the BS. They can be connected by a flat cable of the Serial Peripheral Interface (SPI) bus (e.g., [26] ) or the Inter-Integrated Circuit (I2C) bus (e.g., [27] ). More specifically, the con- figuration for a rotor blade is the following.

Table 1. Key components of the electronic equipment for a three-blade rotor of a wind turbine according to the present approach. The communication hardware comprises the components in Rows 2 and 4 - 6.

* if one orders at the quantity of 300.

First, the bus cable of the length of about 210 is attached to the inner surface of the BS (see Row 2 of Table 1) in the form of a meander.

Next, 100 sensors are rigidly attached (stuck) to the same surface along, and in a close proximity to, the cable at the distances of about 2 between any two neighboring sensors. Note that the cable and sensors are placed in such a way that each sensor corresponds to the surface area of about four square meters. Then each of the sensors is connected to the cable via an amplifying circuit (e.g., see [23] for the recommended circuit, which includes the amplifier) and the micro-controller (see Rows 3 and 4 of Table 1).

Finally, each of the three cables is carried out from a respective blade into the rotor hub and connected to a micro-controller, a GSM/GPRS communication module, and a rechargable long-life battery that are rigidly attached to the solid body of the hub (see Rows 5 and 6 of Table 1). The macro-controller can be of the same type as the one indicated in Row 4 of Table 1. The battery is recharged from the energy produced by the turbine.

The GSM/GPRS module wirelessly transmits the measured data to a remote PC, which is also equipped with a GSM/GPRS module, processes the data for identification of the material parameters of the AI that can be accreted on the BS, and controls the sensor array. The corresponding estimated cost for the described hardware does not exceed 31 kSEK per one wind turbine with three 50-meter blades (see the last row and column of Table 1). As follows from the last sentence in Remark 2.2, the power consumed by the above electronic system necessary for the operation of 300 sensors does not exceed 6.

The outcomes of the present section is the answer to the question in the first bullet in Section 1. The answer to the question in the second bullet is developed in Appendixes A-C.

3. Obtained Results and Concluding Remarks

Summing up the present work, one can note the following.

The present work is based on the third-order partial differential equation (PDE) of acoustics of viscoelastic solids for the quasi-equilibrium (QE) component of the average normal stress derived and used in the previous papers of the authors. This PDE includes the stress-relaxation time (SRT) for the material and is applicable at any value of the SRT.

The work specifies the notion of a smart deicing system (SDS) for blade shells (BSs) of a wind turbine. The stress in a BS is considered as the one caused by the operational load on the BS. The work developed key design issue of a prospective ice-detection system (IDS) able to supply an array of the heating elements of an SDS with the element-individual spatiotemporal data (see Section 2) and procedures for identifi- cation of the material parameters of atmospheric ice (AI) layer accreted on the outer surfaces of the BSs (see Appendixes A-C). Both the SDS and IDS flexibly allow for complex, curvilinear and space-time-varying shapes of BSs.

The proposed IDS presumes monitoring of the QE components of the normal stresses in BSs. The IDS is supposed to include an array of force-sensing resistors (FSRs) and communication hardware, as well as the parameter-identification software package (PISP), which provides the identification on the basis of the aforementioned PDE and the data measured by the FSRs. The IDS does not have hardware components located outside the outer surfaces of, or implanted in, the BSs. The FSR array and communication hardware are:

・ Reliable because they comprise standard manufactured (or off-the-shelf) products only, which can, moreover, operate at the temperatures between −40˚C and +40˚C;

・ Cost efficient because their estimated cost is 30 - 35 kSEK for a rotor with three 50-meter blades;

・ Energy efficient because their estimated power consumption is within 10 watts in the case of the above rotor.

The present work extends methods of structural-health/operational-load monitoring (SH/OL-M) with measurements of the op- erational-load-caused stress in closed solid shells and, if the prospective PISP is used, endows the methods with identification of material parameters of the shells. The identification algorithms that can underlie the PISP are computationally efficient and suitable for implementation in the real-time mode.

The identification model and algorithms can deal with not only the single-layer systems such as the BS layer without the AI layer (see Appendix A as well as Table A1 for the input data and the parameters that can be identified) or two-layer systems such as the BS with the AI layer accreted on it (see Appendix C as well as Table C1 for the input data and the parameters that can be identified) but also multi-layer systems (see Appendix B). The outcomes are applicable to not only the BSs of wind turbines but also the non-QE closed single- or multi-layer deformable solid shells of various engineering systems (e.g., the shells of driver or passenger compartments of ships, cars, busses, airplanes, and other vehicles). The proposed monitoring of the normal-stress QE component in the mentioned shells extends methods of SH/OL-M.

The outcomes of the present work complement and further develop the results of the previous works of the authors, more specifically, papers [1] , [16] , and [32] . The topic for the nearest research is a better adjustment of the settings for the FSR-based mea- surement of the normal-stress QE components in BSs and a calibration (e.g., see Remark A.2) of the parameter-identification model and algorithms, as well as the resulting improvement of the PISP.

Acknowledgements

The authors express their gratitude to the Swedish Energy Agency for a partial support of the present work via the project 37286-1 in the “Wind power in cold climates” program. The authors also thank Andrey Koptyug, Sports Tech Research Centre, Department of Quality Technology, Mechanical Engineering and Mathematics, Mid Sweden University, Östersund, Sweden, for drawing the attention to possible use of force- sensing resistors and suggestion on the hardware configuration described in Section 2.

Cite this paper

Mamontov, E. and Berbyuk, V. (2016) The Third-Order Viscoelastic Acoustic Model Enables an Ice- Detection System for a Smart Deicing of Wind-Turbine Blade Shells. Journal of Applied Mathematics and Physics, 4, 1949- 1976. http://dx.doi.org/10.4236/jamp.2016.410197

References

- 1. Mamontov, E. and Berbyuk, V. (2015) Passive Acoustic Signal Sensing Approach to Detection of Ice on the Rotor Blades of Wind Turbines. 16th International of Workshop on Atmospheric Icing of Structures (IWAIS), Uppsala, 28 June-3 July 2015, 75/248-80/248.

- 2. Sommerfeld, R.A. (1982) A Review of Snow Acoustics. Reviews of Geophysics and Space Physics, 20, 62-66.

http://dx.doi.org/10.1029/RG020i001p00062 - 3. Gibson, R.F. (2012) Principles of Composite Material Mechanics. CRC Press, Boca Raton.

- 4. Landau, L.D. and Lifshitz, E.M. (1986) Theory of Elasticity. Pergamon Press, Oxford.

- 5. Gross, B. (1953) Mathematical Structure of the Theories of Viscoelasticity. Hermann & Cie, Paris.

- 6. Junisbekov, T.M., Kestelman, V.N. and Malinin, N.I. (2003) Stress Relaxation in Viscoelastic Materials. Science Publishers, Enfield.

- 7. Hess, H. (1902) Elasticität und innere Reibung des Eises [Elasticity and Viscosity of Ice]. Annalen der Physik, 313, 405-431.

http://dx.doi.org/10.1002/andp.19023130612 - 8. Weinberg, B. (1905) über die innere Rei-bung des Eises [Viscosity of Ice]. Annalen der Physik, 323, 81-91.

http://dx.doi.org/10.1002/andp.19053231103 - 9. Weinberg, B. (1907) über die innere Reibung des Eises. II. Annalen der Physik, 327, 321-332.

http://dx.doi.org/10.1002/andp.19073270208 - 10. Deeley, R.M. (1908) The Viscosity of Ice. Proceedings of the Royal Society of London Series A, 81, 250-259.

http://dx.doi.org/10.1098/rspa.1908.0077 - 11. Kobeko, P.P., Shishkin, N.I., Marei, F.I. and Ivanova, N.S. (1946) Plastic Deformation and Viscosity of Ice. Journal of Technical Physics, 16, 263-272.

- 12. Hobbs, P.V. (1974) Ice Physics. Clarendon Press, Oxford.

- 13. Gao, H. and Rose, J.L. (2009) Ice Detection and Classification on an Aircraft Wing with Ultrasonic Shear Horizontal Guided Waves. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 56, 334-344.

http://dx.doi.org/10.1109/TUFFC.2009.1042 - 14. White, J.R., Adams, D.E. and Rumsey, M.A. (2009) Operational Load Estimation of a Smart Wind Turbine Rotor Blade. Proceedings of SPIE, 7295, 72952D/1-72952D/12.

http://dx.doi.org/10.1117/12.815802 - 15. Smith, B.A. and Maheri, A. (2012) Optimisation of the Efficiency of Carbon Fibre Heating Elements Implanted in Wind Turbine Blades. 2nd International Symposium on Environment-Friendly Energies and Applications (EFEA), Newcastle upon Tyne, 25-27 June 2012, 410-414.

http://dx.doi.org/10.1109/efea.2012.6294045 - 16. Mamontov, E. and Berbyuk, V. (2015) Identification of Material Parameters of Thin Curvilinear Viscoelastic Solid Layers in Ships and Ocean Structures by Sensing the Bulk Acoustic Signals. 6th International Conference on Computational Methods in Marine Engineering, Rome, 15-17 June 2015, 502-513.

- 17. https://en.wikipedia.org/wiki/Structural_health_monitoring https://en.wikipedia.org/wiki/Operational_loads_monitoring

- 18. https://en.wikipedia.org/wiki/Structural_dynamics

- 19. https://en.wikipedia.org/wiki/Lookup_table

- 20. Schroeder, K., Ecke, W., Apitz, J., Lembke, E. and Lenschow, G. (2006) A Fibre Bragg Grating Sensor System Monitors Operational Load in a Wind Turbine Rotor Blade. Measurement Science & Technology, 17, 1167-1172.

http://dx.doi.org/10.1088/0957-0233/17/5/S39 - 21. Schoess, J.N. (2001) Conduc-tive Polymer Sensor Arrays: A New Approach for Structural Health Monitoring. Proceedings of SPIE, 4335, 9-19.

http://dx.doi.org/10.1117/12.434164 - 22. https://www.tekscan.com/products-solutions/force-sensors/a301

- 23. “The FLX-A301-A.pdf” File Can Be Downloaded from the Web-Site .

- 24. Pollard, H.F. (1077) Sound Waves in Solids. Pion, Lon-don.

- 25. https://en.wikipedia.org/wiki/Wind_turbine_design#Blade_materials

- 26. https://en.wikipe-dia.org/wiki/Serial_Peripheral_Interface_Bus

- 27. https://en.wikipedia.org/wiki/I%C2%B2C

- 28. CA Mätsystem AB (2016) Täby, Sweden.

www.camatsystem.com - 29. http://se.farnell.com/

- 30. https://www.elfa.se

- 31. http://simcomm2m.com/En/module/?type=19

- 32. Mamontov, E. and Berbyuk, V. (2014) A Scalar Acoustic Equation for gases, Liquids, and Solids, Including Viscoelastic Media. Journal of Applied Mathematics and Physics, 2, 960-970.

http://dx.doi.org/10.4236/jamp.2014.210109

Appendixes

This section comprises Appendixes A-C. They consider the stress in a layer system as the one caused by the operational load on the system and present necessary details on the models and methods for identification of the material parameters of the BS and AI layers.

A. Identification of the Material Parameters of the BS of an Operating Wind Turbine

The present section considers the case where the AI layer is not present at the outer surface of the BS. The QE component of ANS,

which is the non-homogeneous generalization of partial differential equation (PDE) ( [16] , (2.11)). In (A.1), x, y, and z are the spatial coordinates and term

The meanings of two other terms in (A.1) are the following:

hold due to the physical meanings of the two parameters. Speed

where

There are other contributions of the operational load. For example,

Remark A.1. Parameters

This enables one to evaluate

The material parameters of the BS to be identified,

However, before rejecting it, one can consider particular, more specific cases of this description in hope that a better specificity will change the role of the unknown terms in such a way that it will be possible to include the “successors” of them in the identifi- cation procedure. For the reason explained in Section 2, one can focus on the distri- bution of

In order to pass to the x-version of Equation (A.1), we first rewrite it in the following equivalent form

where

and then substitute equalities (A.8) into (A.9). This results in

where

Without a loss of generality, one can assume that the x-axis is normal to the BS layer and point

The inner air is located to the left from this interface. As noted in Section 2, it remains at the atmospheric pressure,.

Let

For the sake of simplicity, we consider the air acceleration indicated in (A.6) to be identically zero. Then, the effects of the phenomena (A.5) and (A.6) at point

where

It is in one spatial coordinate and is formally simpler than description (A.1), (A.5), (A.6) in three spatial coordinates. Still, the new settings do not enable one to obtain solutions of equation (A.11) because term

Indeed, if one, at point

which expresses the continuity of the stresses at the mentioned interface. The passing from (A.14) to (A.17) make it possible to obtain a prototype for an ordinary differential equation (ODE), which can be used for the identification. Indeed, applying value

that, after substitution of (A.17), takes the following form

where the derivatives on the left-hand side are known because values of function

The simplest way to this expression is based on an approximation for

where the t-independent integer number

is the degree of the polynomial. Representation (A.20) provides the estimation for the aforementioned spatial derivative, namely

Substitution of (A.20) into (A.15)-(A.17) results in

Combination of (A.22) and (A.24) transforms (A.19) into ODE

for function

Note that, by virtue of (A.2) and (A.21), inequality

holds. We also note that, in view of the role, which parameter

plays in ODE (A.26) for value (A.17) of a solution of PDE (A.11), this parameter can be interpreted as the characteristic wave number for the mentioned value.

Equation (A.26) presents an ODE with:

・ Solution

・ Unknown parameters

・ Function

The latter feature indicates that function

One considers ODE (A.26) at any three successive time points, say,

where

Table A1. Identification method for one-layer systems: The input data and the parameters that can be identified.

this interval. This feature allows to assume that

Equations (A.32) present a system of bilinear equations with constant coefficients for unknown numbers

one easily calculates the

If the inequality in relation (A.33) is not valid, then the rank of the matrix in this relation is less than three. Consideration of this special case is not difficult. However, it is beyond the scope of the present work.

Solution of system (A.34)-(A.36) with respect to

If

If

If

The case where

Substitution of (A.37) into (A.35) transforms the latter into quadratic equation

If this equation has exactly one root, which meets condition (A.3), and the cor- responding value of

Remark A.2. In each of the above cases, parameter

Thus, the input data cannot be obtained without measured data for stress

Remark A.3. Importantly, the above identification of parameters

The above also shows that the proposed method is applicable in spite of the presence of the unknown terms in the model. This is an important practical advantage of the method. □

As soon as

Remark A.4 (cp., the discussion in ( [16] , Section 4). The proposed method identifies the parameters in a time interval comprising three successive time points, thereby presuming that the parameters are independent of time in this interval. The method can be applied to each of the three-successive-point intervals that can be considered in the time-point sequence indicated as a prat of the input data for the method (see the upper half of Table A1). As a result, one obtains each of the identified parameters in the form of a piecewise constant function of the time. This function need is not single- valued because the three-point intervals are mutually intersecting and, at the intersections, the function can have two values. The time dependences of this type are rather irregular and need special techniques for smoothing or other processing. These techniques are beyond the scope of the present work. □

The next section outlines how the proposed approach can be generalized for multi- layer systems.

B. Generalization of the Parameter Identification from One-Layer Systems to Multi-Layer Systems

The previous section proposes a method for the identification of the material para- meters of the BS layer of an operating wind-turbine rotor. The present section explains how this approach is generalized for the identification of the parameters of multi-layer system.

One can consider the l-layer system where

Equations (A.18) or (A.19) corresponds to the left boundary of the x-interval considered in the one-layer treatment. The counterparts of (A.19), i.e., the equations corresponding to the left boundaries of the above l intervals are

The boundary data at the layer surfaces are

Relation (B.3) is similar to (A.17) because it is set at the inner surface of the layer system. Relations (B.6) and (B.7) are similar to (A.15) and (A.16) because they are set at the outer surface of the layer system. Relations (B.4) and (B.5) express the continuity of the normal stress and normal acceleration at the interfaces between the layers.

Remark B.1. The number of the boundary equalities (B.3)-(B.7) is

Terms

which is similar to (A.19). One can also consider a possibility to express boundary values

Proceeding in these directions, one can involve a polynomial similar to (A.20) for each layer. This results in

where n and

The number of the coefficients of polynomials (B.9) and (B.10) is

The above generalization for multi-layer systems is exemplified with application to a two-layer system, which comprises the BS and AI layers, in the next section.

C. Identification of the Parameters of the AI Layer Accreted on the BS of an Operating Wind Turbine

Section A considers the case where the x -interval for the BS is

We specify the two-layer version of equations (B.8), (B.2), boundary data (B.3)-(B.7), polynomials (B.9), (B.10), and terms (B.11), (B.12) in the following forms

where P is the QE component of the ANS in the AI and the coefficients without the subscript “s” corresponds to the AI. Note that, in view of (C.9),

One can determine the five coefficients of polynomials (C.8) and (C.9) from the five boundary relations (C.3)-(C.7). The results are:

where

Remark C.1. In the limit case as

Application of (C.14) and (C.16) to (C.10) and (C.11), respectively, leads to

Substituting (C.19) and (C.20) into the right-hand sides of (C.1) and (C.2), re- spectively, one obtains

where

Table C1. Identification method for two-layer systems: The input data and the parameters that can be identified.

In view of (C.23) and (C.18), the acceptable values of v are such that

Equalities (C.21) and (C.22) present two different ODEs for function

The ODEs can be used for identification of the AI layer parameters q and

The corresponding procedure can follow the already familiar way (see the text on (A.31) and (A.32)). More specifically, one considers ODEs (C.21), (C.22) in the interval comprising any three successive time points, say,

where

By solving system (C.30) of two linear algebraic equations, one determines v and

If

If

As soon as q is available, parameter s is evaluated from (C.24) (where h is determined with (C.33)). Then (cp., Remark A.1),

(see the upper half of Table C1 for function

The proposed identification method is a generalization of the one of Appendix A for two-layer systems. However, the discussion on the one-layer method, in particular, Remarks A.3 and A.4 (along with Remark A.2 already mention in the present section) are equally applicable to the present, two-layer case.

Notations

Abbreviations

AI―atmospheric ice

ANS―average normal stress

BS―blade shell

FD―finite difference

FSR―force-sensing resistor

IDS―ice-detection system

ODE―ordinary differential equation

PC―personal computer

PDE―partial differential equation

PISP―parameter-identification software package

QE―quasi-equilibrium

SDS―smart deicing system

SH/OL-M―structural-health/operational-load monitoring

SRT―stress-relaxation time

Roman Uppercase Letters

mass of a BS

Appendix C

Roman Lowercase Letters

AI on

Greek Uppercase Letters

Greek Lowercase Letters

Submit or recommend next manuscript to SCIRP and we will provide best service for you:

Accepting pre-submission inquiries through Email, Facebook, LinkedIn, Twitter, etc.

A wide selection of journals (inclusive of 9 subjects, more than 200 journals)

Providing 24-hour high-quality service

User-friendly online submission system

Fair and swift peer-review system

Efficient typesetting and proofreading procedure

Display of the result of downloads and visits, as well as the number of cited articles

Maximum dissemination of your research work

Submit your manuscript at: http://papersubmission.scirp.org/

Or contact jamp@scirp.org